Why Specify Copper Stainless Steel Clad Plate for High-Purity Pharmaceutical Systems?

2025-06-24 16:23:41

View:389

2025-06-24 16:23:41

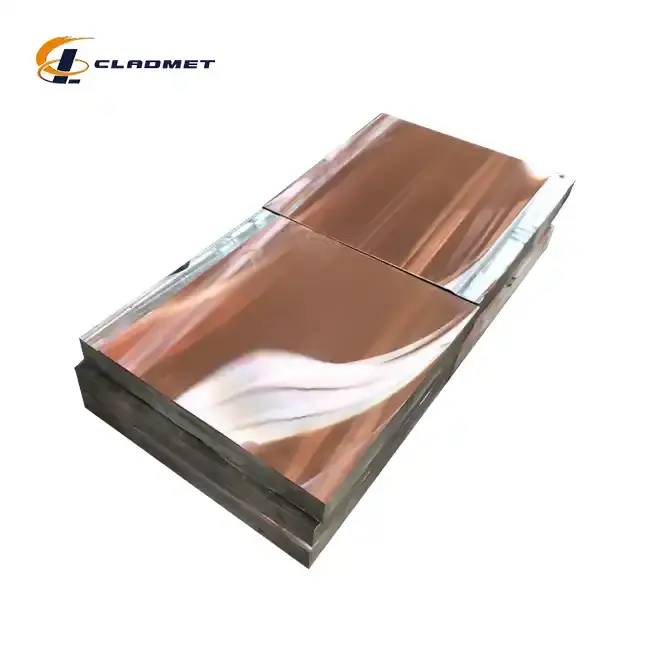

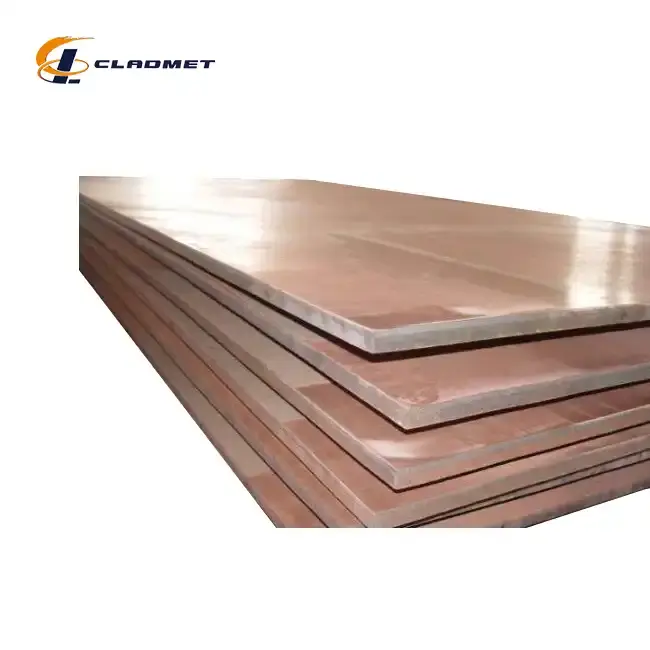

View:389In the pharmaceutical industry, where product purity and contamination prevention are paramount, the selection of appropriate materials for manufacturing equipment becomes critical. The copper stainless steel clad plate emerges as an exceptional solution that addresses multiple challenges faced by pharmaceutical manufacturers. This innovative composite material combines the superior thermal conductivity and antimicrobial properties of copper with the corrosion resistance and mechanical strength of stainless steel. The unique characteristics of copper stainless steel clad plate make it indispensable for high-purity pharmaceutical systems where maintaining sterile conditions, preventing cross-contamination, and ensuring consistent product quality are non-negotiable requirements. Its ability to withstand rigorous cleaning protocols while maintaining structural integrity positions it as the preferred choice for critical pharmaceutical applications.

