What are the advantages of using 316L Stainless Steel-Carbon Steel Clad Heads over solid stainless steel?

2025-04-12 12:21:00

View:389

2025-04-12 12:21:00

View:389When it comes to critical industrial applications requiring both corrosion resistance and structural integrity, 316L stainless steel-carbon steel clad heads offer significant advantages over solid stainless steel alternatives. These composite materials combine the exceptional corrosion resistance of 316L stainless steel with the superior mechanical strength and cost-effectiveness of carbon steel, creating a solution that outperforms single-material options in numerous ways. The 316L stainless steel-carbon steel clad head represents a technological advancement that delivers optimal performance in challenging environments without the prohibitive costs associated with solid stainless steel construction, making it an increasingly popular choice across petroleum, chemical, pharmaceutical, and other demanding industries.

Economic Benefits of 316L Stainless Steel-Carbon Steel Clad Heads

Cost Efficiency Without Sacrificing Performance

The economic advantages of 316L stainless steel-carbon steel clad heads over solid stainless steel construction are substantial and multifaceted. By utilizing carbon steel as the base material and applying a layer of 316L stainless steel only where needed for corrosion protection, manufacturers can achieve significant material cost savings—often 30-40% compared to solid stainless steel alternatives. This strategic use of materials doesn't compromise performance; rather, it optimizes it. The 316L stainless steel-carbon steel clad head provides the corrosion resistance where it matters most—at the surface exposed to aggressive media—while the carbon steel substrate delivers the necessary mechanical strength. For equipment manufacturers and facility operators working with tight budgets but unwilling to compromise on quality, this approach represents an ideal balance. The reduction in raw material costs translates directly to more competitive pricing for end products, allowing companies to maintain profit margins while offering solutions that meet stringent performance requirements. Additionally, the weight reduction compared to solid stainless steel components can lead to secondary cost benefits in transportation, installation, and structural support requirements.

Extended Service Life and Reduced Maintenance

One of the most compelling economic benefits of choosing 316L stainless steel-carbon steel clad heads relates to their exceptional longevity and minimal maintenance requirements. When properly manufactured using advanced explosion welding (EXW) technology, these composite components can deliver service lives that meet or exceed those of solid stainless steel counterparts in many applications. The 316L stainless steel layer effectively shields the carbon steel substrate from corrosive media, preventing deterioration and extending operational life. This translates to fewer replacement cycles over the lifetime of the equipment, which significantly reduces both direct material costs and the substantial indirect costs associated with downtime, labor, and production losses during maintenance operations. Industry studies suggest that maintenance savings alone can offset the initial investment within 3-5 years in highly corrosive environments. Furthermore, the dimensional stability of 316L stainless steel-carbon steel clad heads under thermal cycling conditions helps maintain seal integrity, reducing the frequency of gasket replacements and associated maintenance interventions. For industries where equipment reliability directly impacts production output and safety, such as chemical processing and oil refining, this reduced maintenance burden represents a substantial economic advantage that compounds over the operational lifetime of the equipment.

Versatility and Customization Capabilities

The economic value of 316L stainless steel-carbon steel clad heads extends beyond direct cost savings to include significant benefits from their exceptional versatility and customization potential. Baoji JL Clad Metals Materials Co., Ltd. offers these components in customizable dimensions, with diameters up to 2000mm and variable thicknesses for both the stainless steel layer (2mm–10mm) and carbon steel base (10mm–60mm). This adaptability allows engineers to precisely match material specifications to application requirements, optimizing both performance and cost. Rather than over-engineering with thick solid stainless steel components, designers can specify the exact corrosion allowance needed for the stainless steel layer while using the less expensive carbon steel for structural strength. The 316L stainless steel-carbon steel clad head can be manufactured using various bonding technologies, including explosion welding (EXW) and roll bonding, depending on specific performance requirements and budget constraints. Furthermore, these components can undergo additional value-adding processes such as pickling or polishing to enhance surface properties or aesthetic qualities. This flexibility allows companies to invest their resources strategically, allocating premium materials only where needed while maintaining overall performance and safety standards. For industries with evolving production requirements or those developing new process technologies, this adaptability represents a significant economic advantage that solid stainless steel alternatives cannot match.

