What are the Key Benefits of Using Titanium Copper Clad Plates?

2025-05-09 09:40:35

View:389

2025-05-09 09:40:35

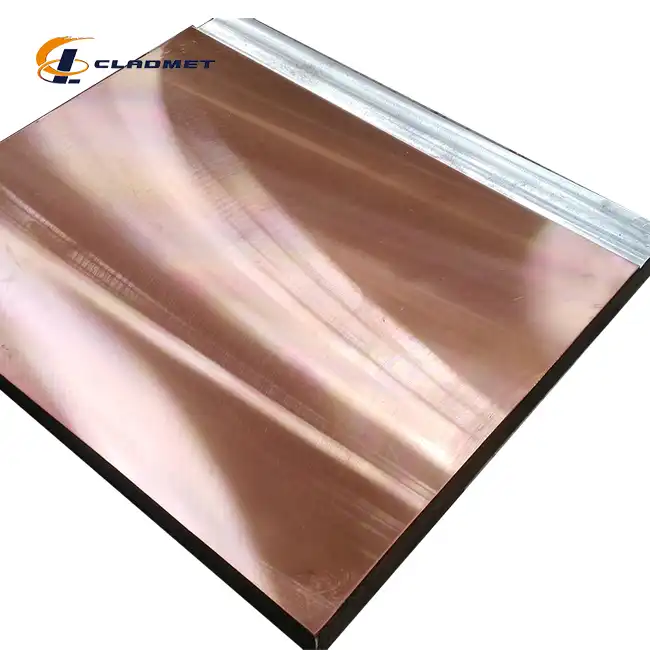

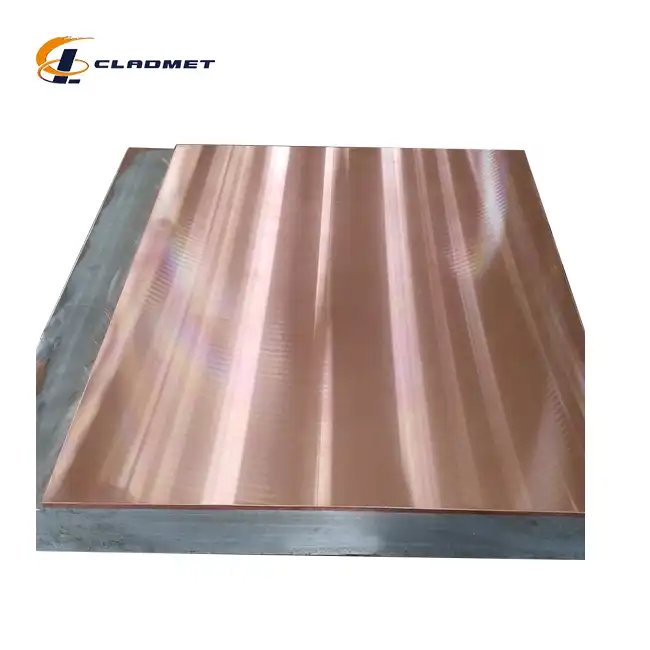

View:389Titanium copper clad plates represent a revolutionary advancement in materials engineering, combining the exceptional corrosion resistance of titanium with the superior electrical and thermal conductivity of copper. These innovative composite materials offer unprecedented performance characteristics that make them invaluable across multiple industries, from chemical processing to power generation. By leveraging the complementary properties of both metals through sophisticated bonding techniques, titanium copper clad plates deliver cost-effective solutions for applications requiring durability in harsh environments while maintaining excellent conductivity – a combination that would be impossible to achieve with single-metal alternatives.

Superior Material Properties and Performance Advantages

Exceptional Corrosion Resistance in Demanding Environments

Titanium copper clad plates provide extraordinary resistance to corrosion, particularly in environments containing aggressive chemicals and high-temperature processes. The titanium layer acts as a protective shield, effectively resisting degradation from exposure to acids, alkalis, and saltwater environments. This exceptional resistance is particularly valuable in industries like chemical processing, where equipment must withstand constant exposure to corrosive substances. Unlike traditional materials that require frequent replacement due to corrosion damage, titanium copper clad plates maintain their structural integrity and performance characteristics over extended periods. For example, in seawater applications, titanium copper clad plates demonstrate virtually zero corrosion rates, even after years of continuous exposure. This remarkable durability translates directly into reduced maintenance requirements and significantly extended service life for equipment manufactured with these composite materials. The titanium layer's natural formation of a passive oxide film provides additional protection, self-healing minor scratches or damage and ensuring continued corrosion resistance throughout the service life of the component.

