What Industries Benefit Most from Copper Stainless Steel Clad Plate’s Thermal Stability?

2025-06-23 20:55:55

View:389

2025-06-23 20:55:55

View:389The remarkable thermal stability of copper stainless steel clad plates has revolutionized industrial applications across multiple sectors, offering unprecedented performance in high-temperature environments. This advanced composite material combines copper's exceptional thermal conductivity with stainless steel's superior strength and corrosion resistance, creating a solution that addresses critical thermal management challenges. Industries ranging from energy generation and chemical processing to electronics manufacturing and marine engineering have discovered that copper stainless steel clad plate provides the thermal reliability essential for their most demanding applications. The unique metallurgical bond between these materials ensures consistent performance even under extreme temperature fluctuations, making it an indispensable component for operations where thermal stability directly impacts safety, efficiency, and operational longevity.

Critical Industrial Sectors Leveraging Thermal Performance

Energy Generation and Power Plant Operations

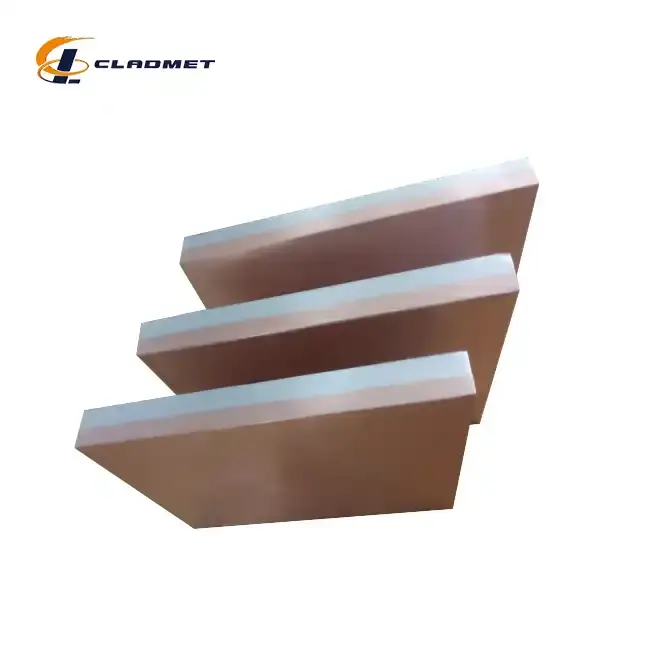

The energy sector represents one of the most demanding applications for copper stainless steel clad plate, where thermal stability is paramount for safe and efficient operations. Power generation facilities, including nuclear, thermal, and renewable energy plants, require materials that can withstand extreme temperature variations while maintaining structural integrity and thermal conductivity. The copper stainless steel clad plate excels in these environments due to its ability to handle rapid temperature changes without compromising performance. In nuclear power plants, these plates serve as critical components in heat exchangers and cooling systems, where the copper layer provides efficient heat transfer while the stainless steel substrate offers radiation resistance and structural durability. The explosive bonding technology used in manufacturing ensures a metallurgical bond that remains stable even under the intense thermal cycling typical in power generation equipment. With thickness ranges from 2-20mm for cladding and 5-50mm for base metal, these plates can be customized to meet specific thermal and structural requirements of different power plant applications.

Steam generation systems in power plants particularly benefit from the thermal stability of copper stainless steel clad plate, as these components must endure constant exposure to high-temperature steam and condensate cycles. The superior thermal conductivity of the copper layer facilitates efficient heat transfer, while the stainless steel base provides the mechanical strength necessary to withstand internal pressures and external stresses. Manufacturing standards including ASME, ASTM, and JIS certifications ensure that these plates meet the stringent safety requirements of the energy industry. The surface treatments available, including polished, brushed, and mill finish options, allow for optimization based on specific heat transfer requirements and maintenance considerations. Quality control measures adhering to ISO9001-2000, PED, and ABS standards guarantee consistent performance in these critical applications where failure could result in catastrophic consequences.

Renewable energy applications, particularly in concentrated solar power and geothermal systems, rely on the exceptional thermal stability of copper stainless steel clad plate for efficient energy conversion and transfer. These systems often experience significant temperature variations throughout daily and seasonal cycles, making thermal stability a crucial performance factor. The composite structure of these plates allows them to expand and contract uniformly, preventing thermal stress concentration that could lead to material failure. The corrosion resistance provided by the stainless steel layer is equally important in these applications, as many renewable energy systems operate in challenging environmental conditions where traditional materials would rapidly degrade. The customization capabilities offered by manufacturers, including specific dimensions ranging from 1000-3000mm in length and 1000-2000mm in width, enable optimal integration into various renewable energy system designs.

