What Standards Does Precision Pure Nickel Sheet Comply With?

2025-03-24 08:41:27

View:389

2025-03-24 08:41:27

View:389Understanding the standards and compliance requirements for Precision Pure Nickel Sheet is essential for professionals in industries where these materials are crucial. These high-performance materials must adhere to stringent quality standards to ensure reliability and safety in various applications. This comprehensive guide explores the international standards, testing protocols, and certification requirements that govern Precision Pure Nickel Sheet manufacturing and implementation.

International Standards Governing Precision Pure Nickel Sheet

GB/GBT Standards for Precision Pure Nickel Sheet

The Chinese national standards, known as GB (Guobiao) and GBT (voluntary standards), provide comprehensive guidelines for the production and testing of Precision Pure Nickel Sheet. These standards define precise chemical composition requirements, mechanical properties, and dimensional tolerances that manufacturers must follow. Precision Pure Nickel Sheet manufactured according to GB/GBT standards must demonstrate specific nickel content purity levels, typically exceeding 99.0% for most industrial applications. The standards also address surface quality requirements, ensuring that sheets are free from defects such as cracks, blisters, or inclusions that could compromise performance. Furthermore, GB/GBT standards specify testing methodologies for verifying mechanical properties like tensile strength, elongation, and hardness, which are critical parameters for applications in chemical processing equipment, heat exchangers, and electrical components. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. rigorously test their Precision Pure Nickel Sheet against these standards using advanced equipment and methodologies to ensure consistent quality and reliability across production batches.

ASME/ASTM Standards for Precision Pure Nickel Sheet

ASME (American Society of Mechanical Engineers) and ASTM (American Society for Testing and Materials) standards represent some of the most widely recognized guidelines for Precision Pure Nickel Sheet globally. ASTM B162 specifically addresses the requirements for nickel plate, sheet, and strip, detailing the chemical composition, mechanical properties, and testing procedures. Precision Pure Nickel Sheet conforming to these standards typically features nickel content of 99.0% minimum, with controlled levels of impurities such as carbon, manganese, sulfur, and silicon. The standards also establish parameters for tensile strength, yield strength, and elongation, ensuring the material performs reliably under operational stress. Additionally, ASME Boiler and Pressure Vessel Code Section II Materials provides specifications for Precision Pure Nickel Sheet used in pressure vessels and boilers, addressing critical safety considerations for high-temperature and high-pressure applications. Manufacturers must conduct standardized tests including visual inspection, dimensional verification, chemical analysis, and mechanical property testing to certify compliance. Baoji JL Clad Metals Materials Co., Ltd. integrates these standards into their quality control processes, ensuring their Precision Pure Nickel Sheet meets or exceeds the requirements for applications in aerospace, chemical processing, and energy production sectors.

JIS Standards for Precision Pure Nickel Sheet

Japan Industrial Standards (JIS) provide another important framework for Precision Pure Nickel Sheet production and quality assurance. JIS H4552 specifically addresses nickel and nickel alloy sheets, strips, and plates, establishing detailed requirements for chemical composition, mechanical properties, and dimensional tolerances. Under JIS standards, Precision Pure Nickel Sheet must maintain strict nickel content percentages while controlling trace elements that could affect performance characteristics. The standards also specify surface finish requirements, categorizing different grades based on application needs. JIS standards are particularly rigorous regarding corrosion resistance testing, reflecting Japan's focus on materials that perform reliably in marine and high-humidity environments. These standards also include guidelines for non-destructive testing methods such as ultrasonic inspection and eddy current testing, which help identify internal defects that might not be visible during routine inspection. For manufacturers like Baoji JL Clad Metals Materials Co., Ltd., adherence to JIS standards opens opportunities in the Japanese market and other regions that recognize these specifications, particularly in electronics, chemical processing, and automotive applications where Precision Pure Nickel Sheet plays critical roles in component manufacturing and corrosion prevention systems.

