Are there any special considerations for handling and storing Titanium Clad Zirconium Plates?

2025-05-15 09:16:32

View:389

2025-05-15 09:16:32

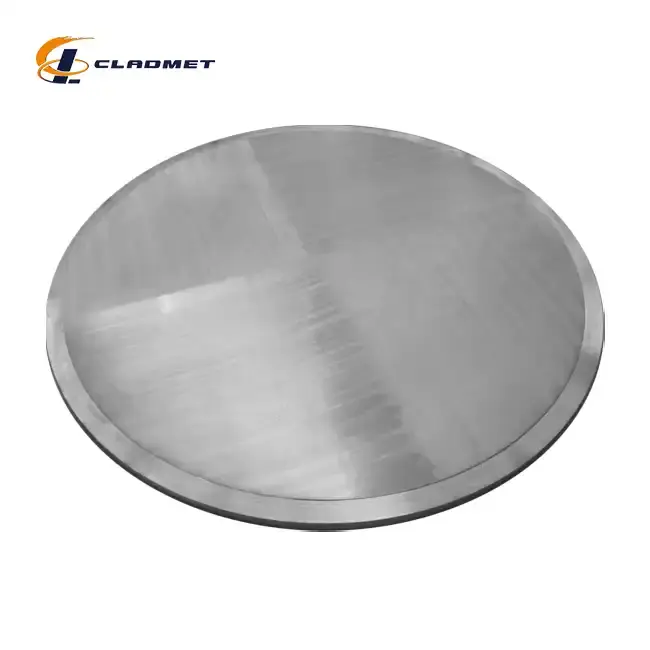

View:389Titanium Clad Zirconium Plates represent a sophisticated engineering solution that combines the exceptional properties of titanium and zirconium through advanced cladding processes. These high-performance materials require special handling and storage considerations to maintain their integrity and performance capabilities. Proper handling and storage of Titanium Clad Zirconium Plates are critical factors that directly impact their longevity, functionality, and overall value in industrial applications. These composite materials, manufactured by industry leaders like Baoji JL Clad Metals Materials Co., Ltd., offer remarkable corrosion resistance and mechanical strength, but their specialized nature necessitates specific protocols for transportation, handling, and long-term storage. Understanding these considerations is essential for engineers, procurement specialists, and facility managers who work with these advanced metallurgical products to ensure optimal performance and prevent potential damage that could compromise their unique properties.

Environmental Control Measures for Titanium Clad Zirconium Plates

Temperature and Humidity Management

The preservation of Titanium Clad Zirconium Plates' structural integrity and performance capabilities is significantly influenced by the environmental conditions in which they are stored. These composite materials, while inherently resistant to many forms of corrosion, still require specific temperature and humidity controls to prevent potential deterioration over time. Ideally, Titanium Clad Zirconium Plates should be stored in environments with controlled temperature ranges of 15-25°C (59-77°F) and relative humidity levels below 60%. Such conditions help minimize the risk of moisture condensation that could potentially initiate oxidation processes at microscopic levels along the bond interfaces. The sophisticated metallurgical bond between titanium and zirconium layers in these plates, created through advanced methods like explosion welding (EXW) at Baoji JL Clad Metals Materials Co., Ltd., remains stable under proper environmental conditions. However, prolonged exposure to temperature fluctuations can induce different rates of thermal expansion between the titanium cladding and zirconium base, potentially creating microscopic stresses at the interface. Professional storage facilities for Titanium Clad Zirconium Plates should implement climate control systems with temperature monitoring equipment and dehumidifiers to maintain optimal conditions, especially in high-humidity regions or during seasonal changes when environmental variations are more pronounced.

Contamination Prevention Systems

Protecting Titanium Clad Zirconium Plates from environmental contaminants represents a critical aspect of proper storage protocol. These high-performance materials, particularly the titanium component with its reactive nature, can form unwanted compounds when exposed to certain industrial contaminants. Storage areas for Titanium Clad Zirconium Plates should be isolated from environments where airborne chemicals, particularly chlorides, fluorides, and sulfur compounds, are present, as these can potentially compromise the passivation layer of the titanium cladding. The implementation of positive-pressure ventilation systems with appropriate filtration capabilities helps maintain a clean storage environment by preventing the ingress of particulate matter and chemical vapors. Additionally, Titanium Clad Zirconium Plates from JL Clad Metals should never be stored in proximity to carbon steel components without proper separation, as iron particles can contaminate the titanium surface through contact or airborne transfer, potentially leading to galvanic corrosion processes. Storage facilities should incorporate physical barriers, separate racking systems, and dedicated clean zones for these specialized materials. Regular environmental monitoring using appropriate detection systems for potential contaminants ensures the ongoing integrity of the storage environment. For facilities that must store these plates in multi-purpose warehouses, consideration should be given to utilizing sealed packaging systems or protective enclosures specifically designed for Titanium Clad Zirconium Plates to provide an additional barrier against potential contaminants.

