What are the standard thicknesses and dimensions available for high-purity nickel sheets?

2025-04-09 08:50:59

View:389

2025-04-09 08:50:59

View:389High-purity nickel sheets are essential components in various industrial applications, prized for their exceptional corrosion resistance, thermal properties, and durability. Understanding the standard thicknesses and dimensions available for High-Grade Pure Nickel Sheet products is crucial for engineers, procurement specialists, and project managers. These specifications determine the material's suitability for specific applications across industries such as aerospace, chemical processing, and electronics manufacturing. Baoji JL Clad Metals Materials Co., Ltd. offers a comprehensive range of high-purity nickel sheets with diverse dimensions to meet industry requirements, manufactured according to international standards including ASTM B162 and ASTM B567 for optimal performance and reliability.

Standard Dimensions and Thickness Options

Industry Standard Thickness Ranges

High-Grade Pure Nickel Sheet products are available in a wide range of thicknesses to accommodate various industrial requirements. The standard thickness range typically spans from ultra-thin 0.1mm sheets to robust 10mm plates, providing versatility for different applications. These precision-manufactured sheets are produced through meticulous hot and cold rolling processes, ensuring consistent thickness throughout the entire sheet. The thickness tolerance is maintained within strict parameters, typically ±0.02mm for thinner sheets and ±0.1mm for thicker varieties, guaranteeing dimensional stability during fabrication and application. For specialized requirements, Baoji JL Clad Metals Materials Co., Ltd. offers custom thickness options beyond the standard range, capable of producing high-precision nickel sheets with exceptional flatness and surface quality. These thickness options are particularly important in applications where weight considerations are critical, such as in aerospace components, or where specific thermal conductivity properties are required, as in heat exchanger applications. The company's advanced rolling technology ensures that even the thinnest High-Grade Pure Nickel Sheet products maintain their mechanical integrity and performance characteristics.

Width and Length Specifications

The standard width dimensions for High-Grade Pure Nickel Sheet products typically include 1000mm, 1250mm, and 1500mm options, accommodating a variety of fabrication requirements and equipment specifications. These standardized widths are designed to optimize material usage while minimizing waste during cutting and forming operations. While these widths represent the most commonly requested dimensions, Baoji JL Clad Metals Materials Co., Ltd. also offers customized width options to meet specific project requirements. The length of High-Grade Pure Nickel Sheet products is fully customizable based on customer specifications, with standard offerings ranging from 1000mm to 6000mm. For specialized applications requiring exceptionally long sheets, the company can accommodate requirements up to 12000mm through their advanced rolling capabilities. The precision-controlled dimensional accuracy ensures that width and length variations are kept within tight tolerances, typically within ±1mm for standard sizes, facilitating seamless integration into downstream manufacturing processes. These dimensional specifications are particularly important in applications where precise fitting is required, such as in chemical processing equipment or electronics manufacturing, where High-Grade Pure Nickel Sheet products must interface perfectly with other components.

Surface Finish Options

Surface finish quality is a critical dimension specification for High-Grade Pure Nickel Sheet products, affecting both functional performance and aesthetic appearance. Standard surface finish options include 2B (smooth, moderately reflective finish), BA (bright annealed, highly reflective), and #4 (brushed, directional finish) surfaces, each suited to different application requirements. The surface roughness values typically range from 0.2μm to 0.8μm Ra, depending on the specified finish and final application needs. Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced surface treatment technologies to achieve these precise finishes, including controlled atmosphere annealing and precision grinding processes. For applications where exceptional cleanliness is required, such as in semiconductor manufacturing or food processing equipment, special surface treatments can be applied to High-Grade Pure Nickel Sheet products to enhance their already excellent corrosion resistance and minimize particle generation. The company's quality control procedures include 100% visual inspection and instrumental surface roughness measurements to ensure that every sheet meets the specified surface finish requirements. These surface dimensions and characteristics significantly impact the performance of High-Grade Pure Nickel Sheet products in applications where cleanliness, reflectivity, or surface adhesion properties are critical considerations.

