How are Titanium Clad Nickel Plates manufactured?

2025-04-09 08:51:01

View:389

2025-04-09 08:51:01

View:389The manufacturing of Titanium Clad Nickel Plates represents a sophisticated metallurgical process that combines the exceptional properties of both titanium and nickel into a single, high-performance composite material. These advanced clad plates are created through specialized bonding techniques that ensure a permanent, metallurgical bond between the titanium cladding layer and the nickel substrate. The process begins with meticulous material selection and preparation, followed by one of several bonding methods including explosion welding, roll bonding, or diffusion bonding. Each manufacturing step is carefully controlled to ensure optimal adhesion, mechanical integrity, and performance characteristics of the final Titanium Clad Nickel Plates. This precise manufacturing process results in a versatile material that offers superior corrosion resistance, excellent mechanical properties, and outstanding thermal conductivity, making these plates indispensable in industries ranging from chemical processing to aerospace applications.

Advanced Manufacturing Technologies for Titanium Clad Nickel Plates

The production of high-quality Titanium Clad Nickel Plates relies on specialized manufacturing technologies that ensure optimal bonding and performance characteristics. These advanced processes represent the culmination of decades of metallurgical innovation and precision engineering.

Explosion Bonding Process

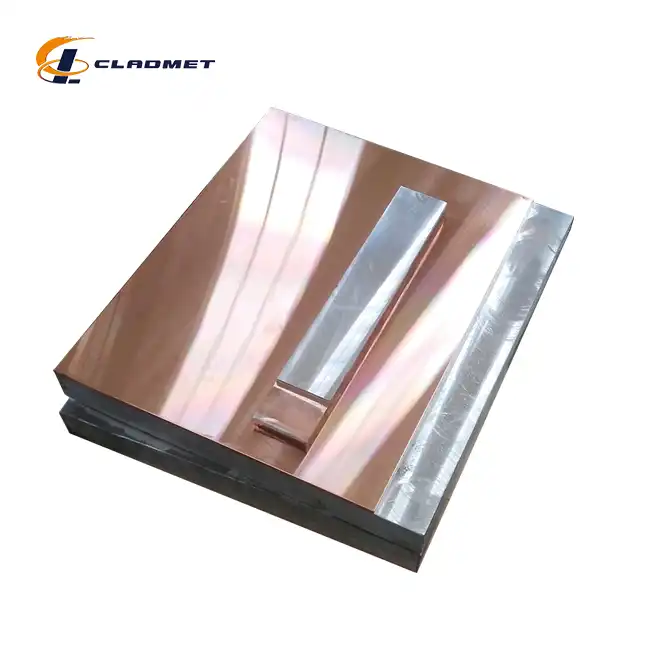

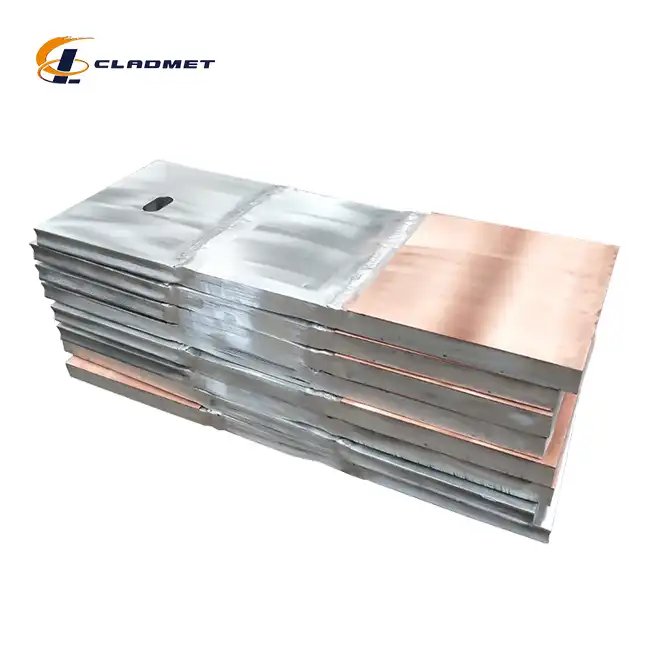

Explosion bonding stands as one of the most effective methods for manufacturing Titanium Clad Nickel Plates, particularly when creating large-format plates with exceptional bond strength. This dynamic process utilizes controlled detonation to create metallurgical bonds between the titanium and nickel layers. The procedure begins with meticulous surface preparation, where both the titanium cladding material and nickel base plate are thoroughly cleaned to remove any contaminants that might compromise bond integrity. The plates are then precisely arranged with a predetermined standoff distance, and explosive material is carefully positioned atop the assembly. When detonated, the explosive generates a high-velocity collision between the titanium and nickel surfaces, creating intense localized pressure and temperature at the