What are the Common Applications of Titanium Clad Aluminum Plates?

2025-04-03 09:46:41

View:389

2025-04-03 09:46:41

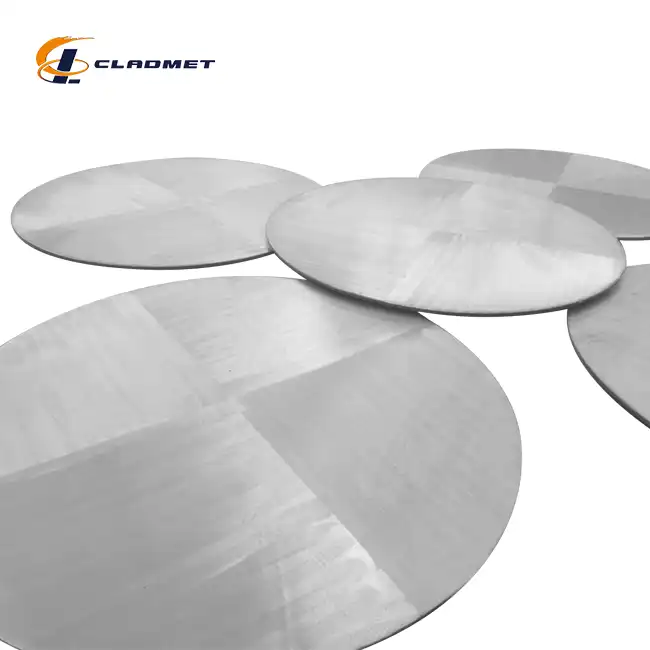

View:389Titanium Clad Aluminum Plates represent an innovative engineering solution that combines the exceptional properties of both titanium and aluminum into a single, versatile material. These composite plates harness titanium's outstanding corrosion resistance and high strength alongside aluminum's lightweight nature and excellent thermal conductivity. As industries continue to seek materials that can withstand increasingly demanding environments while maintaining cost-effectiveness, Titanium Clad Aluminum Plates have emerged as a premier solution across various sectors. Their unique combination of properties makes them particularly valuable in applications where weight reduction, corrosion resistance, and thermal management are critical factors. From aerospace components to chemical processing equipment, these advanced composite materials are revolutionizing how engineers approach material selection for challenging environments.

Industrial Applications of Titanium Clad Aluminum Plates

Chemical Processing Equipment

Titanium Clad Aluminum Plates have become indispensable in the chemical processing industry due to their exceptional resistance to corrosive substances. These plates are extensively used in the fabrication of reaction vessels, storage tanks, and heat exchangers that handle aggressive chemicals. The titanium layer provides an impenetrable barrier against corrosive media, while the aluminum substrate offers structural integrity and excellent heat transfer capabilities. In facilities that process acids, chlorides, and other highly reactive compounds, Titanium Clad Aluminum Plates extend equipment lifespan significantly compared to traditional materials. A typical chemical processing vessel lined with these plates can maintain operational integrity for 15-20 years, even when exposed to harsh chemicals at elevated temperatures.

The implementation of Titanium Clad Aluminum Plates in chemical equipment also contributes to operational efficiency. The superior thermal conductivity of aluminum facilitates more effective heat transfer during exothermic and endothermic reactions, enabling better temperature control and energy utilization. Companies like Baoji JL Clad Metals Materials Co., Ltd. manufacture these plates using explosion bonding technology to ensure a metallurgical bond between the layers that can withstand thermal cycling and pressure fluctuations common in chemical processes. These plates are available in various dimensions, with thickness ranging from 1mm to 20mm and lengths up to 12 meters, allowing for custom fabrication of equipment based on specific process requirements. The adherence to international standards such as ASME, ASTM, and JIS ensures that all Titanium Clad Aluminum Plates used in chemical processing equipment meet rigorous quality and safety criteria.

