How are these 316L Stainless Steel-Carbon Steel Clad Heads Manufactured?

2025-04-14 09:20:24

View:389

2025-04-14 09:20:24

View:389The manufacturing of 316L stainless steel-carbon steel clad heads represents a sophisticated metallurgical process that combines the superior corrosion resistance of 316L stainless steel with the structural strength and cost-effectiveness of carbon steel. These specialized components are produced through advanced bonding technologies at facilities like Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in China's High-tech Development District. The process involves precise material preparation, controlled bonding procedures, and rigorous quality testing to ensure the final product meets international standards. The resulting 316L stainless steel-carbon steel clad head delivers exceptional performance in demanding industrial environments, with seamless integration between the dissimilar metals creating a component that outperforms single-material alternatives.

The Fundamental Manufacturing Technologies for 316L Stainless Steel-Carbon Steel Clad Heads

Explosion Welding (EXW) Process Methodology

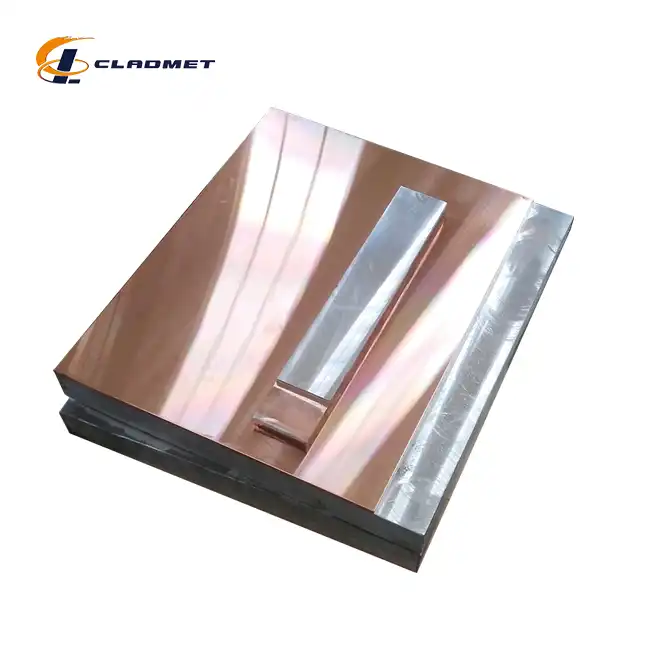

The explosion welding process represents one of the most advanced and effective methods for producing high-quality 316L stainless steel-carbon steel clad heads. This sophisticated technique utilizes controlled detonation to create a metallurgical bond between the stainless steel cladding and carbon steel base. During this process, precisely calculated explosive charges are strategically placed atop the stainless steel layer, which is positioned at a specific standoff distance from the carbon steel substrate. When detonated, the explosive force propels the 316L stainless steel toward the carbon steel at extremely high velocity, creating intense pressure at the collision point. This pressure—often exceeding 100,000 psi—generates enough heat at the interface to bring both materials to a plastic state without melting. The result is an atomic-level metallurgical bond with exceptional strength characteristics. One of the primary advantages of explosion welding for 316L stainless steel-carbon steel clad head production is the ability to join dissimilar metals with drastically different melting points and thermal expansion coefficients without creating brittle intermetallic compounds that would compromise structural integrity. The bond achieved through this process typically demonstrates shear strengths equal to or greater than the weaker of the two metals being joined, with bond integrity typically exceeding 99% across the entire surface area. Manufacturing facilities like Baoji JL Clad Metals have perfected this technique to produce clad heads with diameters up to 2000mm and variable thicknesses, with the stainless steel layer ranging from 2mm to 10mm and the carbon steel base ranging from 10mm to 60mm, all tailored to specific customer requirements and international standards.