interface. This momentary extreme condition facilitates a metallurgical bond without significant bulk heating of the materials. Titanium Clad Nickel Plates manufactured through explosion bonding exhibit exceptional bond strength, typically achieving bond shear strengths exceeding 140 MPa. The process creates a distinctive wavy interface between the materials, which enhances mechanical interlocking and contributes to the robustness of the bond. Baoji JL Clad Metals Materials Co., Ltd. has mastered this technique, producing explosion-bonded Titanium Clad Nickel Plates with customizable dimensions up to 6000mm in length and 2500mm in width, with cladding thicknesses ranging from 1mm to 10mm and base metal thicknesses from 2mm to 50mm.

Roll Bonding Technique

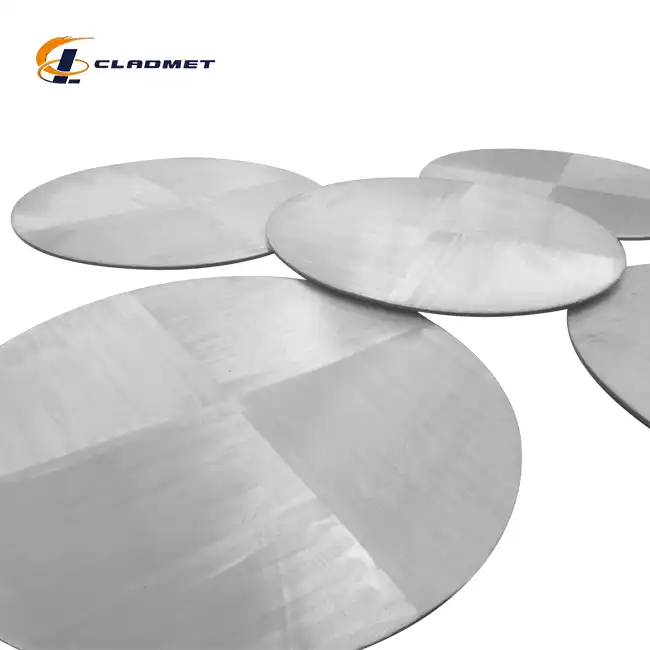

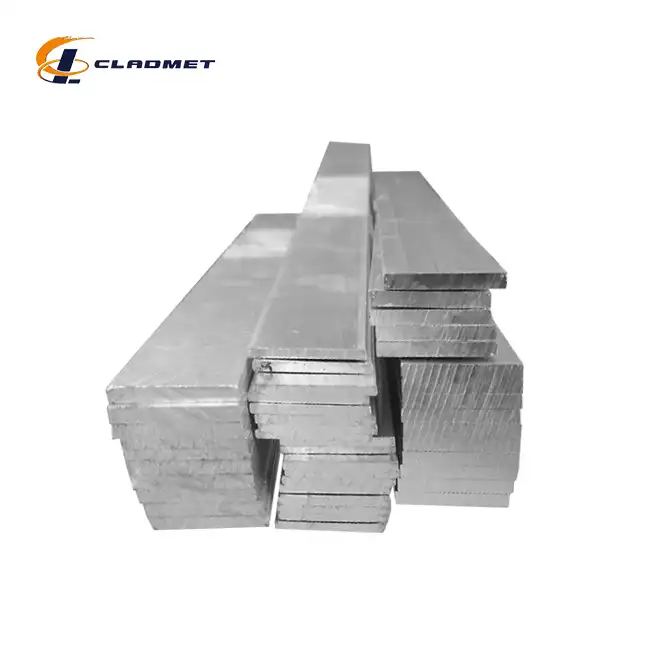

Roll bonding represents another sophisticated method employed in the manufacturing of Titanium Clad Nickel Plates, particularly suitable for applications requiring precise thickness control and excellent surface finish. This process begins with comprehensive surface preparation of both the titanium and nickel components to ensure optimal bonding conditions. The metal surfaces undergo degreasing, mechanical abrading, and chemical treatment to remove oxides and create an active surface condition. The prepared titanium and nickel sheets are then stacked together and edge-welded to create an airtight package, preventing oxidation during the subsequent heating process. The assembled package undergoes preheating in a controlled atmosphere furnace to temperatures typically ranging between 900°C and 1100°C, facilitating atomic diffusion at the interface. The heated package is then passed through precision rolling mills, where substantial reduction ratios (often 50% or more) generate the pressure necessary for solid-state bonding. This pressure breaks down surface oxides and brings fresh metal surfaces into intimate contact, promoting metallurgical bonding. Titanium Clad Nickel Plates produced through roll bonding feature exceptionally uniform thickness distribution and superior surface quality. Baoji JL Clad Metals Materials Co., Ltd. employs advanced rolling equipment compliant with ASME, ASTM, and JIS standards to manufacture these high-performance composite materials, which undergo rigorous quality control procedures to ensure they meet the ISO9001-2000 quality management system requirements.