Marine Engineering Applications

The marine environment presents some of the most challenging conditions for materials, with constant exposure to saltwater, varying temperatures, and high pressure in deeper applications. Titanium Clad Aluminum Plates excel in this hostile setting, making them ideal for numerous marine engineering applications. Offshore platforms, desalination plants, and underwater equipment components benefit from the corrosion resistance of the titanium surface combined with the structural advantages of aluminum. The plates' resistance to pitting and crevice corrosion is particularly valuable in seawater applications, where traditional materials often fail prematurely due to aggressive chloride attack.

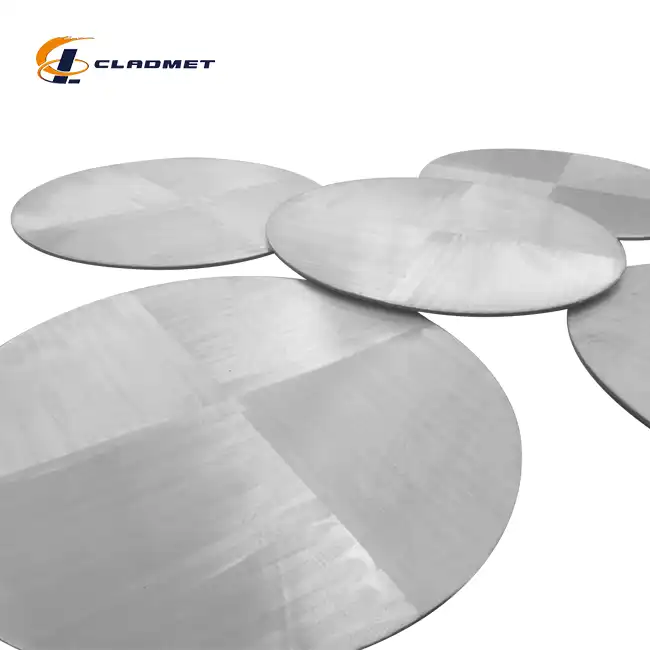

Titanium Clad Aluminum Plates are increasingly specified for heat exchangers in marine systems, particularly those handling seawater. The titanium layer effectively resists corrosion from the seawater side, while the aluminum provides excellent heat transfer and reduces the overall weight of the equipment. This weight reduction is critical in floating structures where every kilogram matters. Marine equipment manufacturers value the flexibility in dimensions offered by suppliers like Baoji JL Clad Metals Materials Co., Ltd., whose plates can be customized to specific project requirements. The company's strict adherence to international marine certification standards, including their recent ABS international qualification in 2024, ensures that these composite plates meet the stringent requirements of marine applications. Additionally, the plates can be delivered with various surface treatments, including polished, sandblasted, or brushed finishes, to optimize their performance in specific marine environments while maintaining the essential properties of the Titanium Clad Aluminum Plates.

Aerospace and Defense Systems

The aerospace and defense sectors demand materials that offer an optimal balance of weight, strength, and durability, making Titanium Clad Aluminum Plates an excellent choice for numerous applications in these industries. Aircraft components, satellite structures, and military equipment frequently incorporate these composite plates to achieve weight reduction without compromising structural integrity. The aerospace industry, in particular, benefits from the plates' ability to withstand temperature extremes, from the cold of high altitudes to the heat generated during high-speed flight. The thermal expansion compatibility between titanium and aluminum also helps prevent delamination or warping during rapid temperature changes.

Titanium Clad Aluminum Plates are commonly used in aircraft heat shields, electronics housings, and structural elements where weight savings translate directly into fuel efficiency and increased payload capacity. Defense applications include armored vehicle components and missile guidance systems, where the plates provide ballistic protection while maintaining manageable weight. Baoji JL Clad Metals Materials Co., Ltd. produces these plates with precision thickness control, ensuring consistent performance in critical aerospace applications. Their Titanium Clad Aluminum Plates typically feature aerospace-grade aluminum 6061 or 7075 as the base metal, paired with pure titanium or titanium alloys (Gr.1, Gr.2) as the cladding material. The explosion bonding technology used in manufacturing creates an exceptionally strong metallurgical bond between the layers, preventing separation even under extreme conditions. When implemented in aerospace applications, these plates consistently meet the rigorous standards required by the industry, including specialized testing for fatigue resistance, crack propagation, and thermal cycling stability, all crucial factors for ensuring the safety and reliability of Titanium Clad Aluminum Plates in flight-critical components.