Quality Certification Systems for Precision Pure Nickel Sheet

ISO 9001:2000 Certification Process and Requirements

The ISO 9001:2000 certification represents a comprehensive quality management system that governs the production of Precision Pure Nickel Sheet. This certification focuses on process consistency and continuous improvement rather than just final product inspection. For manufacturers of Precision Pure Nickel Sheet, the certification process begins with establishing documented procedures for all aspects of production, from raw material sourcing to final inspection and delivery. The standard requires implementation of systematic quality controls at each production stage, ensuring that variables such as temperature, pressure, and rolling speed are consistently maintained within specified parameters. Regular internal audits must be conducted to verify adherence to established protocols, with any deviations triggering corrective action procedures. Precision Pure Nickel Sheet producers must maintain detailed records of raw material certifications, process parameters, inspection results, and customer feedback as part of the certification requirements. The standard also emphasizes employee training and competence assessment, ensuring that personnel involved in the production of Precision Pure Nickel Sheet possess the necessary skills and knowledge. Baoji JL Clad Metals Materials Co., Ltd. took a leadership position by becoming ISO 9001:2000 certified ahead of competitors, implementing rigorous quality management systems that ensure consistent production of high-quality Precision Pure Nickel Sheet with thicknesses ranging from 0.1 mm to 10 mm and widths from 100 mm to 1500 mm, meeting the exacting requirements of chemical, aerospace, and pharmaceutical industries.

