What specifications and standards apply to Titanium Clad Nickel Plates?

2025-04-04 19:02:32

View:389

2025-04-04 19:02:32

View:389Titanium Clad Nickel Plates represent a sophisticated engineering solution that combines the exceptional properties of titanium and nickel into a single, high-performance material. These composite plates must adhere to rigorous specifications and industry standards to ensure their reliability in critical applications. The specifications for Titanium Clad Nickel Plates encompass material composition, dimensional tolerances, bonding integrity, and performance characteristics. These plates are manufactured according to international standards including ASME, ASTM, and JIS, with companies like Baoji JL Clad Metals Materials Co., Ltd. leading the industry with certifications such as ISO9001-2000, PED, and ABS qualifications. Understanding these specifications and standards is essential for engineers and procurement specialists working in industries where material integrity and performance are paramount.

International Standards and Certifications for Titanium Clad Nickel Plates

ASME and ASTM Standards Compliance

Titanium Clad Nickel Plates are manufactured to meet stringent requirements established by the American Society of Mechanical Engineers (ASME) and American Society for Testing and Materials (ASTM). These standards govern crucial aspects of material quality, performance, and safety. ASME Section VIII, Division 1 and 2 provide comprehensive guidelines for pressure vessels that often incorporate Titanium Clad Nickel Plates in their construction. These standards specify the minimum requirements for the design, fabrication, inspection, and testing of these composite materials. ASTM B898 specifically addresses the requirements for reactive metal-clad plates, including Titanium Clad Nickel Plates, focusing on bond integrity and material properties. Additionally, ASTM A264 governs the general requirements for stainless chromium-nickel steel-clad plates, which includes provisions applicable to titanium cladding on nickel substrates. These standards ensure that Titanium Clad Nickel Plates maintain consistent quality and performance across different manufacturing batches and suppliers, making them reliable for critical applications in chemical processing, marine environments, and other demanding industries. Compliance with these standards is not merely a formality but a critical assurance of material integrity that engineers and procurement specialists depend upon when specifying Titanium Clad Nickel Plates for their projects.

ISO and European Standards Requirements

The global acceptance and application of Titanium Clad Nickel Plates are significantly enhanced by their compliance with ISO (International Organization for Standardization) and European standards. ISO 9001-2000 certification, which companies like Baoji JL Clad Metals Materials Co., Ltd. have achieved, verifies that a manufacturer has implemented a robust quality management system that ensures consistent product quality. This certification demonstrates a commitment to meeting customer requirements and enhancing customer satisfaction through continual improvement processes. For Titanium Clad Nickel Plates intended for the European market, compliance with the Pressure Equipment Directive (PED) is essential. The PED certification ensures that these composite materials meet safety standards for pressure equipment such as vessels, piping, and heat exchangers. European Standard EN 13445 further specifies requirements for unfired pressure vessels, including those constructed from clad materials. These standards address critical aspects such as material combinations, cladding ratios, and testing procedures specific to Titanium Clad Nickel Plates. The harmonization of these standards across international markets facilitates global trade and ensures that regardless of the manufacturer's location, Titanium Clad Nickel Plates will perform consistently and reliably under specified conditions, providing engineers with confidence when designing systems for international deployment.

Japanese Industrial Standards (JIS) Specifications

Japanese Industrial Standards (JIS) have established a comprehensive framework for the production and quality assurance of Titanium Clad Nickel Plates, reflecting Japan's significant role in advanced materials manufacturing. JIS G3601 and JIS G3602 specifically address clad steel plates and sheets, providing detailed requirements for the production process, material composition, mechanical properties, and testing methodologies. For Titanium Clad Nickel Plates, these standards define acceptable bonding techniques, shear strength requirements, and bond integrity verification methods. The JIS framework also includes specific standards for titanium (JIS H4600) and nickel (JIS H4551) that govern the base materials used in these composite plates. Manufacturers of Titanium Clad Nickel Plates who comply with JIS standards must adhere to strict quality control procedures, including ultrasonic testing to detect any bonding defects and tensile testing to verify mechanical properties. These rigorous specifications have made JIS-compliant Titanium Clad Nickel Plates particularly valued in shipbuilding, chemical processing equipment, and nuclear applications where material failure could have severe consequences. The adoption of JIS standards by international manufacturers like Baoji JL Clad Metals Materials Co., Ltd. demonstrates the global recognition of these specifications as benchmarks for quality and reliability in the production of high-performance clad materials for critical industrial applications.

