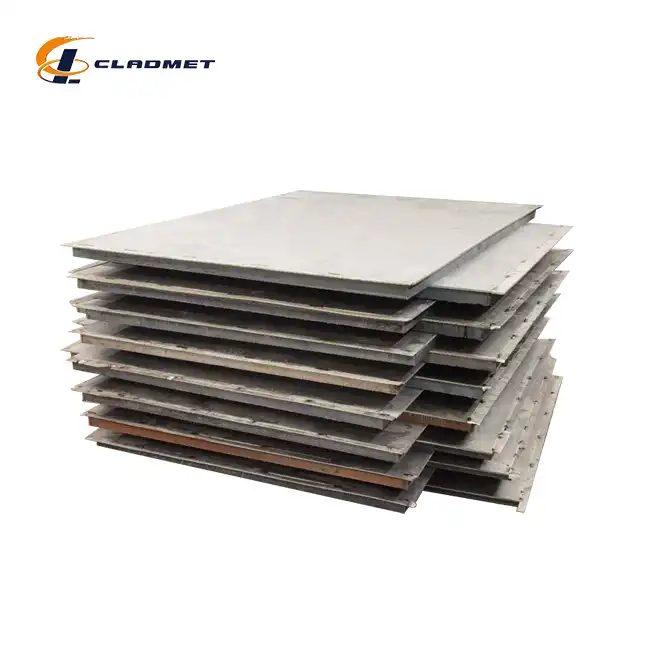

Titanium Clad Steel Sheet High Strength

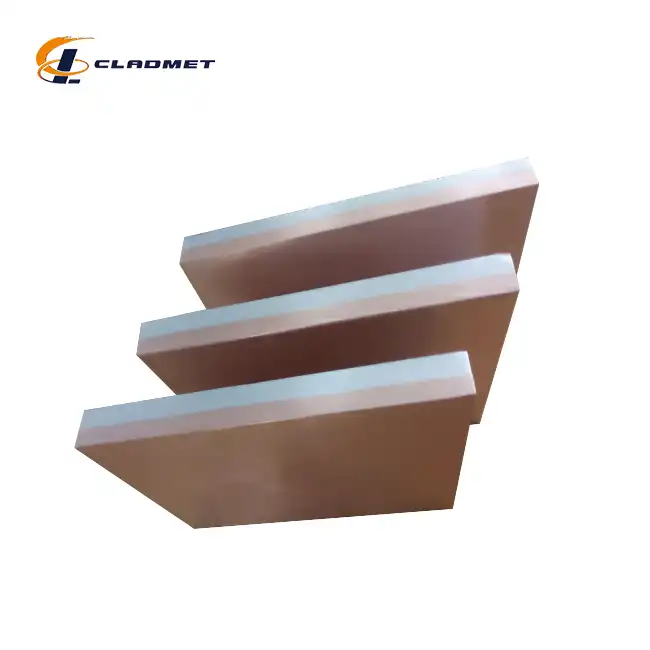

Base material: titanium plate. Covering layer: steel plate.