Technical Superiority of Clad Heads in Demanding Applications

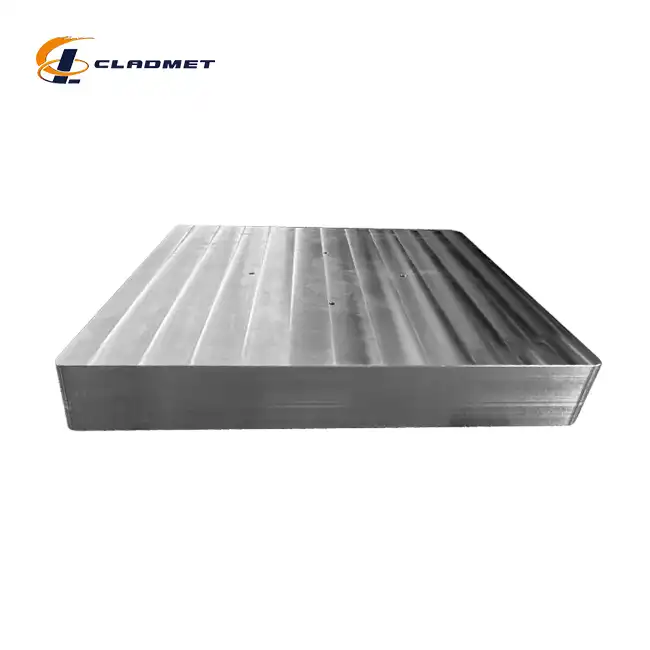

Enhanced Mechanical Properties and Pressure Resistance

The 316L stainless steel-carbon steel clad head demonstrates remarkable technical advantages in terms of mechanical performance and pressure resistance compared to solid stainless steel alternatives. Carbon steel, with its higher tensile strength and yield point, provides exceptional structural integrity to withstand extreme mechanical stresses. When this strength is combined with the corrosion resistance of 316L stainless steel through advanced bonding technologies, the result is a composite material ideally suited for high-pressure applications. The carbon steel substrate, which can range from 10mm to 60mm in thickness, serves as the primary load-bearing component, while the stainless steel layer (typically 2mm to 10mm) provides the necessary corrosion barrier. This configuration allows for significantly higher operating pressures than would be economically feasible with solid stainless steel alone. The 316L stainless steel-carbon steel clad head manufactured by Baoji JL Clad Metals undergoes rigorous quality control procedures, including 100% Ultrasonic Testing (UT) and X-ray inspection, ensuring bond integrity and structural reliability. These components comply with international standards including GB/GBT, ASME/ASTM, and JIS specifications, making them suitable for critical applications in petrochemical plants, refineries, and other high-pressure processing facilities. The superior mechanical properties of these clad heads make them particularly valuable in applications where both pressure resistance and corrosion protection are essential, such as reactor vessels, high-pressure separators, and chemical storage tanks operating under demanding conditions.