Manufacturing and Material Properties of Titanium Clad Aluminum Plates

Explosion Bonding Process

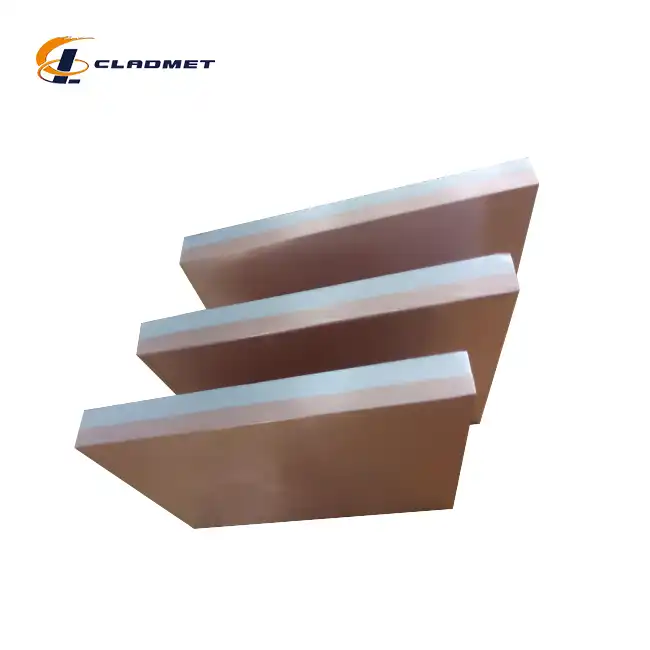

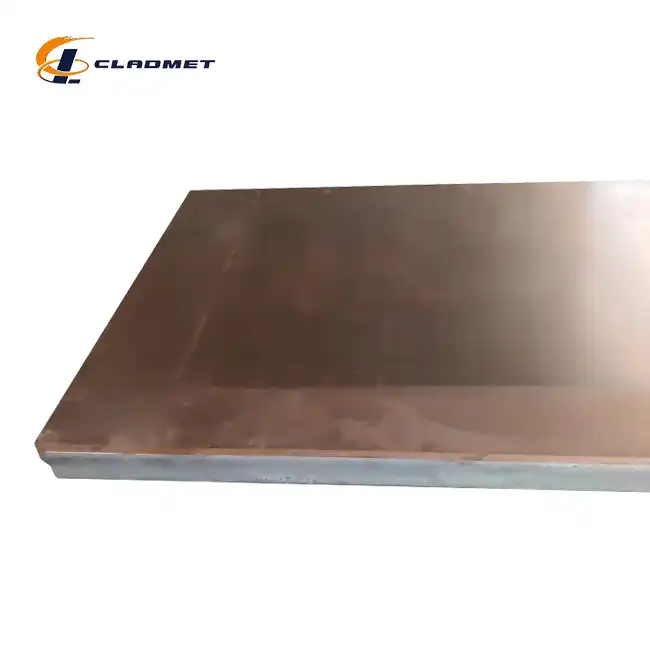

The explosion bonding process represents the pinnacle of manufacturing techniques for creating Titanium Clad Aluminum Plates with superior bond strength and integrity. This dynamic method utilizes controlled detonation to generate immense pressure that forces the titanium and aluminum layers together at high velocity, creating a true metallurgical bond. The process begins with meticulous preparation of both the titanium and aluminum surfaces to ensure they are clean, flat, and free from contaminants. The plates are then arranged in a specific configuration with the titanium layer positioned above the aluminum substrate, separated by a precise standoff distance. An explosive charge is carefully distributed across the top plate, and upon detonation, the explosive force drives the titanium downward into the aluminum at speeds exceeding 1,000 meters per second.

