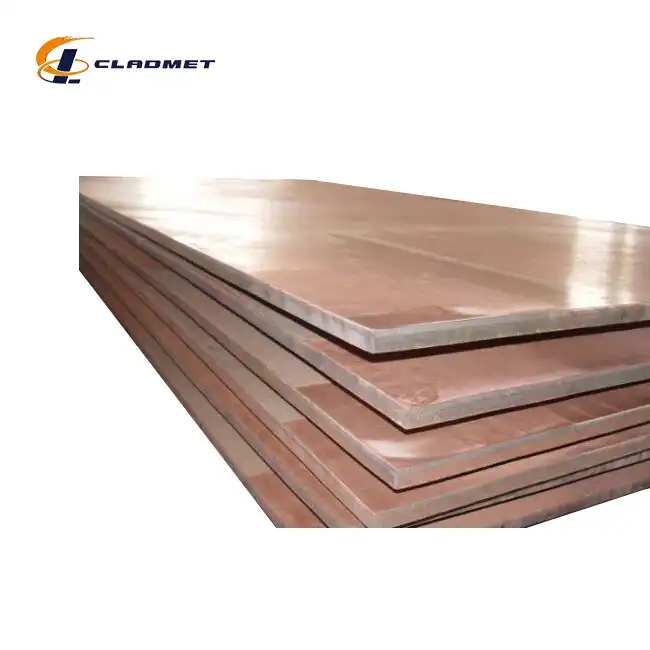

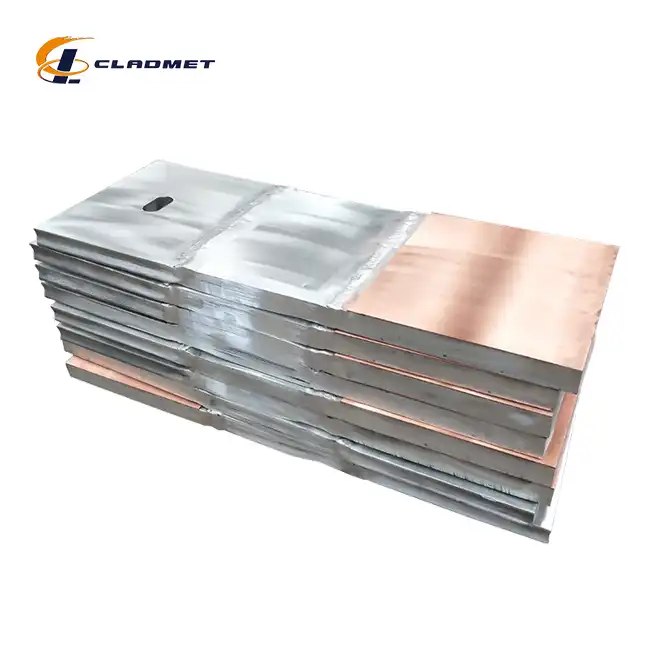

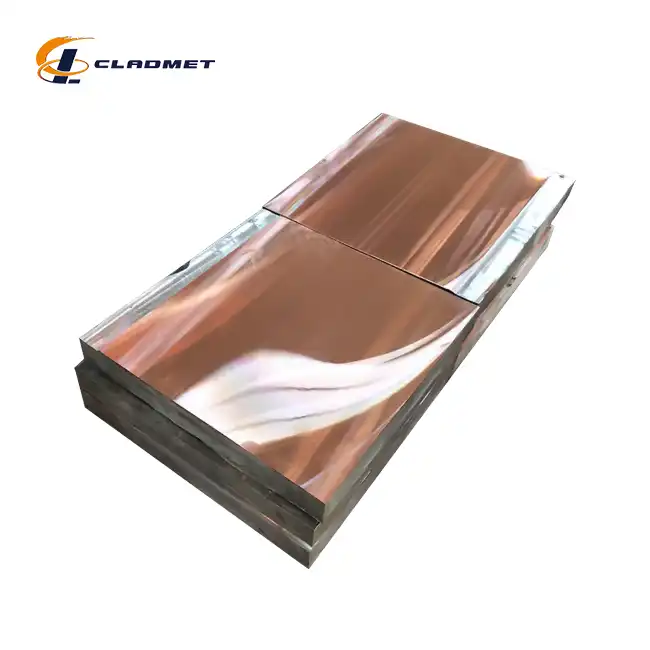

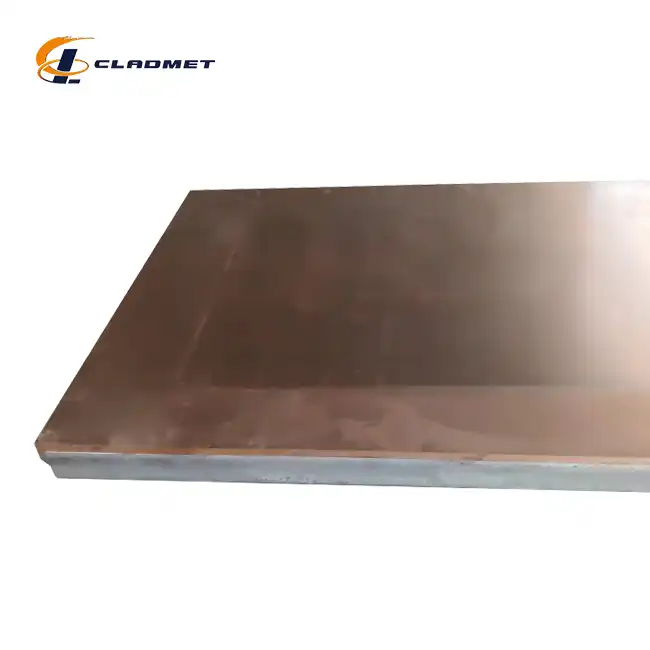

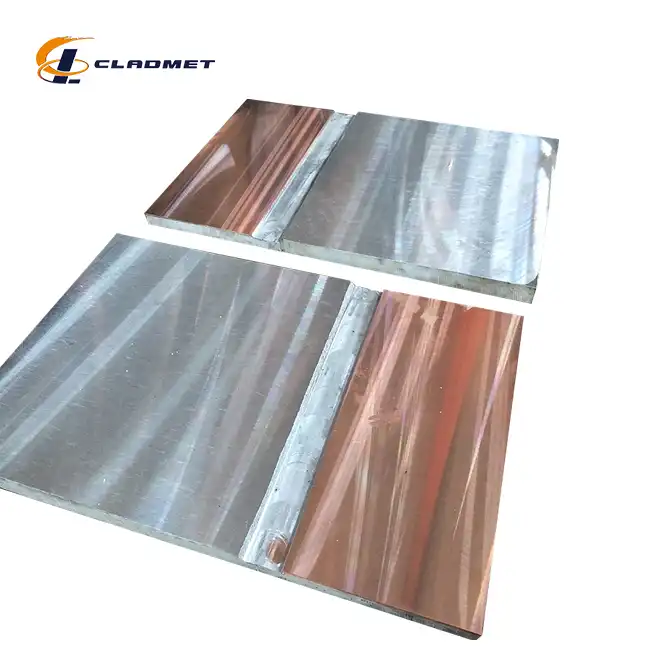

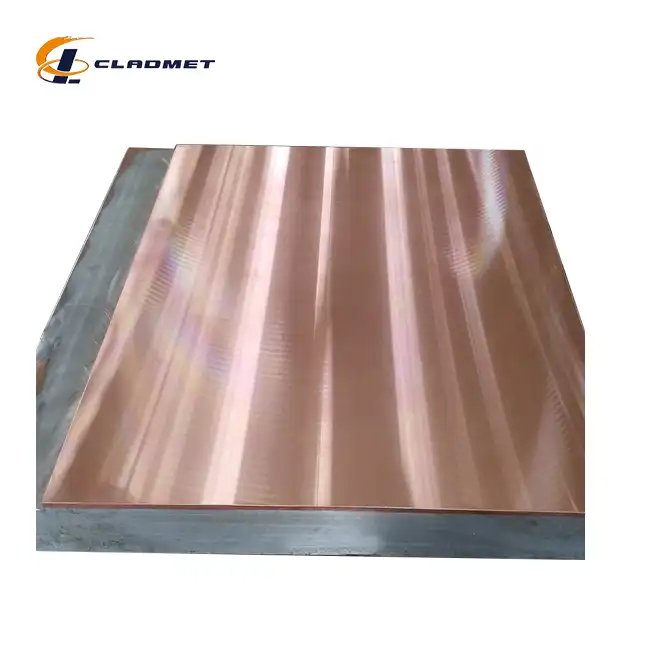