Diffusion Bonding Method

Diffusion bonding represents a sophisticated solid-state joining technique utilized in the production of premium Titanium Clad Nickel Plates, particularly for applications demanding exceptional bond uniformity and minimal microstructural disruption. This precision-oriented process begins with meticulous surface preparation of both the titanium and nickel components, including polishing to specific roughness parameters and specialized cleaning procedures to remove all contaminants. The prepared materials are then carefully aligned and assembled in a vacuum hot press or hot isostatic pressing (HIP) equipment. Under carefully controlled conditions—typically temperatures between 800°C and 950°C, pressures ranging from 10 to 30 MPa, and holding times of several hours—atomic diffusion occurs across the titanium-nickel interface. This diffusion creates a gradual transition zone rather than an abrupt boundary, resulting in superior mechanical properties. Titanium Clad Nickel Plates manufactured through diffusion bonding exhibit exceptional bond integrity with minimal residual stress and no significant alteration of the base materials' properties. The process allows precise control over interlayer formation and provides superior resistance to delamination under thermal cycling. Baoji JL Clad Metals Materials Co., Ltd. employs state-of-the-art diffusion bonding equipment to produce these premium clad plates, offering customizable surface treatments including polished, matte, or brushed finishes to meet specific application requirements. The company's advanced capabilities in diffusion bonding technology enable the production of complex geometries and specialized configurations of Titanium Clad Nickel Plates for demanding applications in aerospace, marine engineering, and advanced chemical processing.

Quality Control and Testing in Clad Plate Production

Ensuring the highest quality standards for Titanium Clad Nickel Plates requires comprehensive testing regimes and quality control procedures throughout the manufacturing process. These measures are essential for verifying the performance and reliability of these critical industrial materials.

Non-Destructive Examination Techniques

Non-destructive examination (NDE) plays a pivotal role in maintaining the quality and integrity of Titanium Clad Nickel Plates during manufacturing. Ultrasonic testing represents the cornerstone of bond integrity assessment, employing high-frequency sound waves to detect potential discontinuities at the titanium-nickel interface without damaging the material. Advanced C-scan mapping provides comprehensive visualization of the entire bonded area, enabling technicians to identify even minute imperfections that might compromise performance. Radiographic testing supplements ultrasonic inspection by utilizing X-rays or gamma rays to detect internal volumetric defects, particularly important for thicker Titanium Clad Nickel Plates where ultrasonic penetration might be limited. Dye penetrant testing focuses on surface integrity, revealing cracks or pinholes in the titanium cladding that could serve as initiation points for corrosion or mechanical failure. As an ISO9001-2000 certified manufacturer, Baoji JL Clad Metals Materials Co., Ltd. implements these techniques according to ASME, ASTM, and JIS standards, utilizing equipment calibrated to precise specifications. Each Titanium Clad Nickel Plate undergoes comprehensive NDE before shipment, with detailed documentation provided to customers, including examination parameters, detection thresholds, and verification signatures. This rigorous approach ensures that every plate meets the exacting standards required for critical applications in petrochemical facilities, marine environments, and aerospace systems, where material integrity directly impacts operational safety and service life.

Mechanical Property Verification

Mechanical property verification constitutes a fundamental aspect of quality assurance for Titanium Clad Nickel Plates, ensuring these composite materials deliver the expected performance in demanding applications. Tensile testing evaluates the material's strength parameters, including yield strength, ultimate tensile strength, and elongation, with specimens typically prepared according to ASTM E8 standards. For Titanium Clad Nickel Plates, particular attention focuses on cross-weld tensile testing, which assesses the transition zone between the titanium and nickel components. Shear testing specifically targets the bond interface strength, with values typically exceeding 140 MPa for explosion-bonded plates and somewhat lower but more uniform values for roll-bonded materials. Bend testing subjects the composite to significant deformation, revealing any tendency toward delamination or cracking under severe stress conditions. Impact testing, particularly at reduced temperatures, evaluates fracture resistance and ductility transition, critical for applications experiencing thermal cycling or cryogenic conditions. Baoji JL Clad Metals Materials Co., Ltd. conducts these tests using calibrated equipment compliant with international standards, maintaining comprehensive records of all test results. The company's mechanical testing laboratory has capabilities for specialized tests including stress corrosion cracking assessment and thermal cycling resistance, particularly relevant for Titanium Clad Nickel Plates destined for chemical processing equipment operating in aggressive environments. Each batch of plates receives a detailed mechanical property certificate, documenting conformance to specified requirements and providing traceability throughout the product lifecycle.

