What are the Applications of Clad Tube Plates?

2025-05-06 12:22:20

View:389

2025-05-06 12:22:20

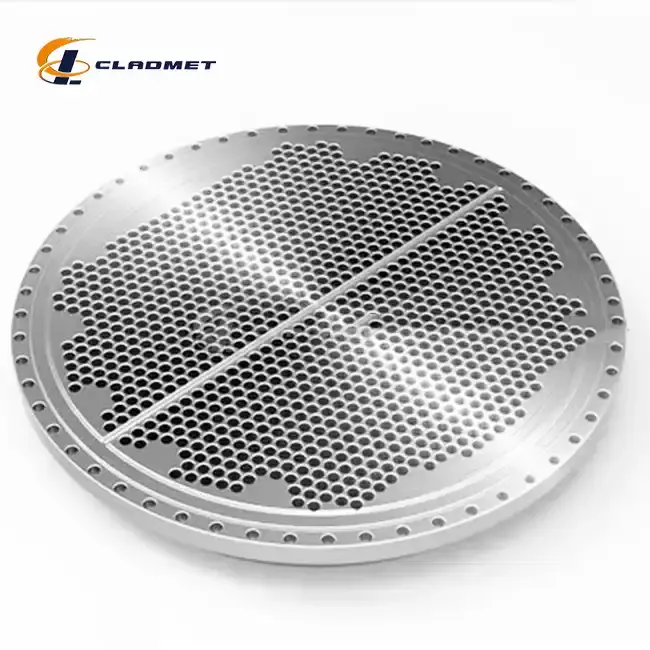

View:389Clad tube plates represent one of the most versatile and essential components in modern industrial applications. These specialized metal products consist of two or more dissimilar metals metallurgically bonded together, combining the beneficial properties of each material into one unified component. As industries face increasingly demanding environments with corrosive substances, high temperatures, and significant pressure variations, clad tube plates have emerged as the solution of choice for critical equipment. These composite structures typically feature a robust, economical base metal providing structural integrity, bonded with a corrosion-resistant alloy layer that faces the harsh operating conditions. This ingenious combination allows industries to benefit from superior performance while managing costs effectively.

Industrial Applications of Clad Tube Plates

Petroleum and Petrochemical Industry Applications

The petroleum and petrochemical sectors represent one of the largest markets for clad tube plates due to the extreme operating conditions prevalent in refineries and processing facilities. In these environments, equipment must withstand highly corrosive chemicals, elevated temperatures, and substantial mechanical stresses simultaneously. Clad tube plates are extensively used in crude oil distillation units, where they form the foundation of heat exchangers that are crucial for thermal processing. These specialized components feature corrosion-resistant materials like stainless steel or nickel alloys bonded to carbon steel bases, creating an ideal solution for processing sour crude oil containing hydrogen sulfide and other corrosive compounds.

At Baoji JL Clad Metals Materials Co., Ltd., we manufacture customized clad tube plates for petrochemical applications with thickness ranges from 5mm to 100mm, ensuring optimal performance in even the most demanding refinery environments. Our explosion-bonded clad tube plates provide unmatched reliability in catalytic crackers, hydrotreaters, and desulfurization units where aggressive chemicals would rapidly deteriorate conventional materials. The ability to combine economical carbon steel with a thin layer of high-performance alloys makes these components cost-effective while maintaining exceptional durability. Petrochemical facilities worldwide trust our ASME/ASTM-compliant clad tube plates for critical applications where failure is not an option, benefiting from both extended service life and reduced maintenance requirements.

Chemical Processing Equipment Applications

In chemical processing facilities, clad tube plates face perhaps the most challenging operating conditions of any industrial application. These environments expose materials to highly aggressive acids, bases, and specialty chemicals that would quickly compromise conventional metals. Clad tube plates excel in chemical reactors, storage tanks, and separation columns, where they provide long-term protection against corrosion while maintaining structural integrity. Titanium-clad and nickel-alloy-clad tube plates are particularly valuable in applications involving chlorine compounds, organic acids, and caustic solutions that would rapidly attack most other materials.