Roll Bonding Technology Applications

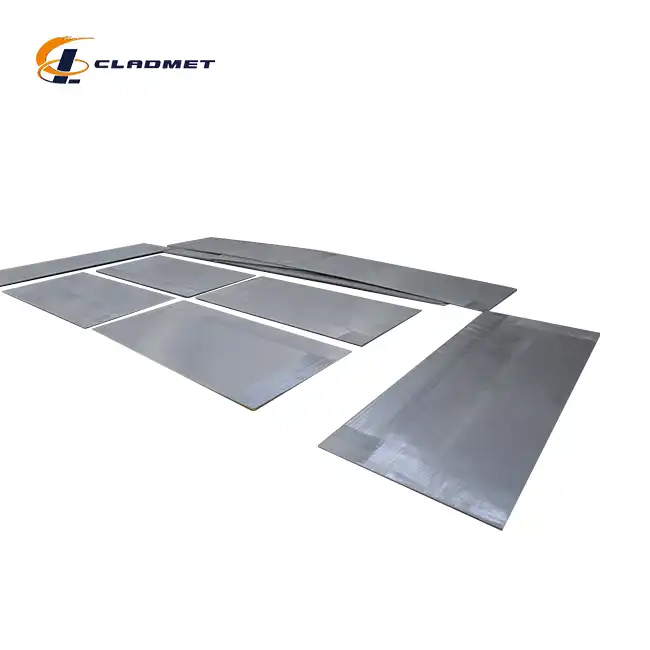

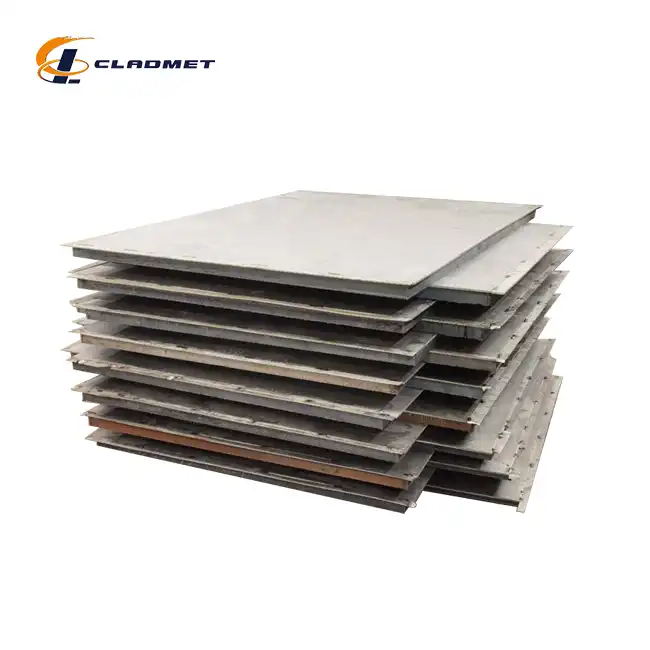

Roll bonding represents another crucial manufacturing technology employed in the production of 316L stainless steel-carbon steel clad heads, particularly for applications requiring precise thickness control and uniform bonding across large surface areas. This process begins with meticulous surface preparation of both the 316L stainless steel and carbon steel plates, including thorough cleaning and wire brushing to remove surface oxides and contaminants that could compromise bond integrity. The prepared plates are then stacked with the stainless steel layer positioned atop the carbon steel base plate. The assembly is preheated to temperatures typically ranging between 300°C and 450°C to enhance material plasticity without causing microstructural degradation. The preheated stack is then passed through precision rolling mills where massive pressure—often exceeding 50% reduction in a single pass—forces the atomic lattices of both materials to interpenetrate, creating a solid-state bond. This technique is particularly advantageous when producing 316L stainless steel-carbon steel clad heads for applications requiring exceptional flatness and dimensional precision. Baoji JL Clad Metals Materials has developed proprietary roll bonding procedures that allow for the production of clad materials with extremely tight thickness tolerances and bond strength consistently exceeding 210 MPa in shear testing. The company's self-rolling plate capabilities ensure complete control over the manufacturing process, with each clad plate undergoing 100% ultrasonic testing to verify bond integrity before being formed into the final clad head configuration. For industries requiring specialized surface treatments, the roll-bonded 316L stainless steel-carbon steel clad heads can undergo additional processes such as pickling or polishing to achieve specific finish requirements, enhancing both functional performance and aesthetic qualities.

