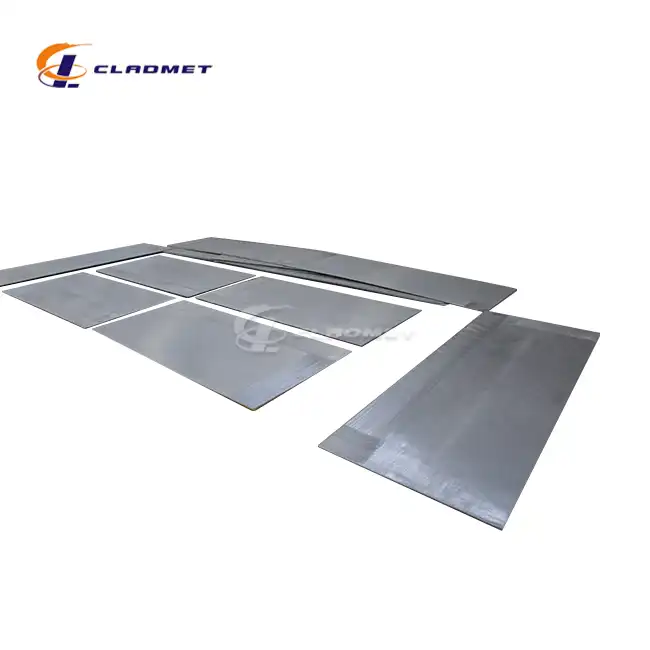

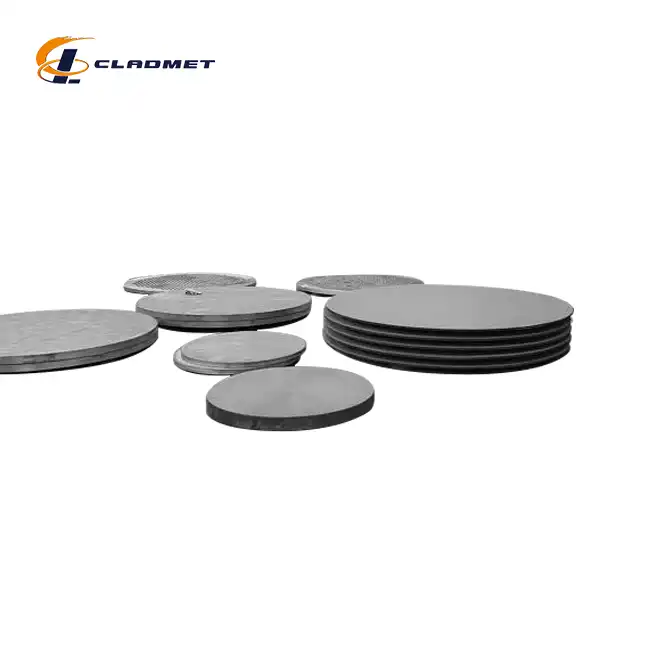

Titanium Steel Composite Plate for Chemical Industry

Base material: titanium plate. Covering layer: steel plate.

