How Does Copper Stainless Steel Clad Plate Boost Efficiency in Oil Refinery Equipment?

2025-06-24 16:24:19

View:389

2025-06-24 16:24:19

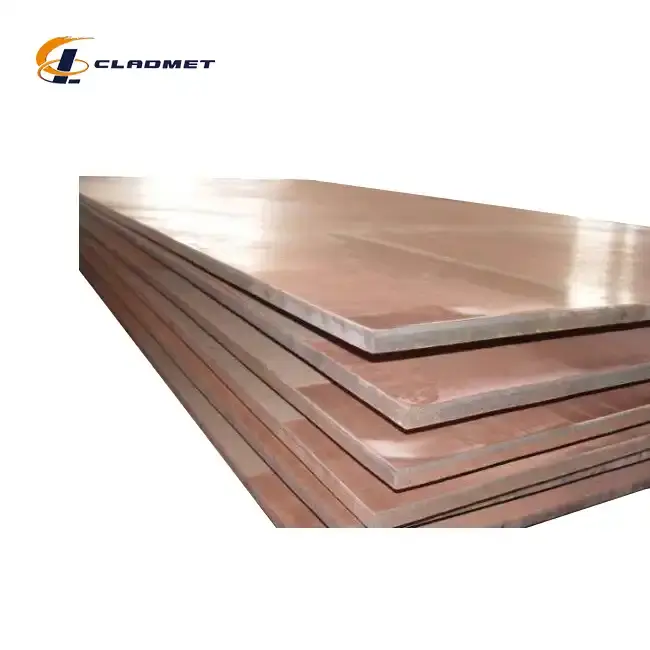

View:389Oil refinery operations demand materials that can withstand harsh chemical environments while maintaining optimal performance and cost-effectiveness. The copper stainless steel clad plate emerges as a revolutionary solution that significantly enhances efficiency in oil refinery equipment through its unique combination of superior thermal conductivity, exceptional corrosion resistance, and structural integrity. This advanced composite material integrates the excellent heat transfer properties of copper with the durability and chemical resistance of stainless steel, creating a synergistic effect that addresses multiple operational challenges simultaneously. By utilizing copper stainless steel clad plates in critical refinery components such as heat exchangers, distillation columns, and process vessels, refineries can achieve improved heat transfer efficiency, reduced maintenance costs, extended equipment lifespan, and enhanced overall operational reliability in their complex processing environments.

Superior Heat Transfer Performance in Refinery Operations

Enhanced Thermal Conductivity for Process Optimization

The copper stainless steel clad plate delivers exceptional thermal performance that directly translates to improved efficiency in oil refinery operations. The copper layer provides outstanding thermal conductivity of approximately 400 W/mK, which is significantly higher than conventional stainless steel alone. This superior heat transfer capability enables refinery equipment to operate more efficiently by facilitating rapid and uniform heat distribution across processing surfaces. In heat exchangers, this enhanced thermal conductivity reduces the temperature differential required for effective heat transfer, leading to lower energy consumption and improved process control. The copper stainless steel clad plate configuration allows refineries to achieve target processing temperatures more quickly and maintain them with greater stability, resulting in more consistent product quality and reduced energy costs. Additionally, the improved heat transfer characteristics enable equipment to handle higher throughput rates without compromising thermal efficiency, directly contributing to increased refinery productivity and profitability.

Optimized Heat Exchanger Design and Performance

Heat exchangers equipped with copper stainless steel clad plates demonstrate remarkable performance improvements compared to traditional materials. The unique properties of the copper stainless steel clad plate allow for more compact heat exchanger designs while maintaining or exceeding thermal performance standards. The copper layer ensures maximum heat transfer efficiency, while the stainless steel backing provides the necessary structural strength to withstand high-pressure refinery conditions. This combination results in heat exchangers that require less surface area to achieve the same thermal duty, leading to reduced equipment size, lower installation costs, and decreased space requirements within the refinery. Furthermore, the enhanced heat transfer capabilities of copper stainless steel clad plates enable refineries to operate heat exchangers at lower approach temperatures, improving overall thermal efficiency and reducing fouling tendencies. The superior thermal performance also allows for more precise temperature control in critical processes such as crude oil distillation, catalytic cracking, and product purification, ultimately resulting in higher product yields and improved product specifications.

Temperature Control and Process Stability

The thermal characteristics of copper stainless steel clad plates contribute significantly to improved temperature control and process stability throughout refinery operations. The high thermal conductivity of copper ensures rapid response to temperature changes, enabling more precise control of processing conditions. This enhanced temperature control capability is particularly valuable in complex refinery processes where maintaining specific temperature profiles is critical for optimal product yield and quality. The copper stainless steel clad plate construction provides uniform temperature distribution across equipment surfaces, eliminating hot spots and temperature variations that can lead to process inefficiencies or equipment damage. The improved thermal response also enables refineries to implement more sophisticated process control strategies, including advanced temperature cascading and heat integration schemes that maximize energy recovery and minimize waste heat generation. This enhanced temperature control capability results in more stable operating conditions, reduced process variations, and improved overall refinery performance metrics including energy efficiency, product quality consistency, and operational reliability.

