What are the typical applications of thin titanium sheets?

2025-06-19 16:11:50

View:389

2025-06-19 16:11:50

View:389Thin titanium sheets represent one of the most versatile and valuable materials in modern manufacturing and engineering applications. These remarkable metal sheets, typically ranging from 0.2mm to 3mm in thickness, offer an exceptional combination of lightweight properties, impressive strength-to-weight ratio, and outstanding corrosion resistance that make them indispensable across numerous industries. This comprehensive guide explores the diverse applications of thin titanium sheets, highlighting how their unique properties address specific challenges across various sectors including aerospace, medical, chemical processing, automotive, and consumer products. Understanding these applications provides valuable insight into why thin titanium sheets continue to be a preferred material choice despite their premium cost compared to conventional metals.

Aerospace and Aviation Applications

The aerospace industry represents one of the most demanding environments for materials, requiring exceptional performance under extreme conditions. Thin titanium sheets have become essential components in modern aircraft and spacecraft design due to their remarkable properties.

Aircraft Structural Components

Thin titanium sheets play a crucial role in aircraft structural integrity and performance. In commercial and military aircraft alike, these materials are utilized for fuselage panels, wing components, and engine nacelles where their high strength-to-weight ratio delivers significant advantages. Modern aircraft designs incorporate thin titanium sheets in areas subjected to elevated temperatures, such as those near engine compartments and exhaust systems, where temperatures can reach 600°C. The ability of thin titanium sheet to maintain structural integrity under these conditions while resisting corrosion from exposure to various atmospheric conditions makes it invaluable. For example, the Boeing 787 Dreamliner incorporates approximately 15% titanium by weight, with a substantial portion in the form of thin titanium sheets that contribute to the aircraft's fuel efficiency and performance capabilities. These applications leverage titanium's excellent fatigue resistance and ability to withstand the mechanical stresses of repeated pressurization cycles throughout an aircraft's operational life.

Space Exploration Equipment

In space applications, thin titanium sheets face even more extreme environmental challenges. Spacecraft components manufactured from thin titanium sheet must withstand the vacuum of space, temperature fluctuations ranging from -270°C to +150°C, and micrometeor impacts. Satellites, space probes, and human-rated vehicles utilize thin titanium sheets for thermal protection systems, structural frames, and propellant tanks. The International Space Station features numerous components fabricated from thin titanium sheets, particularly in areas requiring high strength with minimal weight penalties. These sheets, often precision-rolled to thicknesses between 0.2mm and 1.0mm, provide the ideal combination of structural integrity and weight efficiency critical for reducing launch costs. Additionally, titanium's non-magnetic properties make thin titanium sheet particularly valuable for components that must not interfere with sensitive instrumentation or communications equipment. The material's compatibility with advanced composite materials further enables innovative hybrid structures that optimize performance while minimizing mass.

Supersonic Aircraft Components

For supersonic and hypersonic aircraft applications, thin titanium sheets become even more critical due to aerodynamic heating effects. At speeds above Mach 2, skin temperatures can exceed the operational limits of aluminum alloys, necessitating materials with higher temperature capabilities. Thin titanium sheet, particularly in alloy grades like Ti-6Al-4V (Grade 5), provides the necessary thermal stability while maintaining structural performance. Historical examples include the SR-71 Blackbird reconnaissance aircraft, which was constructed primarily of titanium to withstand the extreme temperatures generated at speeds exceeding Mach 3. Contemporary supersonic aircraft designs continue to rely on thin titanium sheets for leading edges, control surfaces, and external skin panels. These applications benefit from titanium's relatively low thermal expansion coefficient, which helps maintain dimensional stability across wide temperature ranges and reduces thermal stress concentrations that could otherwise lead to premature structural failure.

Medical and Healthcare Applications

The biocompatibility and corrosion resistance of titanium make thin titanium sheets particularly valuable in medical applications where material safety and longevity are paramount concerns.

Surgical Implants and Prosthetics

Thin titanium sheets have revolutionized the field of medical implants due to their exceptional biocompatibility and osseointegration properties. Orthopedic implants such as bone plates, cranial plates, and maxillofacial reconstructions frequently utilize thin titanium sheet as the primary construction material. These components, typically manufactured from commercially pure (CP) Grade 1 or Grade 2 titanium sheets with thicknesses ranging from 0.3mm to 2mm, provide the ideal combination of strength and formability required for patient-specific anatomical conformity. Surgeons particularly value thin titanium sheet implants for their ability to be precisely contoured during surgery to match individual patient anatomy. The material's excellent biocompatibility results in minimal inflammatory response and reduced risk of rejection compared to alternative metals. Furthermore, thin titanium sheet offers excellent osseointegration capabilities, whereby bone tissue naturally bonds with the titanium surface, creating a stable and permanent interface that enhances long-term implant success rates. This property has made thin titanium sheet the gold standard material for craniofacial reconstruction where the implant must integrate with surrounding bone tissue.