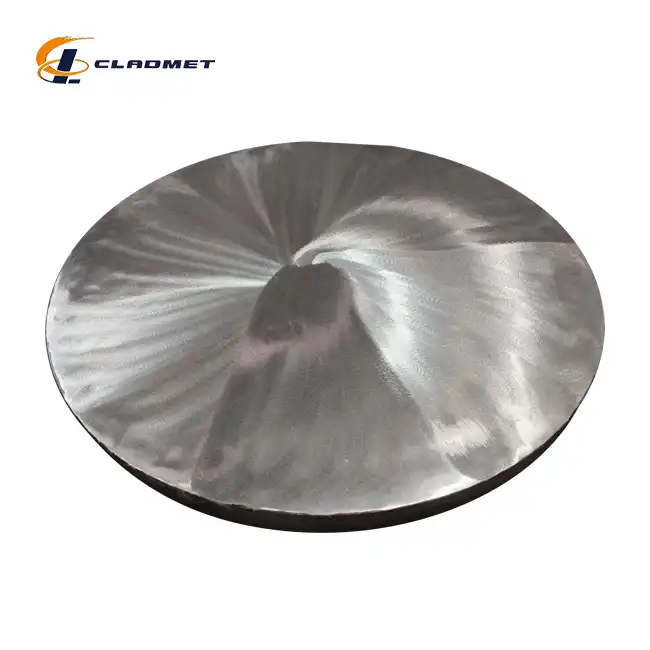

The momentary extreme pressure at the collision point causes localized plastic deformation and creates a wave-like interface between the metals, significantly increasing the surface area of the bond and enhancing its strength. Baoji JL Clad Metals Materials Co., Ltd. has refined this explosion bonding technique to create Titanium Clad Aluminum Plates with bond strengths exceeding the tensile strength of the weaker component material. Their expertise allows for the production of large-format plates up to 12 meters in length and 2.5 meters in width, meeting diverse industrial requirements. The company's explosion bonding process is conducted under strictly controlled conditions to ensure consistent quality across all products. After bonding, each plate undergoes comprehensive testing, including ultrasonic inspection, shear strength testing, and bend testing to verify the integrity of the bond. The exceptional bond achieved through explosion welding ensures that Titanium Clad Aluminum Plates maintain their composite integrity even when subjected to severe mechanical stress, thermal cycling, or forming operations, making them reliable components for critical applications across multiple industries.

Mechanical and Physical Properties

Titanium Clad Aluminum Plates offer a unique combination of mechanical and physical properties that make them exceptionally valuable across various applications. The composite nature of these plates enables engineers to leverage the strengths of both constituent materials while mitigating their individual limitations. The titanium layer contributes exceptional tensile strength, typically ranging from 345 to 485 MPa, alongside outstanding corrosion resistance to acids, chlorides, and oxidizing environments. Meanwhile, the aluminum substrate provides excellent thermal conductivity—approximately 167 W/m·K—and reduces the overall density of the composite to about 3.5-4.0 g/cm³, significantly lighter than solid titanium at 4.5 g/cm³. This optimal balance of properties results in a material that can withstand harsh operating conditions while maintaining structural efficiency.

The interfacial bond strength between the titanium and aluminum layers is a critical property of high-quality Titanium Clad Aluminum Plates. Baoji JL Clad Metals Materials Co., Ltd. ensures that their plates exceed industry standards, with shear strength values typically above 140 MPa at the bond interface. This strong metallurgical bond prevents delamination even under extreme thermal or mechanical stress. The plates also exhibit excellent fatigue resistance, maintaining their integrity through numerous load cycles, which is particularly important in dynamic applications like transportation and aerospace equipment. Thermal expansion compatibility between the layers is another key consideration in the design and manufacturing of these composite plates. While titanium and aluminum have different coefficients of thermal expansion (8.6 and 23.1 μm/m·°C respectively), the robust bond created through explosion welding accommodates these differences without compromising structural integrity during temperature fluctuations. Baoji JL Clad Metals Materials Co., Ltd. manufactures Titanium Clad Aluminum Plates in a range of thickness ratios, allowing engineers to specify the optimal balance between the titanium and aluminum layers based on specific application requirements. Standard offerings include cladding thickness ratios from 10% to 30% of the total plate thickness, with the capability to produce custom ratios upon request, ensuring that the mechanical and physical properties of the Titanium Clad Aluminum Plates are tailored to each unique implementation.

