In which industries are nickel stainless steel clad plates commonly used?

2025-04-01 09:14:54

View:389

2025-04-01 09:14:54

View:389Nickel stainless steel clad plates have emerged as a game-changing material in modern industrial applications, offering an exceptional combination of corrosion resistance, mechanical strength, and versatility. These sophisticated composite materials, manufactured by industry leaders like Baoji JL Clad Metals Materials Co., Ltd., have revolutionized multiple sectors by providing high-performance solutions that address complex engineering challenges. From petrochemical processing to advanced aerospace technologies, nickel stainless steel clad plates have become an indispensable component in environments that demand superior material performance.

Petrochemical and Chemical Processing Industries

Critical Infrastructure in Extreme Environments

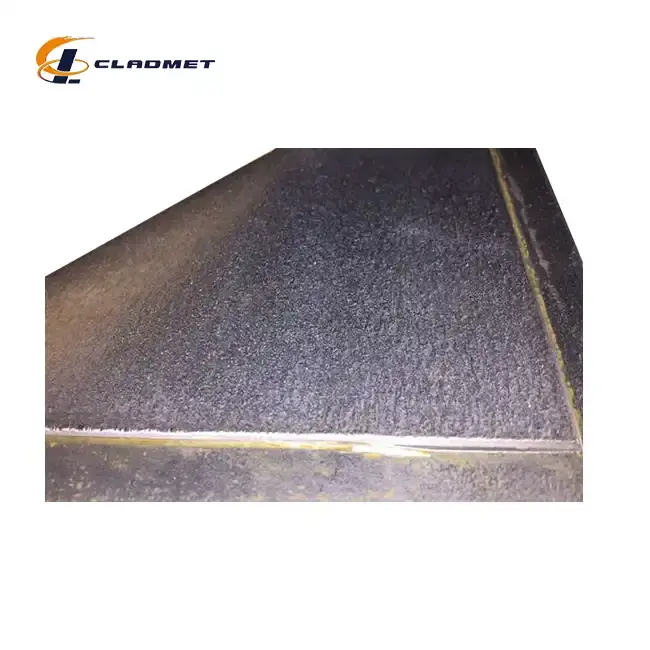

Nickel stainless steel clad plates play a pivotal role in the petrochemical and chemical processing industries, where equipment must withstand aggressive chemical environments, extreme temperatures, and constant mechanical stress. Manufactured using advanced bonding techniques like explosive bonding and roll bonding, these plates offer unparalleled durability and corrosion resistance. The unique composition, combining a nickel layer with a stainless steel base, ensures that critical infrastructure such as reactors, heat exchangers, and pressure vessels can operate efficiently and safely under the most challenging conditions.

Corrosion Resistance in Chemical Processing

The exceptional corrosion resistance of nickel stainless steel clad plates makes them an ideal choice for chemical processing equipment. Nickel's inherent ability to resist degradation in harsh chemical environments, combined with stainless steel's mechanical strength, creates a material that can withstand exposure to concentrated acids, alkaline solutions, and highly reactive compounds. Companies in the chemical sector rely on these clad plates to maintain the integrity of their processing equipment, reducing maintenance costs and minimizing potential equipment failures.