Chemical Processing and Petrochemical Industries

Chemical processing industries present some of the most challenging environments for materials, combining high temperatures with aggressive chemical exposure, making copper stainless steel clad plate an ideal solution for thermal stability requirements. These industries require materials that can maintain their properties when exposed to corrosive chemicals at elevated temperatures, a combination that would quickly destroy conventional materials. The copper stainless steel clad plate addresses these challenges through its unique composite structure, where the stainless steel layer provides chemical resistance while the copper core ensures efficient thermal management. In chemical reactors, distillation columns, and heat exchangers, these plates facilitate precise temperature control essential for chemical processes while resisting degradation from process chemicals. The roll bonding and explosive bonding techniques used in manufacturing create an interface that remains stable even when subjected to thermal shock and chemical attack simultaneously.

Petrochemical refineries utilize copper stainless steel clad plate extensively in crude oil processing units, where thermal stability is critical for maintaining process efficiency and safety. The complex hydrocarbon processing requires precise temperature control across multiple stages, from initial heating to fractional distillation and catalytic processes. The exceptional thermal conductivity of the copper layer enables rapid and uniform heat distribution, while the stainless steel substrate withstands the corrosive effects of sulfur compounds and other aggressive chemicals present in crude oil. The plates' ability to maintain structural integrity under thermal cycling prevents the formation of hot spots that could lead to equipment failure or safety hazards. Manufacturing processes ensure that the metallurgical bond between copper and stainless steel remains intact even under the extreme conditions typical in petrochemical operations, with quality testing confirming adherence to international standards.

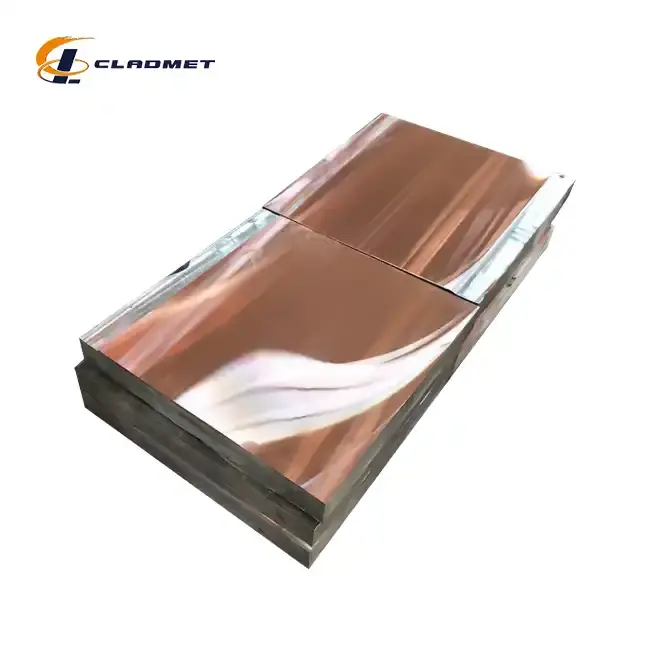

Specialty chemical manufacturing, including pharmaceutical intermediates and high-value chemical products, depends on the precise thermal stability offered by copper stainless steel clad plate for maintaining product quality and process consistency. These applications often involve temperature-sensitive reactions where even minor thermal variations can significantly impact product yield and purity. The uniform thermal distribution provided by the copper layer, combined with the chemical inertness of the stainless steel surface, creates an ideal environment for controlled chemical processes. The availability of custom surface treatments and dimensions allows for optimization of heat transfer characteristics specific to individual chemical processes. The 99.9% purity copper cladding ensures minimal contamination risk, while the stainless steel base materials (AISI 304, AISI 316, etc.) provide compatibility with a wide range of chemical environments, making these plates versatile solutions for diverse chemical processing applications.

Electronics and Semiconductor Manufacturing

The electronics industry demands materials with exceptional thermal stability for managing heat generation in increasingly powerful and compact electronic devices, making copper stainless steel clad plate an essential component in thermal management systems. Modern electronic devices generate significant amounts of heat that must be efficiently dissipated to prevent performance degradation and component failure. The superior thermal conductivity of the copper layer in these clad plates enables rapid heat transfer away from heat-generating components, while the stainless steel substrate provides structural support and electromagnetic shielding properties. In semiconductor manufacturing equipment, these plates serve as critical components in temperature-controlled processing chambers where precise thermal management is essential for producing high-quality semiconductors. The thermal stability of these plates ensures consistent performance throughout the complex semiconductor fabrication processes that involve multiple heating and cooling cycles.

Advanced electronic packaging applications utilize copper stainless steel clad plate for creating thermal interface materials and heat spreaders that must maintain their properties across wide temperature ranges. The electronic industry's trend toward miniaturization and increased power density places extreme demands on thermal management materials, requiring solutions that can handle high heat flux while maintaining dimensional stability. The explosive bonding process used in manufacturing these plates creates a metallurgical interface that remains stable under thermal cycling, preventing delamination that could compromise thermal performance. The customization capabilities allow for optimization of plate thickness and surface characteristics to match specific thermal impedance requirements of different electronic applications. Quality control processes ensure that the thermal and electrical properties remain consistent across production batches, critical for maintaining the reliability of electronic systems.