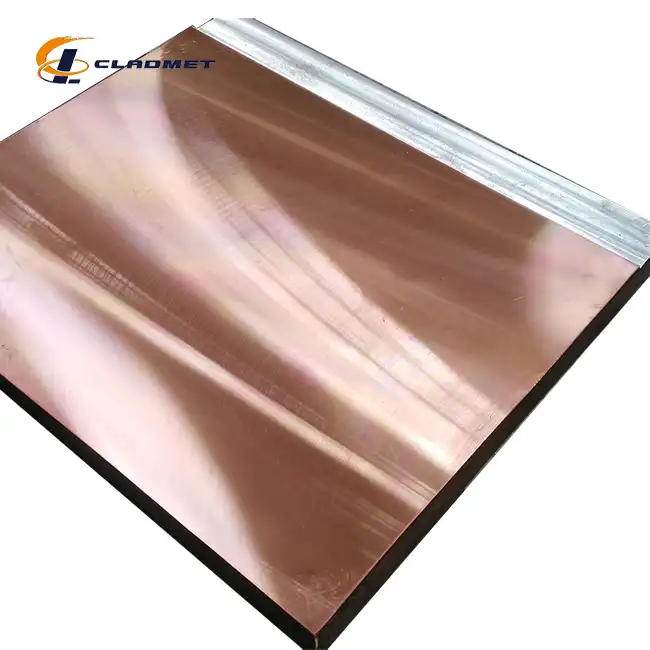

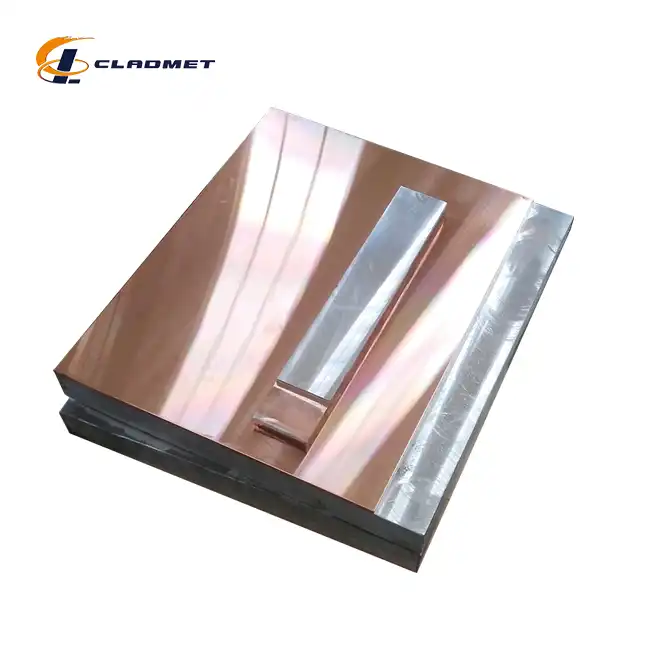

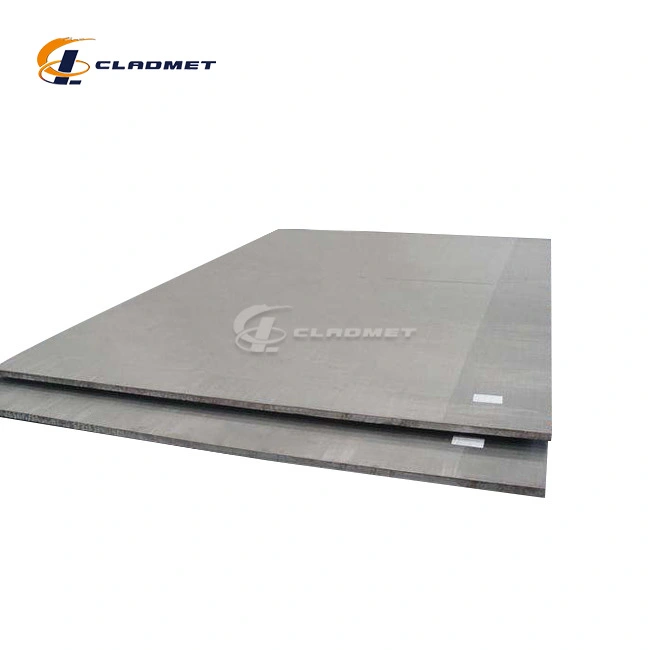

copper clad steel sheet

Available Sizes:Standard and custom sizes available upon request

Product Applications:Used in electroplating, chemical, and marine industries

Processing Technology:Explosive bonding and hot-rolled processing techniques

Quality Control and Testing: Strict testing ensures adherence to ISO9001-2000, PED, ABS standards

