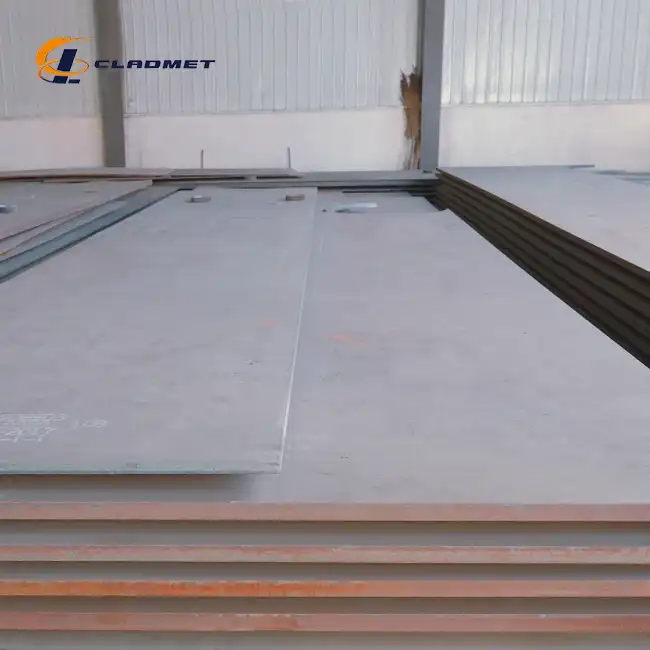

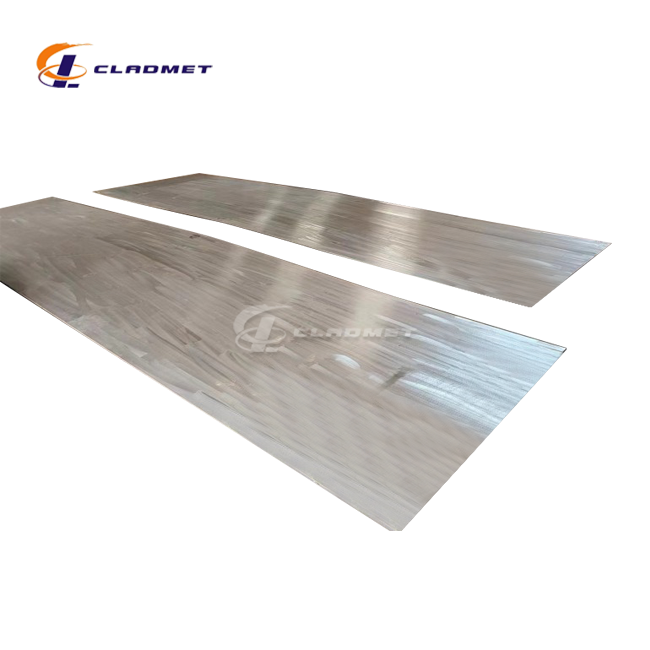

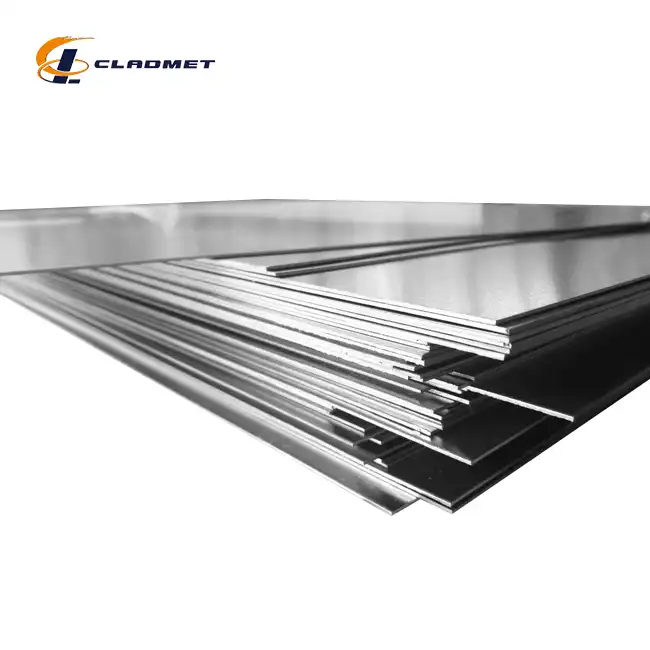

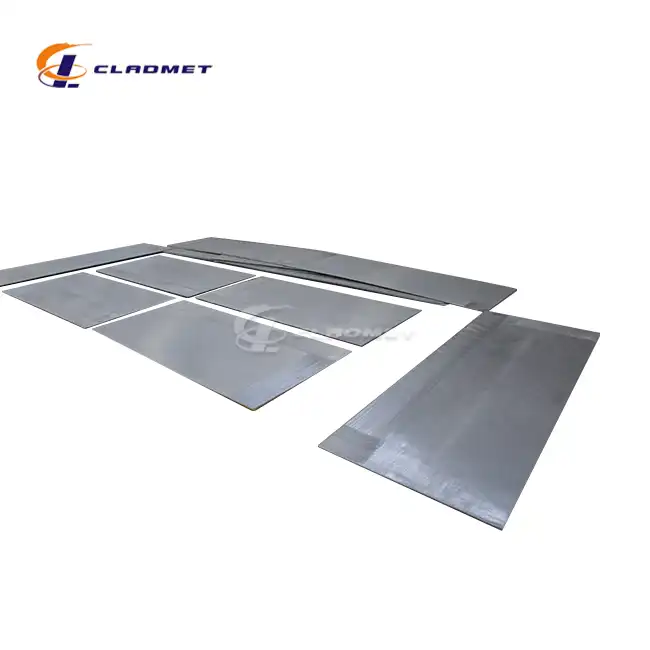

Explosion Bonded Titanium Clad Steel Plate

Base material: titanium plate. Covering layer: steel plate.

Available Sizes:Standard and custom sizes available.

Product Applications:Widely used in oil, gas, shipbuilding, and chemical industries.

Processing Technology: Advanced explosive bonding and hot rolling technology.

Quality Control & Testing: Strict in-house testing ensures durability and compliance.

Implementation Standards:ASME, ASTM, JIS certified. ISO9001-2000, PED, ABS certifications.

Delivery:Global shipping options available via sea or air freight.

Packaging: Durable wooden crates for safe transport.

Explosion Bonded Titanium Clad Steel Plates