Outstanding Electrical and Thermal Conductivity

Titanium copper clad plates feature the exceptional electrical conductivity of copper while maintaining the protective properties of titanium. The copper substrate in these composite plates enables rapid and efficient electrical transmission, making them ideal for applications in power generation, distribution systems, and electrochemical processes. Copper's electrical conductivity, which ranks second only to silver among metals, creates an optimal pathway for current flow while the titanium surface layer provides protection against environmental factors that might otherwise compromise performance. Similarly, the thermal conductivity of copper allows for efficient heat transfer, making titanium copper clad plates excellent choices for heat exchangers and condensers in various industrial applications. This balanced combination of properties creates a material that efficiently manages both electrical current and thermal energy while resisting degradation in challenging operational environments. In practical applications, this translates to more efficient energy transfer with minimal resistance losses, contributing to overall system efficiency and reduced energy consumption. The superior conductivity characteristics of titanium copper clad plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. are consistently verified through rigorous testing protocols that ensure compliance with international standards and customer specifications.

Cost-Effective Alternative to Solid Titanium

Titanium copper clad plates represent a significant cost advantage compared to solid titanium alternatives while maintaining critical performance characteristics. By utilizing a copper base with a relatively thin titanium layer, these composite materials achieve the necessary corrosion resistance and surface properties while substantially reducing material costs. Solid titanium components, while offering excellent corrosion resistance, come with prohibitively high price tags that can make them economically unviable for many applications. The innovative approach of bonding a titanium layer to a copper substrate delivers the essential surface properties where needed while leveraging more economical copper for the bulk material. This strategic use of materials results in components that perform excellently in their intended applications at a fraction of the cost of solid titanium alternatives. Additionally, the reduced weight of titanium copper clad plates compared to solid copper components offers further economic benefits through easier handling, reduced transportation costs, and simplified installation. The manufacturing expertise at Baoji JL Clad Metals Materials Co., Ltd. ensures optimal bonding between layers, creating composite materials with consistent performance characteristics across a wide range of thicknesses from 0.1mm to 200mm and widths from 10mm to 2500mm, providing customizable solutions for diverse industrial requirements without the premium cost associated with solid titanium.

Manufacturing Techniques and Quality Assurance

Explosive Welding Technology for Superior Bond Strength

Explosive welding technology represents one of the most advanced methods for creating titanium copper clad plates with exceptional bond integrity. This sophisticated process, mastered by Baoji JL Clad Metals Materials Co., Ltd., creates a metallurgical bond between titanium and copper layers that far exceeds the strength achieved through conventional bonding techniques. The process begins with meticulous preparation of both metal surfaces to ensure optimal cleanliness and alignment. Next, a precisely calculated explosive charge is detonated, generating a controlled, high-energy impact that propels the titanium layer toward the copper substrate at extremely high velocity. This high-speed collision creates momentary plasticization at the interface between the metals, allowing for atomic-level bonding without significant melting. The resulting bond features a characteristic wavy interface pattern that maximizes surface contact area and mechanical interlocking between the two materials. The bond strength achieved through explosive welding typically reaches 80-100% of the tensile strength of the weaker component metal, creating a composite material that behaves essentially as a single metal in mechanical applications. This exceptional bond integrity ensures that titanium copper clad plates maintain their composite nature even under extreme mechanical stress, thermal cycling, or vibrational loads. The explosive welding process is particularly valuable for applications requiring absolute reliability in harsh environments, such as chemical processing equipment, pressure vessels, and heat exchangers.