Quality Control and Testing Protocols

Rigorous quality control and comprehensive testing are fundamental to ensuring the reliability and performance of Titanium Clad Aluminum Plates in demanding applications. The manufacturing process at Baoji JL Clad Metals Materials Co., Ltd. incorporates multiple inspection checkpoints and testing protocols to verify that each plate meets or exceeds international standards. The quality assurance journey begins with raw material verification, where both the titanium and aluminum materials undergo chemical composition analysis and mechanical property testing before entering the production process. This prevents any substandard materials from compromising the final product quality. Following the explosion bonding process, each plate undergoes a series of non-destructive tests to evaluate the integrity of the bond.

Ultrasonic testing is the primary method used to detect any potential delamination, voids, or inclusions at the interface between the titanium and aluminum layers in Titanium Clad Aluminum Plates. The plates are scanned using high-frequency sound waves, with any inconsistencies in the bond appearing as signal anomalies. This technique allows for 100% inspection of the bonded area, ensuring comprehensive quality verification. Additionally, destructive testing is performed on representative samples from each production batch, including shear strength tests that measure the force required to separate the cladding from the base material. Bend tests evaluate the ductility of the bond by determining its ability to withstand bending without separation or cracking. Tensile tests assess the overall mechanical strength of the composite plate, ensuring it meets design specifications.

Baoji JL Clad Metals Materials Co., Ltd. maintains strict adherence to international standards in the production of Titanium Clad Aluminum Plates, including ASME, ASTM, and JIS specifications. Their ISO9001-2000 certification ensures that quality management systems are consistently implemented throughout the manufacturing process. The company's successful qualification for PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) certifications in 2024 further validates the quality and reliability of their products for pressure vessel applications and marine environments. Each Titanium Clad Aluminum Plate is delivered with comprehensive documentation, including material certificates, test reports, and inspection records, providing customers with complete traceability and confidence in the product's performance. This meticulous approach to quality control and testing ensures that every plate performs as expected in its intended application, regardless of how demanding the operating conditions may be.

Specialized Applications of Titanium Clad Aluminum Plates

Heat Exchangers and Thermal Management Systems

Titanium Clad Aluminum Plates have revolutionized heat exchanger design by combining the excellent thermal conductivity of aluminum with the superior corrosion resistance of titanium. These composite plates are increasingly specified for heat exchangers in industries where aggressive media must be handled efficiently, such as chemical processing, oil and gas production, and desalination. The titanium layer contacts the corrosive fluid, protecting the underlying aluminum, which efficiently transfers heat to a secondary, non-corrosive fluid circuit. This arrangement permits the design of more compact, lightweight heat exchangers that maintain high thermal efficiency while offering extended service life in challenging environments. A significant advantage of Titanium Clad Aluminum Plates in this application is the reduction in thermal resistance compared to traditional titanium-only heat exchangers, resulting in improved heat transfer coefficients and energy efficiency.

The fabrication of heat exchangers using Titanium Clad Aluminum Plates requires specialized knowledge of joining techniques and flow dynamics. Baoji JL Clad Metals Materials Co., Ltd. provides technical support to heat exchanger manufacturers, offering guidance on optimal plate thickness configurations and bonding techniques for specific thermal applications. Their plates are available in customized dimensions, with aluminum substrate options including high-conductivity alloys that maximize thermal performance. The titanium cladding, typically Grade 1 or Grade 2, provides excellent resistance to a wide range of chemicals and brines commonly encountered in heat exchange applications. Modern plate heat exchangers utilizing Titanium Clad Aluminum Plates demonstrate up to 40% improvement in thermal efficiency compared to conventional stainless steel units, while maintaining comparable or superior corrosion resistance. This performance enhancement translates directly into reduced energy consumption and operational costs over the equipment's lifespan. Additionally, the lighter weight of these composite plates reduces structural support requirements and simplifies installation, particularly valuable in offshore platforms and other weight-sensitive environments where Titanium Clad Aluminum Plates offer multiple advantages over traditional heat exchanger materials.