Product Implementation Standards:ASME, ASTM, JIS certified

Delivery:Available via sea, air, and express shipping

Packaging:Secure wooden crates for international transport

Introduction

Copper clad steel sheets are a composite material that combines the corrosion resistance of copper with the strength and durability of steel. This innovative solution offers excellent mechanical properties and high conductivity, making it ideal for industries where both electrical performance and structural integrity are required. Baoji JL Clad Metals Materials Co., Ltd., with decades of expertise in producing clad materials, provides the top-quality steel sheets that meet international standards, offering reliability and cost-effectiveness to various industries.

Product Specifications

| Parameter | Description |

|---|---|

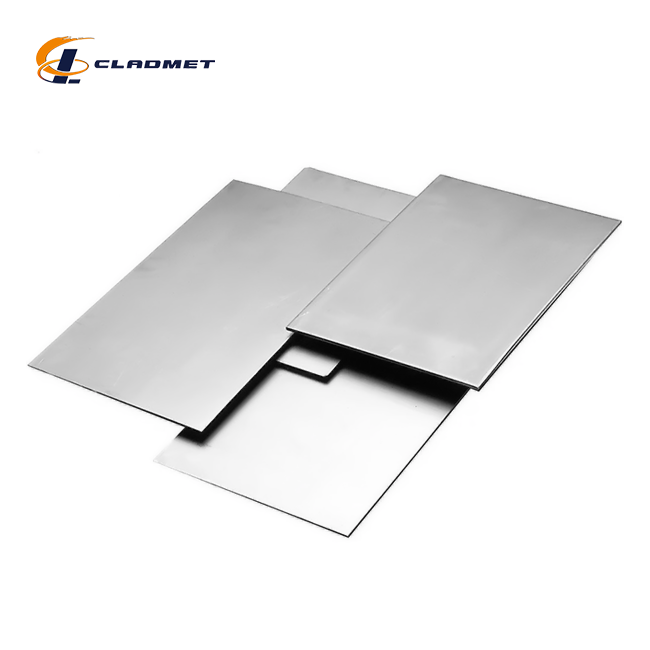

| Base Material | Carbon Steel or Low Alloy Steel (e.g., Q235B, Q345B, A516 Gr.70, etc.) |

