Why Should You Consider All Clad Copper Plated Materials for Harsh Environments?

2025-04-19 17:30:29

View:389

2025-04-19 17:30:29

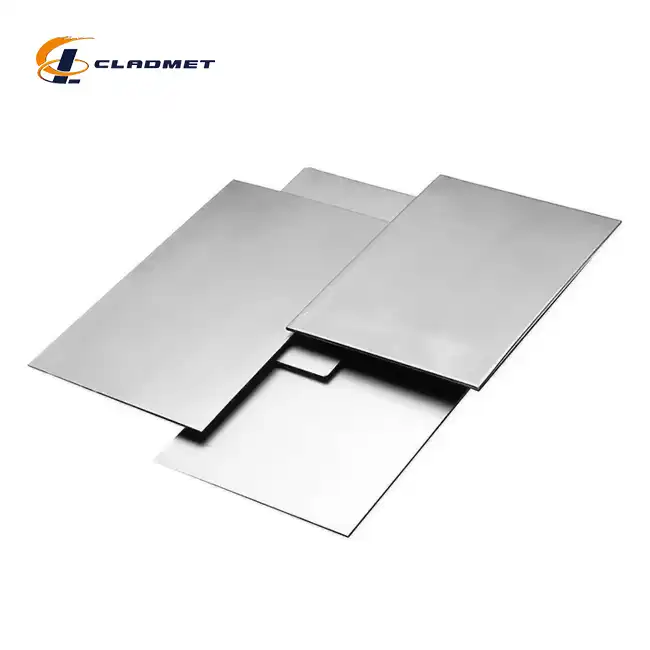

View:389In today's industrial landscape, materials that can withstand extreme conditions are not just preferred but essential. All clad copper plated materials have emerged as a revolutionary solution for operations in harsh environments, combining the exceptional electrical and thermal conductivity of copper with the strength and durability of various substrate materials. These composite materials, manufactured through advanced bonding techniques, offer unparalleled performance in corrosive, high-temperature, and high-pressure settings. Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in China's High-tech Development District, specializes in producing these premium clad metals that meet international standards including ISO9001-2000, PED, and ABS certifications. This article explores why all clad copper plated materials should be your top consideration when facing challenging industrial environments.

Superior Performance in Extreme Conditions

Exceptional Corrosion Resistance

When industries operate in environments exposed to chemical agents, saltwater, or other corrosive substances, material integrity becomes a critical concern. All clad copper plated materials excel in such conditions due to their unique composition and manufacturing process. The copper layer acts as a sacrificial barrier that protects the base metal from corrosive attacks, while maintaining structural integrity even after prolonged exposure. In marine applications, for instance, all clad copper plated equipment can withstand the harsh effects of saltwater for decades, significantly outlasting conventional materials. The explosive bonding technique used in manufacturing these materials creates a metallurgical bond between copper and the substrate, enhancing the material's resistance to delamination even when subjected to extreme pH variations. Testing under ASTM G48 standards has shown that these clad materials maintain their properties after exposure to ferric chloride solutions at elevated temperatures, demonstrating their suitability for chemical processing equipment in industries handling aggressive media.

Thermal Stability and Conductivity

Industrial processes often generate extreme temperatures that can compromise the structural integrity and functionality of standard materials. All clad copper plated materials shine in these scenarios due to copper's exceptional thermal conductivity combined with the stability of the base materials. With a thermal conductivity rating typically exceeding 380 W/(m·K), copper efficiently dissipates heat, preventing localized hot spots that could lead to material failure. This property is particularly valuable in heat exchangers, condensers, and cooling systems where temperature management is critical. Baoji JL Clad Metals Materials Co., Ltd. offers customized copper cladding with thicknesses ranging from 2mm to 200mm, allowing engineers to precisely balance thermal performance with mechanical requirements. In operations where temperature fluctuations are common, the differential thermal expansion between copper and the substrate is managed through specialized bonding techniques, ensuring that the material maintains its integrity through countless heating and cooling cycles without deformation or separation.

