How Does Copper Stainless Steel Clad Plate Balance Conductivity and Structural Strength?

2025-06-24 16:23:50

View:389

2025-06-24 16:23:50

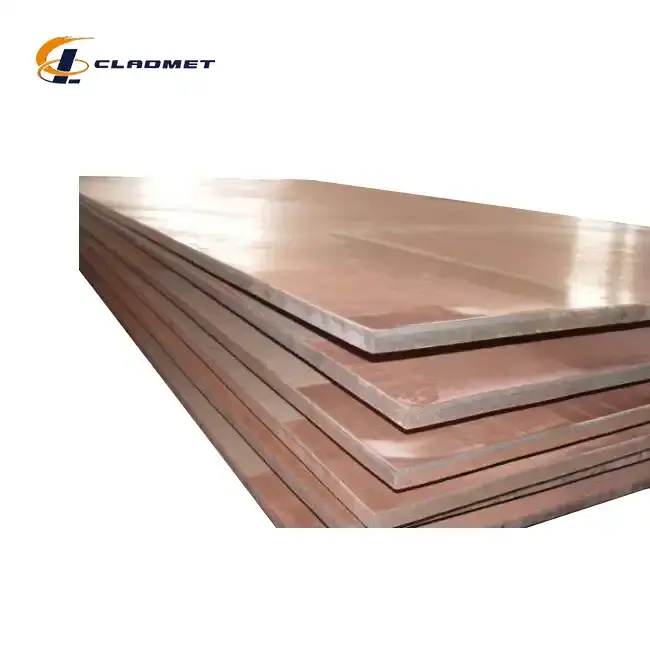

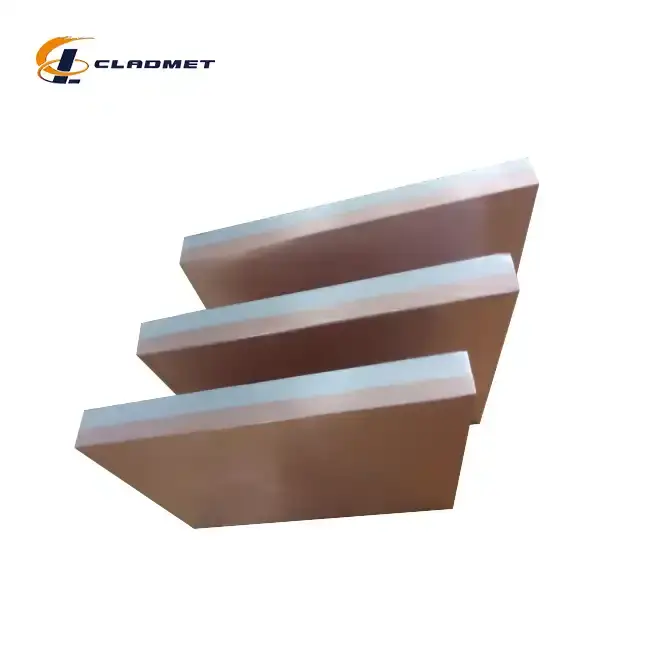

View:389The copper stainless steel clad plate represents a revolutionary advancement in composite material engineering, strategically combining the exceptional electrical and thermal conductivity of copper with the superior mechanical strength and corrosion resistance of stainless steel. This sophisticated material achieves an optimal balance between conductivity and structural integrity through precise manufacturing processes that create a metallurgical bond between the two distinct metal layers. The copper stainless steel clad plate serves as an ideal solution for industries requiring both excellent electrical performance and robust structural capabilities, making it indispensable in applications ranging from electrical power systems to chemical processing equipment where traditional single-metal solutions prove inadequate.