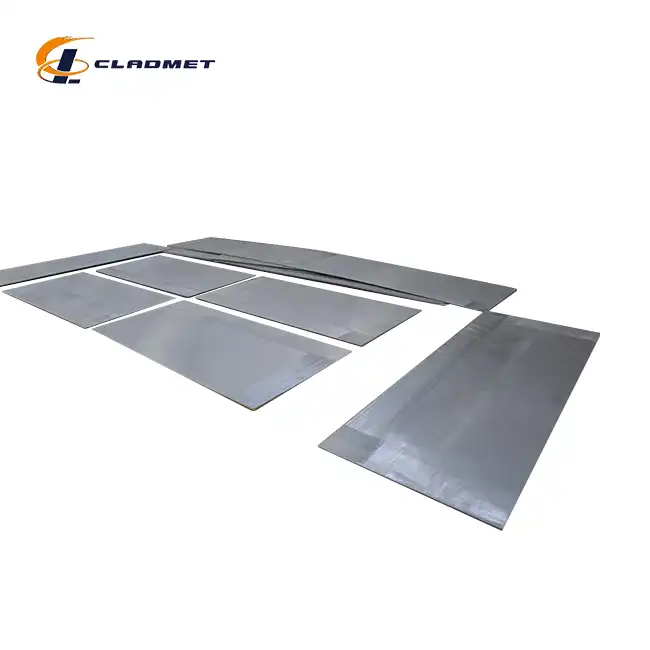

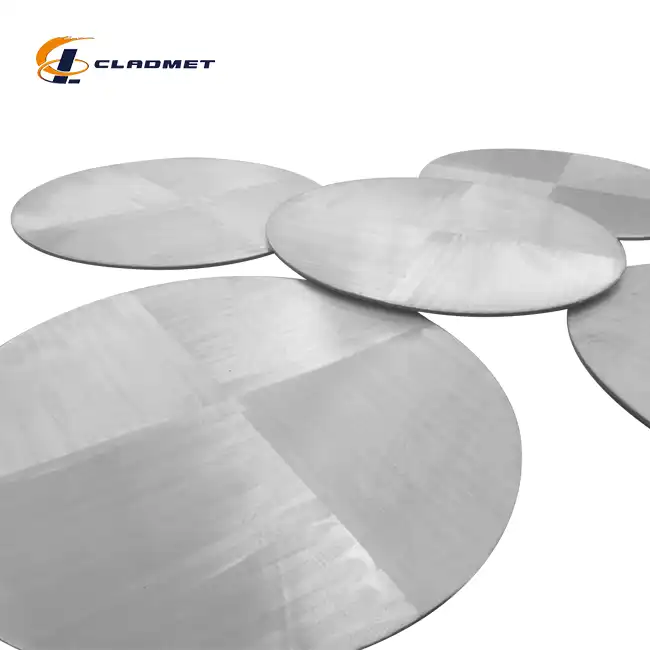

Size: standard and customized sizes.

Application: widely used in oil, gas, shipbuilding and chemical industries.

Processing technology: advanced explosion welding and hot rolling technology.

Quality Control and Testing: strict internal testing ensures durability and compliance.

Execution Standard: ASME, ASTM, JIS certification. ISO9001-2000, PED, ABS certification.

Delivery: global shipping methods such as sea or air are available.

Packing: durable wooden boxes are used to ensure safe transportation.

Premium Titanium Steel Composite Plate Solutions

INDUSTRIAL-GRADE COMPOSITE PLATES

Baoji JL Clad Metals Materials Co., Ltd. specializes in manufacturing advanced titanium-steel composite plates engineered for extreme chemical environments. Our 40+ years of metallurgical expertise ensures exceptional corrosion resistance and structural integrity - critical for chemical processing equipment longevity.

