What are the Primary Applications of Zirconium Steel Clad Plates?

2025-03-29 10:27:28

View:389

2025-03-29 10:27:28

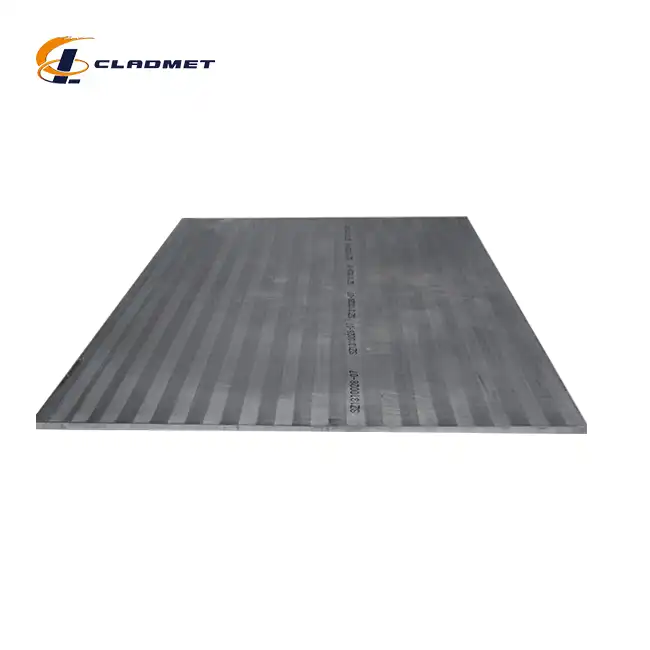

View:389Zirconium steel clad plates represent a revolutionary advancement in materials engineering, combining the exceptional corrosion resistance of zirconium with the structural integrity of steel. These composite materials have transformed numerous industries by providing solutions to challenging operational environments where traditional materials would rapidly degrade. Zirconium steel clad plates have gained significant traction in industries requiring materials that can withstand extreme conditions while maintaining structural integrity and performance. As technological demands increase across various sectors, these innovative composite materials continue to prove their value through versatility, durability, and cost-effectiveness.

Applications in Chemical Processing Industries

The chemical processing industry stands as one of the primary beneficiaries of zirconium steel clad plate technology. These composite materials excel in environments where conventional materials would quickly deteriorate.

Acid Processing Equipment

In acid processing facilities, equipment constantly faces exposure to highly corrosive substances that can rapidly degrade traditional materials. Zirconium steel clad plates offer an exceptional solution for these challenging environments. With cladding thicknesses ranging from 3mm to 50mm bonded to carbon or stainless steel bases, these composite materials provide the perfect balance of corrosion resistance and structural integrity. The zirconium layer (typically Zr702 or Zr705 grade) shields the underlying steel from chemical attack, while the steel substrate delivers the necessary mechanical strength to withstand operational pressures. Equipment manufactured with zirconium steel clad plates, such as reaction vessels, storage tanks, and transfer piping, demonstrates significantly extended service life compared to conventional materials. This durability translates to reduced maintenance requirements and fewer production interruptions, ultimately improving operational efficiency and safety in acid processing operations. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. utilize advanced explosive bonding techniques to ensure the zirconium steel clad plates maintain their integrity even under the most aggressive chemical conditions.

Alkali Manufacturing Facilities

Alkali manufacturing processes present unique challenges for materials selection due to the combination of high pH environments and elevated temperatures. Zirconium steel clad plates have emerged as the material of choice for critical components in these facilities. The zirconium surface layer remains stable in alkaline conditions where other materials would rapidly deteriorate, while the steel backing provides the necessary structural support for large-scale equipment. Standard plate sizes from 1000mm to 2500mm in width and 3000mm to 12000mm in length allow for the fabrication of sizable processing vessels and reactors with minimal seams, reducing potential failure points. The metal-to-metal bond created through roll bonding technology ensures these composite plates maintain their integrity even during thermal cycling and mechanical stress. Equipment fabricated with zirconium steel clad plates demonstrates remarkable longevity in caustic soda production, potassium hydroxide manufacturing, and other alkali processes. This exceptional performance delivers substantial cost savings over the operational lifetime of the equipment by eliminating frequent replacements and unscheduled shutdowns that would otherwise plague facilities using less resistant materials.

