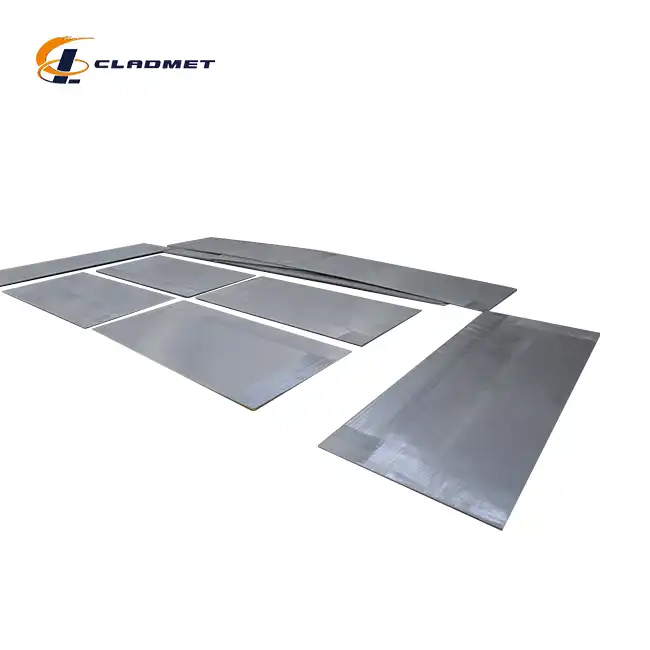

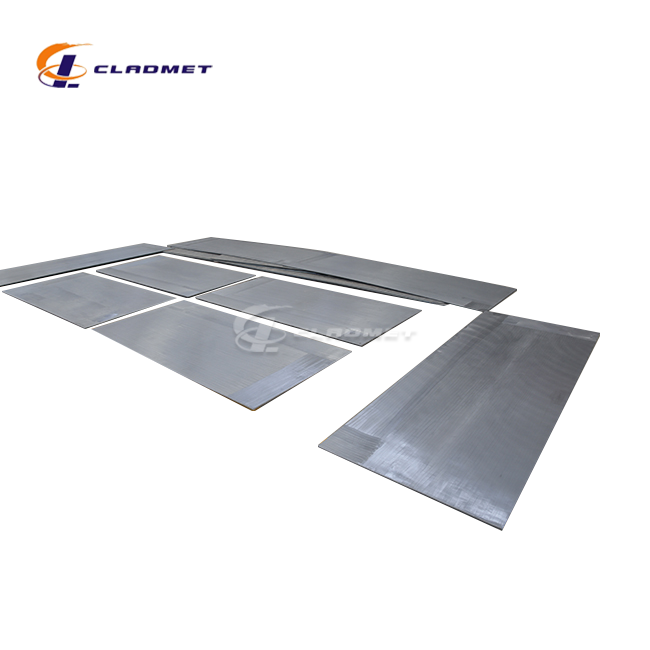

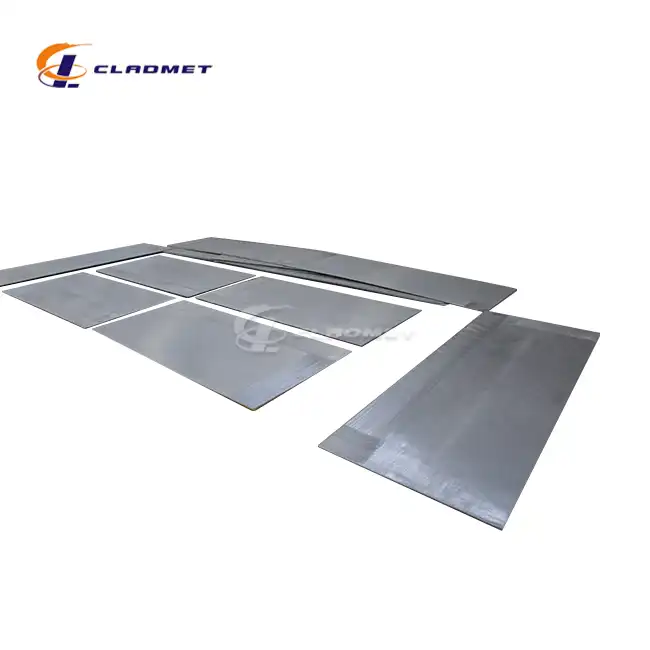

Titanium Clad Steel Plate ASTM B898

Available Sizes:Standard and custom sizes available.

Product Applications:Widely used in oil, gas, shipbuilding, and chemical industries.

Processing Technology: Advanced explosive bonding and hot rolling technology.

Quality Control & Testing: Strict in-house testing ensures durability and compliance.

Implementation Standards:ASME, ASTM, JIS certified. ISO9001-2000, PED, ABS certifications.

Delivery:Global shipping options available via sea or air freight.

Packaging: Durable wooden crates for safe transport.