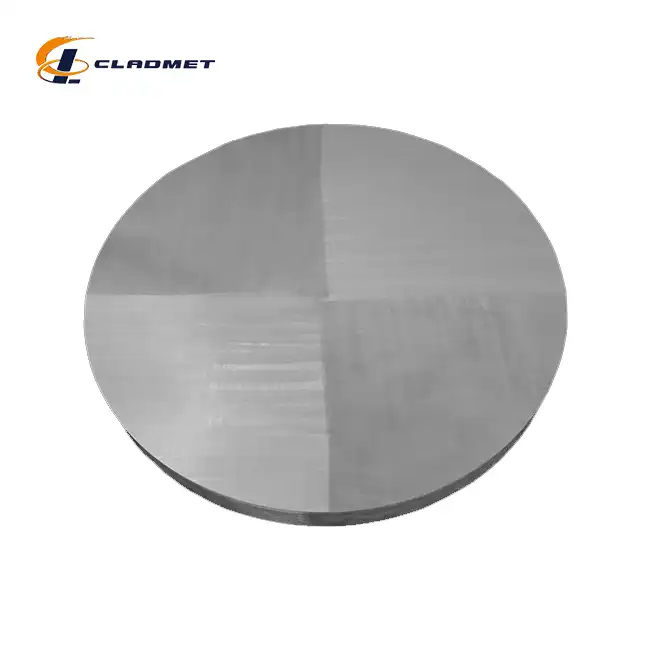

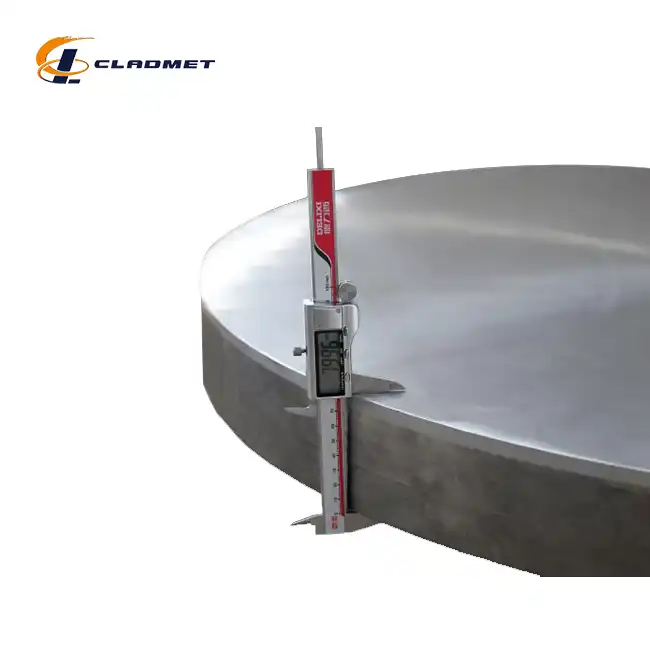

Utilizing proprietary explosive welding technology, we achieve perfect molecular bonding between titanium layers (0.5-10mm) and carbon steel substrates (10-200mm). This creates cost-effective solutions combining titanium's superior chemical stability with steel's mechanical strength.

Years Experience

Annual Production(Tons)

Quality Pass Rate

Technical Patents

Key Application Industries

Chemical Processing

Petrochemical Plants

Pharmaceutical Manufacturing

Marine Engineering

Power Generation

Waste Treatment Systems

Technical Advantages

Engineered for Extreme Chemical Resistance

Superior Corrosion Resistance

Withstands concentrated acids (HCl, H2SO4, HNO3), alkalis, and salt solutions up to 200°C. Titanium layer thickness customized from 0.5mm to 10mm based on corrosion requirements.

01

High-Pressure Capacity

Bond strength ≥210MPa, working pressure up to 6.4MPa. Suitable for reactor vessels, heat exchangers, and high-pressure piping systems.

02

Cost Efficiency

30-50% cost reduction compared to solid titanium equipment. Steel substrate thickness ranges 10-200mm for structural stability.

03

Custom Fabrication

Available in sheets (2000×6000mm max) or prefabricated components. Surface finishes from Ra 3.2μm to mirror polish (Ra 0.4μm).

04

Why Choose JL Clad Metals?

Certified Quality

ISO 9001:2015, PED 2014/68/EU, and ABS certified manufacturing processes

Advanced R&D

Doctor-led team with 15+ metallurgical patents in clad metal technology

Global Logistics

45,500m² production base with 2000+ ton annual output capacity

Technical Support

Complete material certificates (MTC) and welding procedure specifications

Contact Our Material Experts

Tel: +86 15353335118 | Email: stephanie@cladmet.com

Address: Fenghuang 4 Road, High-tech District, Baoji City, Shaanxi Province

_1737007724117.webp)

_1740558024479.webp)