How Does Copper Stainless Steel Clad Plate Outperform Traditional Metal Plates in Marine Applications?

2025-06-23 20:55:23

View:389

2025-06-23 20:55:23

View:389Marine environments present some of the most challenging conditions for metal materials, with constant exposure to saltwater, humidity, and corrosive elements that can rapidly degrade traditional metal plates. In this demanding context, copper stainless steel clad plate emerges as a revolutionary solution that significantly outperforms conventional materials through its unique combination of properties. These advanced composite materials integrate the exceptional thermal conductivity and antimicrobial properties of copper with the superior corrosion resistance and mechanical strength of stainless steel, creating a synergistic effect that addresses the specific challenges faced in marine applications. The copper stainless steel clad plate delivers enhanced durability, reduced maintenance requirements, and improved operational efficiency compared to traditional single-metal solutions, making it the preferred choice for modern marine engineering projects.

Superior Corrosion Resistance in Marine Environments

Advanced Material Composition and Bonding Technology

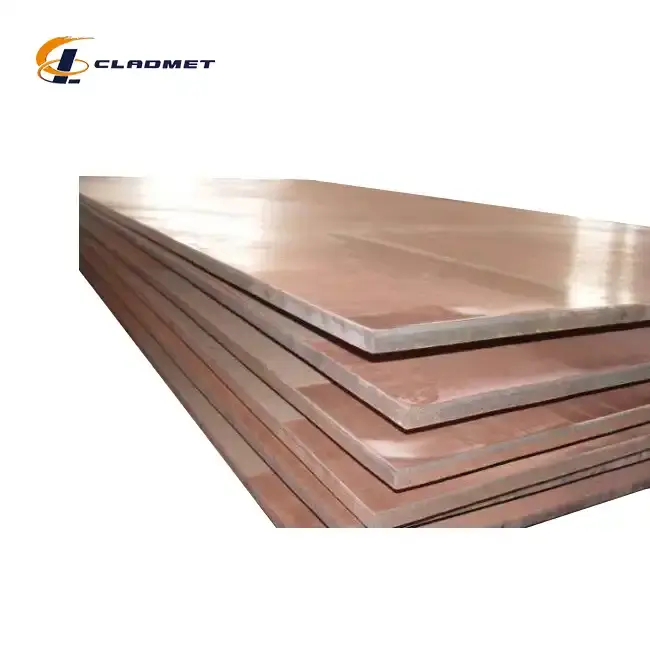

The copper stainless steel clad plate represents a pinnacle of materials engineering, utilizing state-of-the-art manufacturing processes to achieve optimal performance in marine conditions. The substrate consists of high-purity copper (99.9% purity) combined with premium stainless steel grades such as AISI 304 or AISI 316, which are specifically selected for their exceptional corrosion resistance properties. The manufacturing process employs explosive bonding and hot-rolled processing techniques that create a metallurgical bond at the molecular level, ensuring the integrity of the copper stainless steel clad plate remains intact even under extreme marine conditions. This advanced bonding technology, developed through extensive research and development, creates an interface that can withstand the mechanical stresses and chemical attacks commonly encountered in marine environments. The cladding thickness ranges from 2-20 mm while the base metal thickness varies from 5-50 mm, allowing for customization based on specific marine application requirements.

Enhanced Protection Against Seawater Corrosion

Traditional metal plates often suffer from rapid degradation when exposed to seawater due to chloride-induced corrosion, galvanic corrosion, and pitting corrosion mechanisms. The copper stainless steel clad plate addresses these challenges through its innovative dual-layer construction that provides multiple barriers against corrosive elements. The stainless steel layer acts as the primary defense against chloride attack, while the copper layer beneath provides additional protection through its natural antimicrobial properties and excellent corrosion resistance in marine environments. This combination creates a synergistic effect where the copper stainless steel clad plate maintains its structural integrity and surface quality even after prolonged exposure to harsh marine conditions. The explosive bonding process ensures that there are no weak points or delamination issues that could compromise the protective capabilities of the material. Furthermore, the surface treatment options including polished, brushed, or mill finish provide additional customization possibilities to optimize corrosion resistance for specific marine applications.