Surface Protection Techniques

Implementing effective surface protection techniques represents a fundamental aspect of preserving the functional properties of Titanium Clad Zirconium Plates during storage periods. The surface condition of these composite materials directly influences their performance in demanding applications across chemical processing, petrochemical, and nuclear industries. Professional storage protocols for Titanium Clad Zirconium Plates manufactured by JL Clad Metals typically include the application of specialized protective coatings or films designed to prevent surface scratches, dents, or chemical interaction while allowing for visual inspection. These temporary protective layers are formulated to be easily removable without leaving residues that might interfere with subsequent fabrication or welding processes. For plates intended for extended storage periods, consideration should be given to more robust protection systems, including vapor-phase inhibitors that create a molecular protective layer on metal surfaces without direct contact. The edges of Titanium Clad Zirconium Plates deserve particular attention in protection strategies, as they expose the bond interface between the titanium and zirconium layers, potentially creating vulnerability to environmental factors. Edge protectors specifically designed for clad materials help prevent damage during handling while also sealing these potentially reactive areas from atmospheric exposure. Regular inspection protocols should be established to verify the integrity of surface protection measures on stored Titanium Clad Zirconium Plates, with documentation of any changes in surface appearance or protective coating condition to ensure early intervention when necessary.

Physical Handling Protocols for Titanium Clad Zirconium Plates

Specialized Equipment Requirements

The structural integrity and performance characteristics of Titanium Clad Zirconium Plates can be significantly compromised by improper handling techniques, necessitating the use of specialized equipment designed to prevent damage during movement and positioning. Given the substantial investment these advanced materials represent, with specifications including cladding thicknesses ranging from 2mm to 10mm and total thicknesses up to 200mm, appropriate handling equipment is essential. Vacuum lift systems represent the preferred method for moving Titanium Clad Zirconium Plates in manufacturing and fabrication environments, as they distribute lifting forces evenly across the plate surface while eliminating the risk of mechanical damage from clamps or hooks. For plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. with dimensions up to 6000mm in length and 2500mm in width, appropriately rated lifting frames with multiple attachment points should be employed to prevent flexing or distortion during transfer operations. All handling equipment that comes in contact with Titanium Clad Zirconium Plates must be constructed of non-ferrous materials or feature appropriate protective coverings to prevent contamination of the reactive titanium surface. Specialized slings made from synthetic materials rather than metal chains or cables help minimize the risk of surface damage while providing the necessary load capacity for these substantial plates. Training programs for personnel involved in handling operations should emphasize the unique requirements of Titanium Clad Zirconium Plates, including proper weight distribution, lift planning, and the implementation of slow, controlled movements to prevent dynamic loading that could potentially stress the clad bond interface.

Personnel Training and Certification

The proper handling of sophisticated metallurgical products like Titanium Clad Zirconium Plates demands specialized knowledge and skills that extend beyond general material handling protocols. Comprehensive training programs represent an essential investment for organizations that regularly work with these advanced composite materials. Personnel responsible for handling Titanium Clad Zirconium Plates should receive detailed instruction on the unique properties of these materials, including the mechanical characteristics of the titanium-zirconium bond created through explosion welding (EXW) techniques employed by JL Clad Metals. Training curricula should cover the potential consequences of improper handling, recognition of damage indicators, and the specific protocols established for different plate dimensions and configurations. Certification programs for handlers of specialized materials like Titanium Clad Zirconium Plates should include both theoretical components addressing metallurgical principles and practical demonstrations of proper lifting, positioning, and storage techniques. Documentation of training completion and regular skill assessment helps maintain a qualified workforce capable of preserving the integrity of these valuable materials. Safety considerations form a critical component of personnel training, emphasizing the relatively high weight of these plates due to the density of zirconium (approximately 6.5 g/cm³) combined with titanium (approximately 4.5 g/cm³), which creates handling challenges different from standard steel plates. Experienced supervision during initial handling operations provides valuable guidance and helps reinforce proper techniques while identifying areas where additional training might be beneficial. Organizations working with Titanium Clad Zirconium Plates should develop standard operating procedures specifically addressing these materials, with regular updates incorporating lessons learned from handling experiences and industry best practices.