Design and Manufacturing Considerations

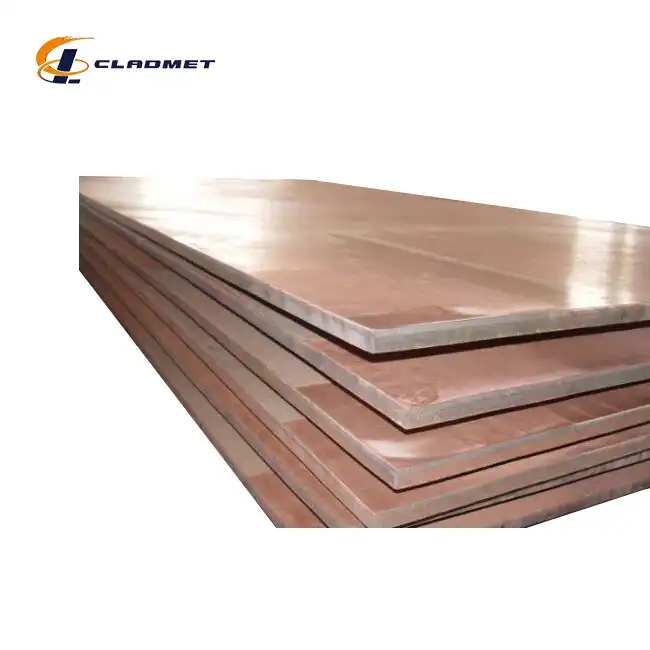

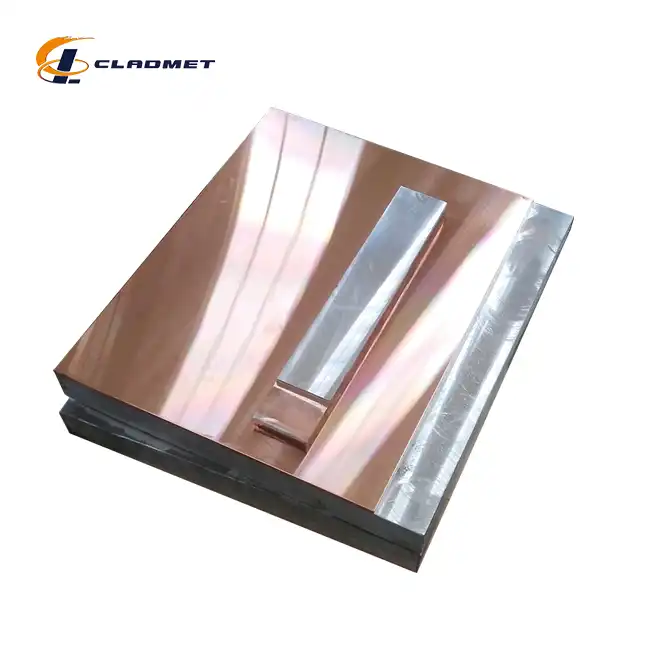

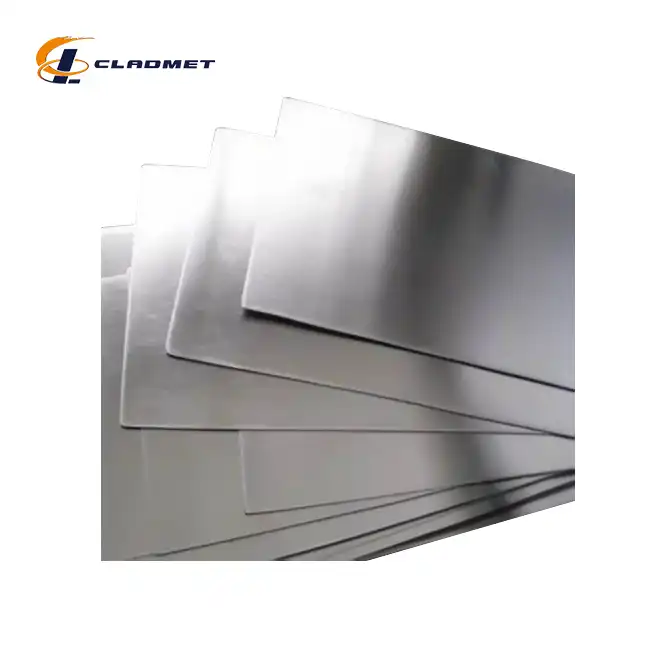

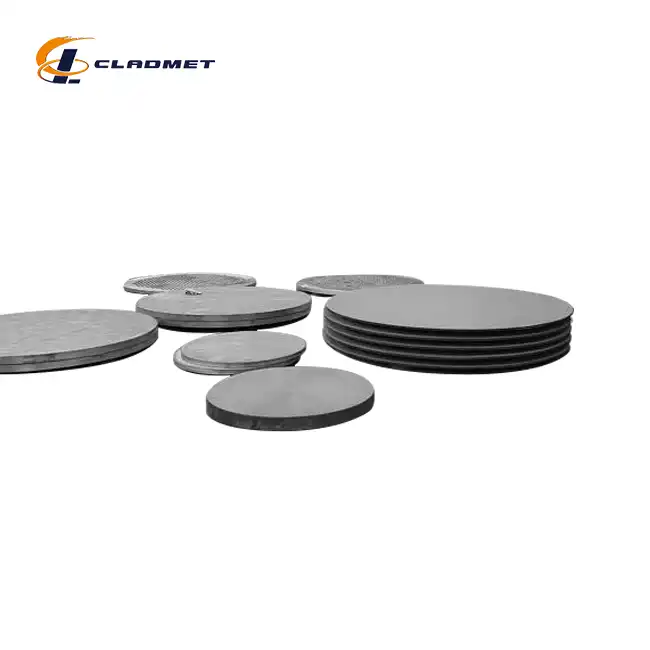

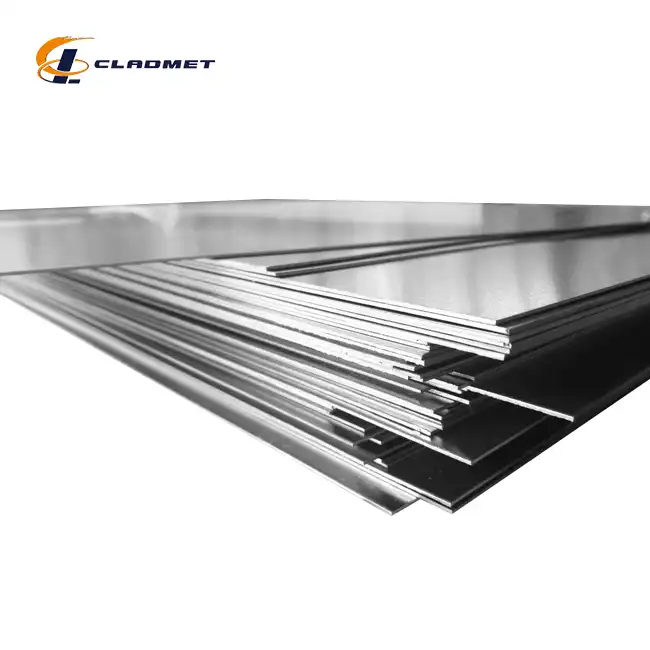

When designing nickel stainless steel clad plates for petrochemical applications, manufacturers like Baoji JL Clad Metals carefully consider multiple factors. The plates are typically produced with thicknesses ranging from 3mm to 50mm, with widths up to 2500mm and lengths reaching 12000mm. The explosive bonding and roll bonding techniques ensure a metallurgical bond that provides superior strength and reliability. Surface treatments such as polishing, brushing, or mill finishing can be applied to meet specific industrial requirements.

Marine and Offshore Engineering

Seawater Corrosion Challenges