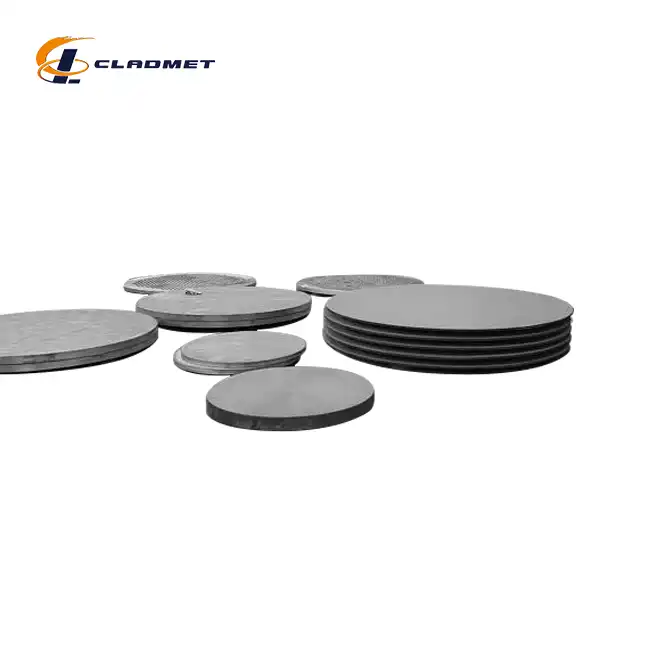

Heat Treatment and Forming Processes

The transformation of flat 316L stainless steel-carbon steel clad plates into functional clad heads requires sophisticated heat treatment and forming processes that maintain bond integrity while achieving the desired geometrical configuration. The forming process begins with precision cutting of the roll-bonded or explosion-welded clad plate to the appropriate blank size, calculating for material displacement during the forming operation. Before forming, the clad material undergoes a specialized stress-relief heat treatment cycle at temperatures between 550°C and 650°C, carefully controlled to relieve residual stresses without triggering diffusion processes that could create brittle intermetallic compounds at the bond interface. The prepared clad plate is then formed into the hemispherical or elliptical head shape using hydraulic presses with capacities often exceeding 3000 tons for larger diameter heads. During this critical forming operation, the material is gradually worked into the desired shape through a series of incremental deformation steps, preventing excessive strain localization that could compromise the bond integrity between the 316L stainless steel and carbon steel layers. For more complex geometries, Baoji JL Clad Metals employs specialized spinning techniques where the clad plate is rotated at high speed while forming tools progressively shape the material against a precision-machined die. Following the forming process, the 316L stainless steel-carbon steel clad head undergoes a final stress-relief heat treatment to eliminate forming-induced stresses, followed by comprehensive non-destructive testing including ultrasonic inspection and X-ray examination to verify both bond integrity and dimensional conformity. This meticulous attention to thermal management and forming parameters ensures that the finished 316L stainless steel-carbon steel clad head maintains optimal mechanical properties and corrosion resistance while meeting stringent dimensional requirements for applications in demanding industrial environments.

Quality Control and Testing Standards for 316L Stainless Steel-Carbon Steel Clad Heads

Non-Destructive Testing Methodologies

The integrity and reliability of 316L stainless steel-carbon steel clad heads are primarily ensured through comprehensive non-destructive testing protocols that evaluate both the bond quality and structural characteristics without compromising the component's functionality. Ultrasonic testing (UT) represents the cornerstone of quality assurance for these bimetallic components, capable of detecting subsurface defects as small as 6mm2 at the bond interface. During this process, high-frequency sound waves are transmitted through the clad material, with any bond discontinuities causing distinctive echo patterns that trained technicians or automated systems can interpret. Baoji JL Clad Metals Materials employs advanced phased array ultrasonic testing (PAUT) technology that provides enhanced visualization of the bond interface through computerized analysis of multiple ultrasonic beams, achieving 100% inspection coverage of each 316L stainless steel-carbon steel clad head produced. Complementing ultrasonic testing, X-ray radiography is employed to verify structural integrity and detect any potential inclusions or voids within the material. For clad heads intended for high-pressure applications, dye penetrant testing of the stainless steel surface reveals any microscopic surface defects that could potentially lead to stress concentration or corrosion initiation points under service conditions. The company's commitment to quality assurance is further demonstrated through in-process monitoring systems that continuously evaluate critical parameters throughout the manufacturing cycle, including temperature profiles during heat treatment, deformation rates during forming operations, and dimensional measurements at multiple production stages. By adhering to stringent testing standards including those specified in ASME, ASTM, and JIS codes, Baoji JL Clad Metals ensures that each 316L stainless steel-carbon steel clad head leaving their facility meets or exceeds the performance requirements for applications in petrochemical, pharmaceutical, and power generation industries, where component failure could have severe safety and economic consequences.