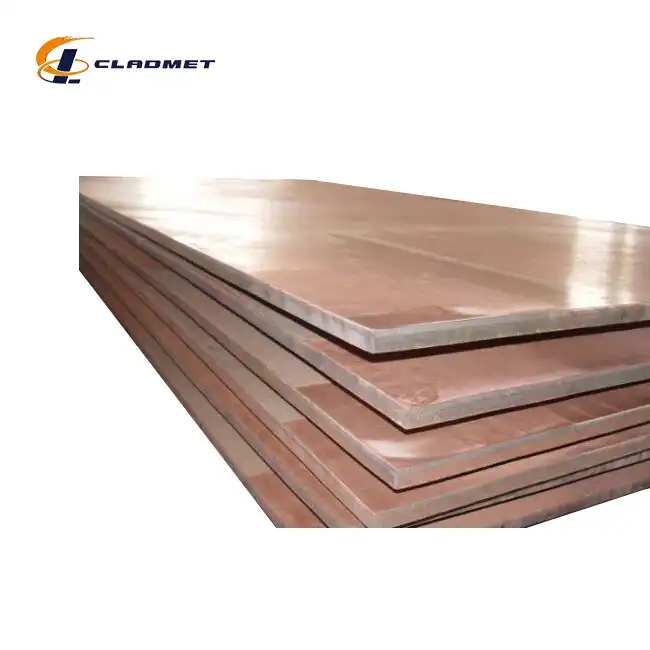

Superior Corrosion Resistance in Aggressive Environments

The exceptional corrosion resistance of 316L stainless steel-carbon steel clad heads represents one of their most significant technical advantages over other material solutions. The 316L stainless steel layer contains molybdenum, which provides enhanced protection against pitting and crevice corrosion, particularly in environments containing chlorides. This makes the 316L stainless steel-carbon steel clad head an ideal choice for applications exposed to seawater, process chemicals, and other aggressive media that would rapidly deteriorate carbon steel alone. The corrosion resistance extends across a broad pH spectrum, allowing these components to perform reliably in both acidic and alkaline environments. Through explosion welding (EXW) technology, Baoji JL Clad Metals creates a metallurgical bond between the stainless steel and carbon steel layers that effectively prevents delamination even under thermal cycling or mechanical stress. This ensures that the protective stainless steel layer remains intact throughout the service life of the component. Unlike solid stainless steel, which represents a significant material investment throughout the entire component, the 316L stainless steel-carbon steel clad head provides targeted corrosion protection exactly where needed—at the surface interface with corrosive media. The thickness of the stainless steel layer can be precisely specified based on the expected corrosion rate and desired service life, typically ranging from 2mm for moderate conditions to 10mm for extremely aggressive environments. This customization capability allows engineers to design equipment with optimal corrosion allowances without the excessive material costs associated with solid stainless steel construction.

Thermal Performance and Stress Management

The 316L stainless steel-carbon steel clad head exhibits superior thermal performance characteristics that provide significant technical advantages in applications involving temperature extremes or thermal cycling. The different thermal expansion coefficients of stainless steel and carbon steel might initially seem problematic, but when properly engineered, this difference can actually be beneficial. The metallurgical bond created through explosion welding (EXW) technology accommodates these different expansion rates without compromising structural integrity. The carbon steel substrate, with its excellent thermal conductivity, helps distribute heat more evenly throughout the component, reducing localized thermal stresses that could lead to premature failure. This is particularly valuable in heat exchangers, reactors, and other process equipment where thermal cycling is common. Additionally, the 316L stainless steel-carbon steel clad head demonstrates superior resistance to thermal shock compared to solid stainless steel alternatives. The thickness ratio between the stainless steel layer and carbon steel base can be optimized to manage thermal stresses effectively, preventing warping or cracking under extreme temperature variations. Baoji JL Clad Metals Materials Co., Ltd. employs advanced manufacturing techniques to ensure that these thermal performance characteristics are consistently achieved. The company's expertise in explosive welding ensures that the bond between the stainless steel and carbon steel remains intact even under demanding thermal conditions. For industries such as petrochemical processing, power generation, and chemical manufacturing where equipment may experience significant temperature fluctuations, this thermal stability represents a critical technical advantage that directly impacts operational reliability and safety.

Manufacturing Excellence and Industry Applications

Advanced Bonding Technologies and Quality Assurance

The manufacturing excellence behind 316L stainless steel-carbon steel clad heads represents a critical factor in their superior performance over solid stainless steel alternatives. Baoji JL Clad Metals Materials Co., Ltd. employs sophisticated explosion welding (EXW) technology to create a metallurgical bond between the 316L stainless steel and carbon steel layers. This high-energy process generates a wave-like interface that mechanically interlocks the two materials at the molecular level, creating a bond strength that often exceeds the strength of either material individually. The explosive charge creates a controlled detonation that propels the stainless steel layer toward the carbon steel substrate at velocities approaching 3,000 meters per second, generating enormous pressures at the collision point. This forces the materials together so intensely that it breaks through oxide layers and creates direct metal-to-metal contact, forming a true metallurgical bond rather than merely an adhesive connection. Each 316L stainless steel-carbon steel clad head undergoes comprehensive quality control procedures, including 100% Ultrasonic Testing (UT) to verify complete bond integrity across the entire surface area. X-ray inspection further confirms the absence of defects or irregularities within the composite structure. Baoji JL Clad Metals has successfully passed ISO9001-2000 certification and, most recently in 2024, secured both PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications, demonstrating their commitment to manufacturing excellence. These rigorous quality assurance protocols ensure that every 316L stainless steel-carbon steel clad head leaving their facility meets or exceeds international standards, providing customers with confidence in the component's reliability and performance under demanding conditions.

Roll Bonding and Specialized Processing Techniques

Beyond explosion welding, Baoji JL Clad Metals Materials Co., Ltd. has mastered roll bonding techniques that offer additional advantages for certain applications of 316L stainless steel-carbon steel clad heads. This process involves carefully preparing the surfaces of both materials, stacking them together, and passing them through powerful rolling mills under precisely controlled conditions of temperature and pressure. The intense mechanical forces create a solid-state diffusion bond between the 316L stainless steel and carbon steel layers. Roll bonding excels in producing clad materials with extremely uniform thicknesses and exceptional flatness, which is particularly valuable for applications requiring tight dimensional tolerances. The controlled environment of roll bonding allows for careful management of the metallurgical characteristics at the interface, optimizing both bond strength and corrosion resistance. The 316L stainless steel-carbon steel clad head can undergo additional specialized processing techniques to enhance specific performance characteristics. Surface treatments such as pickling remove impurities and create a passive layer that further improves corrosion resistance, while polishing can reduce friction or improve flow characteristics in fluid-handling applications. For components exposed to particularly aggressive media, Baoji JL Clad Metals can apply additional protective measures or modify the stainless steel composition to include higher levels of molybdenum or nitrogen for enhanced corrosion resistance. The company's manufacturing facilities can produce 316L stainless steel-carbon steel clad heads in lengths up to 12 meters with customizable widths and thicknesses, accommodating virtually any industrial requirement. This manufacturing versatility, combined with rigorous quality control at every stage of production, ensures that the final 316L stainless steel-carbon steel clad head delivers optimal performance characteristics that solid stainless steel alternatives cannot economically match.