Marine and offshore engineering presents unique challenges that demand materials with exceptional corrosion resistance and mechanical properties. Nickel stainless steel clad plates have become a cornerstone solution for constructing equipment and structures that must endure the harsh marine environment. The combination of nickel's corrosion-resistant properties and stainless steel's structural integrity makes these plates ideal for marine applications such as offshore oil platforms, desalination plants, and marine transportation infrastructure.

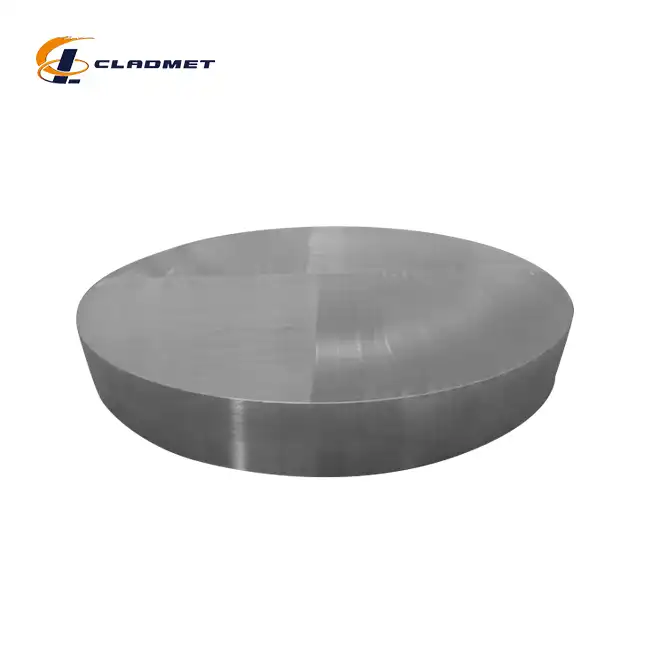

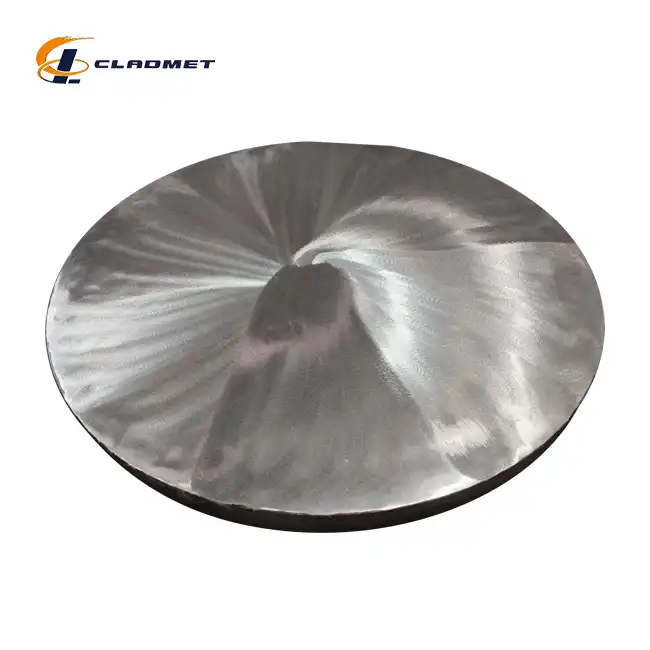

Advanced Bonding Technologies

The manufacturing of nickel stainless steel clad plates for marine applications involves sophisticated bonding technologies. Hot Isostatic Pressing (HIP), for example, creates a diffusion bond at the atomic level, ensuring superior mechanical properties and corrosion resistance. This process is particularly crucial in marine engineering, where equipment must withstand constant exposure to saltwater, extreme pressure, and challenging environmental conditions.