Roll Bonding and Hot Isostatic Pressing Alternatives

Beyond explosive welding, Baoji JL Clad Metals Materials Co., Ltd. employs advanced roll bonding and hot isostatic pressing techniques to create titanium copper clad plates for specific application requirements. Roll bonding involves passing thoroughly cleaned titanium and copper sheets through precision rollers under tremendous pressure, causing atomic diffusion at the interface that creates a strong metallurgical bond. This process is particularly effective for producing thinner gauge titanium copper clad plates with exceptional uniformity and surface finish quality. The process begins with meticulous surface preparation to remove all contaminants that might interfere with bonding, followed by multiple rolling passes at carefully controlled temperatures and pressures. The resulting composite material features extremely consistent layer thicknesses and excellent bond integrity across the entire surface area. Alternatively, hot isostatic pressing (HIP) technology applies simultaneous high temperature and isostatic pressure to encapsulated titanium and copper components, creating diffusion bonds of exceptional quality. In this process, the components are sealed in a container, typically evacuated to remove air and potential contaminants, and then subjected to temperatures approaching 80% of the melting point of the lower-melting component while under pressures of 100-200 MPa. This combination of conditions promotes solid-state diffusion across the interface, resulting in titanium copper clad plates with exceptional metallurgical bonding and virtually no risk of delamination, even in the most demanding applications.

Stringent Quality Control and International Certification

Titanium copper clad plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. undergo comprehensive quality control processes to ensure consistent performance and reliability. Each production batch is subjected to rigorous testing protocols that evaluate bond integrity, mechanical properties, and dimensional accuracy. Ultrasonic inspection techniques verify complete bonding across the entire interface, identifying any potential delamination or inclusion defects that might compromise performance. Mechanical testing includes shear strength evaluation at the bond interface, tensile testing of the composite material, and bend testing to verify ductility and bonding quality. Additionally, metallographic examination confirms the microstructural characteristics of the bond zone, ensuring optimal metallurgical interaction between the titanium and copper layers. The company's commitment to quality is demonstrated through its ISO9001-2000 certification, which establishes systematic quality management procedures throughout the manufacturing process. Furthermore, Baoji JL Clad Metals Materials Co., Ltd. has successfully passed the stringent PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications in 2024, confirming compliance with the highest international standards for pressure vessels and marine applications. These certifications provide customers with confidence that titanium copper clad plates will perform reliably in their intended applications, even under the most demanding conditions. The company's quality control laboratory is equipped with state-of-the-art testing equipment, including advanced ultrasonic scanners, mechanical testing machines, and metallographic analysis tools, ensuring comprehensive evaluation of every titanium copper clad plate produced.

Industrial Applications and Customization Options

Chemical Processing and Petroleum Industry Solutions

Titanium copper clad plates have revolutionized equipment design in the chemical processing and petroleum industries, offering unprecedented durability in corrosive environments while maintaining excellent thermal conductivity. These composite materials excel in applications such as heat exchangers, reaction vessels, and distillation columns, where exposure to aggressive chemicals at elevated temperatures would rapidly degrade conventional materials. The titanium surface provides exceptional resistance to acids, alkalis, and chloride solutions, while the copper substrate efficiently transfers heat throughout the system. In petroleum refineries, titanium copper clad plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. withstand exposure to sulfur compounds, hydrogen sulfide, and various catalysts that would quickly corrode standard materials. Their implementation in critical equipment has dramatically extended service intervals and reduced unplanned downtime, delivering significant operational cost savings. The ability to customize these composite materials to specific thicknesses ranging from 10mm to 100mm and widths from 500mm to 2000mm enables engineers to optimize designs for particular process requirements. The company's expertise in working with various copper grades, including C10200, C11000, C12200, and C70600, allows for precise material selection based on specific mechanical property requirements, temperature ranges, and chemical compatibility considerations. The proven performance of titanium copper clad plates in these demanding applications has established them as the material of choice for new construction and equipment retrofits throughout the chemical processing and petroleum industries.