Technical Specifications and Material Properties

Dimensional and Tolerance Requirements

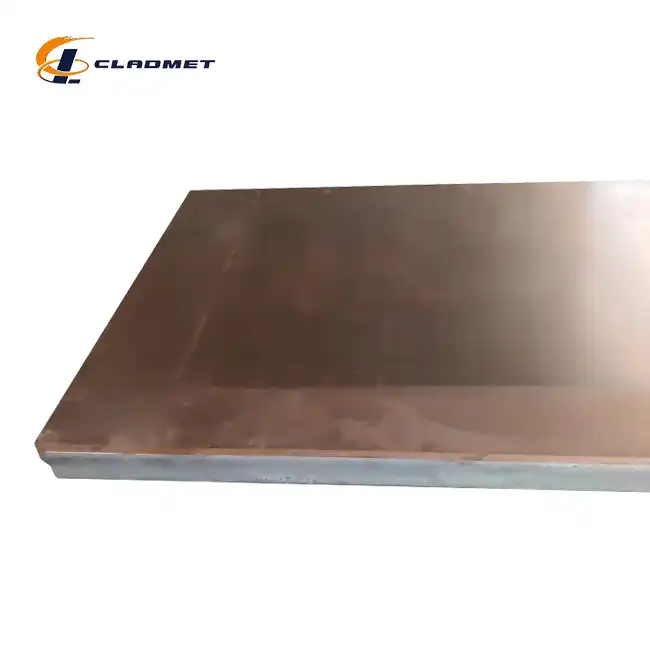

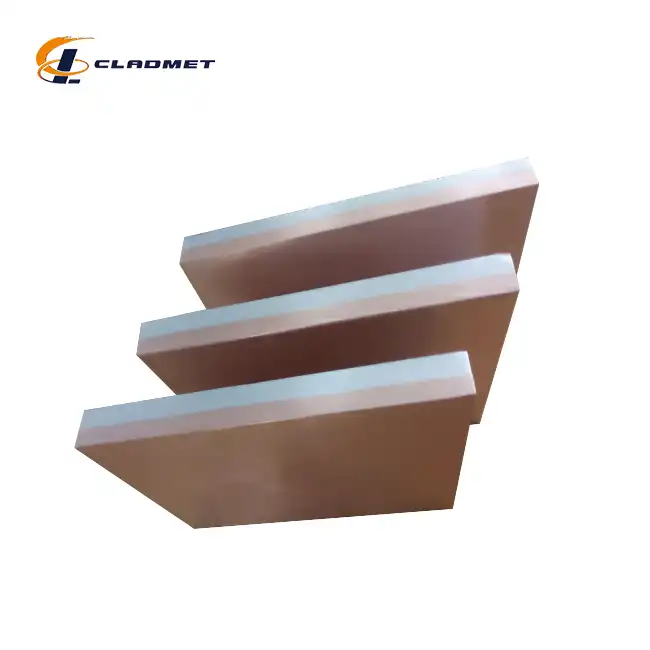

Precise dimensional control and adherence to tolerance requirements are fundamental aspects of Titanium Clad Nickel Plates production. These specifications ensure proper fit, form, and function in various industrial applications. Standard Titanium Clad Nickel Plates are available in widths up to 2500mm and lengths extending to 6000mm, though custom dimensions can be manufactured to meet specific project requirements. The thickness of these composite plates typically ranges from 3mm to 60mm total, with the titanium cladding component generally constituting between 10% and 25% of the total thickness, typically ranging from 1mm to 10mm. The base nickel substrate can range from 2mm to 50mm in thickness. Tolerance requirements for these dimensions are stringent, with thickness tolerances typically maintained at ±5% for plates under 25mm and ±3% for thicker plates. Flatness tolerances are equally demanding, generally specified at 1% of the plate width or less. Edge straightness must typically be maintained within 2mm over a 1-meter length. These exacting dimensional standards are verified through comprehensive measurement protocols including laser scanning and mechanical gauging. For Titanium Clad Nickel Plates used in critical applications such as heat exchangers and reaction vessels, these dimensional specifications are essential to ensure proper sealing, heat transfer efficiency, and structural integrity during operation. The ability to maintain these tight tolerances while producing large-format plates is a key differentiator among manufacturers of Titanium Clad Nickel Plates and directly impacts the performance and service life of the finished industrial equipment.

Bond Integrity and Shear Strength Specifications

The bond between titanium and nickel layers represents the most critical aspect of Titanium Clad Nickel Plates' performance specifications. Industry standards require these bonds to withstand stringent testing procedures to ensure reliability in service. According to ASTM standards, the minimum acceptable bond shear strength for Titanium Clad Nickel Plates typically ranges from 140 MPa to 210 MPa, depending on the specific application requirements. This bond integrity is verified through destructive testing methods such as shear testing of representative samples from each production lot. Non-destructive testing methods, including ultrasonic examination per ASTM A578/A578M, are employed to detect any unbonded areas, with acceptance criteria typically limiting unbonded areas to less than 5% of the total surface with no single unbonded area exceeding 50 square centimeters. Bond integrity testing also includes bend tests, where samples must withstand bending around a mandrel with a diameter equal to three times the total plate thickness