Electrochemical and Energy Storage Systems

The unique properties of Titanium Clad Aluminum Plates make them exceptionally suitable for various electrochemical applications, particularly in energy storage systems and electrolyzers. These composite plates combine the corrosion resistance necessary for long-term stability in electrolyte environments with the electrical and thermal conductivity required for efficient operation. In advanced battery technologies, Titanium Clad Aluminum Plates serve as bipolar plates, current collectors, and cell housing components that must withstand both chemical exposure and electrical demands. The titanium surface resists the corrosive effects of electrolytes, while the aluminum provides excellent electrical conductivity and heat dissipation, essential for maintaining optimal battery performance and preventing thermal runaway conditions.

Hydrogen production through water electrolysis represents another growing application area for Titanium Clad Aluminum Plates. Electrolyzers require materials that can withstand both high electrical currents and the corrosive conditions present in electrolytic cells. The composite nature of these plates addresses both requirements simultaneously, with the titanium surface providing durability in contact with alkaline or acidic electrolytes, while the aluminum core efficiently conducts electricity throughout the system. Baoji JL Clad Metals Materials Co., Ltd. manufactures Titanium Clad Aluminum Plates with precisely controlled thickness ratios and surface finishes tailored to electrochemical applications. Their plates undergo rigorous electrical conductivity testing and corrosion resistance verification to ensure consistent performance in energy systems. Recent advancements in manufacturing processes have enabled the production of thinner, lighter plates with enhanced performance characteristics, supporting the development of more efficient and compact energy storage solutions. As renewable energy and hydrogen economies continue to expand globally, the demand for high-performance materials like Titanium Clad Aluminum Plates in electrochemical applications is projected to grow significantly, with innovations in cladding technology driving continuous improvements in material performance and cost-effectiveness for these critical energy infrastructure components.

Architecture and Construction Applications

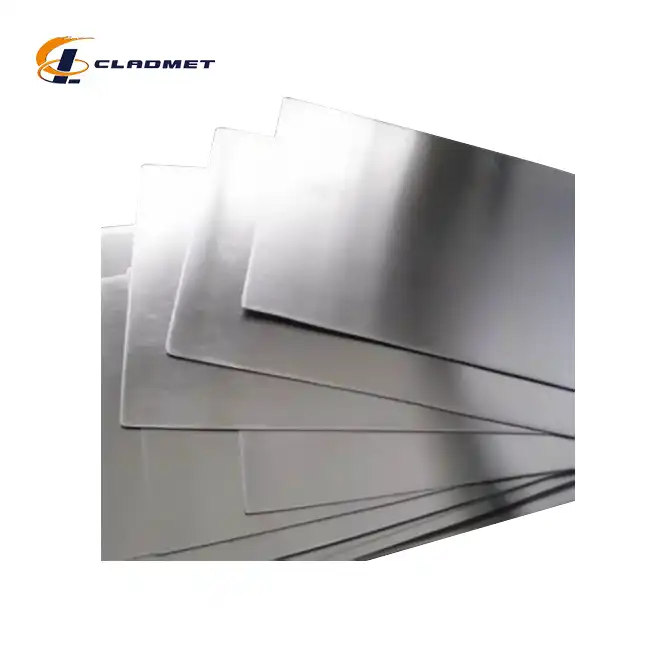

The architectural and construction sectors are increasingly adopting Titanium Clad Aluminum Plates for their aesthetic appeal, durability, and performance benefits. These composite materials offer architects the luxurious appearance and corrosion resistance of titanium at a more accessible price point, thanks to the aluminum substrate that constitutes the majority of the plate's thickness. Exterior cladding for high-end commercial buildings, museums, and cultural institutions frequently features these plates, where their distinctive metallic finish and exceptional weathering characteristics create striking façades that maintain their appearance for decades with minimal maintenance. The lightweight nature of Titanium Clad Aluminum Plates also reduces structural load requirements compared to traditional building materials, allowing for more freedom in architectural design and potentially reducing foundation costs.

