titanium steel

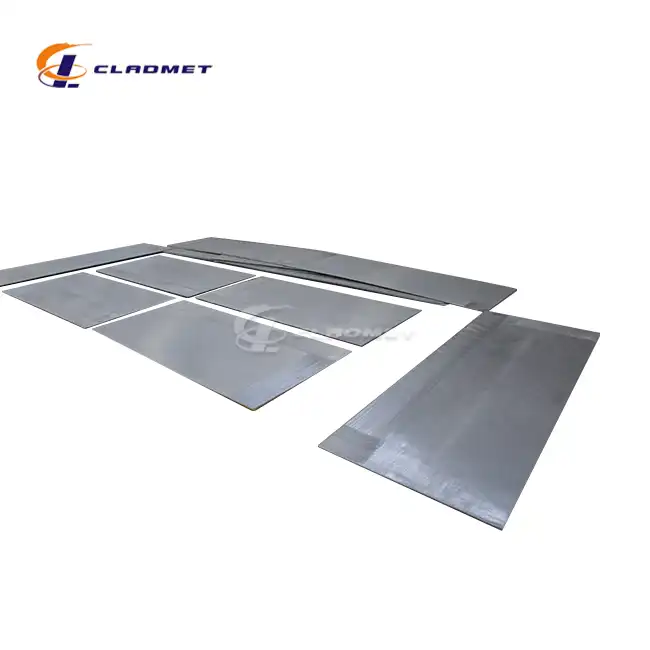

Clad Plate Total Width:Around 3000mm or Customizable

Clad Plate Total Length:Around 10000mm or Customizable

Surface Treatment:Polished, blast cleaned, pickled and passivated as per the applicable standard, or Negotiable.