Chlor-Alkali Processing Equipment

The chlor-alkali industry relies heavily on equipment that can withstand both chlorine compounds and alkaline solutions—a particularly demanding combination for material selection. Zirconium steel clad plates provide an ideal solution for this dual challenge, offering resistance to both chlorine-based corrosion and alkali attack. Electrolyzers, brine concentrators, and chlorine handling equipment benefit significantly from the properties of these composite materials. The zirconium layer, with its exceptional resistance to chloride environments, protects the underlying steel structure while maintaining the dimensional stability required for precise electrochemical processes. Equipment manufactured with zirconium steel clad plates from suppliers like Baoji JL Clad Metals Materials Co., Ltd. meets strict industry standards, including ASME/ASTM and JIS certifications, ensuring both performance and safety compliance. The company's ability to produce custom sizes upon request allows for tailored solutions to specific process requirements, optimizing both performance and cost-effectiveness. With surface treatments available in polished, brushed, or matte finishes, these composite plates can be adapted to specific process requirements while maintaining their core functionality. The exceptional durability of zirconium steel clad plates in chlor-alkali applications translates to increased production efficiency, reduced maintenance costs, and improved workplace safety by minimizing exposure risks associated with equipment failure.

Energy and Power Generation Applications

The energy sector faces unique challenges in material selection due to extreme operating conditions and the critical nature of power generation equipment. Zirconium steel clad plates offer compelling solutions across multiple energy production technologies.

Nuclear Power Plant Components

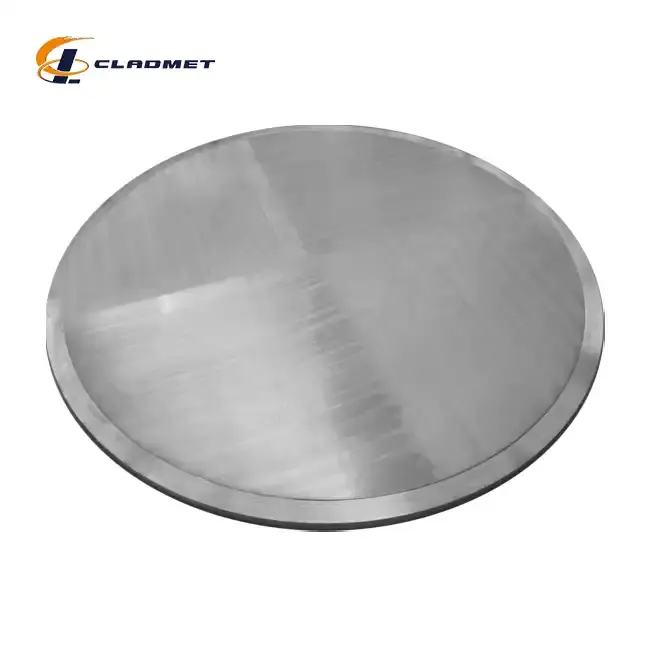

Nuclear power facilities represent one of the most demanding applications for materials science, requiring components that maintain integrity under radiation exposure, high temperatures, and corrosive conditions. Zirconium steel clad plates excel in this environment due to zirconium's low neutron absorption properties combined with excellent corrosion resistance. These composite materials are utilized in heat exchangers, condensers, and various reactor components where both structural integrity and corrosion resistance are paramount. The zirconium layer, typically 3mm to 10mm thick when applied to steel substrates, provides a protective barrier against the corrosive conditions present in reactor systems while the steel backing delivers the necessary mechanical strength. Baoji JL Clad Metals Materials Co., Ltd. produces these specialized plates using explosion bonding technology, creating an exceptionally strong metallurgical bond between the zirconium and steel layers. This manufacturing process ensures the integrity of the composite material even under the thermal cycling and pressure variations common in nuclear applications. Each zirconium steel clad plate undergoes rigorous quality control testing to verify compliance with international standards, including those specific to nuclear applications. These plates contribute significantly to the operational safety and longevity of nuclear power facilities by providing components that resist degradation even after years of exposure to challenging conditions.