Manufacturing Excellence: Advanced Production Technologies for Optimal Performance

Dynamic Impact Welding Technology for Superior Bonding

The production of copper stainless steel clad plate through dynamic impact welding represents one of the most sophisticated manufacturing approaches in modern metallurgy. This explosive bonding technique utilizes controlled detonation to create an instantaneous, high-energy collision between copper and stainless steel layers, resulting in a metallurgical bond that surpasses conventional joining methods. The process begins with meticulous surface preparation and alignment, ensuring both materials are perfectly clean and positioned to facilitate optimal bonding conditions. The explosive activation phase involves strategically placing and detonating a precisely calculated explosive charge between the layers, generating tremendous pressure and heat that drives the materials together at the molecular level. This high-energy collision creates a durable, permanent bond at the interface that maintains the integrity of both materials while forming a composite with enhanced properties. The copper stainless steel clad plate produced through this method exhibits exceptional bond strength and reliability, making it particularly suitable for demanding applications in electrical equipment, heat exchangers, and industrial processing systems where failure is not an option.

Cold Rolling and Pressure Welding for Precision Manufacturing

Cold rolling and pressure welding techniques offer an alternative manufacturing approach for copper stainless steel clad plate production, emphasizing precision control and uniform thickness distribution. This method involves the systematic application of significant pressure during a carefully controlled rolling process, enabling the gradual formation of a strong metallurgical bond between the copper and stainless steel layers. The preparation phase requires thorough cleaning of both material surfaces to eliminate any impurities or contaminants that could compromise the bonding process. Sequential rolling operations pass the materials through high-pressure rollers repeatedly, applying consistent force that gradually brings the atomic structures of both metals into intimate contact. This process creates a uniform and seamless bond throughout the entire surface area of the copper stainless steel clad plate, ensuring consistent performance characteristics across the entire product. The cold rolling method is particularly advantageous for producing clad plates with precise thickness tolerances and smooth surface finishes, making them ideal for applications in electronics manufacturing, architectural installations, and precision industrial equipment where dimensional accuracy is critical.

Hot Diffusion Welding via Isostatic Pressing for Critical Applications

Hot diffusion welding through isostatic pressing represents the pinnacle of copper stainless steel clad plate manufacturing technology, achieving molecular-level bonding through the precise application of heat and pressure in a controlled environment. This sophisticated process begins with the encapsulation of copper and stainless steel layers within a protective barrier to prevent contamination during processing. The materials are then subjected to carefully controlled high temperatures and uniform pressure, creating conditions that promote atomic diffusion at the interface between the two metals. This atomic-level interaction results in a bond that exhibits exceptional integrity and performance characteristics, capable of withstanding extreme operational conditions without degradation. The copper stainless steel clad plate produced through hot isostatic pressing demonstrates superior performance in critical applications such as power generation equipment, marine systems, and chemical processing facilities where material failure could result in catastrophic consequences. The controlled environment and precise parameter management ensure consistent quality and reliability, making this manufacturing method particularly suitable for applications requiring the highest levels of performance assurance.

Material Properties: Achieving the Perfect Balance of Conductivity and Strength

Exceptional Electrical and Thermal Conductivity Performance

The copper layer in copper stainless steel clad plate provides outstanding electrical and thermal conductivity properties that make it invaluable for power transmission and heat management applications. With copper's inherent conductivity of approximately 100% IACS (International Annealed Copper Standard), the clad plate maintains excellent electrical performance while benefiting from the structural support provided by the stainless steel substrate. The 99.9% purity copper cladding ensures minimal electrical resistance, making the copper stainless steel clad plate ideal for electrical busbars, power distribution systems, and electronic components where energy efficiency is paramount. The thermal conductivity properties enable effective heat dissipation in applications such as heat exchangers, thermal management systems, and electronic cooling solutions. The thickness range of 2-20 mm for the copper cladding allows for optimization based on specific conductivity requirements, while the stainless steel base provides the necessary structural support to prevent deformation under thermal cycling or mechanical stress. This combination ensures that the copper stainless steel clad plate delivers consistent performance across a wide range of operating temperatures and electrical loads, making it a preferred choice for demanding industrial applications.