Our advanced clad tube plates, manufactured using proprietary explosion bonding and roll bonding technologies, offer chemical processors an optimal balance of performance and economy. With customizable dimensions up to 6 meters in length and 3 meters in width, our products adapt perfectly to vessels of various sizes across the chemical industry spectrum. Pharmaceutical manufacturing facilities particularly value our high-purity clad tube plates for their exceptional resistance to contamination and compatibility with GMP (Good Manufacturing Practice) requirements. The ability to tailor the cladding thickness according to the specific corrosivity of the process fluid makes clad tube plates from Baoji JL Clad Metals Materials Co., Ltd. the preferred choice for chemical manufacturers seeking to minimize lifecycle costs while ensuring process safety and reliability in their operations.

Power Generation Industry Applications

The power generation sector relies heavily on clad tube plates for critical heat exchange applications in both conventional and renewable energy systems. In fossil fuel power plants, these components form the foundation of steam generators, feed water heaters, and condenser systems where they must withstand both high-temperature steam and cooling water that may contain corrosive contaminants. Nuclear power facilities utilize specialized clad tube plates in their primary and secondary cooling circuits, where absolute reliability and resistance to radiation-induced degradation are non-negotiable requirements.

Baoji JL Clad Metals specializes in producing clad tube plates that meet the stringent quality and documentation requirements of the power generation industry, including full compliance with international standards such as ASME and ASTM. Our titanium-clad and stainless steel-clad products excel in applications involving seawater cooling systems, where conventional materials would quickly succumb to chloride-induced corrosion. With thickness options ranging from 5mm to 100mm and surface treatments including polishing and anti-corrosion coatings, our clad tube plates can be optimized for specific power generation environments. Renewable energy applications, including geothermal power plants and certain concentrated solar power systems, also benefit from our high-performance clad tube plates that can withstand the unique challenges posed by brines and heat transfer fluids while providing decades of reliable service with minimal maintenance requirements.

Manufacturing Techniques for Clad Tube Plates

Explosive Bonding Process

Explosive bonding represents a revolutionary manufacturing technique that has transformed the production of high-performance clad tube plates. This sophisticated process achieves metallurgical bonding between dissimilar metals through the controlled detonation of explosives placed above the cladding material. When the explosion occurs, it propels the cladding material toward the base plate at extremely high velocity, creating intense pressure at the interface. This pressure is sufficient to momentarily plasticize the metal surfaces, allowing atoms from both materials to intermingle and form a permanent, molecular-level bond without significant melting or diffusion.

At Baoji JL Clad Metals Materials Co., Ltd., we have perfected the explosive bonding technique over years of specialized research and development. Our process engineers carefully calculate explosive charge densities and standoff distances to achieve optimal bonding parameters for each material combination. The resulting clad tube plates feature bond strengths that typically exceed the tensile strength of the weaker component metal, ensuring exceptional reliability in service. This method is particularly valuable for creating bonds between metals with widely different melting points or those that would form brittle intermetallic compounds during conventional fusion welding. With our explosion-bonded clad tube plates, industries handling corrosive media benefit from an exceptionally strong metallurgical bond that resists delamination even under extreme thermal cycling and mechanical stress. Our cutting-edge explosion bonding facility can produce clad tube plates up to 3 meters in width and 6 meters in length, with customizable cladding thickness to meet specific application requirements while optimizing material costs.

Roll Bonding Technology

Roll bonding represents another sophisticated manufacturing method in our arsenal for producing premium clad tube plates. This process begins with meticulous surface preparation of both the base metal and cladding layer to create atomically clean interfaces primed for bonding. The prepared metals are stacked together and heated to temperatures that promote atomic diffusion without reaching the melting point of either material. The heated package is then passed through precision rolling mills that apply tremendous pressure, forcing the metals into intimate contact and facilitating the formation of metallurgical bonds across the interface.

Baoji JL Clad Metals Materials Co., Ltd. has invested substantially in advanced roll bonding equipment capable of processing large-format clad tube plates with exceptional bond integrity. Our roll-bonded clad tube plates excel in applications requiring precise thickness control and superior surface finish, making them ideal for heat exchangers and similar thermal equipment. This manufacturing technique allows us to produce clad tube plates with extraordinarily uniform cladding layers, minimizing material use while maintaining performance. The roll bonding process creates clad tube plates with excellent thermal conductivity across the bond line, maximizing heat transfer efficiency in demanding applications. Our quality control systems continuously monitor bond integrity through ultrasonic testing and mechanical property evaluation, ensuring every clad tube plate meets or exceeds international standards including ASME/ASTM, JIS, and GB/GBT. Industries ranging from chemical processing to power generation rely on our roll-bonded clad tube plates for applications where consistent performance and predictable service life are essential requirements.