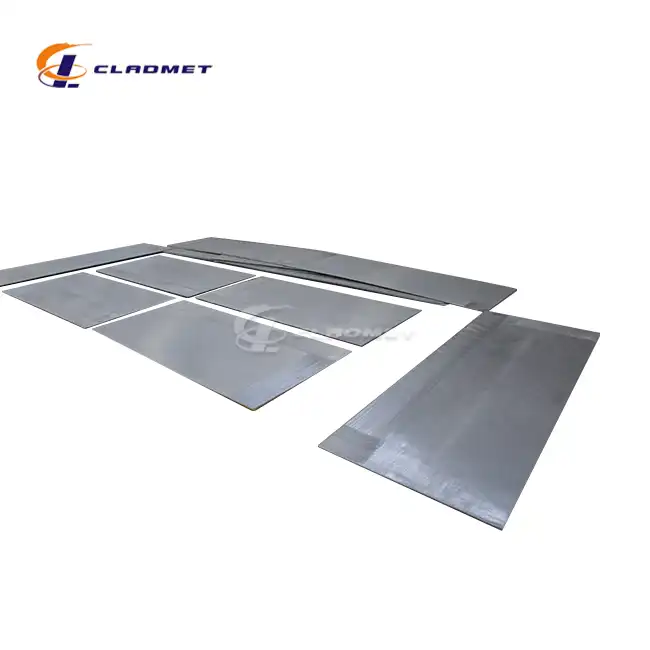

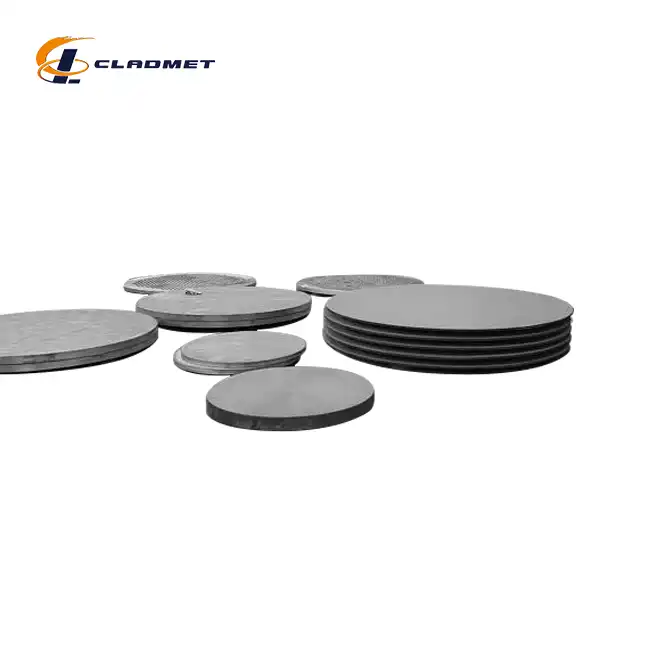

Available Sizes:Standard and custom sizes available.

Product Applications:Widely used in oil, gas, shipbuilding, and chemical industries.

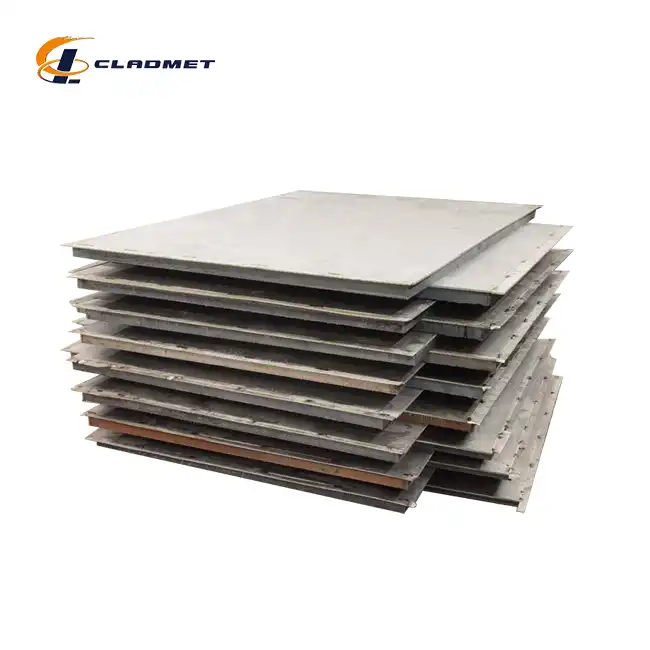

Processing Technology: Advanced explosive bonding and hot rolling technology.

Quality Control & Testing: Strict in-house testing ensures durability and compliance.

Implementation Standards:ASME, ASTM, JIS certified. ISO9001-2000, PED, ABS certifications.

Delivery:Global shipping options available via sea or air freight.

Packaging: Durable wooden crates for safe transport.

HIGH-PERFORMANCE TITANIUM CLAD STEEL SOLUTIONS

Baoji JL Clad Metals Materials Co., Ltd. specializes in manufacturing premium Titanium Clad Steel Sheets that combine titanium's exceptional corrosion resistance with steel's structural strength. Our advanced explosion welding technology ensures perfect metallurgical bonding, achieving shear strength exceeding 210 MPa.