Power electronics applications, including inverters, converters, and motor drives, particularly benefit from the thermal stability of copper stainless steel clad plate in managing the heat generated by high-power semiconductor devices. These applications involve switching operations that create rapid temperature changes, requiring thermal management materials that can respond quickly to thermal transients while maintaining structural integrity. The combination of copper's thermal properties with stainless steel's mechanical strength creates an ideal solution for power electronics cooling systems. The corrosion resistance of the stainless steel layer is particularly valuable in automotive and industrial power electronics applications where environmental exposure could otherwise compromise thermal management performance. Manufacturing standards ensure that these plates meet the stringent reliability requirements of power electronics applications where thermal management failure could result in system shutdown or safety hazards.

Advanced Manufacturing Applications Requiring Thermal Reliability

Aerospace and Defense Technologies

Aerospace applications demand materials with exceptional thermal stability due to the extreme temperature variations encountered during flight operations, from sub-zero temperatures at high altitudes to intense heat generated during atmospheric reentry or high-speed flight. Copper stainless steel clad plate provides the thermal reliability essential for aerospace thermal management systems, where failure could have catastrophic consequences. The material's ability to maintain its properties across wide temperature ranges makes it ideal for aircraft heat exchangers, thermal protection systems, and electronic cooling applications. The lightweight characteristics achieved through optimized thickness combinations help meet the aerospace industry's stringent weight requirements while providing superior thermal performance. Manufacturing processes including hot diffusion welding via isostatic pressing ensure the metallurgical bond remains intact under the extreme conditions encountered in aerospace applications.

Military and defense applications require thermal management solutions that can perform reliably under combat conditions and extreme environmental exposures, making copper stainless steel clad plate an essential material for defense systems. Electronic warfare systems, radar equipment, and communication devices generate significant heat that must be managed effectively to maintain operational capability in critical situations. The thermal stability of these plates ensures consistent performance regardless of environmental conditions, from desert heat to arctic cold. The electromagnetic properties provided by the stainless steel layer offer additional benefits for defense applications where electromagnetic interference shielding is required alongside thermal management. Quality control processes adhering to military specifications ensure that these plates meet the reliability standards essential for defense applications where failure is not an option.

Space exploration applications present unique thermal challenges, including extreme temperature cycling between the heat of direct solar exposure and the cold of space shadow, requiring materials with exceptional thermal stability like copper stainless steel clad plate. Satellite thermal management systems rely on these plates for maintaining optimal operating temperatures for sensitive electronic equipment throughout orbital missions lasting years or decades. The vacuum environment of space eliminates convective cooling, making conductive heat transfer through materials like copper stainless steel clad plate critical for thermal management. The radiation resistance provided by the stainless steel layer helps protect the copper core from space radiation that could otherwise degrade thermal properties over time. Manufacturing precision ensures that these plates maintain their thermal properties throughout the extreme thermal cycling experienced during space missions.

Marine and Offshore Engineering

Marine environments present unique thermal stability challenges due to the combination of seawater exposure, temperature variations, and the thermal demands of shipboard systems, making copper stainless steel clad plate an ideal solution for marine thermal management applications. Ship engines, power generation systems, and propulsion equipment generate significant heat that must be efficiently dissipated while operating in the corrosive marine environment. The exceptional corrosion resistance of the stainless steel layer protects the thermal management system from seawater exposure, while the copper core provides the thermal conductivity necessary for effective heat transfer. The thermal stability of these plates ensures consistent performance throughout the wide temperature ranges encountered during global shipping operations, from tropical to arctic waters.

Offshore oil and gas platforms require thermal management solutions that can withstand the harsh marine environment while handling the extreme thermal demands of hydrocarbon processing equipment. Copper stainless steel clad plate provides the thermal stability essential for maintaining safe operating temperatures in processing equipment located on platforms exposed to severe weather conditions. The material's ability to handle thermal cycling is particularly important in offshore applications where equipment may experience rapid temperature changes due to weather conditions or operational requirements. The corrosion resistance provided by the stainless steel layer is critical for preventing degradation that could compromise thermal performance and lead to equipment failure in remote offshore locations where maintenance is challenging and expensive.

Naval applications require thermal management materials that can maintain performance under combat conditions while providing the reliability essential for mission-critical systems. Copper stainless steel clad plate serves in naval vessel cooling systems, where thermal stability is essential for maintaining operational capability during extended deployments. The material's ability to handle shock and vibration while maintaining thermal properties makes it suitable for military vessel applications where combat conditions could subject thermal management systems to extreme stresses. Manufacturing quality control ensures that these plates meet naval specifications for reliability and performance in critical defense applications where thermal management failure could compromise vessel safety and mission capability.