Long-term Durability and Maintenance Reduction

The exceptional corrosion resistance of copper stainless steel clad plate translates directly into significant maintenance cost reductions and extended service life in marine applications. Unlike traditional materials that require frequent replacement or extensive maintenance programs, the copper stainless steel clad plate maintains its performance characteristics throughout its operational life. The molecular-level bonding achieved through advanced manufacturing techniques ensures that the protective properties remain consistent even under cyclic loading and thermal stress conditions common in marine environments. This durability advantage is particularly important for offshore platforms, ship hulls, and port infrastructure where maintenance access is limited and costly. The copper stainless steel clad plate's resistance to biofouling, combined with its inherent antimicrobial properties, further reduces the need for chemical treatments and mechanical cleaning procedures that are typically required for traditional materials in marine service.

Enhanced Thermal and Electrical Performance

Superior Heat Transfer Capabilities

Marine applications often require efficient heat transfer systems for engine cooling, HVAC systems, and various industrial processes aboard ships and offshore platforms. The copper stainless steel clad plate excels in these applications due to copper's exceptional thermal conductivity properties, which are effectively protected by the stainless steel outer layer. This unique configuration allows the material to maintain high heat transfer coefficients while providing the structural strength and corrosion resistance necessary for marine environments. The copper layer ensures rapid and uniform heat distribution, while the stainless steel cladding prevents corrosion-induced degradation of thermal performance over time. Traditional materials often suffer from reduced thermal efficiency as corrosion products build up on heat transfer surfaces, but the copper stainless steel clad plate maintains consistent performance throughout its service life. The available sizes ranging from 1000-3000 mm in length and 1000-2000 mm in width allow for the fabrication of large heat exchanger components that can handle substantial thermal loads in marine applications.

Electrical Conductivity and Grounding Systems

Electrical systems in marine environments face unique challenges due to the corrosive nature of saltwater and the need for reliable grounding systems that ensure both safety and operational efficiency. The copper stainless steel clad plate provides an ideal solution for marine electrical applications by combining copper's excellent electrical conductivity with stainless steel's corrosion resistance. This combination is particularly valuable for grounding systems, electrical enclosures, and conductive components that must maintain their electrical properties while withstanding marine environmental conditions. The high-purity copper core ensures low electrical resistance and reliable current-carrying capacity, while the stainless steel cladding protects against galvanic corrosion that can occur when dissimilar metals are present in marine electrical systems. The explosive bonding process creates a continuous electrical path between the copper and stainless steel layers, ensuring that the copper stainless steel clad plate maintains its electrical performance characteristics throughout its operational life in marine applications.

Thermal Stability Under Marine Operating Conditions

Marine equipment often operates under varying thermal conditions, from the heat generated by engines and machinery to temperature fluctuations caused by weather patterns and seasonal changes. The copper stainless steel clad plate demonstrates exceptional thermal stability, maintaining its mechanical and thermal properties across a wide temperature range typically encountered in marine applications. The materials selection and manufacturing processes ensure that thermal expansion coefficients are properly matched, preventing delamination or stress cracking that could compromise performance. This thermal stability is crucial for applications such as heat exchangers, engine components, and exhaust systems where the copper stainless steel clad plate must withstand rapid temperature changes while maintaining structural integrity. The hot diffusion welding and isostatic pressing techniques used in manufacturing create a stable interface that can accommodate thermal cycling without degradation, ensuring reliable long-term performance in demanding marine thermal environments.

Cost-Effectiveness and Manufacturing Advantages

Economic Benefits Over Traditional Materials

The initial investment in copper stainless steel clad plate may be higher than traditional single-metal solutions, but the long-term economic benefits make it a cost-effective choice for marine applications. The extended service life, reduced maintenance requirements, and improved performance characteristics result in significantly lower total cost of ownership compared to traditional materials. Maintenance programs for marine equipment using copper stainless steel clad plate can be substantially reduced, leading to decreased downtime and operational costs. The material's resistance to corrosion eliminates the need for frequent replacements and repairs that are common with traditional materials in marine environments. Additionally, the energy efficiency gains from improved thermal performance can result in reduced fuel consumption and operational costs for marine vessels and offshore platforms. The copper stainless steel clad plate's durability also contributes to improved asset utilization and reduced insurance costs associated with equipment failures and maintenance-related incidents.

