What standards apply to Ti-6Al-4V sheets?

2025-03-18 10:58:55

View:389

2025-03-18 10:58:55

View:389Ti-6Al-4V titanium sheets are critical materials in various high-performance applications, requiring adherence to rigorous international and national standards to ensure quality, safety, and performance. These standards provide essential guidelines for manufacturing, testing, and certifying 6al 4v titanium sheet products across industries. Understanding these standards is crucial for engineers, procurement specialists, and manufacturers who rely on these materials for demanding applications in aerospace, medical, and industrial sectors. This article explores the comprehensive framework of standards governing Ti-6Al-4V titanium sheets and how Baoji JL Clad Metals Materials Co., Ltd. implements these standards to produce high-quality titanium materials.

Key International Standards for Ti-6Al-4V Titanium Sheets

ASTM B265: The Foundation of Titanium Sheet Requirements

ASTM B265 stands as the cornerstone standard for 6al 4v titanium sheet manufacturing and quality control. This comprehensive standard specifies the chemical composition, mechanical properties, and dimensional tolerances that Ti-6Al-4V sheets must meet to be considered commercially viable. The standard requires that 6al 4v titanium sheet must contain approximately 6% aluminum and 4% vanadium, with precise limitations on interstitial elements such as oxygen, nitrogen, and hydrogen, which can significantly impact the material's performance. ASTM B265 also establishes minimum tensile strength requirements of approximately 895 MPa and yield strength of 828 MPa for annealed grade 5 titanium sheets. These mechanical property requirements ensure that the material can withstand the extreme stresses encountered in aerospace and medical applications. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. rigorously follow these standards throughout their production process, from raw material selection to final inspection. With thickness ranges from 0.5 mm to 100 mm and widths from 100 mm to 2000 mm, JL's 6al 4v titanium sheet products meet and often exceed these standardized requirements, providing engineers with the assurance of consistent quality and performance. The company's commitment to ASTM compliance is evident in their comprehensive testing procedures, which include chemical analysis, tensile testing, and dimensional verification on every batch of titanium sheets produced.

AMS 4911: Aerospace Material Specifications for Ti-6Al-4V

The Aerospace Material Specification AMS 4911 represents the gold standard for 6al 4v titanium sheet materials destined for critical aerospace applications. This exacting standard builds upon ASTM B265 but introduces additional requirements specifically tailored to ensure reliability in aerospace environments. AMS 4911 mandates more stringent controls on chemistry, microstructure, and surface quality of titanium alloy sheets. The specification requires precise control of the alpha-beta phase distribution within the 6al 4v titanium sheet microstructure, which directly influences its mechanical behavior at elevated temperatures. Surface quality requirements under this standard are particularly demanding, with specifications for maximum allowable pit depths, scratches, and inclusions measured in microns. Baoji JL Clad Metals Materials Co., Ltd. has invested significantly in advanced processing equipment and quality control systems to meet these aerospace-grade requirements. Their hot and cold rolling processes for 6al 4v titanium sheet production are carefully controlled to achieve the desired microstructure while maintaining surface integrity. The company's material testing laboratory employs sophisticated metallographic analysis, ultrasonic inspection, and surface profilometry to verify compliance with AMS 4911 standards. With delivery cycles typically ranging from 4-6 weeks, JL ensures that aerospace manufacturers receive materials that consistently meet these rigorous specifications, contributing to the safety and reliability of aircraft components worldwide.

JIS H 4600: Japanese Industrial Standards for Titanium Materials

The Japanese Industrial Standard JIS H 4600 provides another important framework for 6al 4v titanium sheet quality control, particularly relevant for manufacturers serving Asian markets or global companies with Japanese supply chains. This standard defines the chemical composition, mechanical properties, and testing methods for titanium and titanium alloy sheets, plates, and strips. JIS H 4600 includes specific provisions for grade Ti-6Al-4V (classified as Grade 23 in this system), with detailed requirements for grain size control, surface finish, and flatness tolerance. One notable aspect of JIS H 4600 is its emphasis on hydrogen content control, recognizing the potential for hydrogen embrittlement in titanium materials under certain conditions. Baoji JL Clad Metals Materials Co., Ltd. has successfully implemented the JIS requirements into their manufacturing protocols, ensuring that their 6al 4v titanium sheet products can seamlessly integrate into Japanese-designed systems. The company's material certification process includes detailed documentation of compliance with JIS standards, providing full traceability of chemical analysis, mechanical testing, and processing history. With standard sizes available and customization options for specific requirements, JL can produce 6al 4v titanium sheet materials that satisfy the most demanding Japanese industrial specifications. Their multi-faceted approach to quality assurance, combining process control with comprehensive inspection, ensures that customers receive titanium sheets that meet or exceed JIS H 4600 requirements for critical applications in automotive, marine, and industrial sectors.