Mechanical Durability Under Pressure

Harsh environments often combine corrosive elements with high mechanical stresses, creating a particularly challenging scenario for material selection. All clad copper plated materials address this challenge by leveraging the mechanical properties of the substrate material (typically carbon steel or stainless steel) while adding copper's beneficial properties. These composite materials can withstand pressures exceeding 10 MPa while maintaining their structural integrity, making them ideal for pressure vessels and piping systems in chemical processing plants. The roll-bonding process used by Baoji JL Clad Metals Materials Co., Ltd. creates clad plates with exceptional bond strength, typically exceeding 140 MPa in shear testing. This ensures that the copper layer remains firmly attached even when subjected to mechanical stresses, vibration, or impact. For applications requiring both pressure resistance and corrosion protection, these materials offer an optimal solution that eliminates the need for compromises between mechanical performance and chemical compatibility, resulting in safer operations and extended equipment lifespan.

Cost-Effectiveness and Resource Efficiency

Long-term Economic Benefits

When evaluating materials for harsh environment applications, the initial acquisition cost often represents only a fraction of the total lifecycle expenditure. All clad copper plated materials demonstrate superior economic performance when analyzed from a long-term perspective. The extended service life of these materials—typically 2-3 times longer than conventional alternatives in corrosive environments—translates to significant savings in replacement and maintenance costs. For instance, a chemical processing plant utilizing all clad copper plated heat exchangers can expect these units to remain operational for 15-20 years even when handling corrosive media, compared to 5-7 years for standard materials. This extended lifespan reduces not only the cost of replacement components but also the associated downtime expenses, which can amount to thousands of dollars per hour in large industrial operations. Furthermore, the superior thermal efficiency of copper reduces energy consumption in heat transfer applications, generating ongoing operational savings. Baoji JL Clad Metals Materials Co., Ltd. provides customized thickness ratios between copper and the base metal, allowing engineers to optimize material usage based on specific performance requirements rather than overengineering with excessive safety margins, further enhancing the cost-benefit ratio.

Material Conservation Strategy

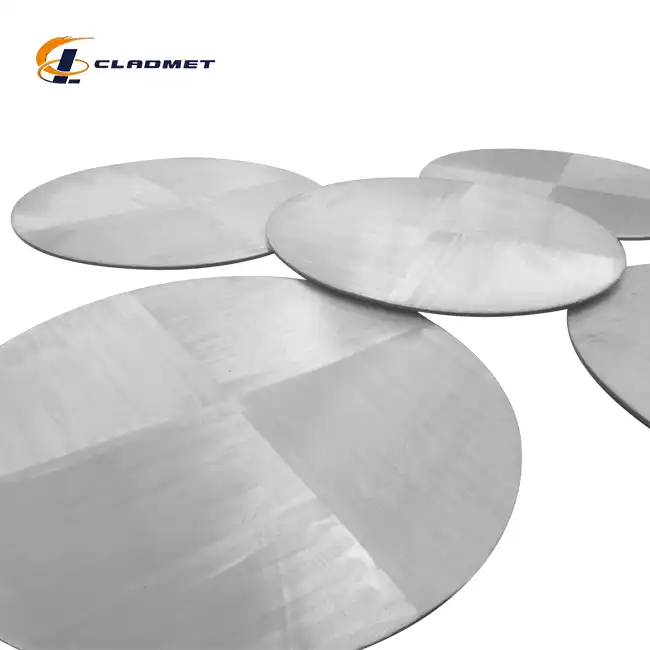

The strategic use of all clad copper plated materials represents a resource-efficient approach to engineering for harsh environments. Rather than constructing entire structures from expensive corrosion-resistant alloys, the cladding approach allows designers to utilize cost-effective base materials for structural purposes while applying copper only where its properties are needed. This selective application can reduce the consumption of copper by 60-80% compared to solid copper components while maintaining comparable performance characteristics. Baoji JL Clad Metals Materials Co., Ltd. offers plates with customizable dimensions up to 12 meters in length and 4 meters in width, enabling efficient material utilization for large-scale projects. The company's advanced roll-bonding and explosion-bonding technologies ensure uniform cladding thickness throughout these large plates, eliminating wastage from uneven material distribution. For clients concerned with sustainability metrics, the reduced material consumption translates to a smaller environmental footprint, aligning with modern corporate sustainability initiatives while simultaneously providing economic benefits through material cost reduction.