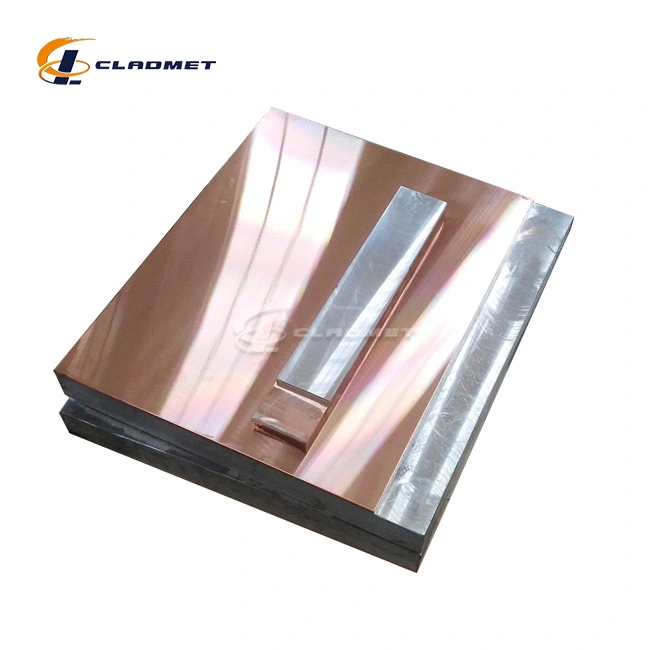

| Cladding Material | Copper (e.g., T1, T2, C11000, C12200, etc.) |

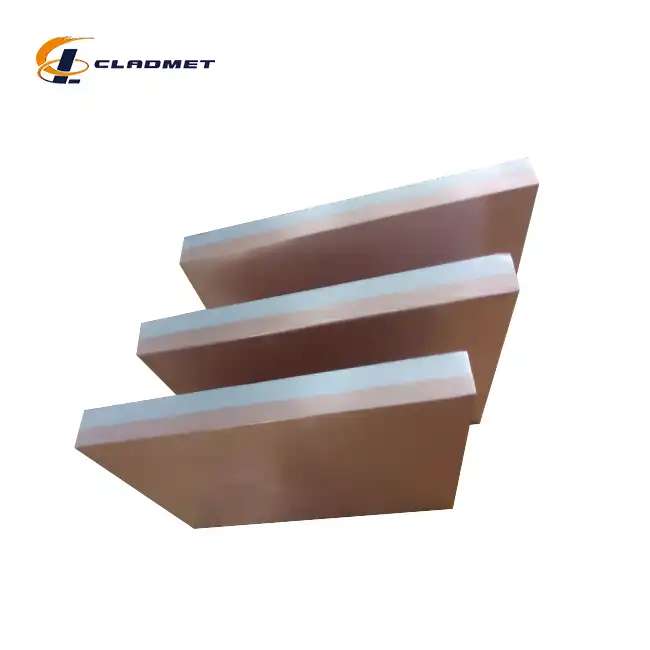

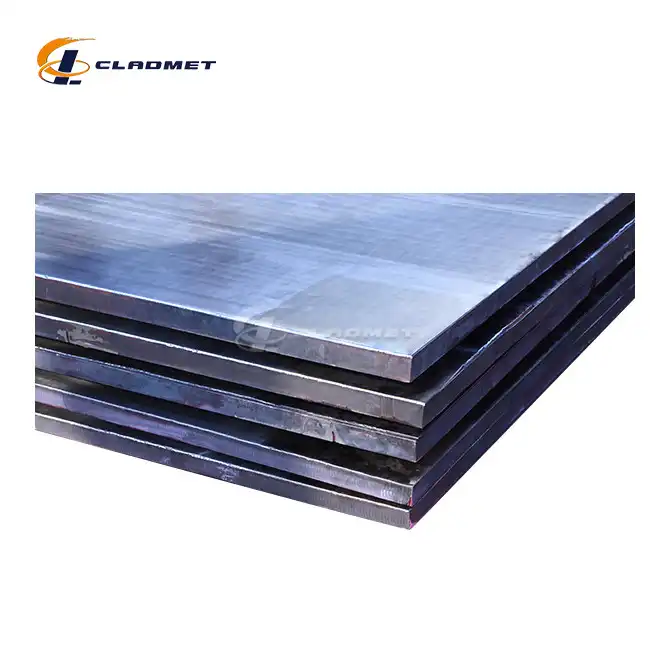

| Total Thickness Range | 3 mm - 50 mm (e.g., 1 mm Copper + 2 mm Steel) |

| Clad Layer Thickness | 0.3 mm - 5 mm (customizable) |

| Base Layer Thickness | 1 mm - 45 mm (customizable) |

| Width Range | Up to 1500 mm |

| Length Range | Up to 6000 mm |

| Bonding Technology | Explosion Bonding, Hot Rolling, or Explosion + Rolling |

| Bonding Strength | ≥ 130 MPa |

| Shear Strength | ≥ 100 MPa |

| Electrical Conductivity | Excellent (~99% IACS for pure copper grades) |

| Corrosion Resistance | Superior resistance to acids, alkalis, and marine environments |

| Heat Resistance | Stable performance under moderate temperatures |

| Application Industries | Electrical Power Systems, Switchgear, Electronics, Architecture, Chemical Processing, etc. |

| Standards Compliance | ASTM B432, ASME SB-432, GB/T 8165, and other international standards |

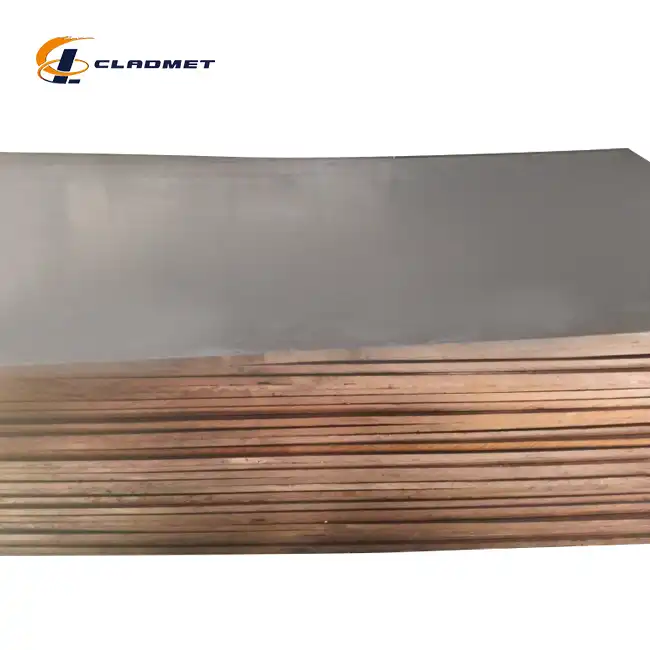

| Surface Finish | Polished, Sandblasted, or Customized |

| Customizations Available | Thickness Ratio, Size, Material Combinations, Surface Finish, etc. |