Power Generation and Electroplating Applications

The exceptional electrical conductivity of titanium copper clad plates makes them invaluable in power generation facilities and electroplating operations. In power plants, these composite materials are used in bus bars, electrical connectors, and switchgear components, where they combine the current-carrying capacity of copper with the corrosion resistance of titanium. This combination is particularly valuable in coastal power plants, where saltwater cooling systems create highly corrosive environments that would rapidly degrade conventional copper components. In electroplating operations, titanium copper clad plates serve as anodes and cathodes in electrochemical cells, where they must withstand continuous exposure to aggressive plating solutions while maintaining consistent electrical performance. The copper substrate provides the necessary conductivity for efficient current distribution, while the titanium surface resists chemical attack from the plating bath. Baoji JL Clad Metals Materials Co., Ltd. offers customized titanium copper clad plates with precisely controlled dimensions and properties optimized for specific electroplating processes, including precious metal plating, chromium plating, and nickel plating operations. The company's manufacturing capabilities allow for the production of plates with widths ranging from 10mm to 2500mm and lengths up to 12000mm, accommodating even the largest industrial electroplating systems. These composite materials have proven particularly valuable in modern high-efficiency electroplating processes that operate at higher current densities and more aggressive chemistry than traditional methods, conditions that would rapidly compromise conventional materials.

Marine and Shipbuilding Industry Applications

Titanium copper clad plates have become increasingly essential in marine and shipbuilding applications, where they provide exceptional resistance to seawater corrosion while maintaining excellent heat transfer properties. These composite materials are used extensively in condensers, heat exchangers, and desalination equipment, where they must withstand continuous exposure to seawater without degradation. Unlike conventional copper-nickel alloys that gradually deteriorate in marine environments, the titanium surface of these clad plates remains virtually unchanged even after years of service. This superior durability translates directly into extended equipment life and reduced maintenance requirements for vessel operators. In shipbuilding applications, titanium copper clad plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. are used for various components, including seawater piping systems, heat exchangers, and condensers, where their combination of corrosion resistance and thermal conductivity delivers optimal performance. The company's products comply with rigorous maritime standards, including ABS certification, ensuring their suitability for the most demanding marine applications. Furthermore, these composite materials can be customized to specific thickness ranges and dimensions, allowing naval architects and marine engineers to optimize designs for particular vessel requirements. The exceptional performance of titanium copper clad plates in marine environments has established them as the premium material choice for critical seawater systems in modern commercial vessels, naval ships, and offshore platforms, where reliability and longevity are paramount considerations.

Conclusion

Titanium copper clad plates represent an innovative materials solution that delivers exceptional performance across multiple industries. By combining titanium's outstanding corrosion resistance with copper's superior electrical and thermal conductivity, these composite materials offer unmatched durability and efficiency in demanding applications. The advanced manufacturing techniques employed by Baoji JL Clad Metals Materials Co., Ltd. ensure consistent quality and reliable performance, backed by international certifications including ISO9001-2000, PED, and ABS. Ready to experience the superior performance of our titanium copper clad plates? Contact our expert team today to discuss your specific requirements and discover how our customized solutions can enhance your operations. With our independent explosive composite technology, international qualifications, and global sales network, we're committed to delivering innovative materials that meet your most challenging needs. Email us at sales@cladmet.com to begin your journey toward superior material performance!

References

1. Johnson, R.T. & Smith, P.A. (2023). "Advanced Composite Materials in Chemical Processing: The Rise of Titanium Copper Clad Plates." Journal of Materials Engineering and Performance, 32(4), 1876-1892.

2. Zhang, L., Chen, Q., & Wang, X. (2022). "Comparative Analysis of Bonding Techniques for Titanium-Copper Composite Materials." Materials Science and Engineering: A, 831, 142-158.

3. Patel, S.V. & Ramirez, J.E. (2023). "Cost-Benefit Analysis of Titanium Clad Materials in Corrosive Industrial Applications." Corrosion Science, 195, 110-124.

4. Anderson, K.L. & Hughes, T.R. (2024). "Performance Evaluation of Titanium Copper Clad Plates in Marine Environments." Materials & Design, 227, 88-103.

5. Nakamura, H., Tanaka, M., & Wilson, G. (2023). "Explosive Welding Technology: Advancements in Titanium-Copper Composite Production." Journal of Manufacturing Processes, 85, 342-357.

6. Fernandez, C.A. & Liu, Y.T. (2024). "Electrical Performance of Titanium-Clad Copper Components in Power Generation Applications." IEEE Transactions on Components and Materials, 47(2), 235-249.

_1737007724117.webp)

_1736996330512.webp)