PRODUCT INTRODUCTION

Titanium Clad Steel Plate ASTM B898 represents the pinnacle of corrosion-resistant composite materials engineering from Baoji JL Clad Metals Materials Co., Ltd. This innovative product combines titanium's exceptional corrosion resistance with steel's structural strength through our proprietary explosive bonding technology.

With over 40 years of expertise in clad metal manufacturing, we deliver ASTM B898 compliant plates that outperform conventional materials in harsh chemical environments, marine applications, and high-temperature processing equipment. Our titanium clad plates undergo rigorous quality control to ensure perfect bonding integrity and dimensional precision.

Years Experience

Square Meters

Annual Output

Employees

PRODUCT SPECIFICATIONS

| Parameter | Specification |

|---|---|

| Standard | ASTM B898, ASME SB898 |

| Cladding Material | Grade 1, 2, 7, 12, 16 Titanium |

| Base Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Thickness Range | 8-200mm (customizable) |

| Width Range | 1000-4000mm |

| Length Range | 2000-12000mm |

| Cladding Ratio | 10%-50% of total thickness |

| Bond Strength | ≥140 MPa |

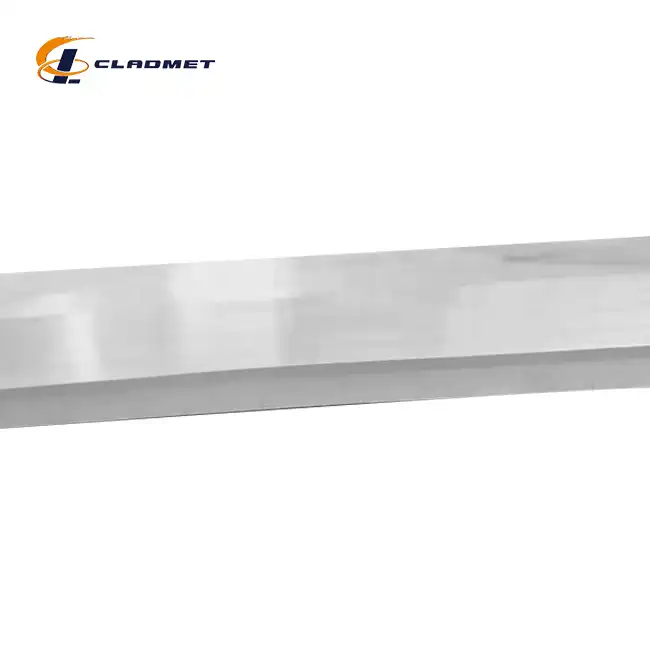

| Surface Treatment | Pickling, Passivation, Sandblasting |

| Testing Standards | ASTM E8, ASTM A578, ASTM E290 |

| Packaging | Wooden Case/Steel Frame with Protective Coating |

| Delivery Time | 3-6 months (negotiable for urgent orders) |

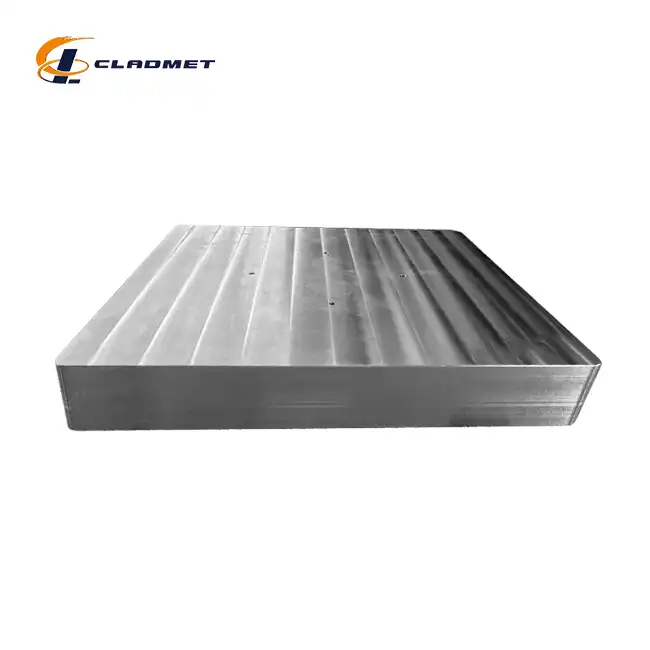

CLADDING TECHNIQUES: EXPLOSIVE BONDING METHOD

Our proprietary explosive bonding technology creates a metallurgical bond between titanium and steel through controlled detonation. This advanced process:

- Creates atomic-level bonding without heat-affected zones

- Preserves the corrosion resistance of titanium

- Maintains the structural strength of steel

- Allows for thicker cladding layers than roll bonding

- Enables bonding of dissimilar metals with minimal intermetallic formation

The process involves precisely placing explosive materials between the titanium and steel layers, then detonating under controlled conditions to create a wave that forces the metals together at velocities exceeding 500 m/s.