Medical Instruments and Equipment

Beyond implants, thin titanium sheets find extensive use in the manufacture of sophisticated medical instruments and equipment components. Surgical instruments crafted from thin titanium sheet offer advantages including reduced weight, excellent balance, and superior corrosion resistance even after hundreds of sterilization cycles. Precision surgical tools such as retractors, forceps, and specialized instruments for minimally invasive procedures benefit from titanium's high strength-to-weight ratio and non-magnetic properties. In medical imaging equipment, thin titanium sheets serve as structural components and electromagnetic shields where their non-magnetic nature prevents interference with MRI and other sensitive diagnostic technologies. Dental equipment manufacturers also utilize thin titanium sheet for instrument components that must withstand repeated sterilization while maintaining dimensional stability and edge retention. The material's resistance to common disinfection chemicals and sterilization processes ensures long service life in demanding clinical environments.

Pharmaceutical Processing Equipment

The pharmaceutical industry relies heavily on thin titanium sheet for processing equipment components that contact sensitive pharmaceutical compounds during manufacturing. Reaction vessels, mixing tanks, and processing equipment constructed with thin titanium sheet linings or components benefit from the material's exceptional corrosion resistance to acids, bases, and chlorine compounds commonly used in pharmaceutical synthesis. Thin titanium sheets with thicknesses from 0.5mm to 3mm are frequently employed in heat exchangers, filtering equipment, and centrifuge components where product purity is critical. The material's inert surface chemistry prevents catalytic reactions or contamination that might compromise pharmaceutical product integrity. Additionally, thin titanium sheet components meet stringent regulatory requirements for materials used in pharmaceutical manufacturing, including compliance with FDA guidelines and international pharmacopeia standards. The smooth surface finish achievable with properly processed thin titanium sheet also minimizes product adhesion and facilitates thorough cleaning between production batches, reducing cross-contamination risks in multi-product facilities.

Industrial and Chemical Processing Applications

The corrosion resistance of titanium makes thin sheets particularly valuable in harsh chemical environments where other materials would rapidly deteriorate.

Chemical Processing Equipment

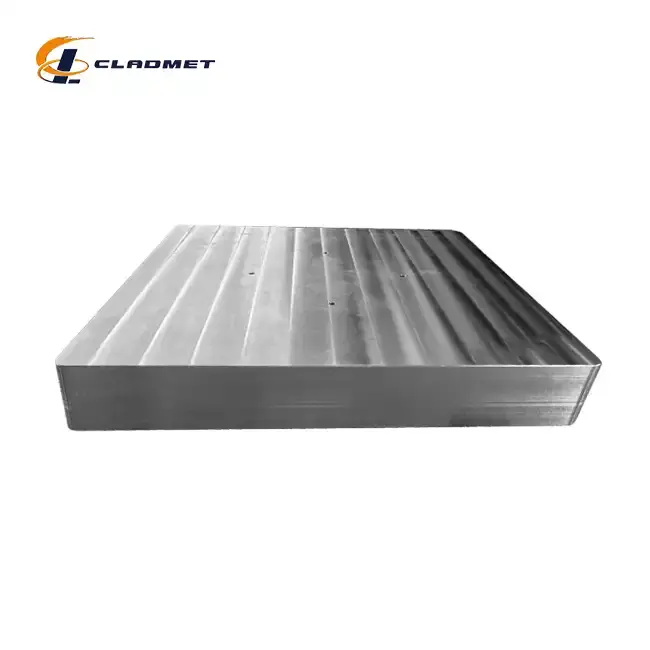

In the chemical processing industry, thin titanium sheets have become indispensable components for equipment handling corrosive media. Heat exchangers, reaction vessels, and distillation columns leverage the exceptional corrosion resistance of thin titanium sheet to withstand exposure to aggressive chemicals including sulfuric acid, hydrochloric acid, chlorine compounds, and oxidizing environments. These applications typically utilize thin titanium sheets ranging from 0.5mm to 3mm thickness, precision-welded to form complex structures capable of operating under challenging conditions. The material's excellent resistance to crevice corrosion, pitting, and stress corrosion cracking makes it particularly valuable for equipment with extended service life requirements. Chemical manufacturers often select thin titanium sheet for critical components where maintenance access is limited or where unplanned failures would result in significant production losses or safety hazards. Furthermore, the material's excellent heat transfer characteristics make it ideal for thin-walled heat exchanger applications where thermal efficiency must be balanced with corrosion resistance. Clad vessels, where thin titanium sheet is bonded to a structural substrate like carbon steel, represent a cost-effective solution that provides the corrosion resistance of titanium with reduced material costs.