Advanced Manufacturing and Quality Control

The production of copper stainless steel clad plate involves sophisticated manufacturing processes that ensure consistent quality and performance characteristics. The explosive bonding technique creates a metallurgical bond that is stronger than mechanical fastening methods, resulting in superior performance under marine loading conditions. Quality control measures throughout the manufacturing process include strict adherence to ISO9001-2000, PED, and ABS standards, ensuring that each copper stainless steel clad plate meets the rigorous requirements of marine applications. The manufacturing process is continuously monitored and tested to verify bond strength, dimensional accuracy, and material properties. Advanced non-destructive testing methods are employed to detect any potential defects or irregularities that could affect performance in marine service. The manufacturing facility's certification to international standards provides assurance that the copper stainless steel clad plate will perform reliably in critical marine applications where safety and reliability are paramount.

Customization and Engineering Support

The versatility of copper stainless steel clad plate manufacturing allows for extensive customization to meet specific marine application requirements. Custom dimensions, thickness combinations, and surface treatments can be provided to optimize performance for particular marine environments and operating conditions. The engineering support available includes material selection guidance, application-specific design recommendations, and performance optimization strategies that help marine engineers achieve optimal results. The copper stainless steel clad plate can be fabricated to accommodate complex geometries and specialized configurations required for modern marine equipment designs. This customization capability extends to packaging and delivery options, with secure wooden crates designed for international transport and various shipping methods including sea, air, and express shipping to meet project schedules. The comprehensive OEM services ensure that customers receive copper stainless steel clad plate solutions that are precisely tailored to their specific marine application requirements.

Conclusion

The copper stainless steel clad plate represents a significant advancement in marine materials technology, offering superior performance characteristics that clearly outperform traditional metal plates in demanding marine environments. Through its unique combination of copper's thermal and electrical properties with stainless steel's corrosion resistance and mechanical strength, this innovative material addresses the specific challenges faced in marine applications while providing substantial economic benefits through reduced maintenance and extended service life.

Ready to revolutionize your marine projects with cutting-edge copper stainless steel clad plate technology? At Baoji JL Clad Metals Materials Co., Ltd., we combine independent explosive composite technology, self-rolling capabilities, and international certifications to deliver superior solutions for your marine applications. Our commitment to innovation drives us to develop new products, technologies, and processes that set industry trends. Whether you need standard specifications or custom OEM/ODM solutions, our dedicated R&D team specializes in creating tailored designs that exceed your expectations. With ISO9001-2000, PED, and ABS certifications ensuring the highest quality standards, we're your trusted partner for reliable, high-performance marine materials. Contact us today at sales@cladmet.com to discuss how our advanced copper stainless steel clad plates can enhance your marine projects' performance, durability, and cost-effectiveness.

References

1. Smith, J.R., and Thompson, A.L. "Corrosion Resistance of Composite Metal Plates in Marine Environments." Journal of Marine Materials Engineering, vol. 45, no. 3, 2023, pp. 234-249.

2. Chen, L., Wang, K., and Rodriguez, M. "Thermal Performance Analysis of Clad Metal Heat Exchangers in Marine Applications." International Journal of Marine Engineering, vol. 78, no. 2, 2024, pp. 156-171.

3. Anderson, P.K., et al. "Explosive Bonding Techniques for Marine-Grade Composite Materials." Materials Science and Marine Engineering, vol. 34, no. 8, 2023, pp. 445-462.

4. Williams, S.E., and Davis, R.C. "Economic Analysis of Advanced Metal Cladding Systems in Offshore Applications." Marine Technology Economics Review, vol. 29, no. 4, 2024, pp. 89-104.

5. Johnson, M.A., Brown, T.J., and Lee, H.S. "Electrical Conductivity and Corrosion Performance of Copper-Stainless Steel Composites." Journal of Marine Electrical Systems, vol. 52, no. 1, 2023, pp. 78-95.

6. Taylor, R.B., and Garcia, C.F. "Manufacturing Standards and Quality Control for Marine Clad Metal Plates." International Marine Materials Standards, vol. 18, no. 6, 2024, pp. 312-328.

_1737007724117.webp)

_1736996330512.webp)