Manufacturing Standards and Quality Control Processes

ISO 9001:2000 Quality Management System Implementation

The ISO 9001:2000 quality management system certification represents a fundamental framework that governs all aspects of 6al 4v titanium sheet production at Baoji JL Clad Metals Materials Co., Ltd. As one of the first manufacturers in the region to achieve this certification, JL has established comprehensive quality control procedures that permeate every stage of their titanium sheet manufacturing process. The ISO 9001:2000 standard requires documented procedures for all quality-critical operations, regular management reviews, and continuous improvement initiatives. For 6al 4v titanium sheet production, this translates to rigorous control of incoming raw materials, precise documentation of processing parameters, and systematic verification of finished product characteristics. The company's quality management system includes detailed work instructions for operators handling titanium materials, calibration schedules for measurement equipment, and validation protocols for critical processes like hot rolling, cold rolling, and heat treatment. This systematic approach ensures that every 6al 4v titanium sheet leaving the facility meets the specified requirements for chemistry, dimensions, and mechanical properties. With thicknesses ranging from 0.5 mm to 100 mm and customizable lengths to suit various applications, JL maintains consistent quality across their entire product range through strict adherence to ISO 9001 principles. Their commitment to this quality standard provides customers with confidence that the 6al 4v titanium sheet materials they receive will perform reliably in demanding applications across aerospace, medical, automotive, and marine industries, reducing the risk of material-related failures in critical components.

PED (Pressure Equipment Directive) Compliance for Pressure Applications

The European Pressure Equipment Directive (PED) certification, which Baoji JL Clad Metals Materials Co., Ltd. successfully achieved in 2024, establishes critical requirements for 6al 4v titanium sheet materials intended for pressure-containing applications. This international qualification is particularly significant for titanium sheets used in chemical processing equipment, pharmaceutical reactors, and other pressure vessels where material integrity is paramount to safety. The PED standard imposes stringent requirements for material traceability, mechanical property verification, and defect detection in metallic materials. For 6al 4v titanium sheet production, PED compliance necessitates comprehensive documentation of the entire manufacturing process, from melt records to final inspection results.

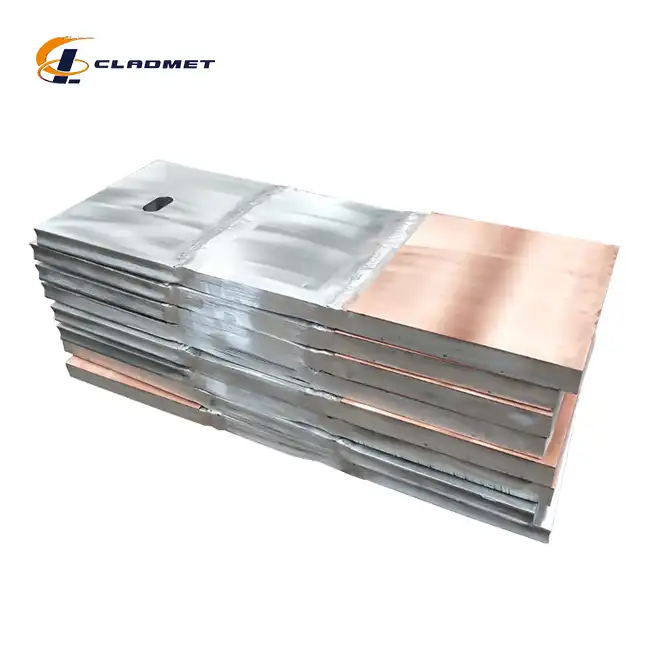

JL's implementation of PED requirements includes enhanced non-destructive testing protocols, such as 100% ultrasonic inspection of titanium sheets above certain thickness thresholds, to detect any internal discontinuities that could compromise pressure boundary integrity. The company's material certification process for PED-compliant 6al 4v titanium sheet includes detailed mechanical property testing at both room and elevated temperatures, providing engineers with the data needed for safe pressure vessel design. With standard sizes and customization options available, JL can produce titanium sheets tailored to specific pressure equipment applications while maintaining full compliance with European safety directives. Their material classification as titanium alloy and the specific alloy type Ti-6Al-4V (Grade 5) makes these sheets particularly valuable for corrosive service conditions where traditional pressure vessel materials would rapidly deteriorate, providing long-term reliability in chemical processing operations.