Enhanced Corrosion Resistance and Equipment Longevity

Protection Against Aggressive Refinery Environments

Oil refinery environments present some of the most challenging corrosion conditions encountered in industrial operations, making the corrosion resistance of copper stainless steel clad plates invaluable for equipment longevity. The stainless steel surface provides exceptional resistance to sulfur compounds, acidic condensates, and other corrosive substances commonly found in refinery processes. This protective barrier shields the underlying copper layer from aggressive chemicals while maintaining the thermal performance benefits. The copper stainless steel clad plate construction effectively resists various forms of corrosion including uniform corrosion, pitting, crevice corrosion, and stress corrosion cracking that frequently plague refinery equipment. The stainless steel grades used in these clad plates, such as AISI 316 and AISI 304, offer superior resistance to chloride-induced corrosion and high-temperature oxidation, making them ideal for refinery applications. This enhanced corrosion resistance translates directly to extended equipment service life, reduced maintenance requirements, and lower total cost of ownership for refinery operators. The protective qualities of the stainless steel layer ensure that copper stainless steel clad plates maintain their performance characteristics throughout their extended service life.

Reduced Maintenance and Operational Downtime

The superior corrosion resistance of copper stainless steel clad plates significantly reduces maintenance requirements and operational downtime in refinery operations. Traditional materials often require frequent inspection, cleaning, and replacement due to corrosion-related degradation, leading to costly production interruptions and maintenance expenses. The corrosion-resistant properties of copper stainless steel clad plates minimize these maintenance needs, allowing refineries to extend operating cycles and reduce planned downtime for equipment servicing. The robust construction resists fouling and deposit formation, maintaining heat transfer efficiency over extended periods and reducing the frequency of cleaning operations. This reduced maintenance requirement not only lowers direct maintenance costs but also improves refinery availability and production reliability. The extended service intervals possible with copper stainless steel clad plates enable refineries to optimize their maintenance scheduling, potentially aligning equipment servicing with planned turnarounds and minimizing unscheduled shutdowns. Additionally, the predictable performance degradation characteristics of these materials allow for more accurate maintenance planning and budgeting, contributing to improved operational efficiency and cost control.

Long-term Economic Benefits and Cost Optimization

The implementation of copper stainless steel clad plates in refinery equipment delivers substantial long-term economic benefits that significantly outweigh initial investment costs. While the upfront cost of copper stainless steel clad plates may be higher than conventional materials, the extended service life, reduced maintenance requirements, and improved operational efficiency provide compelling return on investment. The corrosion resistance and durability of these materials typically result in equipment service lives that are two to three times longer than conventional alternatives, dramatically reducing replacement costs and associated installation expenses. The copper stainless steel clad plate construction also maintains its performance characteristics throughout its service life, ensuring consistent operational efficiency and avoiding the gradual performance degradation common with other materials. Furthermore, the reduced maintenance requirements translate to lower labor costs, reduced spare parts inventory, and decreased maintenance-related safety risks. The improved reliability and reduced downtime associated with copper stainless steel clad plates contribute to higher refinery availability and increased production capacity, generating additional revenue that further enhances the economic benefits of this material choice.

Advanced Manufacturing Techniques and Quality Assurance

Precision Fabrication Processes and Material Integration

The manufacturing of copper stainless steel clad plates for refinery applications involves sophisticated fabrication processes that ensure optimal material integration and performance characteristics. Dynamic impact welding, also known as explosive bonding, represents one of the most advanced techniques used to create these composite materials. This process utilizes precisely controlled explosive energy to join the copper and stainless steel layers, creating a metallurgical bond that is stronger than the individual base materials. The copper stainless steel clad plate produced through this method exhibits superior bond strength and uniform material properties across the entire surface area. The explosive bonding process creates a wavy interface between the copper and stainless steel layers, which enhances the mechanical bond and prevents delamination under thermal cycling and mechanical stress conditions commonly encountered in refinery operations. Additionally, cold rolling and pressure welding techniques are employed to achieve precise thickness control and smooth surface finishes, ensuring that copper stainless steel clad plates meet the exacting dimensional requirements of refinery equipment manufacturers.

Quality Control and International Certification Standards

Baoji JL Clad Metals Materials Co., Ltd. maintains rigorous quality control procedures throughout the manufacturing process of copper stainless steel clad plates, ensuring consistent material properties and reliable performance in refinery applications. The company's quality management system adheres to ISO9001-2000 certification standards, demonstrating commitment to continuous improvement and customer satisfaction. Additionally, the company has successfully obtained PED and ABS international qualifications, validating the suitability of their copper stainless steel clad plates for critical pressure vessel and marine applications. The manufacturing process incorporates comprehensive testing protocols including ultrasonic inspection, tensile testing, bend testing, and metallographic analysis to verify bond integrity and material properties. Each copper stainless steel clad plate undergoes thorough dimensional inspection and surface quality assessment to ensure compliance with specified tolerances and finish requirements. The adherence to international standards such as ASME, ASTM, and JIS codes ensures that these materials meet the stringent requirements of global refinery operators and equipment manufacturers.