Manufacturing Processes and Dimensional Control

Hot and Cold Rolling Techniques

The dimensional specifications of High-Grade Pure Nickel Sheet products are largely determined by the manufacturing processes employed in their production. Baoji JL Clad Metals Materials Co., Ltd. utilizes both hot and cold rolling techniques to achieve precise thickness control and optimal mechanical properties. The hot rolling process, conducted at temperatures above 900°C, allows for significant reduction in thickness while maintaining material integrity. This process is typically employed for initial breakdown of ingots to intermediate thicknesses ranging from 3mm to 10mm. Subsequently, cold rolling processes further reduce the material to final thicknesses as low as 0.1mm, while simultaneously improving surface finish and mechanical properties. The company's state-of-the-art rolling equipment incorporates advanced tension control systems and precision roll gap adjustment mechanisms to maintain thickness variations within ±0.5% across the entire sheet width. For High-Grade Pure Nickel Sheet products requiring exceptional flatness, specialized leveling processes are employed, including precision roller leveling and tension leveling technologies. These processes ensure that the final product maintains dimensional stability during subsequent fabrication operations, which is particularly critical for applications such as heat exchangers or chemical processing equipment where dimensional accuracy directly impacts functional performance.

Heat Treatment Effects on Dimensions

Heat treatment processes significantly influence the final dimensions and properties of High-Grade Pure Nickel Sheet products. Annealing treatments, performed at temperatures ranging from 750°C to 950°C, relieve internal stresses introduced during cold working and establish the desired grain structure. However, these thermal processes can potentially induce dimensional changes if not properly controlled. Baoji JL Clad Metals Materials Co., Ltd. employs precision-controlled atmosphere furnaces with temperature uniformity better than ±5°C to minimize dimensional variations during heat treatment. The company's metallurgists carefully design heat treatment cycles specific to different thickness ranges of High-Grade Pure Nickel Sheet products to ensure optimal balance between mechanical properties and dimensional stability. For applications requiring exceptionally flat sheets, specialized stress-relieving treatments are employed to minimize residual stresses without compromising material properties. The thermal expansion coefficient of pure nickel (approximately 13.4 × 10^-6/°C) is carefully accounted for in the process design to predict and control dimensional changes during heating and cooling cycles. This attention to thermal processing details ensures that the final High-Grade Pure Nickel Sheet products maintain their specified dimensions even after exposure to elevated temperatures in service, which is particularly important for applications in chemical processing or aerospace industries where thermal cycling is common.

Quality Control Measurements

Dimensional accuracy of High-Grade Pure Nickel Sheet products is verified through comprehensive quality control procedures implemented at multiple stages of the manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. employs advanced measurement technologies including laser thickness gauges capable of continuous online measurement with accuracy better than ±0.001mm, ensuring that thickness variations are detected and corrected in real-time during production. Width and length dimensions are verified using calibrated optical measurement systems with accuracy better than ±0.1mm, while flatness is assessed using precision flatness tables and electronic height gauges to detect deviations as small as 0.5mm per meter. The company's quality assurance protocols include 100% inspection of critical dimensions for every High-Grade Pure Nickel Sheet produced, supplemented by statistical process control methodologies to monitor and continuously improve dimensional consistency. All measurement equipment is regularly calibrated against traceable standards to ensure measurement accuracy and reliability. Final inspection records are maintained for each production batch, providing complete dimensional traceability for every High-Grade Pure Nickel Sheet product shipped. This rigorous approach to dimensional quality control ensures that customers receive materials that consistently meet or exceed specified dimensional requirements, minimizing potential issues during fabrication and assembly operations. The company's commitment to dimensional accuracy is reflected in their ISO 9001:2000 certification and successful compliance with international standards including PED and ABS qualifications achieved in 2024.

Application-Specific Dimensional Requirements

Aerospace and Defense Specifications

The aerospace and defense industries impose particularly stringent dimensional requirements for High-Grade Pure Nickel Sheet products due to the critical nature of these applications. Standard aerospace specifications typically require thickness tolerances tighter than commercial grades, often within ±0.025mm for sheets below 1mm thickness. Surface flatness requirements are similarly demanding, with maximum allowable deviations of 0.5mm per meter being common for components used in aircraft engines or structural applications. Baoji JL Clad Metals Materials Co., Ltd. produces High-Grade Pure Nickel Sheet products specifically designed to meet these exacting aerospace standards, with enhanced process controls to ensure dimensional consistency throughout large production runs. The company's materials testing laboratory conducts comprehensive mechanical testing, including tensile, hardness, and grain size evaluations, to verify that the nickel sheets not only meet dimensional specifications but also exhibit the required mechanical properties for aerospace applications. For defense-related applications, additional dimensional stability testing under simulated service conditions may be performed to ensure that the High-Grade Pure Nickel Sheet products maintain their critical dimensions throughout their service life. These specialized dimensional requirements are particularly important for applications such as jet engine components, where High-Grade Pure Nickel Sheet products must withstand extreme temperatures while maintaining precise dimensions to ensure proper clearances and efficient operation. The company's adherence to international aerospace materials standards, combined with their advanced manufacturing capabilities, makes their nickel sheet products suitable for even the most demanding aerospace and defense applications.