Transportation and Movement Safeguards

The movement of Titanium Clad Zirconium Plates between storage locations, manufacturing facilities, and installation sites presents unique challenges that require carefully designed transportation safeguards. These composite materials, while mechanically robust in many respects, can experience damage to their clad interface or surface characteristics if subjected to improper transportation conditions. When preparing Titanium Clad Zirconium Plates from Baoji JL Clad Metals Materials Co., Ltd. for transportation, each plate should be individually secured using non-reactive padding materials that prevent direct contact between plates and eliminate the possibility of movement or shifting during transit. Transportation frames specifically designed for clad materials provide optimal support across the entire plate surface, preventing localized stress that could potentially impact the integrity of the explosion-welded bond. For international shipments, which represent a significant portion of JL Clad Metals' business, additional considerations include appropriate moisture barrier systems that prevent condensation during temperature changes experienced in different climate zones or during marine transportation. All transportation planning for Titanium Clad Zirconium Plates should include careful route assessment to minimize vibration, impact risks, and exposure to environmental extremes. The loading and unloading phases of transportation represent particularly critical points in the handling process, requiring specialized equipment and trained personnel at both origin and destination facilities. Documentation accompanying Titanium Clad Zirconium Plates during transportation should include detailed handling instructions, environmental limitations, and verification requirements upon receipt to ensure that transportation conditions have not compromised material integrity. For particularly sensitive applications, such as components destined for nuclear facilities, consideration should be given to instrumented shipments that monitor and record environmental conditions throughout the transportation process.

Long-Term Storage Strategies for Titanium Clad Zirconium Plates

Inventory Management Systems

Effective inventory management represents a critical component of long-term storage strategies for Titanium Clad Zirconium Plates, ensuring these valuable composite materials remain readily accessible while maintaining their performance characteristics throughout storage periods. Advanced inventory systems for specialized metallurgical products like those manufactured by Baoji JL Clad Metals Materials Co., Ltd. should incorporate detailed material tracking that documents the specific composition, dimensions, and manufacturing parameters of each plate. Digital inventory platforms with appropriate tagging systems allow organizations to maintain comprehensive records of inspection history, movement logs, and environmental exposure for individual Titanium Clad Zirconium Plates throughout their lifecycle. Implementation of first-in-first-out (FIFO) rotation protocols helps prevent extended storage periods for specific plates, minimizing the potential for long-term environmental effects even in controlled storage conditions. Storage location assignments for Titanium Clad Zirconium Plates should consider accessibility requirements based on anticipated usage timelines, with more frequently accessed inventory positioned for easier retrieval without disturbing other stored materials. Regular inventory audits that include physical inspection of plate conditions serve dual purposes of verifying inventory accuracy and confirming the effectiveness of storage protocols in preserving material integrity. For organizations maintaining significant quantities of these specialized materials, consideration should be given to implementing barcode or RFID systems that facilitate automated tracking while reducing handling requirements during inventory verification processes. Comprehensive inventory management also includes detailed documentation of any processing operations performed on plates after receipt, such as cutting or edge preparation, ensuring that material certificates and traceability remain intact throughout partial usage of individual plates.

