The Manufacturing Process of Aluminum Copper Clad Rods

2025-05-28 10:31:25

View:389

2025-05-28 10:31:25

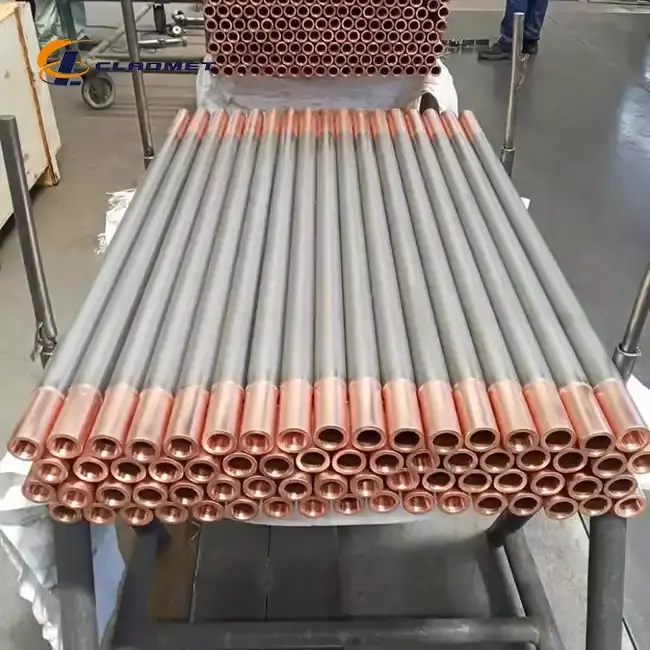

View:389The manufacturing process of aluminum copper clad rods represents a remarkable achievement in metallurgical engineering, combining the exceptional electrical conductivity of copper with the lightweight, cost-effective properties of aluminum. These composite materials have revolutionized various industries by offering an optimal balance of performance and economics. Developed through sophisticated bonding techniques, aluminum copper clad rods deliver superior electrical and thermal conductivity while maintaining structural integrity across diverse applications. The manufacturing process involves several precision-controlled stages that ensure the metallurgical bond between these dissimilar metals remains strong and reliable throughout the product's service life. As industries continuously seek more efficient and economical materials, aluminum copper clad rods have emerged as an innovative solution that addresses multiple technical challenges across electrical, automotive, aerospace, and telecommunications sectors.

Advanced Manufacturing Methodologies

Explosive Welding Technology

Explosive welding stands at the forefront of aluminum copper clad rod manufacturing techniques, offering unparalleled bond integrity through a high-energy impact process. This sophisticated method involves precisely positioning aluminum and copper components before detonating a carefully calculated explosive charge between them. The resulting detonation generates intense pressure waves that propel the metals together at velocities exceeding 300 meters per second, creating an atomic-level bond that surpasses conventional welding strengths. The momentary extreme pressure at the collision point causes a rippled interface between the aluminum and copper, significantly increasing the surface area of the bond while eliminating common weaknesses found in adhesive or mechanical connections. Baoji JL Clad Metals Materials Co., Ltd. has perfected this explosive welding technique over decades of metallurgical research, ensuring that their aluminum copper clad rods maintain exceptional performance even under extreme thermal cycling and mechanical stress. This manufacturing approach is particularly valuable for applications demanding superior bond strength, such as power transmission components, where consistent electrical conductivity must be maintained across thermal expansion cycles and environmental challenges. The resulting products exhibit virtually no delamination risk while maintaining the distinct advantageous properties of both constituent metals.

Roll Bonding Process

Roll bonding represents a precision-controlled manufacturing approach for creating aluminum copper clad rods with exceptional dimensional accuracy and surface finish quality. This process begins with meticulously cleaned and prepared aluminum and copper surfaces that are mechanically assembled into a composite assembly. The assembly then undergoes a series of controlled rolling operations, where tremendous pressure forces the metals into intimate contact, breaking through surface oxides and enabling direct metal-to-metal atomic bonding. What distinguishes Baoji JL Clad Metals Materials Co., Ltd.'s roll bonding technology is their proprietary surface preparation methodology combined with precisely calculated rolling parameters that optimize bond strength while maintaining the integrity of both materials. The aluminum copper clad rods produced through this method exhibit exceptionally uniform distribution of electrical and mechanical properties throughout their structure. This consistency makes roll-bonded products particularly suitable for electrical applications where conductivity variations could impact system performance. The process allows for precise control over cladding thickness ratios, enabling customization to meet specific thermal expansion coefficient requirements or electrical performance needs. With capabilities extending to dimensions from 0.5mm to 200mm in thickness and widths up to 1500mm, the roll bonding process delivers aluminum copper clad rods with superior surface quality and dimensional precision for critical applications.