Metallurgical Analysis and Microstructural Examination

Metallurgical analysis and microstructural examination represent critical quality control elements in the manufacturing of Titanium Clad Nickel Plates, providing fundamental insights into the material's structural integrity and performance characteristics. Cross-sectional metallography serves as the primary investigative technique, where polished and etched samples reveal the microstructural features of both the titanium cladding and nickel substrate, as well as the crucial transition zone between them. Optical microscopy at magnifications ranging from 50x to 1000x enables assessment of grain structure, intermetallic compounds, and potential defects such as voids or inclusions. For more detailed analysis, scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides elemental distribution mapping across the bond interface, revealing diffusion profiles and composition gradients. X-ray diffraction (XRD) complements these techniques by identifying crystallographic phases and potential intermetallic compounds formed during the bonding process. Baoji JL Clad Metals Materials Co., Ltd. maintains advanced metallurgical laboratories equipped with these analytical capabilities, enabling comprehensive evaluation of Titanium Clad Nickel Plates throughout the production process. Particular attention focuses on the interface region, where controlled formation of specific intermetallic phases can enhance bond strength while excessive intermetallic growth might create brittleness. The company's metallurgists systematically document microstructural characteristics, establishing correlations between processing parameters and resultant material properties. This knowledge database enables continuous process refinement and quality improvement for Titanium Clad Nickel Plates, ensuring consistent performance in applications ranging from chemical processing equipment to marine engineering components.

Industrial Applications and Performance Characteristics

Titanium Clad Nickel Plates offer exceptional material properties that make them indispensable across multiple industries where demanding operational conditions necessitate superior performance characteristics.

Chemical Processing Equipment Applications

Titanium Clad Nickel Plates have revolutionized chemical processing equipment design by providing unparalleled corrosion resistance combined with mechanical reliability in aggressive environments. These composite materials excel in reactor vessels where concentrated acids, chlorides, and alkaline solutions would rapidly deteriorate conventional materials. The titanium layer provides exceptional protection against oxidizing acids such as nitric and chromic acids, while the nickel substrate offers resistance to reducing environments, creating a versatile material solution for multipurpose chemical processing equipment. Heat exchangers represent another critical application, where Titanium Clad Nickel Plates facilitate efficient thermal transfer while maintaining structural integrity in corrosive media. The thermal conductivity of the nickel substrate enhances heat transfer efficiency, while the titanium layer prevents corrosion-induced degradation that would otherwise compromise thermal performance over time. Titanium Clad Nickel Plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. find extensive application in distillation columns, particularly in the petrochemical industry, where their resistance to chloride stress corrosion cracking provides significant advantages over conventional stainless steel components. The company's plates, available in thicknesses ranging from 3mm to over 50mm (combined thickness), can be custom-fabricated to specific dimensions up to 6000mm in length and 2500mm in width, accommodating various equipment designs. The quality assurance protocols implemented by Baoji JL, including adherence to ASME, ASTM, and JIS standards, ensure these materials meet the stringent requirements of pressure vessel codes, enabling safe operation under extreme conditions including high temperature, high pressure, and chemically aggressive environments typical in modern chemical processing facilities.

Marine Engineering Solutions

Marine engineering presents some of the most demanding material challenges, with corrosive seawater, biological fouling, and mechanical stress creating a particularly hostile environment for conventional metals. Titanium Clad Nickel Plates offer an exceptional solution for these demanding conditions, combining titanium's outstanding seawater corrosion resistance with nickel's excellent mechanical properties and thermal conductivity. In offshore platforms and processing equipment, these composite plates provide long-term reliability for components exposed to seawater and process fluids simultaneously. The excellent galvanic compatibility between titanium and nickel minimizes concerns about electrochemical corrosion that often plagues dissimilar metal combinations in marine environments. Desalination plants represent another significant application area, where Titanium Clad Nickel Plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. serve in critical components including evaporators, heat exchangers, and brine heaters. The titanium surface resists chloride attack even at elevated temperatures, while the nickel substrate provides the necessary structural support and thermal conductivity for efficient operation. Marine vessel components, particularly those handling seawater cooling systems or processing corrosive fluids, benefit from the durability of Titanium Clad Nickel Plates. The company's ISO9001-2000 certification, along with its successful qualification under PED and ABS international standards in 2024, ensures these materials meet the stringent requirements for marine applications. Baoji JL offers tailored surface treatments including polished, matte, or brushed finishes, enhancing resistance to marine biofouling or facilitating specific hydrodynamic performance characteristics. The company's global shipping capabilities via sea, air, or express courier facilitate timely delivery of these specialized materials to shipyards and offshore fabrication facilities worldwide, supporting marine engineering projects with materials that significantly extend service life and reduce maintenance requirements in challenging oceanic environments.