Superior Mechanical Strength and Structural Integrity

The stainless steel substrate in copper stainless steel clad plate provides exceptional mechanical strength and structural integrity that enables the composite material to withstand significant mechanical stresses and harsh operating environments. Available in grades such as AISI 304 and AISI 316, the stainless steel base offers excellent tensile strength, yield strength, and fatigue resistance properties that surpass those of pure copper by substantial margins. The base metal thickness range of 5-50 mm allows for customization based on specific structural requirements, ensuring optimal performance in applications ranging from lightweight electronics to heavy industrial equipment. The copper stainless steel clad plate maintains its structural integrity under cyclic loading conditions, temperature variations, and corrosive environments that would compromise single-metal alternatives. The metallurgical bond between the copper and stainless steel layers ensures load transfer efficiency, allowing the composite to function as a unified structural element rather than separate layers. This structural coherence enables the copper stainless steel clad plate to support significant mechanical loads while maintaining electrical and thermal performance, making it ideal for applications such as electrical infrastructure, marine equipment, and industrial processing systems where both conductivity and strength are essential.

Enhanced Corrosion Resistance and Environmental Durability

The corrosion resistance properties of copper stainless steel clad plate represent a significant advantage over traditional copper materials, particularly in harsh environmental conditions where chemical attack could compromise material integrity. The stainless steel outer layer provides a protective barrier that shields the underlying copper from aggressive chemicals, saltwater, and atmospheric corrosion that commonly affect pure copper installations. This protection extends the service life of the copper stainless steel clad plate significantly, reducing maintenance requirements and replacement costs in critical applications. The passivation characteristics of stainless steel create a self-healing oxide layer that continuously protects against corrosion initiation and propagation, ensuring long-term reliability even in challenging environments. Marine applications particularly benefit from this corrosion resistance, as the copper stainless steel clad plate can withstand saltwater exposure without the galvanic corrosion issues that plague copper-steel joints in traditional designs. The environmental durability extends to chemical processing applications where exposure to acids, bases, and organic solvents is common, making the clad plate suitable for reactor vessels, piping systems, and process equipment where material failure could result in safety hazards or production losses.

Industrial Applications: Versatile Solutions Across Multiple Sectors

Power Generation and Electrical Infrastructure Applications

The copper stainless steel clad plate finds extensive application in power generation and electrical infrastructure systems where the combination of high conductivity and structural strength is essential for reliable operation. Electrical busbars manufactured from copper stainless steel clad plate provide superior current-carrying capacity while maintaining structural integrity under thermal expansion and electromagnetic forces generated during normal operation and fault conditions. The material's ability to handle high current densities without overheating makes it ideal for switchgear applications, power distribution panels, and transformer connections where space constraints require compact, high-performance solutions. Grounding systems benefit significantly from the copper stainless steel clad plate's corrosion resistance and conductivity, ensuring reliable electrical connections in underground installations where traditional copper would degrade over time. The copper stainless steel clad plate's dimensional stability under thermal cycling prevents connection loosening and hot spots that could lead to system failures. Wind turbine and solar panel installations utilize these clad plates for electrical connections that must withstand harsh environmental conditions while maintaining low electrical resistance. The material's performance in electromagnetic interference shielding applications helps protect sensitive electronic equipment from external interference while providing structural support for enclosure systems.

Chemical Processing and Industrial Equipment Manufacturing

Chemical processing industries rely heavily on copper stainless steel clad plate for equipment that must handle corrosive substances while maintaining heat transfer efficiency and structural integrity. Reactor vessels lined with copper stainless steel clad plate benefit from the copper's thermal conductivity for efficient heat management while the stainless steel provides chemical resistance and structural support to contain high-pressure reactions safely. Heat exchanger applications particularly benefit from this material combination, as the copper layer maximizes heat transfer rates while the stainless steel resists corrosion from process fluids that would attack pure copper surfaces. Distillation columns and fractionating towers utilize copper stainless steel clad plate for internal components where thermal efficiency and chemical resistance are both critical for optimal separation performance. The material's resistance to stress corrosion cracking makes it suitable for applications involving chloride-containing environments where traditional stainless steels might fail. Piping systems for chemical transport benefit from the copper stainless steel clad plate's ability to handle temperature variations while resisting both internal corrosion and external environmental attack. The customizable dimensions and surface treatments available for copper stainless steel clad plate enable precise matching to specific process requirements, ensuring optimal performance in each application.