Delivery Period 3-6 months or Negotiable

Titanium steel

PRODUCT INTRODUCTION

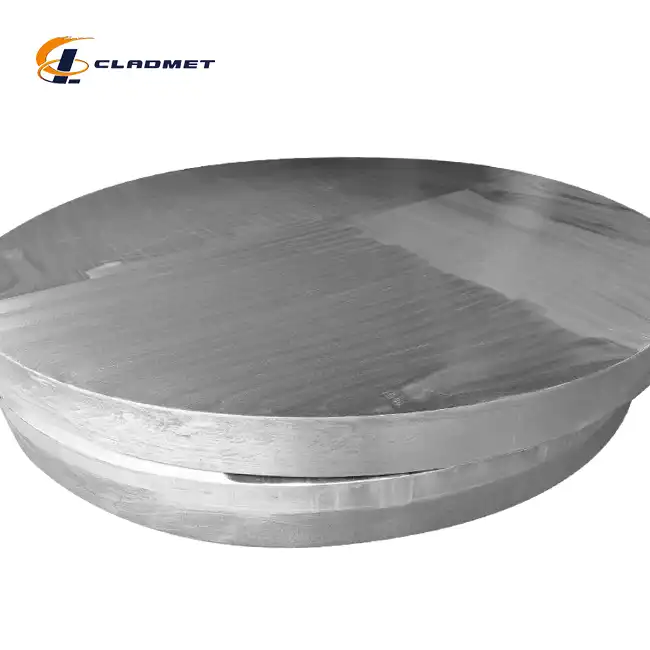

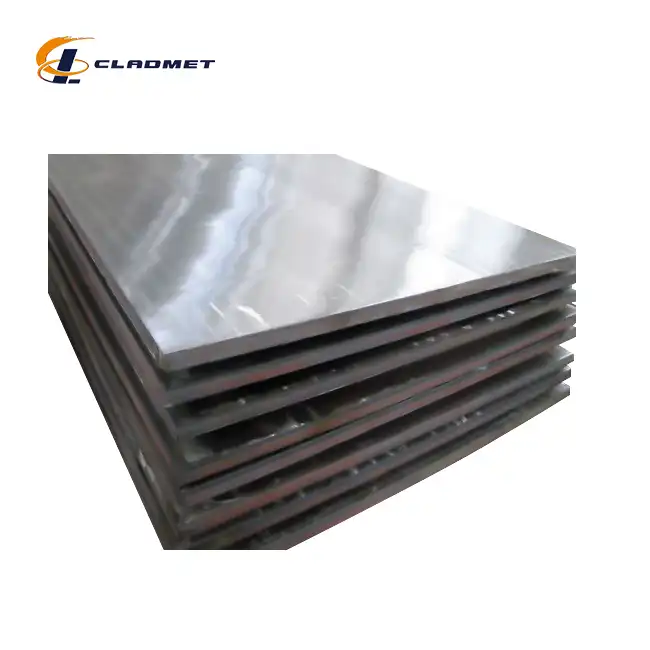

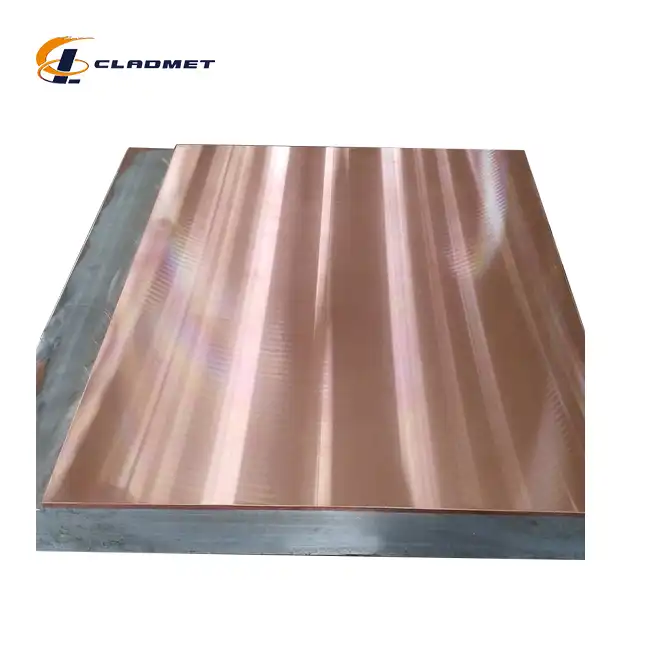

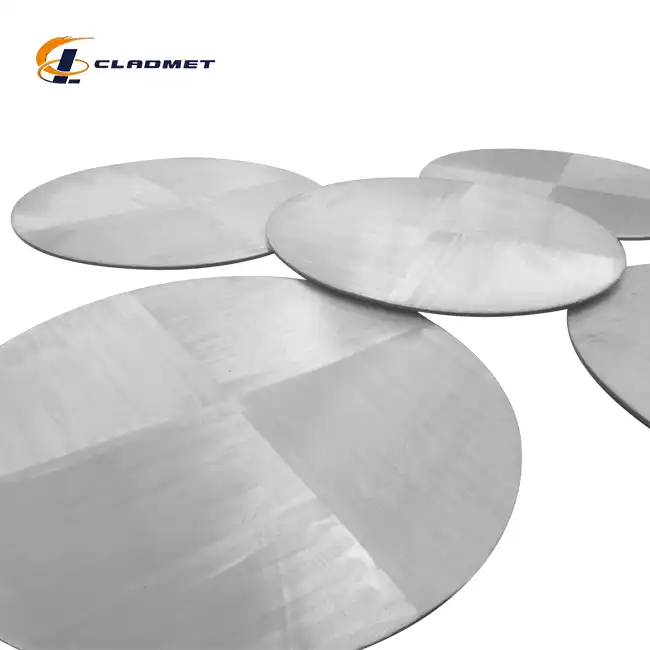

Titanium steel clad plate is a composite material made by bonding corrosion-resistant titanium with a strong and economical steel substrate. This layered structure combines the best properties of both metals—titanium's outstanding corrosion resistance and steel's excellent mechanical strength—making it a cost-effective solution for demanding industrial environments.