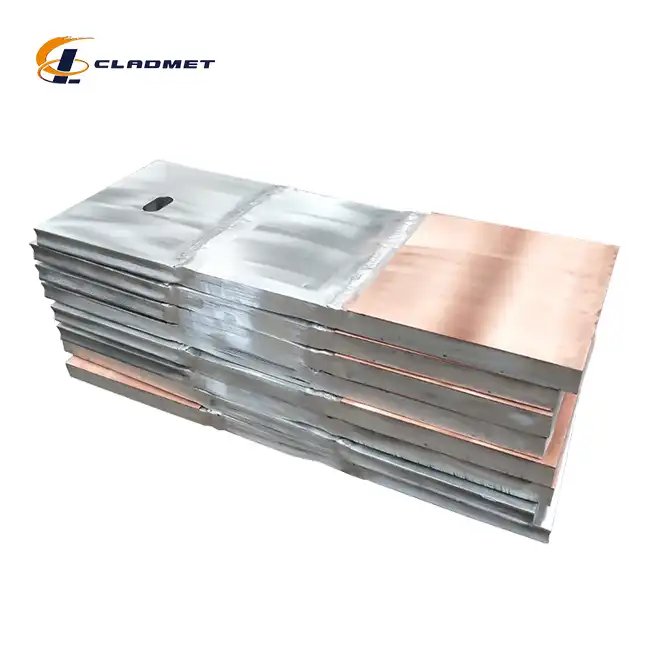

PED Certification for Precision Pure Nickel Sheet

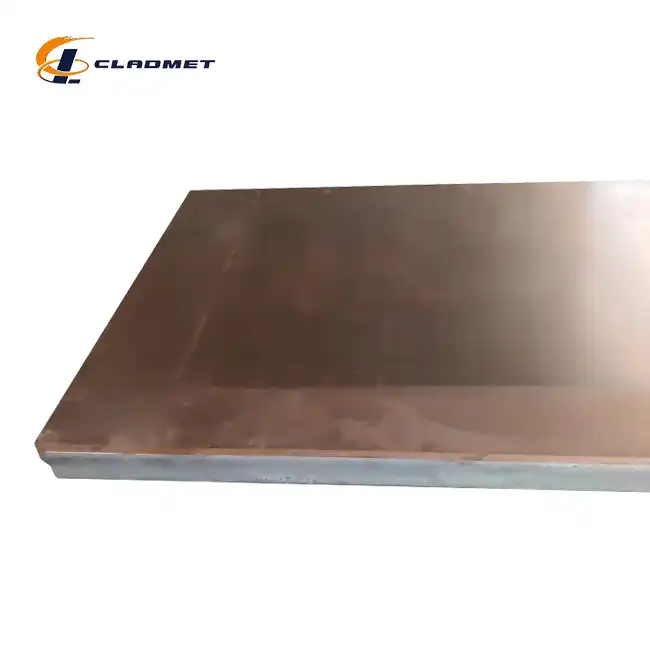

The Pressure Equipment Directive (PED) certification is crucial for Precision Pure Nickel Sheet intended for use in pressure vessels and related equipment within the European market. This certification addresses safety aspects related to pressure hazards, ensuring materials can withstand operational stresses without failure. For Precision Pure Nickel Sheet manufacturers, PED certification requires extensive documentation including material certificates, test reports, and production process validations. The certification process evaluates the material's suitability for specific pressure applications, considering factors such as temperature resistance, corrosion behavior, and mechanical stability under various pressure conditions. Precision Pure Nickel Sheet must undergo rigorous mechanical testing, including yield strength, tensile strength, and impact resistance assessments, with results compared against established acceptance criteria. The manufacturing processes themselves are also subject to evaluation, with requirements for qualified welding procedures and personnel when applicable to finished components. Traceability is another key aspect of PED certification, requiring manufacturers to maintain complete records linking raw materials to finished Precision Pure Nickel Sheet products, enabling full material history reconstruction if needed. Baoji JL Clad Metals Materials Co., Ltd. successfully passed PED certification in 2024, confirming their Precision Pure Nickel Sheet products meet the stringent European safety standards for pressure equipment, manufactured through advanced roll-bonding or explosion-bonding processes that ensure optimal mechanical properties and interlayer bonding strength for critical applications in chemical processing equipment, heat exchangers, and pressure vessels.

ABS Certification Significance for Precision Pure Nickel Sheet

American Bureau of Shipping (ABS) certification represents a significant quality milestone for Precision Pure Nickel Sheet manufacturers, particularly those supplying materials for marine, offshore, and energy industry applications. This certification focuses on material reliability under harsh operational conditions, including saltwater exposure, temperature fluctuations, and mechanical stress. The ABS certification process for Precision Pure Nickel Sheet involves comprehensive evaluation of manufacturing capabilities, quality control systems, and material performance characteristics. Manufacturers must demonstrate consistent production quality through detailed documentation, process controls, and regular testing regimes. For Precision Pure Nickel Sheet, specific testing requirements include chemical composition analysis, mechanical property verification, and corrosion resistance assessment, with particular attention to behavior in marine environments. The certification also evaluates the manufacturer's ability to maintain material traceability throughout the production process, from raw material sourcing to finished product delivery. Regular surveillance audits ensure ongoing compliance with ABS requirements, with any significant process changes requiring re-validation. Baoji JL Clad Metals Materials Co., Ltd. achieved ABS certification in 2024, further validating their Precision Pure Nickel Sheet quality for applications in shipbuilding, offshore platforms, and maritime chemical processing equipment. This certification confirms that their products, available in customizable lengths and various thickness-width combinations, meet the demanding requirements for materials used in critical marine and offshore applications where corrosion resistance and mechanical reliability are paramount.

Application-Specific Standards for Precision Pure Nickel Sheet

Chemical Industry Standards and Applications

The chemical industry imposes some of the most demanding standards for Precision Pure Nickel Sheet due to exposure to corrosive substances and extreme operating conditions. Industry-specific standards such as ASME BPE (Bioprocessing Equipment) provide detailed guidelines for materials used in pharmaceutical and biotechnology applications, addressing cleanability, corrosion resistance, and surface finish requirements. Precision Pure Nickel Sheet used in chemical processing must meet stringent purity standards, typically requiring 99.5% or higher nickel content to ensure optimal corrosion resistance against acids, alkalis, and organic compounds. Surface roughness specifications are particularly important, with average roughness (Ra) values often required to be below 0.5 micrometers for applications involving ultrapure chemical processing. Standards also address weldability characteristics, as many chemical equipment components require joining without compromising corrosion resistance or introducing potential contamination sources. Manufacturers must conduct specialized testing including immersion tests in specific chemical environments to validate performance under actual service conditions. Precision Pure Nickel Sheet from Baoji JL Clad Metals Materials Co., Ltd. undergoes comprehensive chemical resistance testing, ensuring suitability for applications ranging from sulfuric acid handling equipment to caustic soda processing systems. Their roll-bonded and explosion-bonded nickel sheets provide exceptional corrosion resistance while maintaining mechanical integrity, with thicknesses customized to application requirements between 0.1 mm and 10 mm. The company's strict adherence to chemical industry standards ensures their Precision Pure Nickel Sheet delivers reliable performance in reaction vessels, heat exchangers, agitators, and storage tanks handling corrosive chemicals.