without showing any signs of delamination or cracking at the bond interface. For explosion bonded Titanium Clad Nickel Plates, the wave pattern at the interface provides visual confirmation of proper bonding and is often subjected to metallographic examination to verify consistent wave formation and the absence of brittle intermetallic compounds. These rigorous bond integrity specifications ensure that Titanium Clad Nickel Plates maintain their composite properties throughout their service life, even when subjected to thermal cycling, mechanical stress, and corrosive environments common in chemical processing, marine engineering, and aerospace applications. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. maintain detailed records of bond integrity test results for each production lot, providing traceability and quality assurance for these critical components.

Corrosion Resistance and Performance Standards

Exceptional corrosion resistance is the defining performance characteristic of Titanium Clad Nickel Plates, and industry standards establish rigorous requirements to verify this property. According to ASTM G48 methodology for pitting and crevice corrosion testing, properly manufactured Titanium Clad Nickel Plates must demonstrate negligible weight loss and no visible pitting after exposure to ferric chloride solution for 72 hours. The titanium cladding layer, typically Grade 1 or Grade 2 titanium (per ASTM B265), provides outstanding resistance to oxidizing environments including chlorides, wet chlorine, organic chlorides, and chlorine dioxide that would rapidly deteriorate conventional materials. Electrochemical testing according to ASTM G5 standards establishes performance criteria for passive current density and breakdown potential in various electrolytes. For Titanium Clad Nickel Plates, the passive current density must typically remain below 1 μA/cm² in seawater environments, and the breakdown potential should exceed 1.5V versus a saturated calomel electrode. The nickel substrate (typically Nickel 200 or Nickel 201 per ASTM B162) contributes excellent resistance to caustic environments and reducing acids, complementing titanium's performance profile. This combination creates a versatile material capable of withstanding mixed chemical environments that would attack homogeneous materials. Performance standards also address mechanical property retention after corrosion exposure, requiring less than 5% reduction in tensile and yield strength properties after extended exposure to design media. These comprehensive corrosion resistance specifications ensure that Titanium Clad Nickel Plates maintain their structural integrity throughout their designed service life in aggressive chemical processing environments, marine applications, and other demanding scenarios where conventional materials would rapidly deteriorate, making them an indispensable material of construction for critical equipment in these industries.