At Baoji JL Clad Metals Materials Co., Ltd., we offer high-performance titanium clad steel sheets, plates, and boards that meet ASTM B898 and NB/T 47002.3 standards. With over 20 years of experience, we serve global clients in chemical, petroleum, marine, power, and nuclear industries.

Product Specifications

| Parameter | Specification |

|---|---|

| Cladding Material | Titanium Grades: TA1, TA2, TA3, TA9, TA10; ASTM Gr1, Gr2, Gr3, Gr7, Gr12 |

| Base Metal | Carbon Steel or Stainless Steel: ASTM A516, A515, A266, A387, A240, GB/T series |

| Cladding Thickness | 0.3 mm – 60 mm (customizable) |

| Total Plate Thickness | 8 mm – 120 mm |

| Max Width | Up to 3000 mm |

| Max Length | Up to 10000 mm |

| Manufacturing Methods | Explosive Welding, Hot Rolling, or Combined Process |

| Surface Treatment | Pickling, Polishing, Blasting, Passivation |

| Standards Compliance | ASTM B898, NB/T 47002.3, GB/T 8547, GB/T 8165 |

| Delivery Lead Time | 3–6 Months (negotiable) |

| Packaging | Export-grade wooden cases, waterproof film, steel bands |

| Payment Terms | T/T, L/C, or customized per contract |

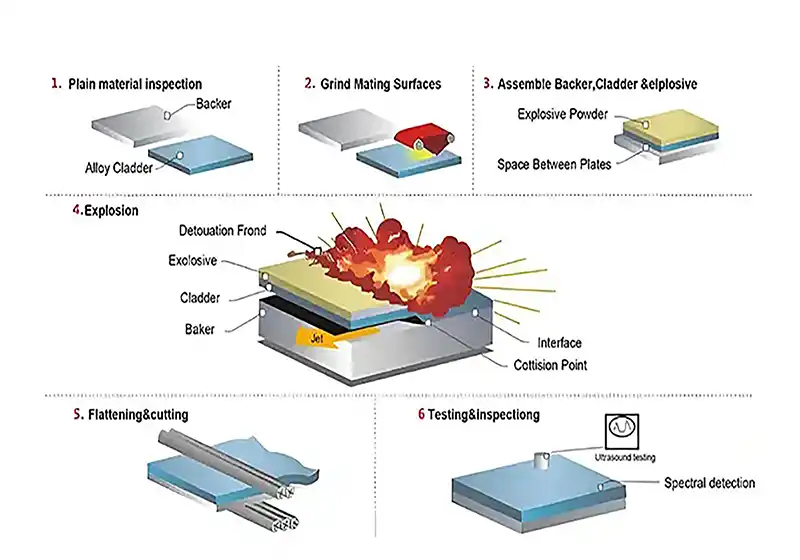

Manufacturing Process

-

Material Inspection: Raw titanium and steel plates are inspected for surface defects and dimensional accuracy.

-

Surface Treatment: Clean, degrease, and roughen surfaces to ensure bond integrity.

-

Explosive Welding or Hot Rolling: Bond titanium and steel via high-energy detonation or hot-pressure rolling.

-

Heat Treatment: Stress relieving or annealing depending on the application.

-

Non-Destructive Testing: Ultrasonic or shear tests to verify clad bond strength.

-

Finishing: Cutting, grinding, polishing, and edge treatment.

-

Final Inspection: Dimensional check, surface finish verification, and document review.

-

Packaging: International export packing standards applied.

Cladding Technique: Explosive Bonding Method

JL CLAD METALS adopts explosive bonding—a high-energy cold welding technique that ensures metallurgical bonding between titanium and copper without melting the base metals. This results in:

- Excellent interfacial strength

- No intermetallic compounds

- Zero porosity and high reliability

- Ability to bond dissimilar metals that are otherwise unjoinable via welding

This method preserves the mechanical integrity of both metals and provides a long-lasting, durable composite.