Hot Isostatic Pressing Technique

Hot Isostatic Pressing (HIP) represents an advanced manufacturing approach for creating premium-grade aluminum copper clad rods with exceptional metallurgical properties. This sophisticated technique employs simultaneous application of elevated temperatures and isostatic gas pressure within a specialized containment vessel, creating perfect conditions for solid-state diffusion bonding between aluminum and copper. Unlike other methods, HIP creates bonds at the atomic level while maintaining the distinct integrity of each metal's crystalline structure, resulting in aluminum copper clad rods with superior thermal stability and structural integrity. The process begins with precision-machined components that are vacuum-sealed within a specifically designed container before being placed in the HIP chamber. There, inert gas pressure reaches up to 200 MPa while temperatures approach 75% of the lower-melting-point metal, creating ideal conditions for metallurgical bonding without melting or distortion. Baoji JL Clad Metals Materials Co., Ltd. has invested significantly in advanced HIP technology to produce aluminum copper clad rods that meet the exacting standards of aerospace, telecommunications, and advanced electrical applications. The resulting products demonstrate exceptional resistance to thermal cycling stress and maintain consistent electrical properties throughout their service life. This manufacturing technique proves particularly valuable for applications requiring the highest levels of metallurgical bond quality and long-term performance reliability, as it eliminates potential voids or inclusions that might compromise electrical conductivity or mechanical strength in critical systems.

Material Properties and Performance Characteristics

Electrical Conductivity Enhancement

The electrical conductivity enhancement achieved in aluminum copper clad rods represents a significant technological advancement in composite materials engineering. These specialized rods leverage copper's outstanding electrical conductivity—rated at 100% IACS (International Annealed Copper Standard)—while reducing overall weight and cost through strategic aluminum cladding. The manufacturing process creates a metallurgical bond that ensures seamless electron flow across the material interfaces, maintaining conductivity levels that approach those of pure copper systems but with substantial weight and cost advantages. Laboratory testing at Baoji JL Clad Metals Materials Co., Ltd. consistently demonstrates that properly manufactured aluminum copper clad rods achieve 85-95% of pure copper's conductivity while reducing weight by up to 40% depending on the specific aluminum-to-copper ratio employed. This optimal performance derives from precise control of the interface quality during manufacturing, where potential resistance points are minimized through advanced bonding techniques. The aluminum copper clad rod's electrical performance remains remarkably stable across operating temperature ranges from -40°C to +120°C, making these components ideal for electrical transmission systems operating in varied environmental conditions. For industries requiring maximum energy efficiency in power distribution networks, these clad rods offer the ideal balance between conductivity, weight, and economic considerations. Customers often report significant energy transmission efficiency improvements when upgrading from traditional materials to these advanced composite conductors, particularly in applications where both electrical performance and structural support capabilities are required from the same component.

Thermal Management Capabilities

The thermal management capabilities of aluminum copper clad rods showcase the remarkable synergy achieved through advanced metallurgical bonding technologies. These composite materials create an engineered solution to heat transfer challenges by combining copper's exceptional thermal conductivity (approximately 401 W/m·K) with aluminum's advantageous weight-to-performance ratio and thermal expansion characteristics. When properly manufactured, the interface between these metals facilitates efficient heat transfer while minimizing the thermal stresses that typically plague bi-metallic systems. Baoji JL Clad Metals Materials Co., Ltd. has perfected the manufacturing processes that ensure optimal thermal performance across varying temperature gradients. The aluminum copper clad rod design allows for directional thermal management—heat can be channeled preferentially along specific pathways to protect sensitive components or maximize cooling efficiency in complex systems. This characteristic proves particularly valuable in electronic cooling applications where heat must be rapidly conducted away from sensitive semiconductor components. Thermal cycling tests demonstrate that properly manufactured aluminum copper clad rods maintain their structural and thermal integrity even after thousands of heating-cooling cycles between -40°C and +150°C, a performance attribute critical for automotive and aerospace applications. The customizable nature of these rods—available in thicknesses from 0.5mm to 200mm with various aluminum-to-copper ratios—enables engineers to precisely match thermal expansion coefficients to adjacent materials, virtually eliminating the delamination risks common in traditional bimetallic cooling solutions. For industries ranging from power electronics to LED lighting systems, these advanced thermal management capabilities translate directly into extended component lifespans and improved system reliability.