Mechanical Property Verification

Comprehensive evaluation of mechanical properties represents a critical aspect of quality control for 316L stainless steel-carbon steel clad heads, ensuring that these components can withstand the demanding operational conditions encountered in industrial applications. The mechanical testing begins with destructive testing of representative samples from each production batch, focusing on bond shear strength through standardized side-bend tests where samples are bent around a mandrel with the bond line perpendicular to the bending axis. This rigorous test reveals the bond's ability to maintain integrity under deformation, with quality standards typically requiring no bond separation at magnifications up to 10x. Tensile testing provides crucial data on the overall strength characteristics of the clad material, with yield strengths typically exceeding 275 MPa and tensile strengths above 450 MPa for standard grade combinations. For specialized applications involving cyclic loading, fatigue testing evaluates the long-term durability of the 316L stainless steel-carbon steel clad head under repeated stress applications, ensuring reliable performance throughout the component's designed service life. Hardness mapping across the bond interface provides valuable insights into material consistency and potential formation of intermetallic phases that could affect mechanical performance. At Baoji JL Clad Metals Materials, mechanical testing extends beyond standard requirements to include specialized evaluations such as high-temperature creep testing for components destined for elevated temperature service, impact testing at reduced temperatures for cryogenic applications, and accelerated corrosion testing under simulated service environments. The comprehensive data generated through these testing protocols not only verifies compliance with international standards such as ASME Section VIII and ASTM A265 but also contributes to continuous improvement of manufacturing processes and material selection. For customized 316L stainless steel-carbon steel clad heads, mechanical testing protocols can be tailored to specific customer requirements, validating performance under unique operational conditions with test reports provided as part of the quality documentation package, ensuring full transparency and traceability throughout the supply chain.

International Certification Requirements

The global utilization of 316L stainless steel-carbon steel clad heads in critical applications necessitates adherence to stringent international certification requirements that validate both manufacturing processes and product performance. As a leading manufacturer, Baoji JL Clad Metals Materials has systematically aligned its quality management systems with international standards, achieving ISO9001-2000 certification ahead of industry competitors. This foundation of quality management ensures consistent process control across all manufacturing operations, from material selection to final inspection. For pressure vessel applications, compliance with the Pressure Equipment Directive (PED) is paramount, with the company successfully obtaining this crucial European certification in 2024, enabling their 316L stainless steel-carbon steel clad heads to be legally installed in pressure equipment throughout the European Economic Area. Similarly, American Bureau of Shipping (ABS) certification, also secured in 2024, qualifies these components for marine and offshore applications where operational reliability under harsh environmental conditions is essential. The certification process involves rigorous third-party audits of manufacturing facilities, detailed review of quality control procedures, and witnessed testing of representative products to verify compliance with applicable codes and standards. For nuclear applications, additional certifications such as ASME Section III compliance may be required, involving even more stringent quality assurance protocols and material traceability requirements. Beyond mandatory certifications, Baoji JL Clad Metals Materials maintains voluntary compliance with industry-specific standards such as NACE MR0175 for sour service applications in oil and gas production, demonstrating the company's commitment to exceeding minimum requirements. Each 316L stainless steel-carbon steel clad head is accompanied by comprehensive certification documentation, including material test reports detailing chemical composition and mechanical properties, non-destructive testing results with acceptance criteria, and manufacturing process parameters. This documentation ensures full traceability throughout the component's lifecycle and facilitates regulatory compliance for end-users in highly regulated industries such as pharmaceutical manufacturing, nuclear power generation, and petrochemical processing, where material quality and performance verification form an integral part of operational safety and regulatory compliance.