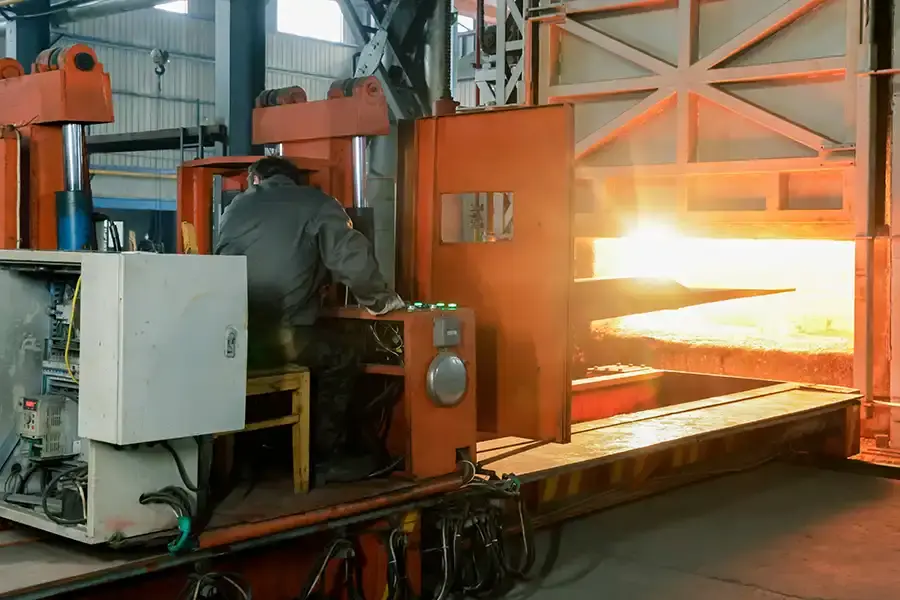

Explosive Composite Plate Production Site

Explosive Setup

Preparing materials for explosive bonding process.

Bonding Process

Our proprietary explosive bonding technology in action.

Product Features

High Strength & Toughness

Steel substrate provides strong mechanical support suitable for pressure vessels and structural applications.

Superior Corrosion Resistance

Titanium cladding offers exceptional resistance to acid, alkali, seawater, and chloride-rich environments.

Lightweight & Cost-effective

Combines the economy of carbon steel with the premium properties of titanium at lower total cost.

Good Weldability & Machinability

Suitable for forming, welding, and machining using standard industrial techniques.

Product Advantages

Compliant with global standards (ASTM, ASME, GB/T, NB/T)

Long service life in aggressive environments

Reduced maintenance cost compared to solid titanium plates

Available in multiple configurations and thicknesses

Engineered for structural stability and corrosion resistance

Product Application Industries

Our Factory

Company gate

Factory

Quality Control Center

Dedicated QC team performing rigorous inspections at every stage.