Aerospace Industry Standards and Requirements

The aerospace industry maintains exceptionally rigorous standards for Precision Pure Nickel Sheet, focusing on material consistency, performance reliability, and complete traceability. Standards such as AMS (Aerospace Material Specifications) provide detailed requirements for nickel and nickel alloys used in aircraft components, addressing chemical composition, mechanical properties, and quality assurance protocols. For aerospace applications, Precision Pure Nickel Sheet must demonstrate extremely low inclusion content and high consistency in mechanical properties throughout the material. Ultrasonic inspection requirements are particularly stringent, often requiring 100% volumetric examination to detect any internal discontinuities that could compromise performance under flight conditions. The standards also establish specific requirements for grain size control and texture uniformity, which directly impact formability and fatigue resistance in aerospace components. Special attention is given to stress corrosion cracking resistance, particularly important for components exposed to both mechanical stress and potentially corrosive environments. Baoji JL Clad Metals Materials Co., Ltd. produces Precision Pure Nickel Sheet that meets these demanding aerospace requirements, with specialized production processes ensuring the material purity and property consistency needed for critical applications. Their products undergo additional non-destructive testing specific to aerospace requirements, including penetrant testing and radiographic examination when required by specifications. The ability to provide customized widths from 100 mm to 1500 mm makes their Precision Pure Nickel Sheet suitable for various aerospace components, from engine parts to electronics shielding applications, all backed by complete material traceability documentation required by industry standards.

Pharmaceutical Industry Compliance Requirements

The pharmaceutical industry applies particularly stringent standards to Precision Pure Nickel Sheet used in manufacturing equipment, focusing on material purity, surface characteristics, and cleanability. Standards such as ASME BPE and FDA guidelines establish specific requirements for materials in contact with pharmaceutical products, addressing potential contamination concerns. Precision Pure Nickel Sheet for pharmaceutical applications must meet exceptionally high purity specifications, typically exceeding 99.6% nickel content with strictly controlled levels of trace elements that could potentially leach into drug products. Surface finish requirements are among the most demanding of any industry, with Ra values often specified below 0.25 micrometers to prevent product adhesion and ensure complete cleanability during manufacturing transitions. Electro-polishing is frequently specified as a surface treatment to achieve both the required smoothness and enhanced corrosion resistance. The standards also address material certification requirements, including detailed documentation of chemical composition, processing methods, and testing results, creating a complete audit trail for regulatory compliance. Material biocompatibility testing may be required for certain applications, ensuring the Precision Pure Nickel Sheet does not introduce toxicity concerns into pharmaceutical processing. Baoji JL Clad Metals Materials Co., Ltd. specializes in producing pharmaceutical-grade Precision Pure Nickel Sheet with the surface characteristics and material purity required for critical applications such as reactors, fermenters, storage vessels, and transfer lines. Their products undergo additional electropolishing and passivation treatments when required for pharmaceutical applications, ensuring compliance with Good Manufacturing Practice (GMP) requirements. The company's ability to provide custom dimensions supports the pharmaceutical industry's need for specialized equipment components, with full material certification documentation supporting regulatory compliance efforts.

Conclusion

Precision Pure Nickel Sheet manufactured by Baoji JL Clad Metals Materials Co., Ltd. meets comprehensive international standards including GB/GBT, ASME/ASTM, and JIS specifications. The company's ISO 9001:2000 certification and recent PED and ABS qualifications demonstrate their commitment to quality excellence across diverse industrial applications.

Looking to elevate your projects with industry-leading materials? Experience the technological superiority that comes with our innovative Precision Pure Nickel Sheet products. Whether you need standard specifications or custom solutions, our independent explosive composite technology and self-rolling capabilities allow us to meet your exact requirements. With our global delivery network, extensive R&D capabilities, and commitment to innovation, we're ready to become your trusted partner in material excellence. Contact our team today at sales@cladmet.com to discuss how our internationally certified products can enhance your next project.

References

1. American Society for Testing and Materials. (2023). ASTM B162: Standard Specification for Nickel Plate, Sheet, and Strip. ASTM International, West Conshohocken, PA.

2. American Society of Mechanical Engineers. (2022). ASME Boiler and Pressure Vessel Code, Section II: Materials. ASME, New York.

3. Japanese Standards Association. (2021). JIS H4552: Nickel and Nickel Alloy Plate, Sheet and Strip. JSA, Tokyo.

4. International Organization for Standardization. (2015). ISO 9001:2015 Quality Management Systems - Requirements. ISO, Geneva.

5. European Committee for Standardization. (2022). Pressure Equipment Directive 2014/68/EU Technical Requirements for Metallic Materials. CEN, Brussels.

6. American Bureau of Shipping. (2024). Rules for Materials and Welding: Part 2 - Materials and Welding. ABS, Houston, TX.

_1737007724117.webp)

_1736996330512.webp)