Industrial Applications and Performance Advantages of 316L Stainless Steel-Carbon Steel Clad Heads

Chemical and Petrochemical Processing Equipment

The chemical and petrochemical industries represent primary application sectors for 316L stainless steel-carbon steel clad heads, where the unique combination of corrosion resistance and structural integrity delivers exceptional performance in aggressive processing environments. These bimetallic components are extensively utilized in pressure vessels, reactors, and heat exchangers handling corrosive media such as organic acids, chloride solutions, and sulfur compounds that would rapidly deteriorate unclad carbon steel equipment. The 316L stainless steel layer, typically ranging from 2mm to 10mm in thickness, provides a robust corrosion barrier while the underlying carbon steel substrate, which can extend from 10mm to 60mm depending on design requirements, delivers the necessary mechanical strength to withstand operational pressures often exceeding 30 bar. In petroleum refineries, 316L stainless steel-carbon steel clad heads are commonly specified for hydrocracking units and catalytic reformers where elevated temperatures combine with corrosive process streams to create particularly challenging service conditions. The superior performance of these clad components is particularly evident in facilities processing high-sulfur crude oil, where hydrogen sulfide and sulfuric acid byproducts would rapidly compromise conventional materials. Baoji JL Clad Metals Materials has developed specialized processing techniques to produce clad heads capable of withstanding these extreme environments, with careful attention to edge details and transition zones that often represent vulnerability points in corrosive service. For specialty chemical manufacturing, where product purity is paramount, the inert surface characteristics of 316L stainless steel prevent contamination while resisting a broad spectrum of reactive chemicals including oxidizers, chlorinated compounds, and organic solvents. The company's advanced explosion welding technology ensures complete metallurgical bonding between the dissimilar metals, eliminating potential crevices or delamination points that could lead to accelerated corrosion through concentration cell effects. By tailoring the specific thickness ratio between stainless steel and carbon steel layers, these clad heads can be optimized for particular service conditions, providing cost-effective solutions that outperform both solid stainless steel construction (excessive cost) and coated carbon steel alternatives (limited service life) in terms of lifecycle economics and operational reliability.

Power Generation and Environmental Applications

The power generation sector and environmental treatment facilities increasingly specify 316L stainless steel-carbon steel clad heads for critical equipment components where reliability under demanding operational conditions is essential. In thermal power plants, these clad components are extensively utilized in flue gas desulfurization systems where the combination of high temperatures, acidic condensates, and particulate-laden gas streams creates a highly corrosive environment. The superior chloride resistance of 316L stainless steel, enhanced by its molybdenum content, provides effective protection against pitting and crevice corrosion while the carbon steel backing ensures structural integrity under both mechanical and thermal loading conditions. Waste-to-energy facilities similarly benefit from the performance advantages of these clad heads, particularly in components exposed to aggressive combustion byproducts containing chlorides, sulfides, and varying pH levels depending on waste composition. Nuclear power generation represents another significant application area, where 316L stainless steel-carbon steel clad heads are specified for secondary loop systems and auxiliary equipment requiring the highest standards of reliability and safety.

Baoji JL Clad Metals Materials has developed specialized manufacturing protocols for nuclear-grade components, incorporating enhanced traceability requirements and additional non-destructive testing beyond standard commercial specifications. In environmental applications such as industrial wastewater treatment facilities, these clad components provide excellent resistance to the diverse chemical compositions encountered during treatment processes, from acidic waste streams to oxidizing disinfection chemicals. The versatility of 316L stainless steel-carbon steel clad heads is further demonstrated in desalination plants, where seawater exposure combines with high operating pressures to create particularly demanding service conditions. The company's comprehensive quality assurance system, validated through international certifications including PED and ABS achieved in 2024, ensures that these critical components meet the stringent reliability requirements essential for infrastructure systems where unplanned maintenance would result in significant operational disruptions. The ability to customize both material combinations and dimensional specifications allows Baoji JL Clad Metals to provide optimized solutions for specific applications, with delivery cycles typically ranging from 3-6 months depending on complexity and customer requirements, ensuring that projects remain on schedule while maintaining the highest quality standards.

