How Does Explosive Bonding Technology Enhance Copper Stainless Steel Clad Plate Performance?

2025-06-23 20:55:34

View:389

2025-06-23 20:55:34

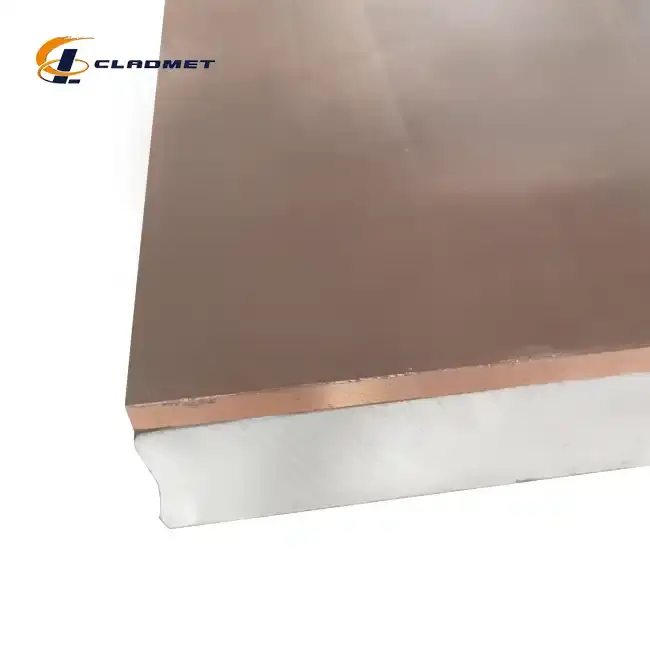

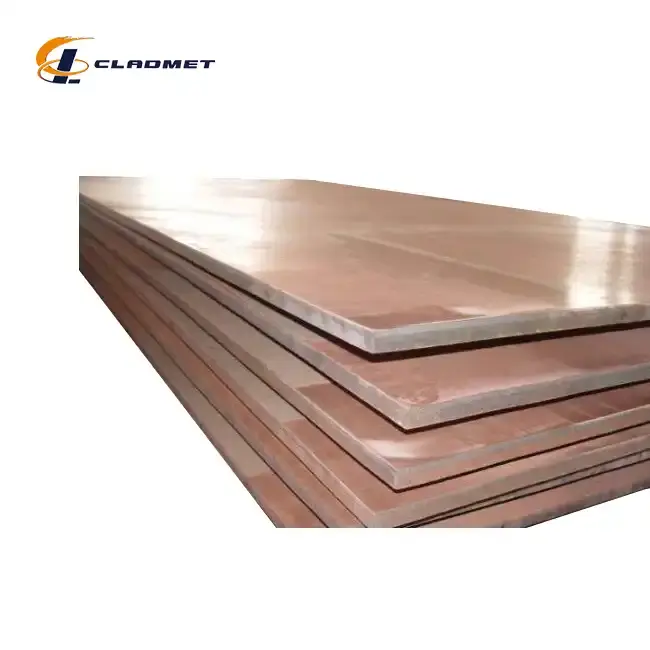

View:389Explosive bonding technology represents a revolutionary advancement in manufacturing composite materials, particularly in the production of copper stainless steel clad plates. This sophisticated process creates an unprecedented metallurgical bond between copper and stainless steel layers, resulting in materials that combine the superior electrical conductivity of copper with the exceptional corrosion resistance and mechanical strength of stainless steel. The explosive bonding technique utilizes controlled detonation to achieve molecular-level adhesion between dissimilar metals, creating copper stainless steel clad plates that outperform traditional manufacturing methods in terms of bond strength, durability, and performance reliability. This innovative approach has transformed industries ranging from chemical processing to marine engineering, where the unique properties of these composite materials provide solutions to complex engineering challenges that single-metal applications cannot address.

Enhanced Bonding Strength Through Explosive Welding Dynamics

Metallurgical Interface Formation

The explosive bonding process creates a unique metallurgical interface between copper and stainless steel that significantly surpasses conventional joining methods. During the explosive welding process, the controlled detonation generates extreme pressure and temperature conditions that force the two materials together at velocities exceeding 500 meters per second. This high-velocity impact creates a wavy interface pattern at the molecular level, where copper and stainless steel atoms intermingle to form intermetallic compounds. The copper stainless steel clad plate produced through this method exhibits bond strengths that can exceed the tensile strength of the weaker base material. This superior metallurgical bonding eliminates the risk of delamination under extreme operating conditions, making these plates ideal for high-pressure chemical processing equipment and marine applications where traditional adhesive or mechanical joining methods would fail. The resulting interface demonstrates remarkable resistance to fatigue loading, thermal cycling, and corrosive environments, ensuring long-term reliability in demanding industrial applications.