ADVANCED CLAD METAL TECHNOLOGY

Baoji JL Clad Metals Materials Co., Ltd. pioneers in explosion bonded titanium-steel composite plate manufacturing since 1988. Our proprietary explosive welding technology creates molecular-level bonding between titanium (Grade 1-12) and carbon steel (Q235B/Q345R) with shear strength exceeding 210MPa, ideal for extreme pressure vessels operating in corrosive environments.

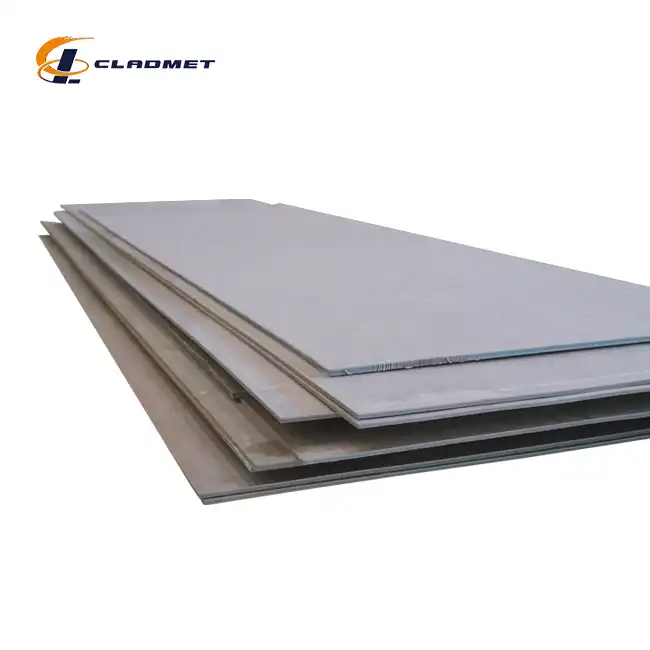

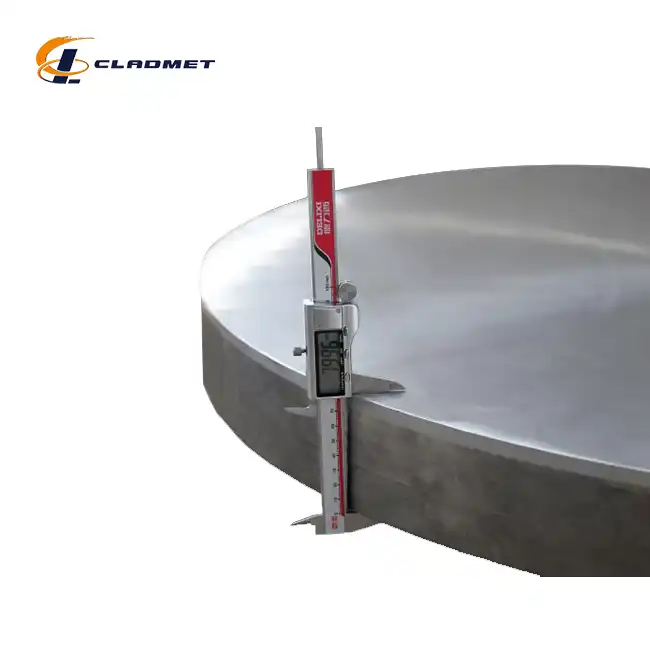

With 40+ years of metallurgical expertise, we deliver clad plates featuring: - Titanium layer thickness: 1.5-20mm - Steel base thickness: 10-300mm - Bonding ratio: ≥98% - Surface finish: Ra 3.2μm to 0.8μm - Maximum plate size: 4000×8000mm

Years Technical Expertise

Bonding Success Rate

Annual Production(Tons)