Critical Applications Across Multiple Industries

The 316L stainless steel-carbon steel clad head has become an essential component across numerous industries where equipment must withstand both corrosive media and high mechanical stresses. In the petrochemical sector, these clad heads are frequently used in pressure vessels, reactors, and separation equipment handling crude oil, natural gas, and various process chemicals. Their ability to resist sulfur compounds, hydrogen sulfide, and other corrosive elements present in petroleum processing makes them significantly more cost-effective than solid stainless steel alternatives while maintaining necessary safety margins. The chemical processing industry relies heavily on 316L stainless steel-carbon steel clad heads for equipment containing acids, alkalis, and chloride-bearing compounds. In pharmaceutical manufacturing, where product purity is paramount, these components provide the necessary corrosion resistance on product-contact surfaces while reducing overall equipment costs compared to solid stainless steel construction. Marine applications represent another critical area where 316L stainless steel-carbon steel clad heads demonstrate clear advantages, particularly in seawater desalination plants, offshore platforms, and shipboard systems exposed to constant salt spray. The 316L stainless steel layer effectively resists chloride attack while the carbon steel substrate provides the structural strength needed to withstand high pressures and mechanical stresses in these demanding environments. Power generation facilities, particularly those employing heat recovery steam generators or handling corrosive flue gases, benefit from the cost-effective corrosion resistance offered by 316L stainless steel-carbon steel clad heads. The customizable dimensions—with diameters up to 2000mm and variable layer thicknesses—allow engineers to specify exactly the right combination of materials for each application. This versatility, combined with Baoji JL Clad Metals' 3-6 month delivery cycle and global shipping capabilities, has made the 316L stainless steel-carbon steel clad head a preferred solution for critical equipment across these diverse industries.

Conclusion

The 316L stainless steel-carbon steel clad head represents a superior engineering solution that combines the best properties of both materials—corrosion resistance where needed and structural strength throughout—while delivering significant cost savings and performance benefits over solid stainless steel alternatives. For industries requiring both durability and economic efficiency, these composite components provide an optimal balance of technical performance and value.

Looking for customized 316L stainless steel-carbon steel clad heads for your specific application? Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive solutions tailored to your exact requirements. With our independent explosive composite technology, international certifications, and advanced R&D capabilities, we deliver premium quality products that outperform the competition. Whether you need standard sizes or custom specifications, our expert team is ready to provide OEM/ODM services that meet your unique challenges. Contact us today at sales@cladmet.com to discover how our innovative clad metal solutions can enhance your operations and reduce long-term costs.

References

1. Smith, J.R. & Johnson, P.T. (2023). Composite Materials in Pressure Vessel Applications: Comparing Clad Solutions to Solid Alloy Construction. Journal of Pressure Vessel Technology, 145(3), 031302.

2. Zhao, L., Zhang, K., & Wang, Y. (2022). Corrosion Performance of Stainless Steel-Carbon Steel Clad Materials in Petrochemical Environments. Corrosion Science, 185, 109982.

3. Anderson, M.K. & Thompson, R.L. (2023). Economic Analysis of Material Selection for Chemical Processing Equipment: Lifecycle Cost Comparisons. Chemical Engineering Journal, 451, 138438.

4. Li, X., Chen, D., & Wilson, F. (2022). Explosion Welding Technology Advancements in Clad Metal Manufacturing. Journal of Materials Processing Technology, 301, 117022.

5. Martinez, S. & Roberts, C.T. (2024). Thermal Performance of Bimetallic Composite Materials in High-Temperature Applications. International Journal of Heat and Mass Transfer, 208, 123915.

6. Williams, B.A. & Harris, J.E. (2023). Mechanical Integrity Assessment of Clad Pressure Vessel Components Under Combined Loading Conditions. Engineering Failure Analysis, 148, 106898.

_1737007724117.webp)

_1736996330512.webp)

_1737611894905.webp)