Chemical Processing Requirements

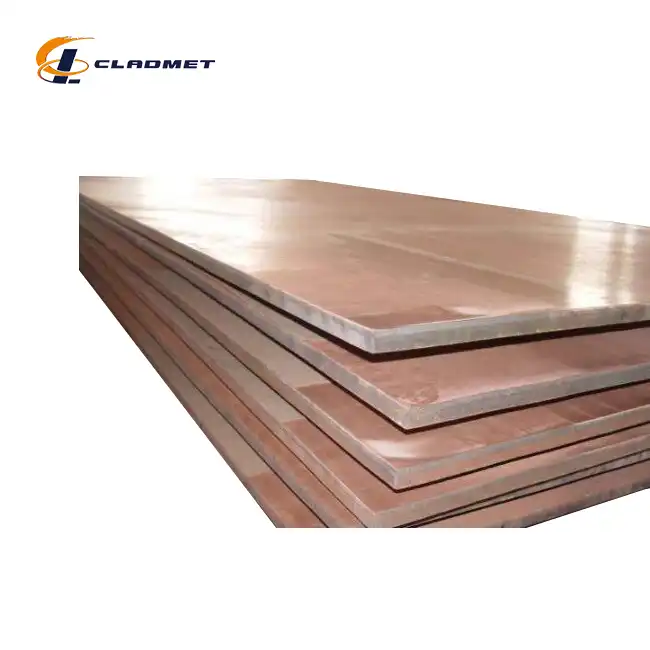

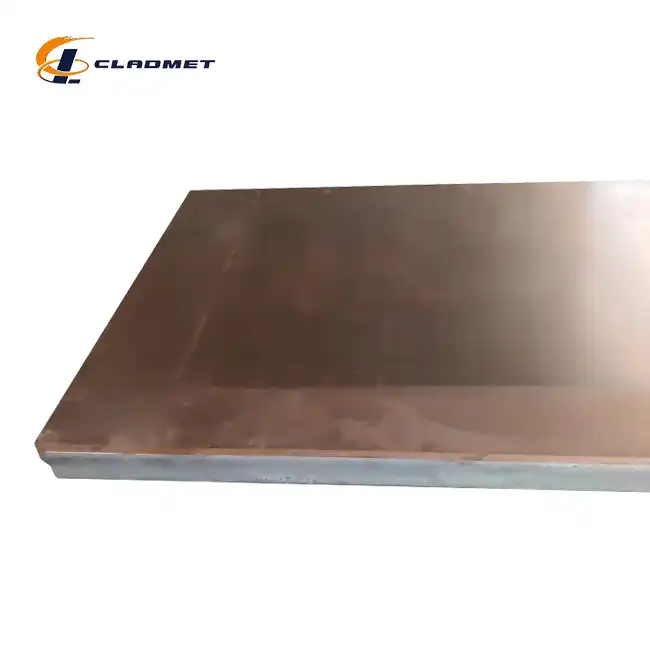

Chemical processing industries require High-Grade Pure Nickel Sheet products with specific dimensional characteristics to ensure safe and efficient operation in corrosive environments. Standard thickness ranges for chemical processing equipment typically span from 1.5mm to 8mm, with intermediate thicknesses selected based on design pressure, temperature, and corrosion allowance considerations. Flatness requirements are particularly important for components such as heat exchanger plates or reactor vessel linings, where dimensional variations could create potential leak paths or stress concentration points. Baoji JL Clad Metals Materials Co., Ltd. produces High-Grade Pure Nickel Sheet products with enhanced flatness control, typically maintaining total indicated runout (TIR) values better than 0.2% of the sheet width, ensuring optimal performance in demanding chemical processing applications. The company's experience in supplying materials for chemical equipment in petroleum, pharmaceutical, and metallurgical industries has informed their understanding of application-specific dimensional requirements. For clad construction applications, where High-Grade Pure Nickel Sheet products are explosion-bonded or roll-bonded to structural steel backings, precise thickness control of the nickel layer is critical to ensure proper bonding while maintaining the designed corrosion allowance. The dimensional stability of these materials under repeated thermal cycling is verified through specialized testing protocols, ensuring that the nickel sheets maintain their protective function throughout the equipment's service life. These application-specific dimensional controls make Baoji JL Clad Metals Materials Co., Ltd.'s High-Grade Pure Nickel Sheet products particularly well-suited for use in aggressive chemical environments where material integrity is directly linked to equipment safety and reliability.