Molding workshop

Melting workshop

Cold rolling workshop

Annealing workshop

Levelling workshop

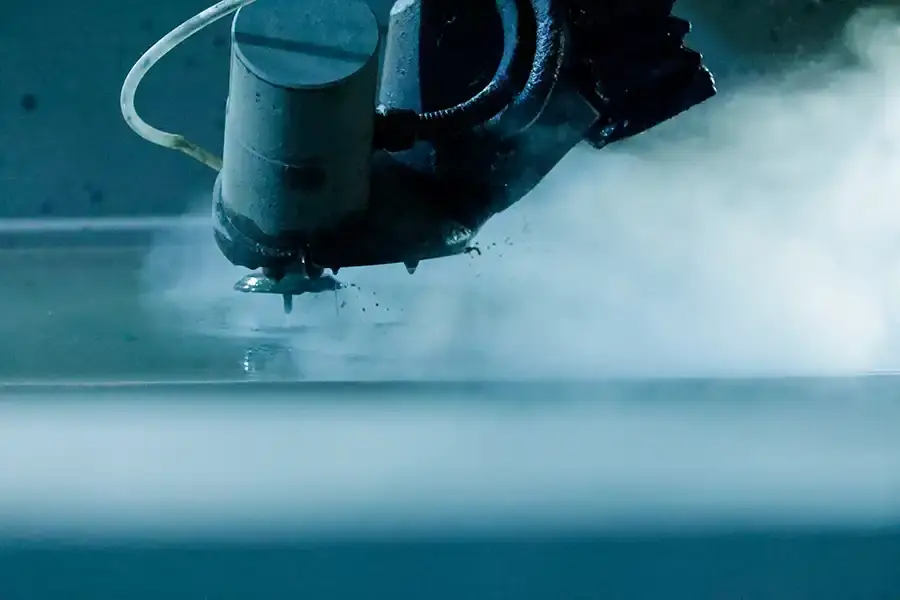

Water cutting workshop

Certificates

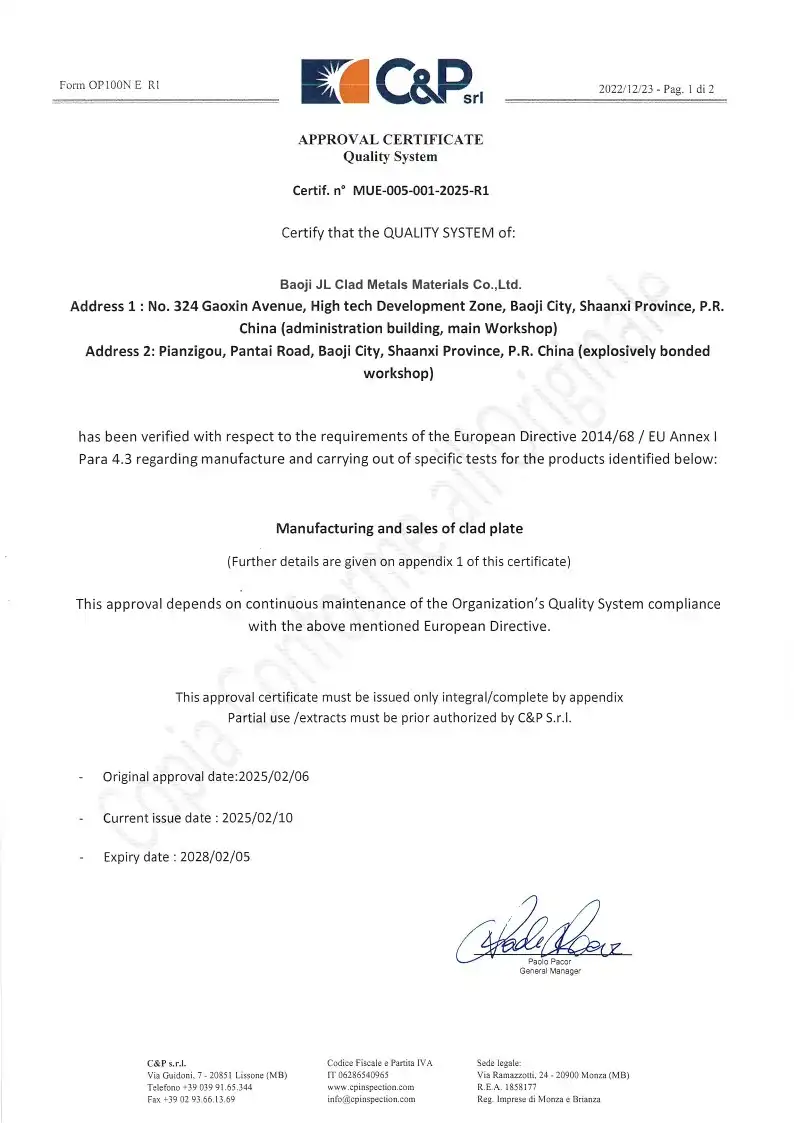

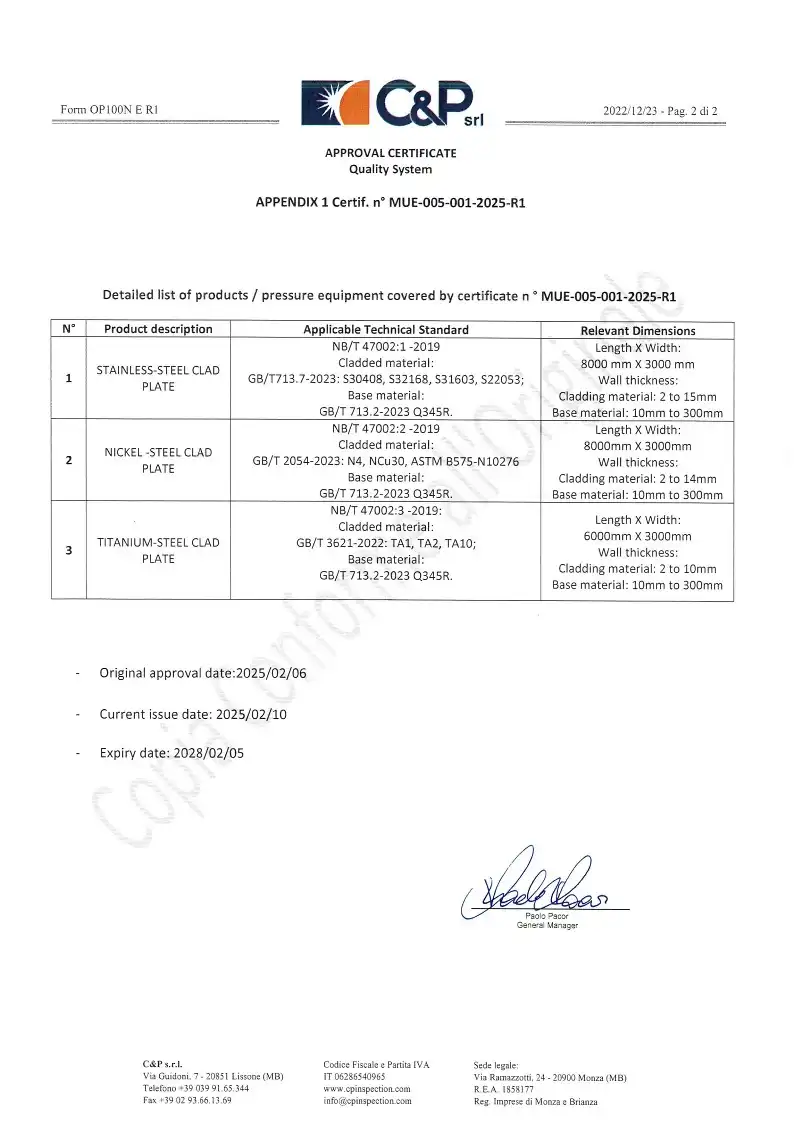

Certif. MUE-005-001-2025-R1

Certif. MUE-005-001-2025-R1

OEM Services

Custom Fabrication

Custom material combinations and thicknesses tailored to your requirements

CNC Machining

Precision cutting, drilling, and bending to your specifications

Technical Support

Dedicated technical consultation and prototyping support

FAQ

Q1: What is the bonding method used for titanium clad plates?

A: We use explosive welding, hot rolling, or a combination of both, depending on customer requirements and material compatibility.

Q2: Can the size and thickness be customized?

A: Yes. We offer fully customized solutions for length, width, and cladding thickness based on the application.

Q3: Do you provide test certificates?

A: Yes. All plates are delivered with material certificates, ultrasonic test reports, and mechanical property documentation.

Q4: Are your products export-ready?

A: Absolutely. We use seaworthy packaging and comply with international shipping standards.

Q5: How long does it take to deliver?

A: Normal lead time is 3–6 months depending on order size and customization level.

Contact Us

BAOJI JL CLAD METALS MATERIALS CO., LTD

WhatsApp: +86 15353335118

Email: stephanie@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)