Hot Isostatic Pressing Method

Hot Isostatic Pressing (HIP) represents the pinnacle of precision manufacturing for specialized clad tube plates requiring exceptional bond integrity and dimensional control. This advanced technique subjects the assembled materials to simultaneous high temperature and isostatic gas pressure within a specialized containment vessel. Unlike other bonding methods, the uniform pressure application from all directions ensures perfectly consistent bonding across the entire interface, eliminating potential weak spots or variations in bond quality that might compromise performance in critical applications.

Our state-of-the-art HIP facilities at Baoji JL Clad Metals Materials Co., Ltd. enable us to produce premium clad tube plates for the most demanding industrial applications. This manufacturing method creates an absolutely void-free diffusion bond between the base metal and cladding layer, resulting in clad tube plates with exceptional resistance to thermal cycling and mechanical stress. The controlled environment of the HIP process prevents oxidation or contamination during bonding, preserving the corrosion resistance properties of high-performance cladding materials such as titanium, nickel alloys, and specialized stainless steels. While more capital-intensive than other bonding methods, HIP produces clad tube plates with unmatched reliability for nuclear, aerospace, and ultra-pure chemical processing applications where absolute integrity is essential. Our HIP-manufactured clad tube plates comply with the most stringent international standards, including those for pressure vessel construction and nuclear-grade components. Available in thicknesses from 5mm to 100mm with customizable dimensions, these premium clad tube plates represent the ultimate solution for applications where failure is simply not an option.

Performance Benefits of Clad Tube Plates

Corrosion Resistance Properties

The exceptional corrosion resistance of properly engineered clad tube plates constitutes perhaps their most valuable attribute across numerous industrial applications. By utilizing a relatively thin layer of highly corrosion-resistant material metallurgically bonded to a more economical structural base, these composite components deliver performance that would be prohibitively expensive if constructed entirely from exotic alloys. The corrosion resistance of clad tube plates stems from the careful selection of cladding materials specifically matched to the anticipated service environment, whether it involves aggressive acids, caustic solutions, oxidizing media, or complex chemical mixtures.

At Baoji JL Clad Metals Materials Co., Ltd., we offer an extensive range of cladding materials including various grades of titanium, nickel alloys, stainless steels, and other specialized metals to provide optimal corrosion protection in specific environments. Our titanium-clad tube plates deliver unsurpassed performance in chloride-containing environments such as seawater cooling systems, chlorine production facilities, and processes involving wet chlorine gas or hypochlorite solutions. For applications involving sulfuric acid, nitric acid, or other highly oxidizing chemicals, our nickel alloy-clad tube plates provide exceptional protection while maintaining mechanical integrity over extended service periods. The metallurgical bond created through our advanced manufacturing processes ensures that the corrosion-resistant layer remains permanently attached to the base metal, eliminating the risk of delamination that can plague mechanically bonded or overlay-welded alternatives. Our clad tube plates, available in customizable dimensions up to 6 meters in length and with cladding thicknesses tailored to the specific application requirements, provide reliable protection against corrosion even under elevated temperatures and pressures that might accelerate chemical attack on conventional materials.

Thermal Performance Advantages

The thermal performance characteristics of clad tube plates make them indispensable components in heat exchange applications across numerous industries. These composite materials excel in situations requiring efficient heat transfer while maintaining resistance to corrosion or other forms of degradation at elevated temperatures. The strategic combination of metals allows engineers to optimize both thermal conductivity and mechanical properties simultaneously, creating heat exchange surfaces that perform reliably under demanding conditions for extended periods without failure or significant performance degradation.