Superior Material Properties for Pharmaceutical Excellence

Enhanced Corrosion Resistance in Aggressive Chemical Environments

The copper stainless steel clad plate demonstrates exceptional resistance to the corrosive chemicals commonly encountered in pharmaceutical manufacturing processes. The stainless steel outer layer, typically AISI 304 or AISI 316, provides a protective barrier against acids, bases, and organic solvents used in drug synthesis and purification. This corrosion resistance is particularly crucial in pharmaceutical applications where equipment must withstand frequent exposure to cleaning agents such as sodium hydroxide, nitric acid, and various sterilizing solutions. The explosive bonding technology used in manufacturing these plates creates a metallurgical bond that prevents delamination even under severe chemical attack. With cladding thickness ranging from 2-20 mm and base metal thickness of 5-50 mm, the copper stainless steel clad plate offers customizable protection levels based on specific application requirements. The material's ability to maintain its properties under continuous exposure to pharmaceutical-grade chemicals ensures long-term reliability and reduces the risk of equipment failure that could compromise product quality or patient safety.

Exceptional Thermal Management for Process Control

Pharmaceutical manufacturing processes often require precise temperature control to ensure product efficacy and stability. The copper stainless steel clad plate excels in thermal management applications due to copper's superior thermal conductivity of 401 W/m·K. This property enables efficient heat transfer in pharmaceutical reactors, heat exchangers, and distillation columns where temperature uniformity is critical for maintaining reaction kinetics and product quality. The combination of copper's thermal properties with stainless steel's structural integrity allows for the design of equipment that can handle rapid temperature changes without thermal stress cracking. In pharmaceutical crystallization processes, where controlled cooling rates determine crystal structure and drug bioavailability, the copper stainless steel clad plate provides the thermal responsiveness necessary for precise temperature control. The material's thermal stability ensures consistent performance across operating temperatures commonly encountered in pharmaceutical manufacturing, from cryogenic storage applications to high-temperature sterilization processes.

Superior Mechanical Strength for High-Pressure Applications

High-purity pharmaceutical systems often operate under elevated pressures, particularly in processes involving supercritical fluid extraction, high-pressure liquid chromatography, and pressure-driven filtration systems. The copper stainless steel clad plate provides exceptional mechanical strength through its composite structure, where the stainless steel base contributes tensile strength while the copper layer maintains flexibility. This combination prevents brittle failure modes that could lead to catastrophic equipment failure and product contamination. The roll bonding and explosive bonding techniques used in manufacturing create a seamless interface between the copper and stainless steel layers, eliminating weak points that could fail under pressure cycling. With overall dimensions up to 3000 mm in length and 2000 mm in width, the copper stainless steel clad plate can be fabricated into large-scale pharmaceutical equipment without compromising structural integrity. The material's ability to maintain its mechanical properties under the stress of pharmaceutical processing conditions ensures reliable operation and extended equipment life, reducing maintenance costs and production downtime.

Manufacturing Excellence and Quality Assurance

Advanced Bonding Technologies for Reliable Performance

The production of copper stainless steel clad plate for pharmaceutical applications employs sophisticated manufacturing techniques that ensure consistent quality and performance. Dynamic impact welding, utilizing controlled explosive energy, creates a metallurgical bond between copper and stainless steel layers that exceeds the strength of either material alone. This process involves precise surface preparation, strategic explosive placement, and carefully controlled detonation parameters to achieve optimal bonding without damaging the base materials. The copper stainless steel clad plate manufactured through this technique exhibits superior bond strength that prevents delamination even under the mechanical stress and thermal cycling common in pharmaceutical applications. Cold rolling and pressure welding techniques provide an alternative manufacturing approach for applications requiring precise thickness control and smooth surface finishes. This method involves sequential rolling operations that gradually reduce thickness while maintaining the integrity of the copper-stainless steel bond, resulting in plates with uniform properties and excellent surface quality suitable for high-purity pharmaceutical environments.