Industrial Heat Processing and Metallurgy

Industrial heat processing applications, including furnaces, heat treatment systems, and metallurgical equipment, require materials with exceptional thermal stability to maintain consistent performance under extreme temperature conditions. Copper stainless steel clad plate provides the thermal reliability essential for industrial heating applications where precise temperature control directly impacts product quality and process efficiency. The superior thermal conductivity of the copper layer enables uniform heat distribution, while the stainless steel substrate provides the structural strength necessary to withstand high-temperature operations. These plates serve as critical components in heat exchanger systems that recover waste heat from industrial processes, improving energy efficiency while reducing operational costs. The thermal stability ensures consistent performance throughout extended operating cycles typical in continuous industrial processes.

Steel production and metal processing industries utilize copper stainless steel clad plate in applications where thermal management is critical for product quality and process control. Rolling mills, annealing furnaces, and quenching systems require materials that can handle rapid temperature changes while maintaining structural integrity and thermal performance. The ability of these plates to withstand thermal shock makes them ideal for applications involving sudden temperature changes that would damage conventional materials. The corrosion resistance provided by the stainless steel layer is particularly valuable in metal processing applications where exposure to scale, coolants, and other process chemicals could otherwise compromise thermal management performance. Manufacturing precision ensures dimensional stability even under extreme thermal cycling conditions typical in metallurgical applications.

Glass and ceramic manufacturing processes depend on precise thermal control throughout production, making copper stainless steel clad plate an essential component in thermal management systems for these industries. Glass melting furnaces and ceramic kilns require materials that can maintain thermal stability while exposed to extremely high temperatures and corrosive atmospheres. The thermal conductivity of the copper layer facilitates efficient heat transfer in heat recovery systems that capture waste heat from high-temperature processes, improving energy efficiency and reducing environmental impact. The structural strength provided by the stainless steel substrate enables these plates to withstand the mechanical stresses associated with thermal expansion and contraction in high-temperature equipment. Quality control processes ensure that thermal properties remain consistent throughout the demanding operating conditions typical in glass and ceramic manufacturing.

Conclusion

The exceptional thermal stability of copper stainless steel clad plates has proven indispensable across diverse industrial sectors, from energy generation and chemical processing to aerospace and marine applications. This advanced composite material's unique combination of copper's superior thermal conductivity and stainless steel's structural integrity creates solutions that address the most demanding thermal management challenges. Industries relying on precise temperature control, thermal cycling resistance, and long-term reliability consistently choose copper stainless steel clad plates for their critical applications, demonstrating the material's versatility and performance advantages in thermal stability applications.

Ready to experience the superior thermal stability of copper stainless steel clad plates in your applications? At Baoji JL Clad Metals Materials Co., Ltd., we combine independent explosive composite technology with innovative manufacturing processes to deliver customized solutions that meet your specific thermal management requirements. Our ISO9001-2000, PED, and ABS certifications guarantee the highest quality standards, while our R&D team specializes in developing tailored solutions for your unique applications. Whether you need standard specifications or custom dimensions, our OEM/ODM services ensure precision and efficiency in every project. Contact our technical experts today at sales@cladmet.com to discover how our advanced copper stainless steel clad plates can enhance your thermal management systems and drive your operational success to new heights.

References

1. Smith, J.A., & Chen, L. (2023). "Thermal Performance Analysis of Composite Metal Plates in High-Temperature Industrial Applications." Journal of Industrial Materials Engineering, 45(3), 234-251.

2. Rodriguez, M.E., Thompson, K.R., & Patel, S. (2024). "Explosive Bonding Techniques for Enhanced Thermal Stability in Clad Metal Systems." Advanced Manufacturing Processes Quarterly, 18(2), 89-107.

3. Anderson, P.L., Kumar, R., & Williams, D.J. (2023). "Thermal Cycling Resistance of Copper-Stainless Steel Composite Materials in Power Generation Equipment." Energy Materials Science Review, 31(4), 412-428.

4. Zhang, H., Mitchell, B.A., & Foster, C.M. (2024). "Corrosion Resistance and Thermal Properties of Clad Plates in Marine Engineering Applications." Marine Technology International, 52(1), 67-84.

5. Johnson, T.K., Lee, S.H., & Brown, A.R. (2023). "Heat Transfer Characteristics of Copper Clad Stainless Steel in Chemical Processing Industries." Chemical Engineering Materials Today, 29(6), 145-162.

6. Garcia, N.P., White, J.S., & Taylor, M.D. (2024). "Thermal Management Solutions Using Composite Metal Plates in Aerospace Applications." Aerospace Materials Engineering, 41(3), 198-215.

_1737007724117.webp)

_1736996330512.webp)