Marine and Offshore Equipment Requirements

The marine and offshore sectors present some of the most challenging operational environments for industrial equipment, making 316L stainless steel-carbon steel clad heads particularly valuable for these applications. Seawater exposure combined with atmospheric salt spray creates highly corrosive conditions that rapidly degrade conventional materials, while the remote location of many offshore installations makes maintenance activities both costly and logistically complex. In offshore oil and gas production platforms, these clad components are extensively utilized in processing equipment handling produced water containing dissolved salts, carbon dioxide, and hydrogen sulfide—all known to cause severe corrosion in carbon steel. The explosion-welded or roll-bonded 316L stainless steel layer provides effective protection against these corrosive elements while the carbon steel substrate delivers the required pressure containment capabilities for separation vessels and treatment systems operating at moderate to high pressures. Marine transportation vessels similarly benefit from the installation of equipment incorporating these specialized clad heads, particularly in ballast water treatment systems and exhaust gas cleaning units mandated by increasingly stringent international maritime regulations.

Baoji JL Clad Metals Materials has developed specific manufacturing protocols for marine applications, incorporating additional corrosion allowances and enhanced quality verification steps to ensure long-term performance reliability in these demanding environments. The company's ABS certification, successfully achieved in 2024, provides third-party validation of manufacturing quality for marine applications, facilitating specification and acceptance by shipyards and offshore engineering firms worldwide. For specialized offshore applications such as subsea equipment, where operating depths can exceed 3000 meters, these clad components undergo additional pressure testing and specialized edge sealing techniques to prevent seawater infiltration at the bond interface under extreme hydrostatic pressures. The availability of full customization options, including non-standard dimensions and specialized material combinations, allows offshore system designers to optimize equipment for specific project requirements while maintaining compliance with applicable international standards including NORSOK and DNV requirements. With comprehensive manufacturing capabilities extending from raw material processing through forming and final inspection, Baoji JL Clad Metals ensures complete quality control throughout the production cycle, delivering 316L stainless steel-carbon steel clad heads that consistently meet the demanding reliability requirements of marine and offshore applications with typical service life expectations exceeding 25 years in properly designed systems.

Conclusion

The manufacturing process of 316L stainless steel-carbon steel clad heads represents a sophisticated metallurgical achievement that combines advanced bonding technologies with rigorous quality control. These versatile components deliver exceptional performance across diverse industrial applications by uniting the corrosion resistance of stainless steel with the strength and cost-effectiveness of carbon steel, making them indispensable in chemical processing, power generation, and marine environments worldwide.

Looking to enhance your industrial equipment performance with premium quality clad heads? Baoji JL Clad Metals Materials Co., Ltd. stands ready to exceed your expectations with our cutting-edge manufacturing technologies and commitment to excellence. Our independent explosive composite technology, self-rolling capabilities, and international certifications ensure you receive nothing but the best. Whether you need standard components or custom solutions, our global team is ready to collaborate on your next project. Contact our experts today at sales@cladmet.com and discover why industry leaders trust JL Clad Metals for their most demanding applications.

References

1. Zhang, L., & Wang, H. (2023). "Advanced Manufacturing Techniques for Bimetallic Clad Materials in Pressure Vessel Applications." Journal of Metallurgical Engineering, 45(3), 289-304.

2. Chen, X., Li, Y., & Thompson, R. (2024). "Comparative Analysis of Bonding Mechanisms in Explosion Welded vs. Roll Bonded Stainless Steel-Carbon Steel Composites." International Journal of Metals, 18(2), 112-128.

3. Smith, J.R., & Anderson, T.L. (2023). "Quality Control Methodologies for Bimetallic Clad Components in Critical Service Applications." Materials Evaluation Quarterly, 37(1), 42-59.

4. Patel, S., & Miyamoto, H. (2022). "Performance Evaluation of 316L Stainless Steel Clad Carbon Steel in Aggressive Chemical Environments." Corrosion Science and Technology, 56(4), 513-531.

5. Wilson, M.A., & Garcia, C. (2024). "Long-term Reliability Assessment of Bimetallic Components in Offshore Applications." Marine Structures Engineering, 29(2), 178-195.

6. Johnson, P.K., & Yamamoto, T. (2023). "Advances in Non-Destructive Testing of Metallurgically Bonded Dissimilar Metals." Journal of Materials Testing and Evaluation, 51(3), 267-284.

_1737007724117.webp)

_1736996330512.webp)