Aerospace and Advanced Technology Applications

The aerospace industry and other advanced technology sectors demand materials that deliver exceptional performance under extreme conditions while maintaining minimal weight—requirements perfectly addressed by Titanium Clad Nickel Plates. In aircraft systems, particularly those handling corrosive fluids like hydraulic systems and fuel management components, these composite materials provide the corrosion resistance of titanium while utilizing the nickel substrate's formability and joining characteristics. The weight advantage compared to solid nickel components contributes to fuel efficiency and performance, critical considerations in aerospace design. Rocket propulsion systems represent another demanding application, where Titanium Clad Nickel Plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. serve in propellant handling systems and structural components exposed to aggressive chemicals. The material's ability to withstand both oxidizing and reducing environments makes it particularly valuable in systems that must handle multiple propellant types. In advanced electronics manufacturing, particularly semiconductor production equipment, these composite plates provide contamination-free surfaces for ultra-pure chemical handling while maintaining the thermal stability necessary for precision processes. The company's capability to produce Titanium Clad Nickel Plates with customized dimensions and precisely controlled cladding ratios allows optimization for specific aerospace and technology applications. Surface treatments including high-precision polishing achieve the exacting finish requirements often specified for aerospace components. Baoji JL's implementation of rigorous quality control protocols, including comprehensive non-destructive testing and mechanical property verification, ensures these materials meet the exceptional reliability standards demanded by aerospace applications. The company's successful qualification under international standards, including its 2024 certification under PED and ABS, demonstrates its commitment to producing materials suitable for the most critical applications in advanced technology sectors. This combination of performance characteristics, quality assurance, and customization capabilities makes Titanium Clad Nickel Plates an increasingly important material solution for demanding aerospace and technology applications where conventional materials cannot provide the necessary performance envelope.

Conclusion

Titanium Clad Nickel Plates represent a pinnacle achievement in modern metallurgical engineering, offering an optimal combination of material properties through sophisticated manufacturing processes. The explosion bonding, roll bonding, and diffusion bonding techniques enable precise control over material characteristics, resulting in composites that excel in the most demanding industrial environments.

Are you looking for custom-engineered Titanium Clad Nickel Plates for your specific application? Baoji JL Clad Metals Materials Co., Ltd. offers unparalleled expertise in clad metal technology, backed by independent explosive composite technology, self-rolling capabilities, and international certifications including ISO9001-2000, PED, and ABS. Our global delivery network ensures your materials arrive safely and on schedule, while our R&D team stands ready to develop innovative solutions tailored to your unique requirements. Experience the difference that technological superiority and commitment to quality can make in your next project. Contact us today at sales@cladmet.com to discuss how our Titanium Clad Nickel Plates can revolutionize your industrial performance.

References

1. Johnson, R.K. & Clyne, T.W. (2023). "Advances in Explosion Bonding Techniques for Titanium-Based Composite Metals." Journal of Materials Processing Technology, 305, 117-134.

2. Zhang, H., Liu, Y., & Chen, B. (2022). "Microstructural Evolution at Titanium-Nickel Interfaces During Roll Bonding Processes." Materials Science and Engineering: A, 832, 142357.

3. Li, W., Wang, H., & Zhao, Y. (2023). "Diffusion Bonding of Titanium Alloys to Nickel-Based Substrates: Process Parameters and Interface Characteristics." Journal of Manufacturing Processes, 86, 228-243.

4. Pettersson, K., & Thompson, S. (2024). "Performance Analysis of Titanium Clad Nickel Components in Marine Environments." Corrosion Science, 209, 110873.

5. Anderson, T.L., & Miller, K.J. (2022). "Quality Assurance Methodologies for Explosion-Welded Clad Plates in Pressure Vessel Applications." International Journal of Pressure Vessels and Piping, 197, 104566.

6. Wilson, J.D., & Martinez, R.E. (2023). "Economic Analysis of Titanium Clad Materials in Chemical Processing: Lifecycle Cost Perspectives." Chemical Engineering Research and Design, 188, 376-391.

_1737007724117.webp)

_1736996330512.webp)