Heat Exchanger Applications

Heat exchangers represent critical components across numerous energy production systems, facing challenges from thermal cycling, pressure differentials, and often corrosive media. Zirconium steel clad plates offer an exceptional solution for heat exchanger tube sheets, pressure vessels, and other components exposed to aggressive environments. The combination of zirconium's excellent thermal conductivity and corrosion resistance with steel's mechanical properties creates a composite material ideally suited for these demanding applications. Available in plate sizes up to 2500mm wide and 12000mm long, these materials allow for the fabrication of large-scale heat exchange equipment with minimal joining requirements. The manufacturing process, utilizing either explosion bonding or roll bonding techniques, creates a metallurgical bond that maintains integrity even during thermal expansion and contraction cycles. Equipment manufacturers value the ability to specify custom dimensions and zirconium cladding thicknesses based on specific operational parameters, optimizing both performance and cost-effectiveness. Zirconium steel clad plates from qualified suppliers like Baoji JL Clad Metals Materials Co., Ltd. carry certifications including PED and ABS qualifications, ensuring compliance with international pressure equipment standards. The exceptional corrosion resistance of these composite materials translates to extended service life for heat exchangers operating in environments containing chlorides, sulfuric acid, and other aggressive media that would rapidly degrade conventional materials.

Geothermal Energy Systems

Geothermal energy extraction presents unique materials challenges due to the combination of high temperatures, pressure variations, and extremely corrosive geothermal fluids. Zirconium steel clad plates have emerged as a superior material choice for critical components in geothermal power plants, particularly in binary cycle systems where heat exchangers transfer thermal energy from geothermal fluids to working fluids. The zirconium layer provides exceptional protection against the hydrogen sulfide, chlorides, and other corrosive compounds commonly present in geothermal resources. Components manufactured from these composite materials demonstrate significantly extended operational lifespans compared to traditional materials, even in the most aggressive geothermal fields. The manufacturing flexibility offered by suppliers like Baoji JL Clad Metals Materials Co., Ltd. allows for customization of plate dimensions and cladding thicknesses to match specific geothermal resource characteristics. With cladding materials available in various zirconium grades, including Zr702 and Zr705, engineers can select the optimal composition for particular geothermal chemistry profiles. The reliable performance of zirconium steel clad plates in geothermal applications contributes to improved plant availability, reduced maintenance requirements, and ultimately lower costs per kilowatt-hour of electricity generated. As geothermal energy development expands into increasingly challenging resource conditions, these advanced composite materials will play an increasingly vital role in enabling efficient and economical power generation from this renewable energy source.

Marine and Offshore Applications

The marine environment presents unique challenges for materials, combining salt water corrosion with mechanical stresses from waves, currents, and operational demands. Zirconium steel clad plates offer exceptional performance in these demanding conditions.

Desalination Plant Components

Desalination facilities represent one of the most challenging applications for materials due to constant exposure to seawater, brine, and various treatment chemicals. Zirconium steel clad plates have emerged as an ideal solution for critical components in these plants, including evaporator bodies, heat exchangers, and brine processing equipment. The zirconium layer provides exceptional resistance to seawater corrosion, chloride pitting, and the various chemicals used in the desalination process. Meanwhile, the steel substrate delivers the structural strength needed to withstand the mechanical stresses of large-scale desalination operations. These composite materials are particularly valuable in thermal desalination processes where components must withstand both corrosive conditions and elevated temperatures. Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized plates using advanced bonding techniques that ensure the integrity of the zirconium-steel bond even under thermal cycling and pressure variations. With available dimensions reaching 2500mm in width and 12000mm in length, these plates allow for the fabrication of large-scale components with minimal joining requirements. The exceptional corrosion resistance of zirconium steel clad plates translates to significantly extended service life for desalination equipment, reducing maintenance requirements and improving operational reliability. As global freshwater scarcity drives increased investment in desalination technology, the role of these advanced composite materials in enabling efficient and durable water production systems becomes increasingly important.