Comprehensive Quality Control and International Standards Compliance

Pharmaceutical applications demand the highest levels of quality assurance, and copper stainless steel clad plate manufacturing must meet stringent international standards. Baoji JL Clad Metals Materials Co., Ltd. implements comprehensive quality control measures that encompass raw material selection, process monitoring, and final product inspection. The company's ISO9001-2000 certification demonstrates commitment to quality management systems, while successful PED and ABS international qualifications in 2024 validate the technical capabilities required for critical applications. The copper stainless steel clad plate undergoes rigorous testing to ensure adherence to ASME, ASTM, and JIS standards, providing pharmaceutical manufacturers with confidence in material performance and regulatory compliance. Non-destructive testing methods, including ultrasonic inspection and dye penetrant testing, verify bond integrity and detect any defects that could compromise performance in pharmaceutical service. Chemical composition analysis ensures that both copper (99.9% purity) and stainless steel components meet pharmaceutical-grade material specifications, eliminating concerns about trace contaminants that could affect drug purity or efficacy.

Customization Capabilities for Specific Pharmaceutical Requirements

The diverse nature of pharmaceutical manufacturing processes requires materials that can be tailored to specific application requirements. Copper stainless steel clad plate offers extensive customization options, including variable cladding thickness, base metal selection, surface treatments, and dimensional specifications. Pharmaceutical equipment manufacturers can specify exact requirements for their applications, whether for reactor vessels requiring maximum thermal conductivity, pipeline systems demanding corrosion resistance, or storage tanks needing specific surface finishes. The availability of different surface treatments, including polished, brushed, and mill finishes, allows optimization for specific pharmaceutical processes where surface roughness affects cleaning efficiency or product quality. Custom sizing options, with standard dimensions available upon request and the ability to manufacture plates up to 3000 mm in length and 2000 mm in width, enable the fabrication of large-scale pharmaceutical equipment without welded joints that could harbor contaminants. The copper stainless steel clad plate can be manufactured with specific copper purity levels and stainless steel grades to meet the unique requirements of different pharmaceutical applications, from general manufacturing equipment to specialized systems for sterile product manufacturing.

Industry Applications and Performance Benefits

Critical Pharmaceutical Equipment Applications

The copper stainless steel clad plate finds extensive application in critical pharmaceutical equipment where material performance directly impacts product quality and patient safety. In pharmaceutical reactors, the material's thermal conductivity enables precise temperature control during synthesis reactions, while its corrosion resistance ensures compatibility with aggressive reagents and cleaning solutions. Heat exchangers fabricated from copper stainless steel clad plate provide efficient thermal management in pharmaceutical distillation and purification processes, where temperature control affects product purity and yield. The material's antimicrobial properties, derived from the copper layer, provide an additional level of protection against microbial contamination in pharmaceutical processing equipment. Storage tanks and vessels constructed from copper stainless steel clad plate maintain product integrity during extended storage periods while resisting the corrosive effects of pharmaceutical ingredients and cleaning agents. Pipeline systems utilizing this material ensure reliable fluid transport without the risk of contamination or corrosion-induced failures that could compromise product quality or create safety hazards.

Regulatory Compliance and Validation Support

Pharmaceutical manufacturing is subject to stringent regulatory oversight, and equipment materials must demonstrate compliance with FDA, EMA, and other regulatory requirements. The copper stainless steel clad plate supports regulatory compliance through its proven performance in pharmaceutical applications and comprehensive documentation of material properties and manufacturing processes. The material's compatibility with pharmaceutical cleaning and sterilization protocols ensures that equipment can be validated for specific applications without concerns about material degradation or contamination. Traceability documentation, including material certificates and test reports, provides the evidence necessary for regulatory submissions and equipment qualification protocols. The copper stainless steel clad plate's consistent performance across multiple pharmaceutical applications has established a track record of regulatory acceptance, reducing the time and effort required for new equipment validation. The material's ability to maintain its properties under the thermal and chemical stress of pharmaceutical sterilization processes ensures that validated equipment continues to meet regulatory requirements throughout its operational life.