Certified to ASTM B898 and ASME SA263 standards, these bimetallic sheets feature:

• 0.5-6mm titanium layer thickness

• 6-50mm total thickness range

• Customizable dimensions up to 3000×6000mm

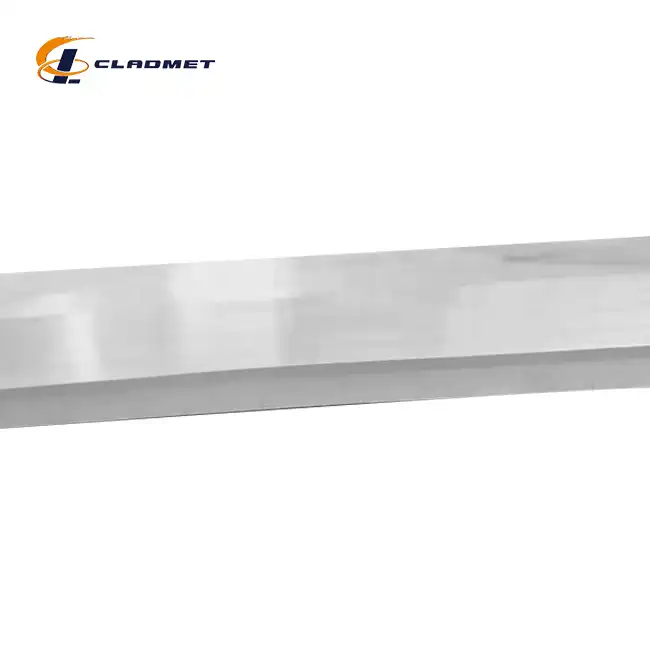

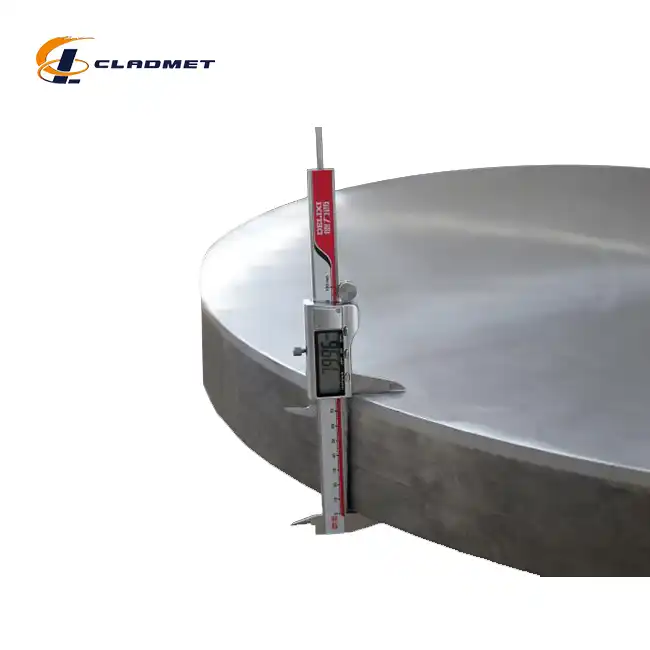

• Surface finishes from RA 0.8μm to 3.2μm

Years Experience

Annual Production(Tons)

Quality Pass Rate

Fastest Delivery

Technical Advantages

Engineered for Extreme Service Conditions

Superior Bond Integrity

Our proprietary EBW-3X explosion welding process creates transition zones <1μm, achieving bond strength exceeding parent metal limits. Third-party tested for:

• 0% interfacial contamination

• >210MPa shear strength

• Full vacuum integrity

01

Advanced Material Options

Available combinations:

• Base Layer: Q345R, SA516 Gr70, SUS316L

• Clad Layer: Gr1-Gr12, Ti-0.3Mo-0.8Ni

• Transition Layers: Ni/Cu interlayers available

• Surface Treatments: Pickling/Passivation

02

Precision Forming

Cold forming tolerance:

• Minimum bend radius: 3T

• Post-weld heat treatment: 580-620°C

• Flatness tolerance: <1.5mm/m²

• Edge preparation: Laser-cut bevels

03

Industrial Applications

Chemical Processing

Marine Engineering

Power Generation

In Clad Metal Manufacturing

Since 1988, we've delivered over 15,000 tons of clad metals to global clients. Our 45,500m² facility features:

- 5 explosion welding lines with 3000-ton capacity

- Class 100 clean rolling environment

- Automated UT testing systems

- Vacuum electron beam welding stations

Why Choose JL Clad Metals?

Material Science Experts

PhD-led R&D team with 23 material patents and 7 process innovations

Full Process Control

Vertical integration from material selection to final inspection

Global Compliance

Certified for ASME, PED, JIS, and GB standards

Rapid Prototyping

15-day sample production with full material certification

- +8615353335118

- Fenghuang 4 road, High-tech district, Baoji City, Shaanxi Province.

_1737007724117.webp)

_1737611764680.webp)

_1737611948854.webp)