Manufacturing Processes and Quality Control

Explosion Bonding and Roll Bonding Methods

The manufacturing specifications for Titanium Clad Nickel Plates encompass two primary bonding methodologies: explosion bonding and roll bonding, each governed by distinct technical parameters and quality standards. Explosion bonding, the predominant method for producing Titanium Clad Nickel Plates, utilizes precisely controlled detonation to create a metallurgical bond between the titanium and nickel layers. This process operates under strict specifications regarding standoff distance (typically 0.5-1.5 times the plate thickness), detonation velocity (4000-7000 m/s), and impact angle (5-25 degrees). These parameters must be precisely calibrated to generate the optimal collision energy that creates the characteristic wavy interface without forming brittle intermetallic compounds. The alternative method, roll bonding, involves extensive surface preparation specifications including surface roughness requirements (Ra value typically between 0.8-1.2 μm) and cleanliness standards that limit contaminants to less than 10 mg/m². Roll bonding further requires precise temperature control (typically 900-1100°C for hot rolling), reduction ratios per pass (15-25% typical), and total reduction (minimum 60%) to ensure proper bonding. Both processes must comply with ASTM B898 requirements for reactive metal clad plate production, which specify minimum bond strengths, testing protocols, and acceptable defect limits. Companies like Baoji JL Clad Metals Materials Co., Ltd. have developed proprietary refinements to these standard processes, including specialized surface activation techniques and controlled atmosphere environments that enhance bond consistency and quality. These manufacturing specifications ensure that Titanium Clad Nickel Plates exhibit uniform properties across their entire surface area, providing reliable performance in demanding applications from chemical processing vessels to desalination equipment. The strict adherence to these manufacturing specifications is essential for producing Titanium Clad Nickel Plates that meet the safety and reliability requirements of industries where material failure could have significant consequences.

Heat Treatment and Surface Finish Requirements

Post-bonding heat treatment and surface finish specifications are critical aspects of Titanium Clad Nickel Plates manufacturing that significantly influence their final performance characteristics. Heat treatment specifications typically require stress relief annealing at temperatures between 550°C and 650°C for 1-4 hours (precise parameters depend on plate thickness and specific material grades) in controlled atmosphere furnaces with oxygen content maintained below 10 ppm to prevent titanium oxidation. This process must achieve a uniform temperature distribution with maximum variations of ±10°C across the plate surface to ensure consistent material properties. Cooling rates are equally important, generally specified at 50-100°C per hour to minimize residual stress development. Surface finish requirements for Titanium Clad Nickel Plates vary by application but typically include specifications for roughness (Ra values from 0.8 to 6.3 μm depending on service conditions), flatness tolerances (generally 3mm deviation maximum per meter length), and freedom from surface defects such as pits, scratches, and inclusions. For applications involving high-purity chemicals or pharmaceuticals, surface finish specifications may require electropolishing or mechanical polishing to achieve Ra values below 0.4 μm and enhanced cleanability. Additional surface treatment specifications may include passivation procedures for the titanium surface, performed according to ASTM B600 guidelines to establish optimal corrosion resistance. Manufacturers must maintain detailed records of all heat treatment parameters and surface finish measurements, with traceability to specific production lots of Titanium Clad Nickel Plates. These stringent specifications ensure that the final product not only achieves the required mechanical and corrosion-resistant properties but also provides the surface characteristics necessary for specific applications such as heat exchangers, chemical reactors, and pharmaceutical processing equipment where product purity and heat transfer efficiency are paramount considerations.