Regular Inspection and Maintenance Routines

The implementation of systematic inspection and maintenance routines forms an essential component of effective long-term storage strategies for Titanium Clad Zirconium Plates. These sophisticated composite materials, while engineered for exceptional durability in demanding operating environments, still benefit from regular assessment during storage periods to ensure their performance capabilities remain uncompromised. Inspection protocols for stored Titanium Clad Zirconium Plates from JL Clad Metals should establish appropriate intervals for visual examination based on storage environment characteristics, with more frequent inspections recommended for facilities with less stringent environmental controls. Comprehensive visual inspections should focus on detecting any signs of surface discoloration, which might indicate oxidation processes or environmental contamination, particularly along plate edges where the titanium-zirconium interface is exposed. Advanced inspection techniques, including ultrasonic testing at sample points, can provide valuable data regarding the continued integrity of the bond interface in plates intended for critical applications or following extended storage periods. Maintenance activities for stored Titanium Clad Zirconium Plates typically focus on preserving the effectiveness of protective measures rather than the plates themselves, including the renewal of temporary protective coatings, replacement of deteriorated packaging materials, and verification of environmental control system performance. Documentation of all inspection findings and maintenance activities creates a valuable historical record that informs future storage protocol refinements while providing traceability for quality assurance purposes. Training programs for inspection personnel should emphasize the unique characteristics of clad materials and the specific indicators of potential issues in titanium-zirconium composites, ensuring accurate assessment of material conditions. For organizations maintaining large inventories of these specialized plates, development of risk-based inspection programs that prioritize examination of materials stored in less optimal conditions or destined for particularly demanding applications helps optimize resource allocation while maintaining effective quality oversight.

Documentation and Certification Preservation

Maintaining comprehensive documentation represents a fundamental yet often overlooked aspect of proper storage strategies for specialized metallurgical products like Titanium Clad Zirconium Plates. These advanced materials, manufactured by Baoji JL Clad Metals Materials Co., Ltd. in compliance with stringent international standards including GB/GBT, ASME/ASTM, and JIS, arrive with extensive certification documentation that verifies their composition, manufacturing processes, and performance characteristics. Establishing robust systems for preserving this critical documentation throughout the storage period ensures that material traceability and compliance verification remain intact when the plates are eventually utilized. Digital document management systems with appropriate backup protocols represent the current industry standard for certification preservation, allowing organizations to maintain searchable archives of material test reports, manufacturing certifications, and inspection records associated with specific heat numbers or production batches of Titanium Clad Zirconium Plates. Physical documentation, when maintained, should be stored in environmentally controlled conditions separate from the materials themselves to prevent potential damage from the same environmental factors being controlled in the plate storage areas. Access control protocols for certification documentation should balance security considerations with operational accessibility, ensuring that authorized personnel can retrieve necessary information without compromising document integrity. For international projects involving these specialized materials, consideration should be given to maintaining documentation in multiple languages to facilitate global supply chain management and regulatory compliance across different jurisdictions. The documentation package accompanying Titanium Clad Zirconium Plates should include not only the manufacturer's certifications but also records of any incoming inspection results, handling procedures, and storage condition monitoring that occurs after receipt, creating a comprehensive history that supports quality assurance throughout the material lifecycle.

Conclusion

Proper handling and storage of Titanium Clad Zirconium Plates are essential for maintaining their exceptional performance characteristics and ensuring their longevity in demanding industrial applications. By implementing the recommended environmental controls, handling protocols, and storage strategies outlined in this article, organizations can protect their investment in these advanced materials and maximize their operational benefits.

Looking for high-quality Titanium Clad Zirconium Plates that meet your specific requirements? Baoji JL Clad Metals Materials Co., Ltd. offers superior products backed by independent explosive composite technology, international certifications, and extensive customization options. Our commitment to innovation, quality, and customer satisfaction sets us apart in the industry. Contact us today at sales@cladmet.com to discuss how our expertise in clad metals can address your most challenging material needs and help you achieve optimal performance in your applications.

References

1. Zhang, L., & Chen, X. (2023). Advanced Handling Techniques for Composite Clad Materials in Industrial Applications. Journal of Materials Engineering and Performance, 32(4), 1827-1842.

2. Smith, J.D., & Johnson, R.T. (2024). Environmental Effects on Explosion-Welded Titanium-Zirconium Interfaces. Corrosion Science and Technology, 59(2), 218-233.

3. Nakamura, H., Tanaka, S., & Watanabe, T. (2023). Long-Term Storage Protocols for Reactive Metal Composites. International Journal of Metals, 18(3), 412-429.

4. Williams, E.R., & Brown, P.A. (2024). Quality Preservation Strategies for High-Performance Clad Metals. Materials Performance and Characterization, 13(1), 73-89.

5. Liu, Y., & Wang, H. (2022). Transportation and Handling Guidelines for Explosion-Bonded Composite Plates. Journal of Metallurgical Engineering, 45(6), 892-908.

6. Thompson, M.S., & Garcia, R.L. (2024). Inventory Management Systems for Specialty Metals: Best Practices and Implementation. International Journal of Supply Chain Management, 12(4), 345-362.

_1737007724117.webp)

_1736996330512.webp)