|

|

|

|

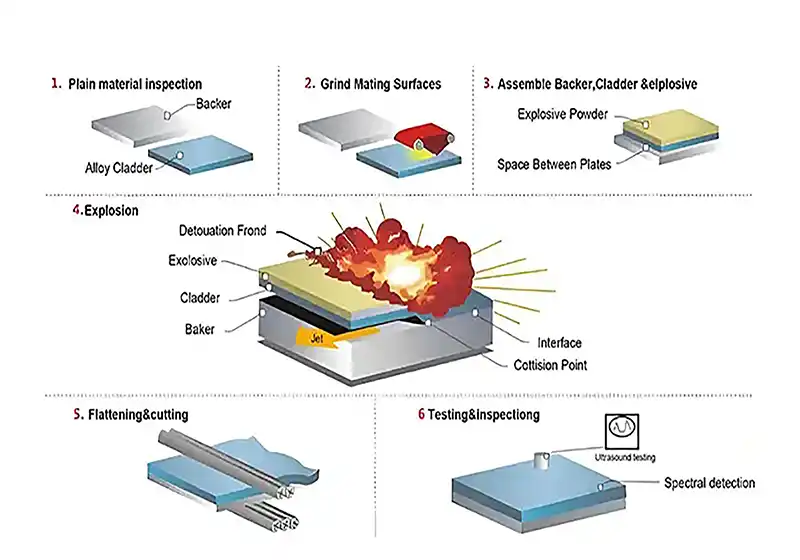

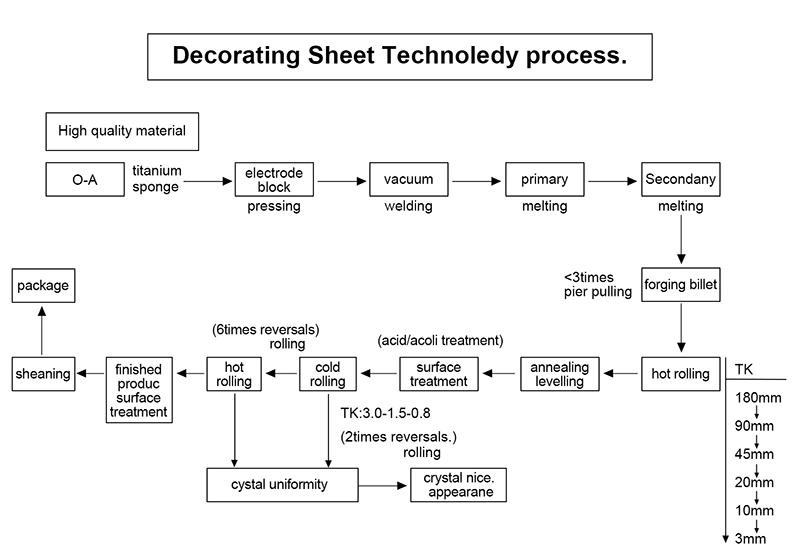

Copper Cladding Process

Cladding Techniques – Explosion Bonding and Combined Hot Rolling Process

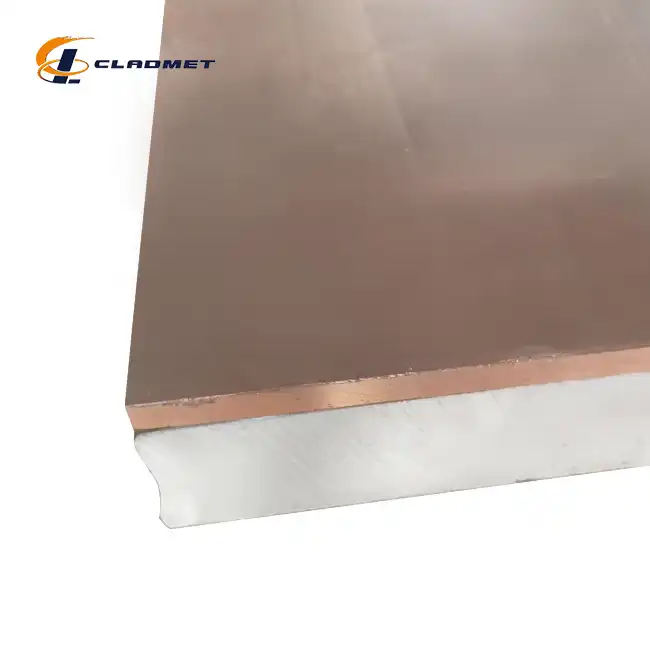

Copper steel clad plates are primarily manufactured using explosion bonding or a hybrid process combining explosion bonding with hot rolling These advanced solid-state cladding techniques enable the metallurgical bonding of two dissimilar metals copper and steel into a single inseparable composite material

Explosion Bonding Process Overview

Explosion bonding is a solid-state welding method that uses the high-energy impact from a controlled detonation to bond a layer of copper to steel It relies on high-velocity impact and extreme pressure to create a metallurgical bond at the atomic level without melting the base materials or requiring filler metals

Main steps of the explosion bonding process include

1 Surface preparation Copper and steel plates are thoroughly cleaned degreased and polished to remove oxides and contaminants.

2 Explosive setup A controlled layer of explosive is laid over the copper plate with calculated standoff distance between the two metals.

3 Detonation The explosives are ignited causing the copper plate to accelerate at high velocity towards the steel plate.

4 Metallurgical bonding Upon impact a wavy interface is formed due to localized plastic deformation and jetting effect resulting in atomic-level bonding.

5 Post-treatment Stress relief annealing may be applied to remove residual stresses and improve stability.

Combined Explosion Bonding and Hot Rolling Process

In some cases the explosion bonded plate undergoes further hot rolling to enhance the bond uniformity refine the grain structure and improve mechanical properties This combined process is particularly useful for applications requiring high thickness precision or large-scale production

The combined process consists of

1 Initial explosion bonding Creating a primary metallurgical bond between copper and steel using the above process.

2 Hot rolling The bonded plate is reheated to a suitable temperature and passed through multiple rolling stages.

3 Enhanced bonding Hot rolling densifies the bonding interface improves layer uniformity and enhances ductility.

