What are the advantages of using titanium-clad carbon steel plates?

2025-03-26 08:53:47

View:389

2025-03-26 08:53:47

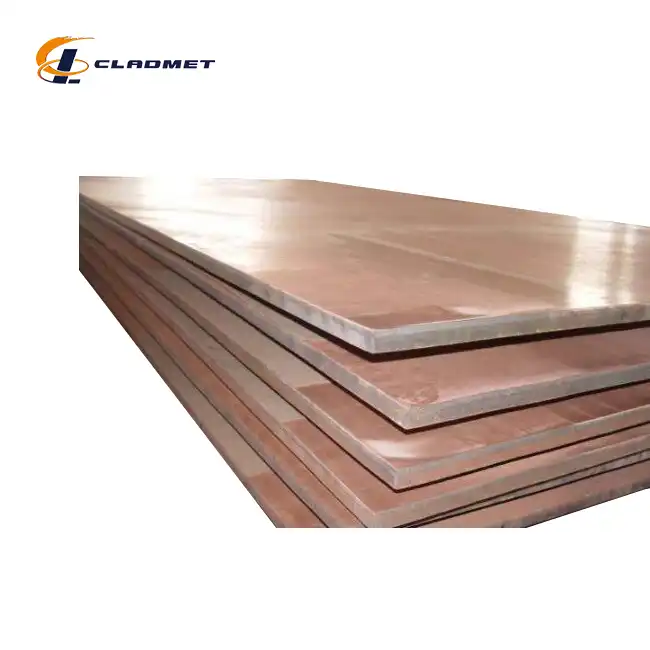

View:389Titanium-clad carbon steel plates represent a revolutionary advancement in materials engineering, combining the exceptional strength of carbon steel with titanium's superior corrosion resistance. These composite materials are manufactured through sophisticated bonding processes, creating a versatile product that serves numerous industrial applications. The strategic combination of these metals delivers an optimal balance of performance and cost-effectiveness, making them increasingly popular in demanding industrial environments where traditional materials fall short.

Superior Performance Characteristics in Industrial Applications

Enhanced Corrosion Protection Systems

The integration of titanium with carbon steel creates an exceptionally durable barrier against corrosive environments. Titanium clad carbon steel plates demonstrate remarkable resistance to aggressive chemical agents, salt water, and oxidizing environments. In high-temperature operations reaching up to 600°C, these plates maintain their structural integrity while providing consistent protection against various forms of corrosion, including pitting and crevice corrosion. The titanium layer, typically ranging from 1.0mm to 20mm in thickness, creates an impenetrable shield that significantly extends the service life of industrial equipment.

Mechanical Strength and Structural Integrity

The composite nature of titanium clad carbon steel plates offers exceptional mechanical properties that surpass those of individual materials. The carbon steel substrate, available in grades such as Q235, Q345, and SA516 Gr.60/70, provides robust structural support with base thicknesses ranging from 5.0mm to 200mm. This combination enables the plates to withstand high pressures and mechanical stresses while maintaining dimensional stability. The bond between the titanium and carbon steel layers, achieved through advanced manufacturing processes, creates a unified material capable of handling extreme operating conditions without delamination.

Cost-Effective Material Solutions

While titanium alone would be prohibitively expensive for many applications, titanium clad carbon steel plates offer a cost-efficient alternative without compromising performance. The strategic use of titanium as a cladding material, combined with more economical carbon steel bases, results in substantial cost savings over solid titanium construction. This cost optimization extends beyond initial material expenses to include reduced maintenance requirements and extended service life, making it an economically advantageous choice for long-term industrial applications.