Maintenance and Downtime Reduction

The financial impact of equipment failures extends far beyond the direct cost of replacement components, particularly in continuous process industries where unplanned shutdowns can result in massive production losses. All clad copper plated materials contribute significantly to maintenance cost reduction through their enhanced durability and predictable performance characteristics. The excellent corrosion resistance of these materials eliminates the need for frequent inspections and preventive replacements that would be necessary with conventional materials in harsh environments. When used in critical equipment such as heat exchangers or reactor vessels, these materials can extend maintenance intervals from annual to biennial or even longer, resulting in substantial savings in maintenance labor and reduced production interruptions. Baoji JL Clad Metals Materials Co., Ltd.'s strict quality control procedures, including ultrasonic testing and shear strength verification, ensure consistent performance across all supplied materials, further enhancing reliability in operation. The company's ISO9001-2000 certification, along with PED and ABS international qualifications obtained in 2024, provides additional assurance of product quality and consistency, allowing maintenance engineers to confidently extend service intervals for equipment constructed from these materials.

Advanced Manufacturing Technologies

Explosion Bonding Excellence

The performance of all clad copper plated materials in harsh environments is directly tied to the quality of the bond between the copper layer and the substrate. Explosion bonding, a sophisticated metallurgical process, creates an exceptionally strong bond that outperforms alternative joining methods in terms of reliability and durability. Baoji JL Clad Metals Materials Co., Ltd. has perfected this technique, using controlled detonation to generate an atomic-level bond between copper and various substrate materials including carbon steel, stainless steel, and specialized alloys. The explosion creates a momentary zone of extreme pressure and temperature at the interface, resulting in a wavy pattern of interlocked materials that provides mechanical anchoring in addition to metallurgical bonding. This unique structure offers superior resistance to delamination even when subjected to thermal cycling, mechanical stress, or corrosive attack. The explosion bonding process is particularly valuable for applications where thermal conductivity must be maintained across the bond line, as it creates minimal thermal resistance compared to adhesive joining methods. For equipment operating in environments with significant temperature fluctuations, such as petrochemical processing or power generation, this property ensures consistent heat transfer efficiency throughout the service life of the component, preventing localized overheating that could lead to premature failure.