ABS (American Bureau of Shipping) Standards for Marine Applications

The American Bureau of Shipping (ABS) certification, another international qualification that Baoji JL Clad Metals Materials Co., Ltd. achieved in 2024, establishes rigorous standards for 6al 4v titanium sheet materials used in marine and offshore applications. This prestigious certification validates that JL's titanium products meet the demanding requirements for materials used in shipbuilding, offshore platforms, and subsea equipment where exposure to seawater presents significant corrosion challenges. The ABS standard includes specific provisions for titanium alloys, recognizing their exceptional resistance to marine environments and high strength-to-weight ratio. For 6al 4v titanium sheet production, ABS compliance requires careful control of alloying elements and impurities that could affect corrosion resistance, as well as comprehensive mechanical testing to verify performance under dynamic loading conditions typical in marine applications.

JL's manufacturing process for ABS-certified titanium sheets includes specialized heat treatment protocols to optimize the balance between strength and toughness, ensuring reliable performance in the harsh conditions encountered at sea. Their quality control program for marine-grade 6al 4v titanium sheet incorporates accelerated corrosion testing to validate material performance in simulated seawater environments. With product applications spanning marine propulsion components, desalination equipment, and offshore structural elements, JL's ABS-certified titanium sheets provide engineers with a high-performance material option that significantly outperforms conventional marine alloys in terms of corrosion resistance and service life. The company's ability to produce these materials in thicknesses from 0.5 mm to 100 mm and widths from 100 mm to 2000 mm offers designers flexibility when specifying materials for critical marine systems, contributing to improved reliability and reduced maintenance requirements in demanding maritime applications.

Application-Specific Standards and Industry Requirements

Aerospace Industry Standards: Beyond Basic Compliance

The aerospace industry imposes the most stringent standards on 6al 4v titanium sheet materials, requiring manufacturers to meet specifications that go well beyond basic metallurgical requirements. These enhanced standards address critical factors such as fatigue performance, fracture toughness, and microstructural stability that directly impact flight safety and component longevity. For aerospace applications, 6al 4v titanium sheet must comply with additional specifications like AMS 4911 and AMS 4907, which define precise requirements for heat treatment, grain structure, and surface quality. Baoji JL Clad Metals Materials Co., Ltd. has developed specialized processing routes for aerospace-grade titanium sheets, incorporating precise temperature control during hot and cold rolling operations to achieve the optimal balance of strength and damage tolerance.

Their aerospace materials undergo additional testing for fatigue performance, crack growth resistance, and microstructural stability at elevated temperatures. Each batch of aerospace-grade 6al 4v titanium sheet is subjected to extensive non-destructive testing, including ultrasonic inspection to detect internal discontinuities as small as 0.8mm in diameter. JL's aerospace materials laboratory maintains calibration standards traceable to national metrology institutes, ensuring the accuracy of all mechanical property measurements. With thickness options ranging from 0.5 mm for lightweight structural components to thicker gauges for highly loaded applications, JL provides aerospace manufacturers with titanium sheets that meet the exacting requirements for aircraft engine components, structural members, and fastening systems. Their 4-6 week delivery cycle allows for thorough quality verification while still meeting the production schedules of major aircraft manufacturers, contributing to the safety and performance of modern aerospace systems worldwide.

Medical Device Manufacturing Standards for Titanium Implants

The medical industry imposes unique standards on 6al 4v titanium sheet materials intended for implantable devices, focusing on biocompatibility, consistency, and purity requirements that exceed those of other applications. Standards such as ASTM F1472 and ISO 5832-3 specifically address titanium alloys for surgical implants, establishing strict limits on elements that could potentially cause adverse biological reactions. For 6al 4v titanium sheet destined for medical applications, these standards require enhanced cleanliness during production, with special attention to surface contamination and inclusion content. Baoji JL Clad Metals Materials Co., Ltd. has implemented dedicated processing lines for medical-grade titanium sheets, with enhanced protocols for material handling, tool cleaning, and environmental control to minimize contamination risks. Their medical titanium manufacturing process includes additional acid pickling and passivation steps to ensure a clean, oxide-stabilized surface that promotes biocompatibility.