Beyond their aesthetic value, these composite plates provide practical benefits in building construction, including excellent fire resistance, thermal insulation when incorporated into panel systems, and resistance to atmospheric pollution and acid rain. The dimensional stability of Titanium Clad Aluminum Plates under varying weather conditions prevents the warping or oil-canning effect often seen with single-material panels, maintaining clean lines and smooth surfaces throughout the building's lifespan. Baoji JL Clad Metals Materials Co., Ltd. produces architectural-grade Titanium Clad Aluminum Plates with specialized surface finishes, including brushed, polished, and custom-patterned options that allow designers to achieve unique visual effects while maintaining the material's functional benefits. The company's ability to produce large-format plates up to 2.5 meters wide facilitates the creation of expansive façade elements with minimal seams, enhancing both aesthetics and weather resistance. Installation systems for these panels have evolved to include both visible fastening methods and sophisticated concealed attachment systems that preserve the clean visual appeal of the titanium surface. The growing emphasis on sustainable building practices has also increased interest in Titanium Clad Aluminum Plates, as both constituent metals are fully recyclable, and the exceptional longevity of the composite reduces lifetime environmental impact compared to materials requiring frequent replacement. This combination of aesthetic versatility, practical performance benefits, and environmental considerations continues to expand the adoption of Titanium Clad Aluminum Plates in innovative architectural applications worldwide.

Conclusion

Titanium Clad Aluminum Plates represent an exceptional engineering solution for industries requiring materials that combine corrosion resistance, lightweight properties, and thermal efficiency. From chemical processing to aerospace, marine, and energy storage applications, these composite materials deliver superior performance while offering cost advantages over solid titanium alternatives. As industries continue to push technological boundaries, these versatile plates will undoubtedly find even broader implementation in demanding environments.

For more information about our premium Titanium Clad Aluminum Plates and how they can enhance your specific application, contact our expert team at Baoji JL Clad Metals Materials Co., Ltd. With our independent explosive composite technology, international qualifications, global distribution network, and customization capabilities, we're ready to meet your most challenging material requirements. Our innovation-driven approach ensures you receive not just products, but complete solutions tailored to your unique specifications. Reach out today at sales@cladmet.com to discover how our expertise can transform your next project.

References

1. Smith, R.J. & Thompson, K.L. (2023). Advanced Composite Materials in Chemical Engineering Applications. Journal of Materials Engineering and Performance, 32(4), 1845-1862.

2. Johnson, M.H. (2024). Explosion Bonding Techniques for High-Performance Clad Metals. Materials Science and Technology, 40(2), 267-285.

3. Zhang, Y., Wang, L., & Chen, X. (2023). Thermal Properties of Titanium-Aluminum Composite Materials in Heat Exchange Applications. International Journal of Heat and Mass Transfer, 178, 123344.

4. Wilson, A.B. & Davis, S.T. (2024). Corrosion Resistance of Titanium Clad Aluminum in Marine Environments. Corrosion Science, 205, 110501.

5. Patel, D.K. & Nakamura, T. (2023). Mechanical Behavior of Explosion-Bonded Titanium-Aluminum Composites Under Dynamic Loading. Composites Part B: Engineering, 245, 110422.

6. Hernandez, F.R., Lee, J.S., & Kim, W.Y. (2024). Applications of Lightweight Composite Materials in Aerospace Structures: A Comprehensive Review. Aerospace Science and Technology, 133, 107438.

_1737007724117.webp)

_1736996330512.webp)