4 Custom thickness Rolling allows accurate control of the total thickness and copper cladding ratio to meet specific requirements.

5 Finishing Final steps include trimming leveling grinding and pickling to produce clean and smooth surfaces.

Features and Benefits

Corrosion Resistance

Copper-clad steel sheets provide exceptional resistance to corrosion, particularly in environments where the materials are exposed to chemicals or harsh conditions. The copper layer acts as a protective barrier against corrosion, while the steel provides structural strength.

Excellent Electrical Conductivity

The copper layer ensures high electrical conductivity, which is vital in applications such as electrical connectors, busbars, and circuit boards. This combination of conductivity and strength makes copper-clad steel sheets suitable for electrical power distribution and industrial electronics.

Thermal Conductivity

In addition to electrical conductivity, copper is an excellent conductor of heat. Copper-clad steel sheets are often used in heat exchangers and cooling systems, where efficient heat transfer is essential for performance.

Enhanced Strength and Durability

Steel provides mechanical strength and toughness, while copper adds resistance to wear and corrosion. This combination results in a highly durable material that is well-suited for high-stress environments, reducing the need for frequent replacements and maintenance.

Customization and Versatility

Copper-clad steel sheets can be customized to meet the specific needs of different industries. Parameters such as copper thickness, steel grade, and surface treatments can be adjusted to suit various applications, from electrical components to structural and chemical processing equipment.

Cost Efficiency

By combining copper with steel, manufacturers can take advantage of copper's properties at a lower cost compared to pure copper materials. Copper-clad steel sheets offer a cost-effective solution for industries where both conductivity and strength are required.

Improved Performance

Copper-clad steel sheets enhance the performance of equipment by combining copper’s ability to conduct electricity and heat with the mechanical robustness of steel. This results in materials that perform efficiently and reliably in demanding applications.