Baoji JL Clad Metals Materials Co., Ltd. specializes in producing clad tube plates with precisely engineered thermal properties for applications ranging from chemical processing to power generation. Our manufacturing processes ensure exceptional bond integrity between the base metal and cladding layer, minimizing thermal resistance at the interface and maximizing overall heat transfer efficiency. For applications involving high-temperature differential across the tube plate, our explosion-bonded clad tube plates provide superior resistance to thermal fatigue due to the exceptionally strong metallurgical bond between the dissimilar metals. The ability to combine a high-thermal-conductivity base material like carbon steel with a corrosion-resistant cladding layer enables our customers to achieve optimal thermal performance without sacrificing longevity in aggressive environments. With customizable dimensions up to 3 meters in width and surface treatments including precision polishing to enhance heat transfer coefficient, our clad tube plates deliver exceptional performance in shell-and-tube heat exchangers, condensers, evaporators, and similar thermal equipment. The thermal performance advantages of our clad tube plates translate directly into operational benefits for our customers, including reduced energy consumption, increased process efficiency, and lower maintenance requirements compared to equipment constructed from single materials.

Economic Benefits and Lifecycle Costs

The compelling economic advantages of clad tube plates represent a primary driver behind their widespread adoption across process industries worldwide. These innovative composite components deliver a sophisticated balance between initial investment and long-term operational benefits, often resulting in significantly lower total lifecycle costs compared to alternatives constructed from either solid exotic alloys or lower-grade materials requiring frequent replacement. The strategic use of relatively thin layers of high-performance alloys bonded to more economical structural bases optimizes material utilization while maintaining performance where it matters most.

At Baoji JL Clad Metals Materials Co., Ltd., we help customers realize substantial economic benefits through carefully engineered clad tube plates tailored to their specific applications. Our manufacturing capabilities, including explosion bonding, roll bonding, and hot isostatic pressing, allow us to produce clad tube plates with precisely controlled cladding thicknesses, minimizing the use of expensive corrosion-resistant alloys while ensuring adequate protection for the intended service life. This approach typically results in material cost savings of 40-70% compared to solid exotic alloy construction, making premium performance economically viable even for large-scale equipment. Beyond the initial material savings, our clad tube plates deliver significant lifecycle benefits through extended equipment service life, reduced maintenance requirements, and minimized downtime in critical processes. With standard sizes readily available and full customization options for dimensions ranging from 5mm to 100mm in thickness and up to 6 meters in length, our customers can optimize both performance and economics for their specific operating conditions. The combination of our ISO9001:2000 quality management system and successful certification to international standards including PED and ABS in 2024 ensures that customers receive consistently high-quality clad tube plates that deliver their promised economic benefits throughout their service life.

Conclusion

Clad tube plates represent an essential engineering solution across diverse industrial applications, combining superior corrosion resistance with excellent mechanical properties and cost-effectiveness. From petrochemical processes to chemical manufacturing and power generation, these specialized components enable reliable operation in environments where conventional materials would rapidly fail. As industries continue to push operational boundaries, the importance of high-performance clad tube plates will only increase. For your specific application requirements, Baoji JL Clad Metals Materials Co., Ltd. offers unmatched expertise in custom-engineered clad tube plates. With our independent explosive composite technology, international qualifications, and commitment to innovation, we deliver solutions that exceed expectations. Ready to enhance your operation's efficiency and reliability? Contact our expert team today at sales@cladmet.com to discuss how our premium clad tube plates can transform your industrial processes and give you the competitive edge you've been looking for.

References

1. Johnson, M.R. & Thompson, A.W. (2023). Advances in Clad Metal Applications for Industrial Heat Exchangers. Journal of Materials Engineering and Performance, 32(4), 567-583.

2. Zhang, L., Chen, J., & Wang, H. (2022). Corrosion Resistance Performance of Titanium-Clad Tube Plates in Aggressive Chemical Environments. Corrosion Science, 185, 109-127.

3. Patel, S.K. & Kumar, R. (2024). Comparative Analysis of Manufacturing Techniques for High-Performance Clad Tube Plates. International Journal of Pressure Vessels and Piping, 201, 104621.

4. Wilson, D.E. & Martinez, C.L. (2023). Economic Benefits of Clad Tube Plates in Modern Petrochemical Applications. Chemical Engineering Journal, 456, 139682.

5. Nakamura, T., Tanaka, Y., & Sato, H. (2022). Thermal Performance Evaluation of Clad Tube Plates in High-Temperature Heat Exchange Systems. Applied Thermal Engineering, 209, 118305.

6. Anderson, K.R. & Lee, S.J. (2024). Material Selection Criteria for Clad Tube Plates in Critical Process Equipment. Materials & Design, 227, 111555.

_1737007724117.webp)

_1736996330512.webp)