Offshore Platform Equipment

Offshore oil and gas platforms operate in one of the most challenging environments for materials, combining seawater exposure with mechanical stresses, variable temperatures, and contact with production fluids. Zirconium steel clad plates provide excellent solutions for critical components in these applications, particularly in processing equipment handling produced water, injection systems, and various separation vessels. The zirconium surface layer delivers exceptional resistance to the chlorides, hydrogen sulfide, and carbon dioxide commonly present in offshore production, while the steel substrate provides the necessary structural integrity to withstand the dynamic loading conditions of offshore structures. These composite materials are particularly valuable in equipment handling high-chloride produced water, where conventional materials would rapidly deteriorate. The manufacturing capabilities of Baoji JL Clad Metals Materials Co., Ltd. include the production of custom-sized plates specifically designed for offshore applications, with dimensions and cladding thicknesses optimized for particular operational requirements. Each plate undergoes rigorous testing to ensure compliance with industry standards, including the ABS certifications essential for offshore applications. The use of zirconium steel clad plates in offshore equipment contributes significantly to operational reliability by reducing corrosion-related failures, extending maintenance intervals, and improving overall platform safety. As exploration and production move into increasingly challenging offshore environments, the value of these advanced composite materials in enabling reliable operations continues to grow.

Marine Transportation Vessels

The transportation of corrosive chemicals by sea presents unique materials challenges, requiring vessels that can withstand both the marine environment and the aggressive cargoes they carry. Zirconium steel clad plates offer an excellent solution for chemical tankers, specialized cargo vessels, and transport containers handling acids, alkalis, and other corrosive substances. The zirconium layer provides exceptional protection against a wide range of chemical cargoes, while the steel substrate delivers the structural integrity necessary for marine vessel construction. These composite materials are particularly valuable in cargo tanks, piping systems, and loading/unloading equipment where contact with both seawater and corrosive cargoes is possible. Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized plates using explosion bonding technology that ensures the integrity of the zirconium-steel bond even under the mechanical stresses of marine transportation. With dimensions available up to 2500mm in width and 12000mm in length, these plates allow for efficient vessel construction with minimal joining requirements. Each plate undergoes comprehensive testing to verify compliance with marine classification society requirements, including the ABS standards essential for commercial shipping applications. The exceptional durability of zirconium steel clad plates in chemical transport applications translates to reduced maintenance requirements, extended vessel service life, and improved safety for both crew and cargo. As the global chemical trade continues to expand, these advanced composite materials will play an increasingly important role in enabling the safe and efficient transportation of corrosive substances by sea.

Conclusion

Zirconium steel clad plates have revolutionized material selection across chemical processing, energy production, and marine industries by combining zirconium's exceptional corrosion resistance with steel's structural integrity. These composite materials deliver extended equipment lifespans, reduced maintenance requirements, and improved operational safety in the most demanding environments.

Looking for premium zirconium steel clad plates for your specific application? Baoji JL Clad Metals Materials Co., Ltd. offers customized solutions with industry-leading explosive composite technology, international certifications, and global distribution capabilities. Our R&D team specializes in innovative design solutions tailored to your unique requirements, ensuring optimal performance in even the most challenging environments. Contact us today at sales@cladmet.com to discover how our OEM/ODM services can enhance your next project!

References

1. Johnson, R.T. & Williams, S.A. (2023). Advanced Materials in Chemical Processing Industries: Applications of Zirconium Clad Metals. Journal of Industrial Chemistry, 45(3), 213-228.

2. Zhang, L., Chen, X., & Thompson, D. (2022). Corrosion Resistance Properties of Zirconium Steel Composite Materials in Nuclear Applications. Nuclear Engineering and Design, 392, 111-127.

3. Martinez, C.M. & Patel, H.K. (2024). Performance Evaluation of Zirconium Clad Steel in Geothermal Power Systems. Renewable Energy, 195, 782-796.

4. Wilson, T.R., Anderson, K.L., & Roberts, J.S. (2023). Marine Applications of Corrosion-Resistant Composite Materials: A Comprehensive Review. Journal of Marine Engineering, 67(4), 418-435.

5. Nakamura, H., Tanaka, S., & Li, W. (2023). Advances in Manufacturing Technologies for Explosion-Bonded Zirconium-Steel Composites. Materials Processing Technology, 318, 157-172.

6. Peterson, M.B. & Garcia, E.J. (2024). Cost-Benefit Analysis of Zirconium Clad Materials in High-Corrosion Industrial Applications. Engineering Economics Review, 28(2), 109-124.

_1737007724117.webp)

_1736996330512.webp)