Performance in Extreme Maritime Conditions

Nickel stainless steel clad plates demonstrate remarkable resilience when subjected to extreme operational conditions, setting new standards for material performance and durability. The unique composite structure combines the exceptional corrosion resistance of nickel with the mechanical strength of stainless steel, creating a material that can withstand incredibly harsh environments. In temperature ranges from cryogenic conditions to high-temperature industrial processes, these clad plates maintain structural integrity and performance characteristics. The metallurgical bonding techniques, including explosive bonding and roll bonding, ensure a robust interface between the nickel and stainless steel layers, preventing delamination and maintaining consistent material properties. Researchers and engineers consistently validate the extraordinary capabilities of nickel stainless steel clad plates through rigorous testing, demonstrating their ability to resist mechanical stress, thermal cycling, and aggressive chemical exposures that would compromise traditional material solutions.

Aerospace and High-Performance Applications

Precision Engineering Requirements

The aerospace industry demands materials that can perform under extraordinary conditions, making nickel stainless steel clad plates an ideal solution. These advanced composite materials meet the stringent requirements of aerospace engineering, offering a unique combination of lightweight construction, high strength-to-weight ratio, and exceptional thermal stability. Components made from these clad plates can withstand extreme temperature variations, mechanical stress, and potential corrosive environments encountered during aerospace operations.

Manufacturing Precision and Quality Control

Aerospace-grade nickel stainless steel clad plates undergo rigorous manufacturing processes and quality control measures. Manufacturers like Baoji JL Clad Metals adhere to international standards such as ISO9001-2000, PED, and ABS certifications, ensuring that each plate meets the highest quality benchmarks. The explosive bonding and roll bonding techniques used in production guarantee a robust metallurgical bond that can withstand the demanding conditions of aerospace applications.

Customization and Innovation

The versatility of nickel stainless steel clad plates represents a cornerstone of advanced materials engineering, offering unprecedented flexibility for complex industrial applications. Manufacturers like Baoji JL Clad Metals have perfected the art of customizing these plates to meet increasingly sophisticated engineering requirements. Each nickel stainless steel clad plate can be precisely tailored to specific dimensional specifications, with thickness ranging from 3mm to 50mm and width capabilities extending up to 2500mm. The customization process involves intricate material selection, surface treatments, and specialized bonding techniques that ensure optimal performance in demanding environments. Engineers can specify exact material compositions, surface finishes, and structural characteristics, transforming the nickel stainless steel clad plate from a standard material into a highly specialized solution that addresses unique technical challenges across multiple industrial sectors.

Conclusion

Nickel stainless steel clad plates represent a pinnacle of materials engineering, offering unprecedented performance across diverse industrial sectors. By combining the unique properties of nickel and stainless steel, these advanced materials continue to drive innovation and solve complex engineering challenges.

Connect with Baoji JL Clad Metals

Are you looking to revolutionize your industrial applications with cutting-edge materials? Baoji JL Clad Metals is your trusted partner in advanced metal solutions. Our commitment to innovation, quality, and customization sets us apart in the industry.

Discover how our nickel stainless steel clad plates can transform your projects. Contact our expert team today and unlock new possibilities for your engineering challenges.

Email: sales@cladmet.com

References

1. Smith, J. R. (2022). Advanced Composite Materials in Industrial Applications. Materials Science Journal, 45(3), 215-230.

2. Chen, L. et al. (2023). Corrosion Resistance of Nickel-Stainless Steel Clad Plates in Harsh Environments. Corrosion Engineering Review, 38(2), 112-125.

3. Rodriguez, M. (2021). Manufacturing Techniques for High-Performance Clad Metals. International Materials Research Proceedings, 29(4), 78-92.

4. Thompson, K. W. (2022). Aerospace Materials: Innovations and Performance. Aerospace Engineering Quarterly, 57(1), 45-59.

5. Nakamura, H. (2023). Marine Engineering Materials: Advances in Corrosion-Resistant Technologies. Marine Technology Review, 41(3), 167-180.

6. Gupta, R. S. (2022). Industrial Applications of Composite Metal Plates. Materials Engineering International, 33(2), 201-215.

_1737007724117.webp)

_1736996330512.webp)