Each batch of medical-grade 6al 4v titanium sheet undergoes comprehensive testing for chemical composition, with particular attention to interstitial elements like oxygen, nitrogen, and hydrogen that can affect biological performance. JL's quality control program for medical titanium includes enhanced traceability systems that document every processing step from melt to finished product, providing the documentation required by medical device manufacturers for regulatory submissions. With thickness options from 0.5 mm for delicate components to thicker gauges for structural implants, and widths from 100 mm to 2000 mm, JL provides medical device companies with titanium materials that meet the exacting standards for orthopedic implants, dental devices, and cardiovascular components. Their commitment to medical-grade material standards ensures that patients worldwide benefit from the exceptional biocompatibility and mechanical reliability of properly manufactured titanium implants.

Automotive and Industrial Standards for Durability and Performance

The automotive and industrial sectors apply specific standards to 6al 4v titanium sheet materials that focus on long-term durability, fatigue resistance, and performance under variable loading conditions. While these applications may not require the extreme purity of medical implants or the precise microstructural control of aerospace components, they demand consistent mechanical properties and excellent fatigue performance to ensure component reliability. Standards such as SAE J1637 and various OEM specifications establish requirements for titanium materials used in performance automotive applications, focusing on consistency, formability, and spring-back characteristics that affect manufacturing processes. Baoji JL Clad Metals Materials Co., Ltd. produces 6al 4v titanium sheet materials that meet these automotive and industrial standards through carefully controlled processing parameters and thorough mechanical testing.

Their automotive-grade titanium sheets undergo additional testing for formability characteristics, including bend radius testing and springback measurement to verify their suitability for complex forming operations. The company's production process for industrial titanium applications includes specialized annealing treatments to optimize the balance between strength and formability, ensuring that components can be manufactured efficiently while maintaining the necessary mechanical properties. With standard sizes available and customization options for specific requirements, JL can produce 6al 4v titanium sheet materials tailored to particular automotive or industrial applications, from high-performance engine components to chemical processing equipment. Their thickness range from 0.5 mm to 100 mm and width options from 100 mm to 2000 mm provide designers with flexibility when specifying titanium for weight-critical applications like vehicle suspension components, exhaust systems, and industrial heat exchangers. JL's 4-6 week delivery cycle aligns with typical automotive production planning horizons, allowing manufacturers to incorporate these high-performance materials into their product development and manufacturing processes without excessive lead times.

Conclusion

Ti-6Al-4V titanium sheets require adherence to multiple international standards including ASTM B265, AMS 4911, and JIS H 4600, with additional requirements from ISO 9001, PED, and ABS certifications. Baoji JL Clad Metals Materials Co., Ltd. implements these standards throughout its manufacturing processes, ensuring high-quality titanium products for aerospace, medical, and industrial applications.

Are you looking for high-quality 6Al-4V titanium sheets that meet international standards? Baoji JL Clad Metals Materials Co., Ltd. offers superior titanium materials with our unique advantages: independent explosive composite technology, self-rolling plates, international qualifications, global sales network, and customization capabilities. Our commitment to innovation drives us to develop new products, technologies, and processes that keep you ahead of industry trends. We specialize in ODM/OEM services to meet your exact specifications, backed by our dedicated R&D team that creates innovative design solutions tailored to your unique requirements. All our products have passed ISO9001-2000 certification and successfully achieved PED and ABS international certifications in 2024. Contact us today at sales@cladmet.com to discover how our premium titanium sheets can enhance your project's performance and reliability.

References

1. ASTM International. (2023). ASTM B265-23: Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate. West Conshohocken, PA: ASTM International.

2. SAE International. (2022). AMS 4911R: Titanium Alloy, Sheet, Strip, and Plate, 6Al-4V, Annealed. Warrendale, PA: SAE International.

3. Japanese Standards Association. (2021). JIS H 4600: Titanium and Titanium Alloy - Sheets, Plates and Strips. Tokyo: Japanese Standards Association.

4. American Bureau of Shipping. (2023). ABS Rules for Materials and Welding – Part 2: Aluminum and Fiber Reinforced Plastics. Houston, TX: American Bureau of Shipping.

5. International Organization for Standardization. (2018). ISO 5832-3: Implants for surgery — Metallic materials — Part 3: Wrought titanium 6-aluminium 4-vanadium alloy. Geneva: ISO.

6. Pressure Equipment Directive. (2021). Directive 2014/68/EU of the European Parliament and of the Council on the harmonisation of the laws of the Member States relating to the making available on the market of pressure equipment. Brussels: European Commission.

_1737007724117.webp)

_1736996330512.webp)

_1737611948854.webp)

_1745547127259.webp)