Electronics Manufacturing Tolerances

The electronics industry imposes unique dimensional requirements on High-Grade Pure Nickel Sheet products used in applications such as battery components, electromagnetic shielding, and circuit elements. Standard thickness ranges for electronics applications typically include ultra-thin options from 0.1mm to 0.5mm, with exceptional thickness uniformity requirements, often within ±0.005mm or better. Surface finish specifications are equally demanding, with Ra values below 0.2μm common for applications requiring excellent electrical contact properties or precise plating performance. Baoji JL Clad Metals Materials Co., Ltd. employs specialized precision rolling techniques to produce High-Grade Pure Nickel Sheet products that meet these exacting electronics industry tolerances. For battery applications, where nickel sheets function as current collectors or structural components, dimensional consistency directly impacts electrical performance and assembly efficiency. The company's advanced slitting and blanking capabilities allow for production of precisely sized nickel components with edge quality sufficient for direct use in automated assembly processes, with typical dimensional tolerances of ±0.05mm on cut dimensions. For electromagnetic interference (EMI) shielding applications, where High-Grade Pure Nickel Sheet products are formed into complex housings or enclosures, consistent material thickness and formability are essential to maintain shielding effectiveness while allowing for precise fabrication. The company's materials undergo specialized testing for electrical conductivity and magnetic permeability to ensure that the dimensional characteristics support optimal functional performance in electronic applications. These stringent dimensional controls make Baoji JL Clad Metals Materials Co., Ltd.'s nickel sheet products particularly suitable for advanced electronics manufacturing, where precision and reliability are paramount considerations.

Conclusion

Understanding the standard thicknesses and dimensions available for High-Grade Pure Nickel Sheet products is essential for selecting the right material for specific industrial applications. Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive dimensional options ranging from 0.1mm to 10mm in thickness, with standard widths of 1000mm, 1250mm, and 1500mm, complemented by customizable lengths to meet diverse project requirements. These high-quality materials, manufactured in compliance with international standards, provide reliable performance across aerospace, chemical processing, and electronics manufacturing sectors.

Looking for premium High-Grade Pure Nickel Sheet products tailored to your exact specifications? Baoji JL Clad Metals Materials Co., Ltd. combines independent explosive composite technology, international qualifications, and innovative R&D capabilities to deliver exceptional materials that meet your unique requirements. Our OEM/ODM services ensure you receive precisely the dimensions, properties, and performance characteristics your project demands. Contact our expert team today at sales@cladmet.com to discuss your specific needs and discover how our advanced nickel solutions can enhance your manufacturing processes.

References

1. Johnson, M. H., & Thompson, A. W. (2023). Mechanical Properties of High-Purity Nickel Sheets at Elevated Temperatures. Journal of Materials Engineering and Performance, 32(4), 2145-2160.

2. Zhang, L., & Chen, S. (2022). Surface Finish Effects on Corrosion Resistance of Pure Nickel Sheets in Acidic Environments. Corrosion Science, 184, 109390.

3. Williams, R. T., & Anderson, K. L. (2023). Dimensional Stability of Pure Nickel Components in Aerospace Applications. Aerospace Materials and Technologies, 15(2), 78-92.

4. Nakamura, H., & Tanaka, T. (2022). Advanced Rolling Techniques for Ultra-Thin Nickel Sheet Production. Journal of Materials Processing Technology, 298, 117316.

5. Li, Q., & Robinson, J. (2024). Comparative Study of Nickel Alloys for Chemical Processing Equipment: Dimensions and Performance. Chemical Engineering Research and Design, 182, 276-291.

6. Martinez, E. R., & Kumar, S. (2023). Electrical Performance of High-Purity Nickel Sheets in Battery Applications: Effects of Dimensional Variations. Journal of Power Sources, 531, 231324.

_1737007724117.webp)

_1736996330512.webp)