Global Patents

Critical Applications Across Industries

Chemical Processing Equipment

Offshore Oil & Gas Platforms

Nuclear Power Components

Seawater Desalination Plants

Acid-resistant Mining Equipment

Pharmaceutical Reactors

Technical Superiority

Advanced Explosive Welding Technology

Superior Metallurgical Bonding

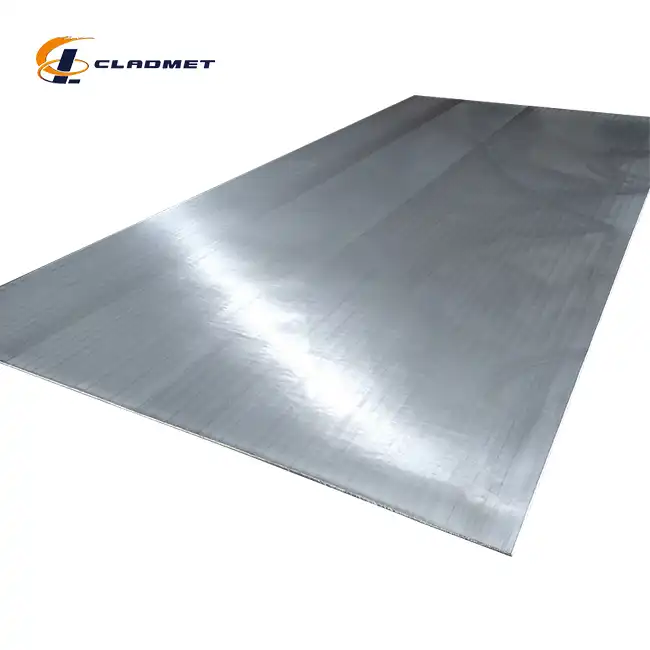

Our explosion welding process achieves 210-320MPa shear strength with <0.5mm wave amplitude, ensuring complete metal continuity between titanium and steel layers. The transition zone remains below 5μm, preventing intermetallic compound formation.

01

Corrosion Resistance

Withstands: - 98% sulfuric acid @ 120°C - 30% hydrochloric acid @ 60°C - Seawater @ 30-year service life - Chloride ions @ 50,000ppm

02

Cost Efficiency

40-60% cost reduction vs solid titanium construction. Our clad plates maintain 550MPa tensile strength while offering 1/3 the material cost of pure titanium equipment.

03

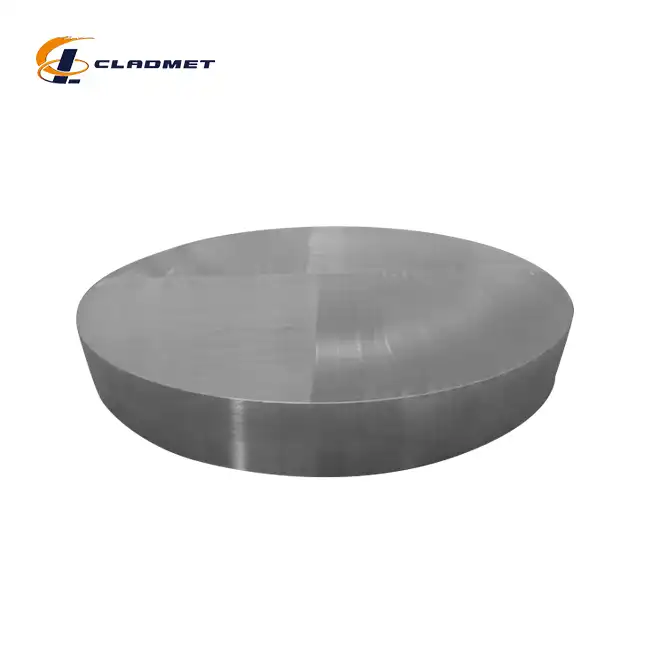

Custom Engineering

Tailored solutions for: - Vessel heads (elliptical/torispherical) - Shell courses (rolled/formed) - Nozzle reinforcements - Heat exchanger tubing

04

In Clad Metal Engineering

As China's pioneer in explosion cladding technology since 1988, Baoji JL Clad Metals operates from a 45,500m² production base with: - 12 explosive welding chambers - 8000-ton hydraulic press - 120m automated annealing line - Class I/II/III pressure vessel certification

Our R&D collaboration with Northwest Nonferrous Metals Research Institute has developed 15 proprietary welding parameters for different material combinations, ensuring optimal bond integrity.

Why Choose JL Clad Metals?

Certified Manufacturing

GB/T 8547-2019, ASME SA265, JIS G3601 compliant production with full MTC reports

Material Science Experts

Doctor-led team with 40+ technical papers on clad metal technology

Global Logistics

2000+ ton annual capacity with 45-day lead time for custom orders

Lifecycle Support

Comprehensive technical support from design to installation

Material Engineering Solutions

Tel: +86 15353335118 | Email: stephanie@cladmet.com

Workshop Address: Fenghuang 4 Road, Baoji Hi-Tech Zone, Shaanxi Province 721013 China

_1737007724117.webp)