PRODUCT FEATURES

Superior Corrosion Resistance

Titanium cladding provides exceptional resistance to acids, chlorides, and seawater corrosion, far exceeding stainless steel performance.

High Strength-to-Weight Ratio

Steel backing provides structural support while titanium offers corrosion protection, creating an optimal balance of strength and weight.

Cost-Effective Solution

Significantly more economical than solid titanium while providing equivalent corrosion protection on wetted surfaces.

Excellent Thermal Conductivity

Superior heat transfer compared to solid titanium, making it ideal for heat exchangers and condensers.

PRODUCT ADVANTAGES

Why choose our Titanium Clad Steel Plates?

Technical Superiority

- 40+ years of explosive bonding expertise

- Advanced NDT testing for 100% bond integrity

- Precision machining capabilities for complex geometries

- Custom alloy combinations available

01

Quality Assurance

- ISO 9001:2015 certified manufacturing

- PED and ABS certified for pressure vessel applications

- Complete traceability from raw materials to finished product

- Third-party inspection available

02

Economic Benefits

- 60-70% cost savings vs. solid titanium

- Extended equipment service life (10-15 years typical)

- Reduced maintenance and downtime costs

- Inventory reduction through standardized sizes

03

Customization

- Wide range of titanium grades available

- Custom thickness ratios to optimize cost/performance

- Pre-fabricated shapes and weld preparations

- Just-in-time delivery programs

04

PRODUCT APPLICATION INDUSTRY

Chemical Processing

Reactors, distillation columns, heat exchangers, and piping systems handling corrosive acids, chlorides, and chemical intermediates.

Oil & Gas

Offshore platforms, FPSO vessels, subsea equipment, sour gas processing, and refinery components exposed to H2S and CO2.

Power Generation

Flue gas desulfurization systems, condenser tubes, seawater cooling systems, and nuclear power plant components.

Marine Engineering

Ship hulls, ballast tanks, seawater piping, offshore structures, and desalination plant components.

Pharmaceutical

Reaction vessels, storage tanks, and piping systems requiring ultra-clean surfaces and corrosion resistance.

Pulp & Paper

Digesters, bleach plants, and chemical recovery systems exposed to corrosive pulping liquors and chlorine compounds.

PRODUCT MANUFACTURING PROCESS

1. Material Selection & Preparation

- Rigorous incoming inspection of titanium and steel materials

- Ultrasonic testing for internal defects

- Precision machining of bonding surfaces

- Chemical cleaning to remove oxides and contaminants

2. Explosive Bonding Process

- Precise placement of explosive materials

- Computer-controlled detonation sequence

- High-velocity impact creates metallurgical bond

- Real-time monitoring of bonding parameters

3. Post-Bonding Processing & Inspection

- Heat treatment for stress relief

- Ultrasonic testing of bond integrity

- Dimensional verification

- Mechanical testing of samples

- Surface finishing per customer requirements

OEM SERVICE

Custom solutions tailored to your specific requirements

Custom Dimensions

Precision cutting to your exact size specifications with tight tolerances (±0.5mm). We accommodate both standard and custom sizes.

Special Alloys

Custom material combinations including nickel alloys, zirconium, tantalum, and other exotic metals clad to your base material.

Pre-Fabrication

Value-added services including forming, welding preparation, nozzle attachments, and complete assembly fabrication.

Testing & Certification

Comprehensive testing packages including PMI, UT, RT, hydrostatic testing, and third-party inspection reports.

FREQUENTLY ASKED QUESTIONS

Q: What is the maximum size of titanium clad steel plates you can produce?

A: Our current maximum production size is 4000mm wide × 12000mm long, with thickness up to 200mm. Larger sizes may be available through special arrangement.

Q: How does the cost compare to solid titanium plates?

A: Titanium clad steel plates typically offer 60-70% cost savings compared to solid titanium while providing equivalent corrosion protection on wetted surfaces.

Q: What quality certifications do you hold?

A: We are ISO 9001:2015 certified and our products meet ASTM B898, ASME SB898, PED, and ABS standards. We can also comply with other international standards upon request.

Q: Can you provide pre-fabricated components?

A: Yes, we offer comprehensive fabrication services including cutting, forming, welding preparation, and complete assembly fabrication to your specifications.

Q: What is your typical lead time?

A: Standard products typically ship within 3-6 months. Urgent orders can be expedited - please contact our sales team for specific timing based on your requirements.

CONTACT US

Get in touch with our technical sales team for expert advice on your titanium clad steel plate requirements

Baoji JL Clad Metals Materials Co., Ltd.

WhatsApp: +8615353335118

Email: stephanie@cladmet.com

Add: Fenghuang 4 Road, High-tech District, Baoji City, Shaanxi, China 721013

_1737007724117.webp)

_1737611764680.webp)