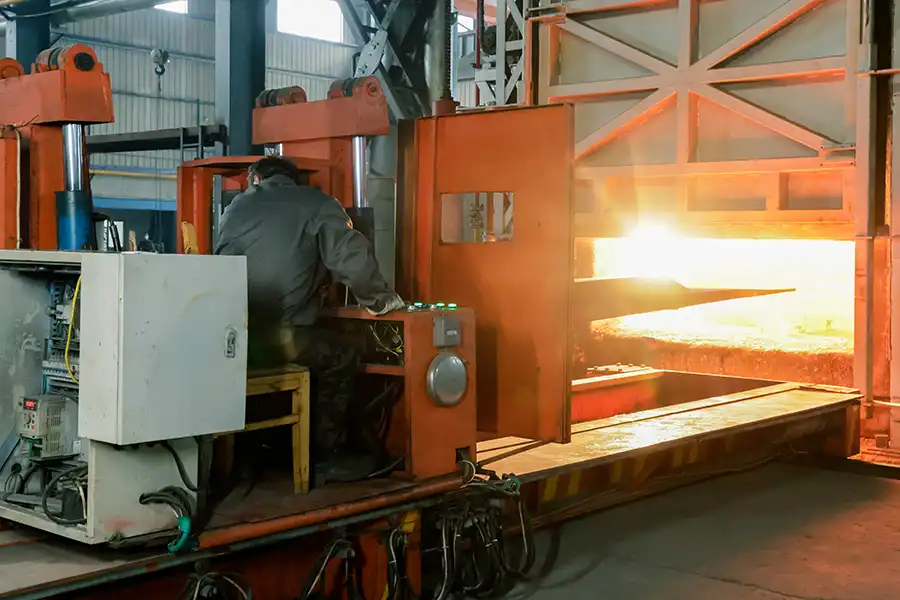

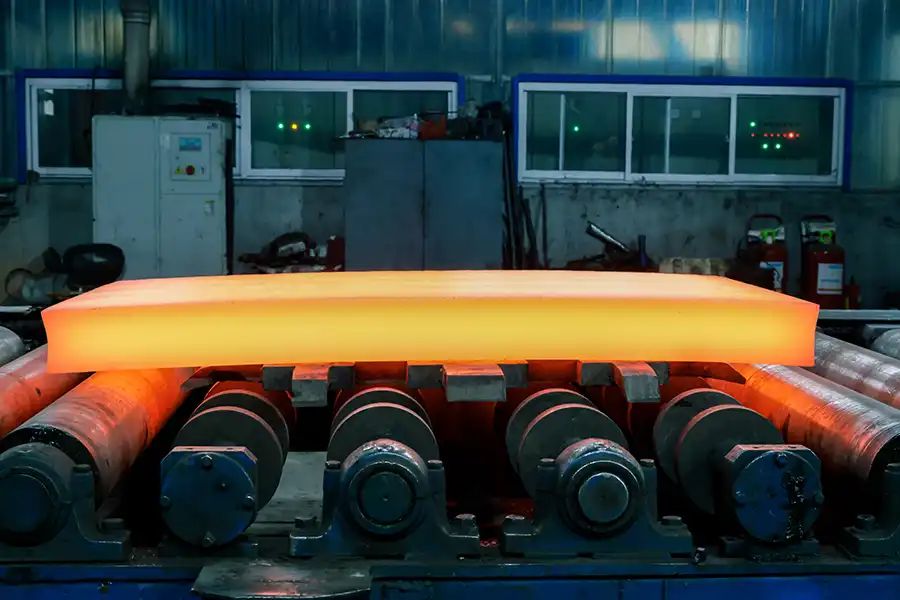

Explosive Composite Plate Production Site

Explosion Welding Process

|

|

Our Factory

Production Site

Hot Rolling

Hot Rolling

Main Products

Main Application Industries

OEM Service

We offer flexible OEM services tailored to your specific project requirements. Our expert team is equipped to handle custom orders, including variations in thickness, length, width, and surface treatment. From initial design to final delivery, we work closely with our clients to ensure every specification is met.

FAQ

Q1: What is the delivery time for the steel sheets?

A: The standard delivery cycle is 3-6 months, but this can be negotiated based on order volume and customization requirements.

Q2: Can the copper clad steel sheet be customized for different applications?

A: Yes, we offer a range of customization options, including size, thickness, and surface treatment, to meet specific industry needs.

Q3: What is the minimum order quantity (MOQ)?

A: The MOQ can vary depending on the project. Please contact us to discuss your specific requirements.

Contact Us

For more information or to place an order, please reach out to us via the following:

WhatsApp: +86 15353335118

Email: stephanie@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

Boost your projects with high-quality sheets from Baoji JL Clad Metals Materials Co., Ltd. Contact us today!

_1737007724117.webp)