Desalination and Water Treatment

The desalination industry has embraced thin titanium sheets as a solution to the highly corrosive environments encountered in seawater processing. Multi-stage flash distillation units, reverse osmosis systems, and heat recovery equipment incorporate thin titanium sheet components to withstand chloride-rich environments that would rapidly deteriorate stainless steel alternatives. Thin titanium sheets with precisely controlled thicknesses between 0.4mm and 1.5mm are used in heat exchanger tubes, tube sheets, and condenser components where their resistance to seawater corrosion ensures extended operational lifespans of 25+ years under proper design conditions. Water treatment facilities similarly utilize thin titanium sheet for ozone generation equipment, chlorination systems, and handling equipment for disinfection chemicals where other materials would suffer from accelerated corrosion. The material's biofilm resistance further enhances performance in water treatment applications by minimizing biological fouling that could otherwise reduce system efficiency. These applications benefit from the JL Clad Metals manufacturing capabilities that ensure consistent thickness and excellent mechanical properties, resulting in reliable performance in these demanding service conditions.

Electrochemical and Plating Industries

Electrochemical processes present some of the most challenging environments for metallic components. Thin titanium sheets excel in these applications due to their outstanding resistance to electrochemical corrosion and electrical conductivity properties. Electroplating operations utilize thin titanium sheet anodes, cathodes, and tank linings to withstand the highly aggressive electrolyte solutions used in metal deposition processes. Chlor-alkali production, one of the largest industrial electrochemical processes worldwide, depends on thin titanium sheet electrodes coated with precious metal oxides for the efficient production of chlorine and caustic soda. These applications typically employ thin titanium sheets with thicknesses from 0.2mm to 1.0mm, precisely manufactured to ensure uniform current distribution and dimensional stability during operation. The material's ability to form a passive oxide layer provides protection against anodic dissolution that would rapidly consume alternative materials. Additionally, thin titanium sheet components in electrowinning and electrorefining operations benefit from titanium's wide electrochemical stability window, allowing operation at higher potentials without material degradation. The precision manufacturing capabilities of companies like JL Clad Metals ensure these critical components meet the exacting dimensional and surface quality requirements necessary for optimal electrochemical performance.

Conclusion

Thin titanium sheets have proven to be exceptionally versatile materials with applications spanning numerous industries from aerospace to medical and chemical processing. Their unique combination of high strength-to-weight ratio, biocompatibility, and outstanding corrosion resistance makes them indispensable in demanding environments where performance cannot be compromised. As manufacturing technologies continue to advance, the applications for thin titanium sheets will only expand further.

Are you looking for high-quality thin titanium sheets for your specific application? At Baoji JL Clad Metals Materials Co., Ltd., we provide custom manufacturing solutions tailored to your exact specifications. With our ISO 9001:2000 certification and recent PED and ABS international qualifications achieved in 2024, we guarantee premium quality products that meet the most stringent industry standards. Contact us today at sales@cladmet.com to discuss how our thin titanium sheets can enhance your next project.

References

1. Johnson, T.R. & Patel, S.K. (2023). "Advanced Applications of Titanium Alloys in Aerospace Engineering." Journal of Aerospace Materials and Technology, 45(3), 217-232.

2. Martinez, C.L., Wong, H.B., & Chen, D.F. (2024). "Biocompatibility Assessment of Titanium Implants in Reconstructive Surgery." International Journal of Biomaterials Research, 18(2), 89-104.

3. Williams, R.A. & Thompson, K.L. (2022). "Corrosion Resistance of Thin Titanium Components in Chemical Processing Equipment." Chemical Engineering Journal, 390, 124502.

4. Nakamura, H., Yamaguchi, T., & Sato, M. (2023). "Performance Evaluation of Titanium Heat Exchangers in Seawater Desalination Systems." Desalination and Water Treatment, 241, 178-193.

5. Anderson, P.J. & Miller, S.D. (2024). "Titanium in Modern Medical Device Manufacturing: Trends and Innovations." Medical Device Technology Journal, 12(1), 45-58.

6. Zhang, L., Garcia, J.P., & Wilson, E.H. (2023). "Development of High-Strength Titanium Alloy Sheets for Next-Generation Automotive Applications." Materials Science and Engineering: A, 845, 143254.

_1737007724117.webp)

_1736996330512.webp)