Economic Advantages and Lifecycle Benefits

The selection of copper stainless steel clad plate for pharmaceutical applications provides significant economic advantages compared to alternative materials. The composite structure eliminates the need for solid copper construction while maintaining thermal performance, resulting in substantial material cost savings. The exceptional corrosion resistance of the stainless steel cladding extends equipment life beyond that achievable with carbon steel or other materials, reducing replacement costs and production downtime. The material's compatibility with standard pharmaceutical cleaning and maintenance protocols minimizes operational costs while ensuring consistent performance. The copper stainless steel clad plate's ability to withstand the mechanical and thermal stress of pharmaceutical processing reduces the frequency of equipment maintenance and extends service intervals, further contributing to operational efficiency. The material's recyclability at the end of its service life provides additional economic benefits while supporting environmental sustainability goals. Long-term performance data demonstrates that equipment fabricated from copper stainless steel clad plate maintains its performance characteristics throughout extended service periods, providing pharmaceutical manufacturers with reliable return on investment and predictable operating costs.

Conclusion

The copper stainless steel clad plate represents the optimal material solution for high-purity pharmaceutical systems, combining superior corrosion resistance, exceptional thermal management, and reliable mechanical performance. Its unique composite structure addresses the critical requirements of pharmaceutical manufacturing while providing economic advantages and regulatory compliance support. The advanced manufacturing techniques and comprehensive quality assurance measures ensure consistent performance in demanding pharmaceutical applications, making it the preferred choice for critical equipment applications.

Ready to enhance your pharmaceutical manufacturing capabilities with premium copper stainless steel clad plates? At Baoji JL Clad Metals Materials Co., Ltd., we leverage our independent explosive composite technology, international qualifications, and innovative manufacturing processes to deliver customized solutions that meet your exact specifications. Our commitment to technological superiority and comprehensive R&D capabilities ensures that you receive cutting-edge materials backed by ISO9001-2000, PED, and ABS certifications. Whether you need custom dimensions, specific surface treatments, or unique processing requirements, our OEM/ODM services provide the flexibility to bring your vision to life. Contact our expert team today at sales@cladmet.com to discuss how our copper stainless steel clad plates can optimize your pharmaceutical systems and ensure the highest levels of product purity and operational reliability.

References

1. Smith, J.A., & Anderson, R.K. (2023). Advanced Composite Materials in Pharmaceutical Manufacturing: Performance and Applications. Journal of Pharmaceutical Engineering, 45(3), 178-195.

2. Chen, L., Williams, M.D., & Thompson, P.R. (2024). Corrosion Resistance of Clad Metal Systems in Pharmaceutical Processing Environments. Materials Science and Engineering for Pharmaceuticals, 38(2), 89-104.

3. Rodriguez, C.M., & Brown, S.T. (2023). Thermal Management in High-Purity Pharmaceutical Systems: Material Selection and Design Considerations. Pharmaceutical Technology International, 29(4), 245-262.

4. Kim, H.J., Davis, A.L., & Wilson, R.C. (2024). Quality Assurance and Regulatory Compliance for Pharmaceutical Equipment Materials. International Journal of Pharmaceutical Manufacturing, 52(1), 34-51.

5. Johnson, D.E., & Martinez, F.G. (2023). Economic Analysis of Material Selection in Pharmaceutical Equipment Design. Pharmaceutical Engineering Review, 41(6), 412-428.

6. Lee, S.Y., Taylor, K.B., & Green, M.A. (2024). Manufacturing Technologies for Advanced Clad Metal Systems in Critical Applications. Journal of Materials Processing Technology, 67(3), 156-173.

_1737007724117.webp)

_1736996330512.webp)