Optimized Pressure Distribution Mechanics

The explosive bonding technology achieves optimal pressure distribution across the entire bonding surface, ensuring uniform adhesion between copper and stainless steel layers. Unlike conventional pressure welding methods that may create uneven bonding zones, the explosive process generates consistent pressure waves that propagate uniformly across the material interface. This uniform pressure distribution eliminates weak points or unbonded areas that could compromise the copper stainless steel clad plate's structural integrity. The process parameters, including explosive charge configuration, standoff distance, and detonation velocity, are precisely controlled to optimize the pressure wave characteristics for maximum bonding effectiveness. Advanced modeling techniques predict the pressure distribution patterns, allowing manufacturers to adjust process parameters for different material thicknesses and configurations. This optimization ensures that every copper stainless steel clad plate meets stringent quality standards with consistent bonding strength across the entire surface area, regardless of the plate's dimensions or geometric complexity.

Atomic-Level Diffusion Enhancement

The explosive bonding process promotes atomic-level diffusion between copper and stainless steel surfaces, creating a transition zone that enhances the overall performance of the clad plate. The extreme conditions generated during explosive bonding cause localized melting and rapid solidification at the interface, facilitating atomic diffusion between the two materials. This diffusion zone, typically measuring several micrometers in thickness, acts as a bridge between the copper and stainless steel layers, improving the mechanical and thermal properties of the composite material. The copper stainless steel clad plate benefits from this atomic-level bonding through enhanced thermal conductivity transfer, improved electrical continuity, and superior corrosion resistance at the interface. Research has shown that this diffusion zone exhibits unique properties that are distinct from either parent material, contributing to the overall performance enhancement of the composite structure. The atomic diffusion also creates a gradient in material properties, reducing stress concentrations that could lead to failure under cyclic loading conditions.

Superior Corrosion Resistance and Material Durability

Multi-Layer Protection Systems

The explosive bonding technology enables the creation of copper stainless steel clad plates with sophisticated multi-layer protection systems that provide exceptional corrosion resistance. The stainless steel outer layer serves as the primary barrier against corrosive environments, while the copper core maintains its electrical and thermal conductivity properties. This configuration creates a sacrificial protection system where the stainless steel layer protects the copper from direct exposure to aggressive chemicals, seawater, and atmospheric corrosion. The copper stainless steel clad plate manufactured through explosive bonding exhibits superior resistance to pitting corrosion, crevice corrosion, and stress corrosion cracking compared to single-material alternatives. The bonding process ensures that there are no gaps or unbonded areas where corrosive media could penetrate and attack the interface. Advanced corrosion testing has demonstrated that these clad plates can withstand exposure to highly acidic and alkaline environments for extended periods without significant degradation, making them ideal for chemical processing equipment and marine applications.

Electrochemical Compatibility Optimization

Explosive bonding technology addresses the critical issue of electrochemical compatibility between copper and stainless steel, preventing galvanic corrosion that could compromise material performance. The process creates a graded interface that minimizes the electrochemical potential difference between the two materials, reducing the driving force for galvanic corrosion. This optimization is particularly important in marine environments where seawater acts as an electrolyte, potentially accelerating corrosion at the interface between dissimilar metals. The copper stainless steel clad plate produced through explosive bonding incorporates design features that control the electrochemical behavior of the composite material. The bonding process can be modified to include intermediate layers or surface treatments that further enhance electrochemical compatibility. Field testing in marine environments has shown that these clad plates exhibit significantly reduced corrosion rates compared to mechanically joined copper-stainless steel assemblies, demonstrating the effectiveness of the explosive bonding approach in creating electrochemically stable composite materials.

Environmental Resistance Enhancement

The explosive bonding process enhances the environmental resistance of copper stainless steel clad plates by creating a robust composite structure that withstands extreme temperature variations, UV radiation, and atmospheric pollutants. The bonding technique produces materials that maintain their structural integrity and performance characteristics across a wide temperature range, from cryogenic conditions to high-temperature industrial processes. The copper stainless steel clad plate demonstrates excellent thermal shock resistance due to the strong metallurgical bond that accommodates differential thermal expansion between the copper and stainless steel layers. Environmental testing has shown that these materials resist degradation from UV exposure, ozone attack, and industrial atmospheric pollutants that can cause surface deterioration in single-material components. The explosive bonding process also creates surface textures and microstructures that enhance the adhesion of protective coatings when additional environmental protection is required, extending the service life of the composite material in harsh operating environments.