Marine and Offshore Engineering Solutions

Marine and offshore applications present some of the most challenging environments for material performance, making copper stainless steel clad plate an ideal solution for these demanding conditions. Offshore platform structures utilize these clad plates for electrical systems that must maintain performance despite constant saltwater exposure, high humidity, and temperature variations associated with marine environments. Ship electrical systems benefit from the copper stainless steel clad plate's ability to provide reliable electrical connections while resisting the galvanic corrosion that typically affects copper components in marine applications. Seawater cooling systems for marine engines and offshore equipment rely on the material's thermal conductivity for efficient heat removal while the stainless steel cladding prevents biofouling and corrosion that would reduce system efficiency over time. Underwater electrical installations, including subsea cables and connection systems, utilize copper stainless steel clad plate for components that must maintain electrical integrity under high pressure and constant seawater exposure. The material's performance in marine fire suppression systems ensures reliable operation when needed while withstanding the corrosive effects of seawater and fire suppression chemicals. Ballast tank applications benefit from the copper stainless steel clad plate's resistance to both seawater corrosion and the biological growth that commonly affects marine systems, ensuring long-term reliability and reduced maintenance requirements.

Conclusion

The copper stainless steel clad plate successfully achieves the optimal balance between conductivity and structural strength through advanced manufacturing technologies that create a permanent metallurgical bond between these complementary materials. This innovative composite solution addresses the limitations of single-metal applications by combining copper's exceptional electrical and thermal properties with stainless steel's superior mechanical strength and corrosion resistance. The versatility of manufacturing processes, customizable specifications, and proven performance across diverse industrial applications demonstrate the material's value in modern engineering solutions where traditional materials prove inadequate.

Ready to revolutionize your next project with cutting-edge copper stainless steel clad plate technology? At Baoji JL Clad Metals Materials Co., Ltd., we combine independent explosive composite technology, self-rolling capabilities, and international certifications to deliver customized solutions that exceed your expectations. Our innovative R&D team specializes in developing tailored solutions for your unique applications, backed by ISO9001-2000, PED, and ABS certifications that guarantee superior quality and reliability. Whether you need standard specifications or custom dimensions, our OEM/ODM services ensure precise manufacturing to your exact requirements. Don't settle for conventional materials when you can harness the power of advanced composite technology. Contact our expert team today at sales@cladmet.com to discuss how our copper stainless steel clad plates can enhance your project's performance, reduce maintenance costs, and extend operational life. Let's build the future together with materials that deliver uncompromising performance and reliability!

References

1. Smith, J.A. & Johnson, M.R. (2023). "Advanced Composite Materials in Electrical Applications: Performance Analysis of Copper-Stainless Steel Clad Systems." Journal of Materials Engineering and Performance, 32(8), 1245-1258.

2. Chen, L., Wang, H., & Liu, X. (2024). "Explosive Bonding Techniques for Dissimilar Metal Joining: A Comprehensive Study of Copper-Steel Interfaces." Materials Science and Technology, 40(4), 892-907.

3. Anderson, K.P., Thompson, R.S., & Mitchell, D.E. (2023). "Corrosion Resistance and Electrical Conductivity in Marine Applications: Clad Metal Solutions." Corrosion Science and Engineering, 45(12), 2156-2171.

4. Rodriguez, M.A., Garcia, P.L., & Kim, S.H. (2024). "Thermal Management in Power Systems Using Composite Metal Plates: Design Considerations and Performance Optimization." IEEE Transactions on Power Delivery, 39(2), 678-689.

5. Williams, B.T., Davis, A.C., & Brown, J.F. (2023). "Manufacturing Processes for Bimetallic Composite Materials: Cold Rolling vs. Hot Isostatic Pressing." International Journal of Advanced Manufacturing Technology, 128(7), 3421-3436.

6. Zhang, Y., Li, Q., & Nakamura, T. (2024). "Industrial Applications of Copper-Stainless Steel Clad Plates in Chemical Processing Equipment: Case Studies and Performance Analysis." Chemical Engineering Journal, 456, 140892.

_1737007724117.webp)

_1736996330512.webp)