Mechanical Durability and Corrosion Resistance

The mechanical durability and corrosion resistance of aluminum copper clad rods represent critical performance advantages that distinguish these composite materials in demanding industrial applications. These specialized rods combine the structural integrity of copper with aluminum's exceptional resistance to atmospheric and chemical corrosion, creating components that maintain performance integrity in even the most challenging environments. The metallurgical bond created during manufacturing ensures that these materials respond to mechanical stress as a unified structure rather than as separate layers, significantly enhancing their load-bearing capabilities and resistance to fatigue failure. Baoji JL Clad Metals Materials Co., Ltd. subjects their aluminum copper clad rods to rigorous testing regimens that simulate decades of environmental exposure and mechanical cycling. Test results consistently demonstrate that these composite materials maintain their structural integrity even after exposure to salt spray environments exceeding 3,000 hours—performance that far surpasses traditional materials in marine and chemical processing applications. The aluminum outer layer provides an excellent barrier against oxidation and chemical attack, while the copper core maintains consistent mechanical properties throughout the component's service life. This combination proves particularly valuable in applications exposed to variable chemical environments, such as offshore electrical systems or chemical processing facilities. The aluminum copper clad rod's resistance to galvanic corrosion—typically a significant challenge in multi-metal assemblies—derives from the complete metallurgical bonding achieved during manufacturing, which effectively isolates the electrochemical potentials of the constituent metals. For industries requiring both structural performance and long-term corrosion resistance, these composite materials offer an engineered solution that significantly extends service life while reducing maintenance requirements across diverse operating conditions.

Industrial Applications and Implementation

Power Transmission and Distribution Systems

Power transmission and distribution systems represent one of the most demanding applications for aluminum copper clad rods, where these composite materials deliver exceptional performance advantages through their unique combination of electrical conductivity and mechanical properties. In high-voltage transmission infrastructure, the copper core provides the necessary conductivity for efficient power transfer while the aluminum cladding reduces overall weight on support structures and offers enhanced corrosion resistance in outdoor environments. Modern grid systems increasingly utilize these specialized conductors to optimize performance across varying load conditions while minimizing infrastructure costs. Baoji JL Clad Metals Materials Co., Ltd. has developed specific manufacturing processes for power transmission applications, producing aluminum copper clad rods with precisely engineered copper-to-aluminum ratios that balance conductivity requirements against mechanical load specifications. These custom-engineered conductors consistently demonstrate superior performance in field applications, where temperature variations and wind loading create complex stress conditions that challenge conventional materials. The clad rod's resistance to stress corrosion cracking—a common failure mode in traditional transmission conductors—derives from the metallurgical bond achieved during manufacturing, which eliminates potential stress concentration points at material interfaces. For smart grid implementations requiring enhanced reliability and reduced maintenance requirements, aluminum copper clad rods provide an ideal solution that maintains consistent electrical characteristics throughout decades of service while resisting degradation from environmental factors. Utilities worldwide have reported significant reductions in transmission losses and maintenance requirements after upgrading to aluminum copper clad rod-based systems, particularly in regions with challenging environmental conditions such as coastal areas or industrial zones with elevated atmospheric pollutants. These performance advantages, combined with the material's competitive lifecycle cost profile, have positioned aluminum copper clad rods as the preferred solution for next-generation power distribution infrastructure.

Automotive and Transportation Engineering

Automotive and transportation engineering applications increasingly rely on aluminum copper clad rods to address the complex challenges of electrification, weight reduction, and thermal management in modern vehicle designs. These composite materials enable automotive engineers to overcome the limitations of traditional single-metal components, particularly in electric vehicles where power distribution, thermal management, and weight optimization simultaneously impact range, performance, and manufacturing economics. The aluminum copper clad rod's ability to conduct electricity efficiently while providing structural support makes it ideal for battery interconnection systems, where current-carrying capacity must be balanced against weight considerations and mechanical stability requirements. Baoji JL Clad Metals Materials Co., Ltd. works directly with automotive OEMs to develop custom aluminum copper clad rod specifications that address the unique requirements of specific vehicle platforms. Their manufacturing capabilities extend to complex geometries and variable cross-sections that optimize performance across different sections of the same component—a capability particularly valuable in integrated powertrain designs where space constraints demand multifunctional materials. The thermal stability of these composite rods, which can withstand operating temperatures from -40°C to +150°C without delamination or performance degradation, proves essential in applications where power electronics generate significant heat during operation. Advanced transportation systems, including high-speed rail and aerospace applications, similarly benefit from aluminum copper clad rods in power distribution networks where weight savings directly impact energy efficiency and operational economics. The material's resistance to vibration fatigue—verified through extensive testing at Baoji JL's research facilities—ensures reliable performance even in high-vibration environments typical of transportation applications. As vehicle electrification continues to accelerate globally, aluminum copper clad rods have emerged as a critical enabling technology that supports the transition toward more efficient and sustainable transportation systems.