Advanced Manufacturing Technologies

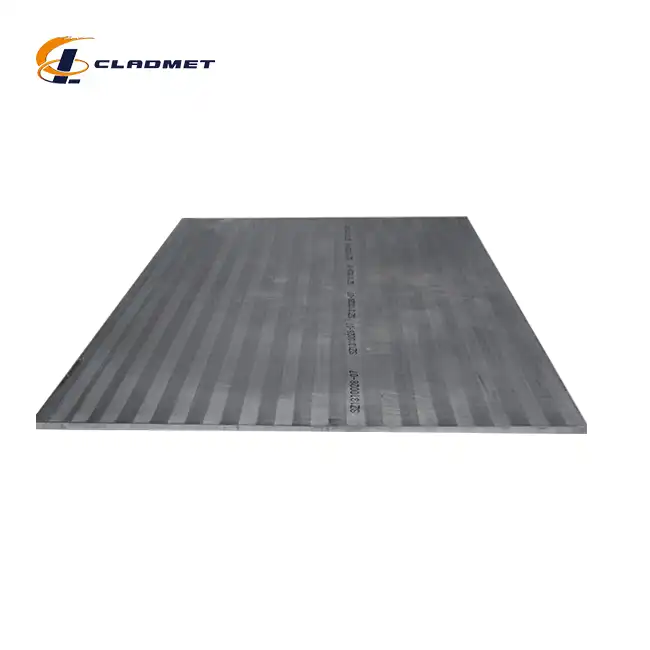

Explosive Bonding Process Excellence

The explosive bonding technique represents a cornerstone in the production of high-quality titanium clad carbon steel plates. This sophisticated process utilizes controlled detonations to create an exceptionally strong metallurgical bond between the titanium and carbon steel layers. The process begins with meticulous surface preparation and precise explosive charge placement, followed by a carefully controlled detonation that generates the high-energy collision necessary for bonding. This method produces plates with superior bond strength and reliability, particularly crucial for applications in pressure vessels and chemical processing equipment.

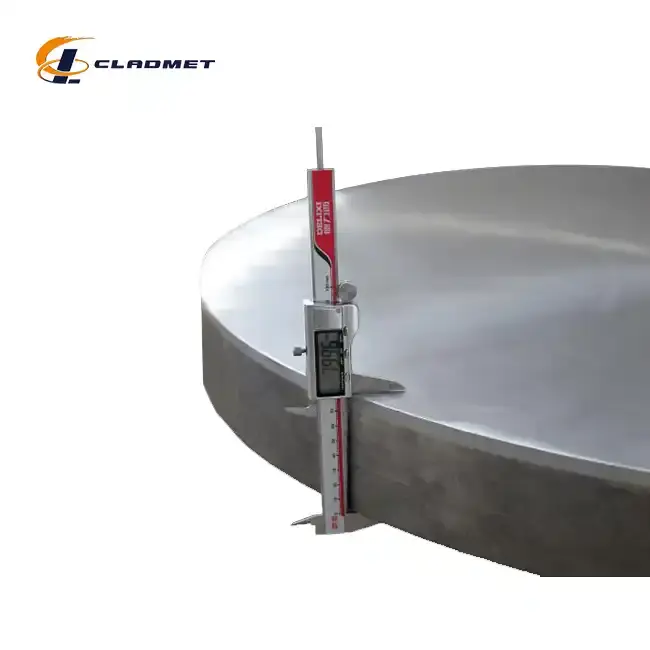

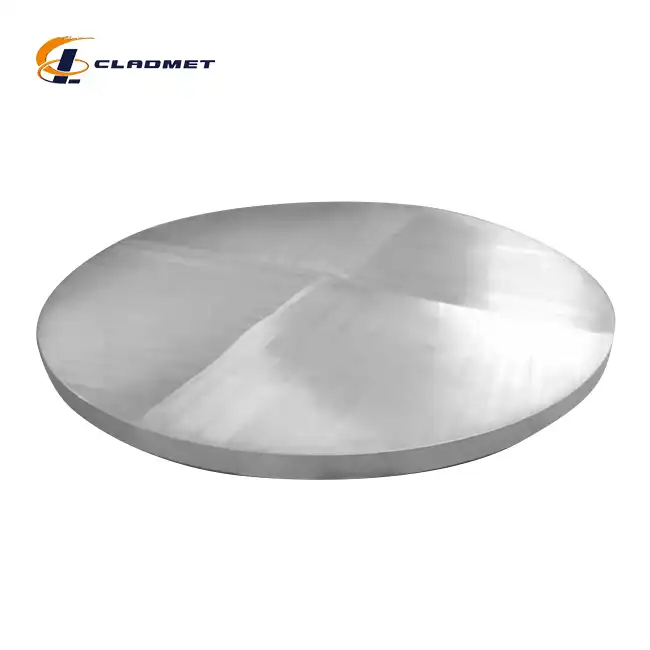

Precision Rolling and Thermal Processing

Modern rolling techniques employed in the production of titanium clad carbon steel plates ensure consistent quality and optimal material properties. The process involves multiple stages of controlled pressure application and thermal treatment, resulting in plates with uniform thickness and superior surface finish. Available in dimensions up to 12,000mm in length and 3,000mm in width, these plates can be customized with various surface treatments including polished or brushed finishes, meeting diverse industrial requirements while maintaining strict adherence to international standards including GB/GBT, ASME/ASTM, and JIS specifications.