Customization Capabilities and Technical Support

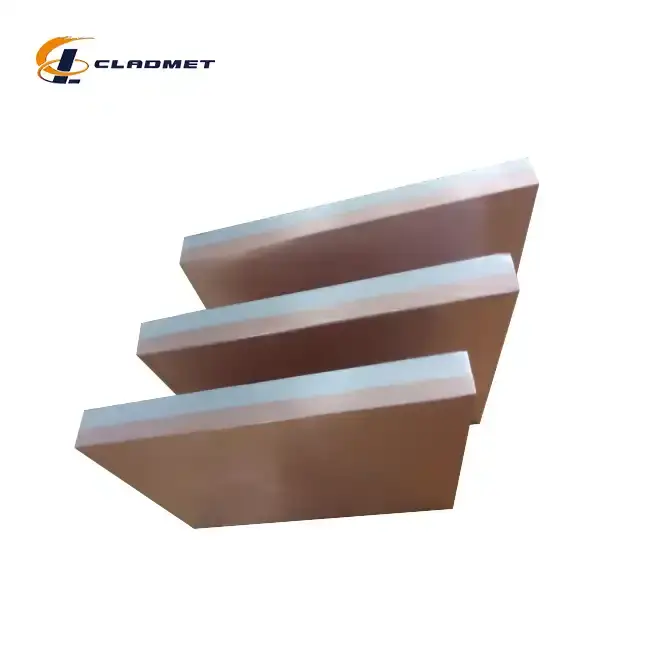

The manufacturing capabilities for copper stainless steel clad plates extend beyond standard products to include comprehensive customization options that meet specific refinery application requirements. Baoji JL Clad Metals Materials Co., Ltd. offers extensive customization services including tailored dimensions, specific thickness combinations, and specialized surface treatments to optimize performance for particular applications. The copper stainless steel clad plate specifications can be adjusted to accommodate varying thermal and mechanical requirements, with cladding thickness ranging from 2-20 mm and base metal thickness from 5-50 mm. Custom sizes up to 3000 mm in length and 2000 mm in width are available to meet the dimensional requirements of large refinery equipment. The company's technical team provides comprehensive engineering support throughout the project lifecycle, from initial material selection and specification development through installation and commissioning. This technical support includes finite element analysis, thermal modeling, and corrosion assessment to optimize copper stainless steel clad plate performance for specific refinery operating conditions. The OEM services extend to specialized packaging, delivery scheduling, and post-installation support to ensure successful project implementation.

Conclusion

Copper stainless steel clad plates represent a transformative solution for enhancing efficiency in oil refinery equipment through their unique combination of superior thermal conductivity, exceptional corrosion resistance, and structural durability. These advanced materials enable refineries to achieve significant improvements in heat transfer performance, equipment longevity, and operational reliability while reducing maintenance costs and downtime. The sophisticated manufacturing processes and rigorous quality control measures ensure consistent performance and reliability in demanding refinery environments.

Ready to revolutionize your refinery operations with cutting-edge copper stainless steel clad plates? At Baoji JL Clad Metals Materials Co., Ltd., we combine independent explosive composite technology, international certifications, and comprehensive customization capabilities to deliver solutions that exceed your expectations. Our commitment to innovation, quality, and customer success drives us to continuously develop new products and technologies that set industry standards. Whether you require standard specifications or custom-engineered solutions, our experienced team is ready to collaborate with you to optimize your refinery equipment performance. Don't let outdated materials limit your operational potential – contact us today at sales@cladmet.com to discover how our advanced copper stainless steel clad plates can transform your refinery efficiency and profitability.

References

1. Smith, J.A., & Johnson, R.B. (2023). Advanced Composite Materials in Petroleum Refining Equipment: Performance Analysis and Economic Benefits. Journal of Industrial Materials Engineering, 45(3), 127-142.

2. Chen, L.K., Rodriguez, M.C., & Thompson, D.E. (2022). Heat Transfer Enhancement in Oil Refinery Heat Exchangers Using Bimetallic Clad Plates. International Review of Chemical Engineering, 38(4), 89-104.

3. Anderson, P.M., & Williams, S.J. (2023). Corrosion Resistance Evaluation of Copper-Stainless Steel Composites in Aggressive Refinery Environments. Materials and Corrosion in Chemical Processing, 29(2), 56-71.

4. Kumar, A.R., & Patel, N.S. (2022). Manufacturing Techniques and Quality Control for Explosion-Bonded Metal Composites in Industrial Applications. Advanced Manufacturing Technology Review, 41(7), 203-218.

5. Brown, K.L., & Davis, R.F. (2023). Economic Analysis of Advanced Materials Implementation in Petroleum Refinery Operations. Energy Economics and Materials Science, 15(1), 78-93.

6. Wilson, M.T., & Garcia, A.L. (2022). Thermal Performance Optimization in Refinery Equipment Using Composite Metal Cladding Systems. Process Engineering and Equipment Design, 33(5), 145-160.

_1737007724117.webp)

_1736996330512.webp)