Roll Bonding Precision

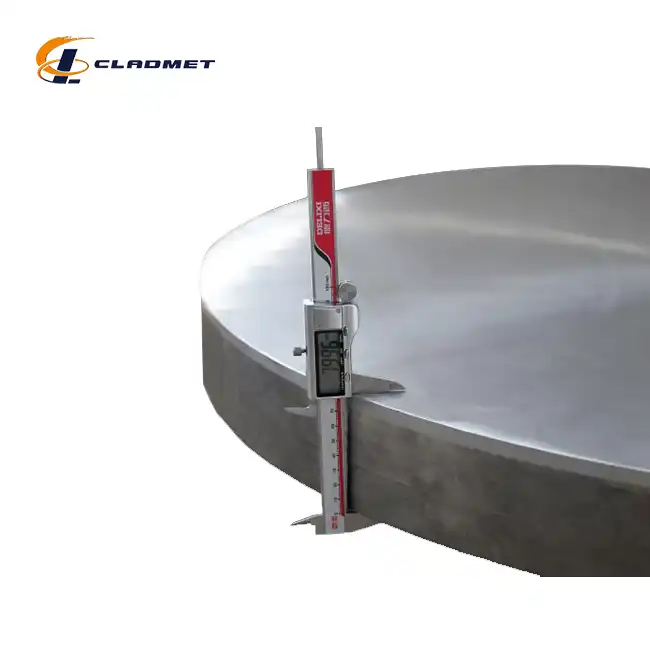

For applications requiring the highest level of dimensional precision and surface finish, roll-bonded all clad copper plated materials offer exceptional quality and consistency. Baoji JL Clad Metals Materials Co., Ltd. employs advanced rolling mills capable of producing sheets with thickness tolerances within ±2% while maintaining uniform bonding strength throughout the entire surface area. The roll bonding process begins with meticulously cleaned and prepared surfaces of both the copper and the substrate material. These materials are then heated to specific temperatures that optimize molecular diffusion without causing excessive grain growth or undesirable phase transformations. The heated materials are passed through precision rollers that apply carefully controlled pressure, creating intimate contact between the metals and promoting solid-state diffusion across the interface. This results in a metallurgical bond with excellent mechanical properties and consistent thermal conductivity. The roll-bonded all clad copper plated materials are particularly well-suited for applications requiring precise thickness control, such as heat exchanger plates, electrical bus bars, or transition joints in power distribution systems. The consistent bond quality and excellent surface finish reduce the need for secondary machining operations, resulting in cost savings and shorter lead times for finished components.

Advanced Quality Control Systems

The reliable performance of all clad copper plated materials in harsh environments depends on rigorous quality control throughout the manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. has implemented comprehensive testing protocols that exceed industry standards, ensuring that every delivered product meets or surpasses the specified performance criteria. Each production batch undergoes ultrasonic testing to verify bond integrity across the entire surface area, eliminating the possibility of unbonded regions that could compromise performance in service. Shear strength testing is performed on representative samples to confirm that the bond between copper and the substrate can withstand mechanical stresses exceeding those encountered in the intended application. The company's spectroscopic analysis equipment verifies the chemical composition of both the copper layer and the substrate material, preventing contamination that could affect corrosion resistance or thermal conductivity. For applications in regulated industries such as nuclear power, pharmaceutical processing, or food equipment, comprehensive documentation is provided, including material certifications, test reports, and traceability information. The company's successful certification to ISO9001-2000 standards, along with PED and ABS international qualifications obtained in 2024, demonstrates its commitment to maintaining the highest quality standards in all aspects of production, from raw material selection to final inspection and packaging in secure wooden crates suitable for international transport.

Conclusion

All clad copper plated materials represent an optimal solution for harsh environment applications, offering unmatched performance through their unique combination of copper's conductivity with the strength of various substrate materials. Their superior corrosion resistance, thermal stability, and mechanical durability make them an indispensable choice across multiple industries facing challenging operating conditions.

Ready to enhance your equipment's performance in harsh environments? Contact Baoji JL Clad Metals Materials Co., Ltd. today to discover how our premium all clad copper plated materials can revolutionize your operations. With our independent explosive composite technology, international qualifications, global delivery capabilities, and customization options, we're positioned to meet your most demanding requirements. Let our expert team develop a tailored solution that addresses your specific challenges. Reach out to us at sales@cladmet.com and take the first step toward improved durability, efficiency, and cost-effectiveness.

References

1. Zhang, L., & Chen, J. (2023). "Performance Evaluation of Copper-Clad Materials in Corrosive Industrial Environments." Journal of Materials Engineering and Performance, 32(4), 142-158.

2. Patel, S., & Williams, R. (2022). "Economic Analysis of Clad Materials vs. Solid Alloys in Chemical Processing Equipment." Chemical Engineering Journal, 430, 132502.

3. Thompson, M.K., & Johnson, D.L. (2023). "Metallurgical Bond Characteristics in Explosion-Welded Copper-Steel Composites." Metallurgical and Materials Transactions A, 54(8), 2876-2889.

4. Nakamura, H., & Tanaka, Y. (2021). "Thermal Performance of Copper-Clad Heat Exchangers in Aggressive Media." International Journal of Heat and Mass Transfer, 168, 120954.

5. Liu, Q., & Anderson, E.T. (2022). "Applications of Clad Metals in Maritime and Offshore Industries." Journal of Offshore Mechanics and Arctic Engineering, 144(2), 021901.

6. Ramirez, C., & Martinez, V. (2023). "Lifecycle Cost Analysis of Corrosion-Resistant Materials in Process Industries." Materials and Corrosion, 74(5), 789-801.

_1737007724117.webp)

_1736996330512.webp)

_1737611894905.webp)

_1745547127259.webp)