Testing and Inspection Protocols

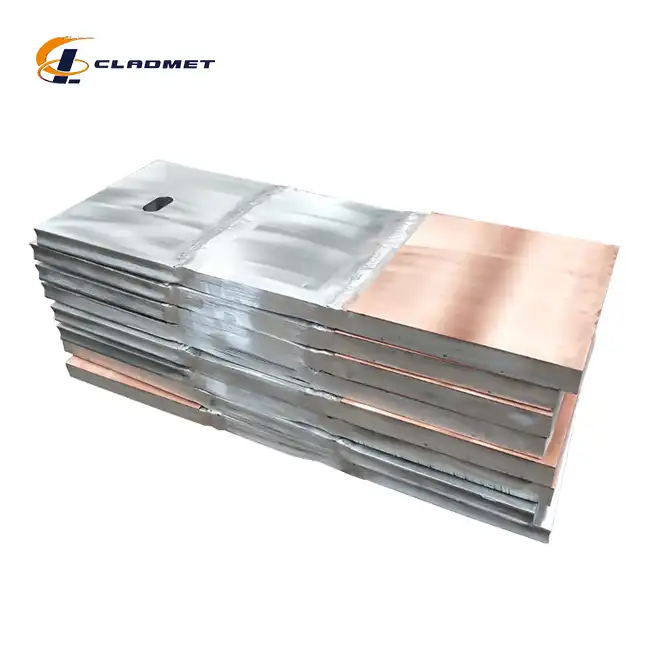

Comprehensive testing and inspection protocols form the backbone of quality assurance for Titanium Clad Nickel Plates, ensuring compliance with industry standards and performance requirements. Ultrasonic testing, conducted according to ASTM A578/A578M specifications, must achieve 100% coverage of the bonded surface with acceptance criteria typically requiring that unbonded areas constitute less than 5% of the total surface area, with no single unbonded area exceeding 25 square centimeters. Destructive testing requirements include shear strength testing per ASTM A264, with minimum acceptable values typically ranging from 140 to 210 MPa depending on material combination and application specifications. Mechanical property testing encompasses tensile testing (ASTM E8), hardness testing (ASTM E18), and bend testing (ASTM E290), with specific acceptance criteria for each plate configuration. Chemical composition verification must be performed using methods such as optical emission spectroscopy or X-ray fluorescence to confirm compliance with material specifications such as ASTM B265 for titanium and ASTM B162 for nickel.

For Titanium Clad Nickel Plates destined for critical applications, additional testing may include radiographic examination, dye penetrant testing of edge areas, and helium leak testing for plates intended for vacuum applications. Each plate must be accompanied by comprehensive documentation including material test reports (MTRs), dimensional inspection reports, and nondestructive examination certifications. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. implement statistical process control methodologies to monitor manufacturing variability and ensure consistent product quality across production runs. These rigorous testing and inspection protocols provide assurance that Titanium Clad Nickel Plates will perform as expected in demanding applications where material failure could compromise safety, product quality, or operational continuity. The traceability established through these inspection procedures enables root cause analysis in the rare event of material non-conformance, supporting continuous improvement of manufacturing processes and product reliability for these critical industrial materials.

Conclusion

Understanding the specifications and standards that govern Titanium Clad Nickel Plates is essential for ensuring optimal performance in demanding industrial applications. These composite materials, when manufactured to international standards like ASME, ASTM, and JIS, provide exceptional corrosion resistance, mechanical integrity, and longevity that justify their use in critical environments. By adhering to these specifications, manufacturers like Baoji JL Clad Metals Materials Co., Ltd. deliver high-quality products that meet the exacting requirements of modern industry.

We invite you to experience the difference that comes with our independent explosive composite technology, international qualifications, and customization capabilities. Whether you need standard plates or custom solutions tailored to your unique specifications, our team is ready to provide expert guidance and superior products. Contact us today at sales@cladmet.com to discuss how our Titanium Clad Nickel Plates can enhance the performance and reliability of your next project.

References

1. American Society of Mechanical Engineers. (2023). ASME Boiler and Pressure Vessel Code, Section VIII: Rules for Construction of Pressure Vessels. ASME International.

2. American Society for Testing and Materials. (2022). ASTM B898: Standard Specification for Reactive and Refractory Metal Clad Plate. ASTM International.

3. Japanese Standards Association. (2023). JIS G3601: Clad Steel Plates and Sheets. JSA Group.

4. International Organization for Standardization. (2022). ISO 9001:2015 Quality Management Systems - Requirements. ISO.

5. European Committee for Standardization. (2022). EN 13445: Unfired Pressure Vessels. CEN.

6. Kobelco Research Institute. (2023). Handbook of Clad Materials: Properties, Manufacturing, and Applications. Metallurgical Press.

_1737007724117.webp)

_1736996330512.webp)