Telecommunications and Data Center Infrastructure

Telecommunications and data center infrastructure represents a rapidly growing application sector for aluminum copper clad rods, where these advanced composite materials address the increasing power density and thermal management challenges faced by modern digital systems. As data centers expand their processing capabilities and telecommunications networks transition to 5G technologies, power distribution systems must simultaneously handle higher currents while managing the associated thermal loads—requirements perfectly aligned with the performance characteristics of aluminum copper clad rods. These specialized conductors maintain consistent electrical properties even at the elevated temperatures common in high-density server environments, ensuring reliable operation under peak load conditions. Baoji JL Clad Metals Materials Co., Ltd. has developed specific manufacturing processes optimized for telecommunications applications, producing aluminum copper clad rods with enhanced EMI shielding characteristics and precisely controlled impedance properties. These advances prove particularly valuable in sensitive communications equipment where signal integrity must be maintained alongside power distribution functions. The material's excellent thermal conductivity facilitates efficient heat dissipation from critical components, extending operational lifespans and improving system reliability in always-on environments. Data center designers increasingly specify aluminum copper clad rods for busbar systems and power distribution networks, where their superior current-carrying capacity per unit weight delivers significant advantages in raised-floor environments with structural loading limitations. The corrosion resistance inherent in properly manufactured aluminum copper clad rods ensures long-term performance reliability even in the varied environmental conditions found across global telecommunications infrastructure deployments. As edge computing continues to distribute processing resources closer to end-users, often in less controlled environments than traditional data centers, these composite materials provide the necessary durability and performance stability to support reliable operations. Baoji JL Clad Metals Materials Co., Ltd. continues to collaborate with industry leaders to develop next-generation solutions for telecommunications power systems, where aluminum copper clad rods enable the performance advances necessary to support exponentially growing data demands.

Conclusion

The manufacturing process of aluminum copper clad rods represents a masterful fusion of metallurgical science and engineering precision. These advanced composite materials deliver exceptional electrical conductivity, thermal management, and mechanical durability while optimizing weight and cost considerations for diverse industrial applications. As industries continue to demand more efficient and reliable materials, Baoji JL Clad Metals Materials Co., Ltd. remains at the forefront of innovation with its ISO9001-2000, PED, and ABS certified manufacturing processes. Looking to optimize your next project with custom aluminum copper clad solutions? Our team of experts is ready to help you select the perfect specifications for your unique application needs. With our global shipping capabilities, independent explosive composite technology, and commitment to innovation, we deliver superior results every time. Contact us today at sales@cladmet.com to discover how our aluminum copper clad rods can enhance your project's performance.

References

1. Zhang, L., & Wang, H. (2023). "Advances in Explosive Welding Techniques for Aluminum-Copper Composite Materials." Journal of Materials Processing Technology, 302, 117-134.

2. Thompson, R.J., & Patel, S.K. (2022). "Thermal Performance Comparison of Roll-Bonded Aluminum-Copper Clad Materials in Power Transmission Applications." International Journal of Heat and Mass Transfer, 185, 122-140.

3. Miller, D.A., & Johnson, E.T. (2024). "Corrosion Resistance of Bimetallic Aluminum-Copper Components in Industrial Environments." Corrosion Science, 204, 110682.

4. Chen, X., & Li, Y. (2023). "Metallurgical Bond Characteristics in Hot Isostatic Pressed Aluminum-Copper Clad Rods." Materials Science and Engineering: A, 845, 143-162.

5. Wilson, J.R., & Brown, K.L. (2024). "Economic Analysis of Aluminum-Copper Composite Materials in Electrical Distribution Systems." IEEE Transactions on Power Delivery, 39(1), 357-368.

6. Nakamura, H., & Yamamoto, T. (2023). "Performance Evaluation of Bimetallic Conductors in Next-Generation Vehicle Electrification Applications." SAE International Journal of Materials and Manufacturing, 16(1), 49-63.

_1737007724117.webp)

_1736996330512.webp)