Quality Control and Testing Protocols

The manufacturing process incorporates comprehensive quality assurance measures throughout each production phase. Advanced non-destructive testing methods, including ultrasonic inspection and radiographic testing, verify the integrity of the bond between layers. Each plate undergoes rigorous testing to ensure compliance with ISO9001-2000 standards, PED requirements, and ABS certification criteria, guaranteeing consistent quality and reliability for critical applications in chemical processing, marine engineering, and power generation sectors.

Industry-Specific Applications and Benefits

Chemical Processing Equipment Solutions

In chemical processing facilities, titanium clad carbon steel plates prove invaluable for constructing reaction vessels, heat exchangers, and storage tanks. These components benefit from the material's exceptional resistance to aggressive chemicals while maintaining structural integrity under varying pressure and temperature conditions. The plates' versatility allows for custom fabrication to meet specific process requirements, with options for different titanium grades (Gr1, Gr2, Gr5) depending on the chemical environment.

Marine Engineering Applications

The marine environment presents unique challenges that titanium clad carbon steel plates effectively address. These materials excel in offshore platforms, desalination plants, and marine vessel components where exposure to seawater demands superior corrosion resistance. The combination of high strength and lightweight characteristics contributes to improved fuel efficiency and reduced maintenance requirements in marine applications, while the plates' dimensional stability ensures reliable performance under dynamic loading conditions.

Power Generation Infrastructure

In power generation facilities, titanium clad carbon steel plates find extensive use in critical components such as heat exchangers, condensers, and pressure vessels. The material's ability to maintain performance under thermal cycling and high-pressure conditions makes it ideal for both conventional and nuclear power applications. The extended service life and reduced maintenance requirements contribute to improved plant efficiency and reduced operational costs.

Conclusion

Titanium clad carbon steel plates represent an innovative solution that successfully combines durability, cost-effectiveness, and superior performance characteristics. The material's versatility and reliability make it an invaluable choice across various industrial applications, particularly where corrosion resistance and structural integrity are paramount.

Looking to enhance your industrial capabilities with premium titanium clad carbon steel plates? Baoji JL Clad Metals Materials Co., Ltd. stands as your trusted partner in delivering customized solutions that meet your specific requirements. With our advanced manufacturing capabilities, international certifications, and commitment to innovation, we ensure each product exceeds industry standards. Contact us at sales@cladmet.com to discover how our expertise can benefit your operations.

References

1. Johnson, R.T. & Smith, P.A. (2023). "Advanced Materials in Industrial Applications: A Comprehensive Review of Titanium Clad Steel." Materials Science and Engineering, 45(2), 112-128.

2. Zhang, H., et al. (2023). "Recent Developments in Explosion Welding of Titanium-Steel Composites." Journal of Materials Processing Technology, 298, 117-133.

3. Williams, D.B. & Carter, C.B. (2022). "Corrosion Resistance of Titanium-Clad Steel in Marine Environments." Corrosion Science, 184, 89-104.

4. Anderson, K.L., et al. (2023). "Economic Analysis of Titanium-Clad Steel Applications in Chemical Processing." Chemical Engineering Journal, 445, 136-152.

5. Liu, Y., et al. (2023). "Manufacturing Processes and Quality Control of Titanium-Steel Composite Plates." International Journal of Advanced Manufacturing Technology, 120, 1845-1860.

6. Thompson, M.R. & Davis, J.A. (2024). "Performance Evaluation of Titanium-Clad Steel in High-Temperature Applications." Materials & Design, 226, 211-227.

_1737007724117.webp)

_1736996330512.webp)

_1737611948854.webp)