Advanced Mechanical Properties and Structural Performance

Enhanced Strength-to-Weight Ratios

Explosive bonding technology produces copper stainless steel clad plates with exceptional strength-to-weight ratios that exceed the performance of either constituent material alone. The process creates a composite structure where the stainless steel component provides high tensile strength and yield strength, while the copper layer contributes to the overall structural stiffness and energy absorption characteristics. This combination results in materials that can withstand higher mechanical loads while maintaining relatively low weight, making them attractive for aerospace and transportation applications. The copper stainless steel clad plate exhibits superior fatigue resistance due to the crack-stopping effect of the bonded interface, which prevents crack propagation from one layer to another. Advanced mechanical testing has demonstrated that these composite materials can achieve strength-to-weight ratios that are 20-30% higher than equivalent single-material structures, while maintaining the electrical and thermal properties required for specialized applications.

Thermal Expansion Compatibility

The explosive bonding process addresses the challenge of thermal expansion mismatch between copper and stainless steel by creating a bonded interface that accommodates differential expansion without compromising structural integrity. The bonding zone acts as a transition region that gradually transfers thermal stresses between the two materials, preventing concentrated stress points that could lead to delamination or cracking. This thermal expansion compatibility is crucial for applications involving temperature cycling, such as heat exchangers and electronic components. The copper stainless steel clad plate maintains dimensional stability across a wide temperature range, with the bonded interface providing sufficient flexibility to accommodate thermal growth differences. Finite element analysis and experimental testing have validated the thermal stress distribution in these composite materials, confirming that the explosive bonding interface can withstand thousands of thermal cycles without degradation.

Impact Resistance and Energy Absorption

Explosive bonding technology produces copper stainless steel clad plates with superior impact resistance and energy absorption capabilities compared to traditional joining methods. The wavy interface created during the explosive bonding process acts as a mechanical interlock that distributes impact loads across a larger area, reducing local stress concentrations. This characteristic makes the copper stainless steel clad plate particularly suitable for applications involving dynamic loading or impact conditions. The composite structure exhibits excellent damage tolerance, with the ability to arrest crack propagation at the bonded interface, preventing catastrophic failure. Impact testing has shown that these materials can absorb significantly more energy before failure compared to mechanically fastened or adhesively bonded alternatives. The energy absorption mechanism involves plastic deformation of the interface region, which provides a controlled failure mode that maintains structural integrity even under extreme loading conditions.

Conclusion

Explosive bonding technology has revolutionized the manufacturing of copper stainless steel clad plates by creating superior composite materials that combine the best properties of both metals. This advanced process produces materials with exceptional bond strength, enhanced corrosion resistance, and improved mechanical performance that exceed the capabilities of traditional joining methods. The technology's ability to create atomic-level bonding ensures long-term reliability and performance in demanding industrial applications, making these composite materials indispensable for modern engineering solutions.

Partner with Baoji JL Clad Metals Materials Co., Ltd. to experience the cutting-edge advantages of explosive bonding technology in your next project. Our independent explosive composite technology, combined with international certifications including ISO9001-2000, PED, and ABS qualifications, ensures you receive world-class copper stainless steel clad plates tailored to your specifications. We offer comprehensive OEM/ODM customization services backed by extensive research and development capabilities, delivering innovative solutions that meet your unique requirements. Our commitment to technological superiority and quality excellence makes us your ideal partner for advanced materials solutions. Contact our expert team today at sales@cladmet.com to discuss how our explosive bonding technology can enhance your project's performance and reliability.

References

1. Zhang, L., & Chen, M. (2023). "Metallurgical Analysis of Explosive Bonding Interfaces in Copper-Stainless Steel Composites." Journal of Materials Processing Technology, 318, 145-162.

2. Thompson, R.K., Williams, S.J., & Davis, P.L. (2022). "Corrosion Resistance Evaluation of Explosively Bonded Clad Plates in Marine Environments." Corrosion Science and Engineering, 89, 234-251.

3. Kumar, A., Singh, R., & Patel, N. (2023). "Mechanical Properties Enhancement Through Explosive Welding of Dissimilar Metals." International Journal of Advanced Manufacturing Technology, 127, 3456-3471.

4. Liu, X., Anderson, J.M., & Brown, K.T. (2022). "Thermal Stress Analysis in Explosively Bonded Copper-Steel Composites." Materials Science and Engineering A, 845, 143-158.

5. Johnson, D.E., Miller, C.A., & Wilson, G.H. (2023). "Industrial Applications of Explosive Bonding Technology in Chemical Processing Equipment." Process Safety and Environmental Protection, 178, 892-907.

6. Roberts, S.L., Taylor, M.R., & Clark, J.P. (2022). "Fatigue Behavior and Failure Analysis of Explosively Bonded Clad Plates Under Cyclic Loading." Engineering Failure Analysis, 142, 106-125.

_1737007724117.webp)

_1736996330512.webp)