What Materials Are Used for Clad Tube Plates?

2025-05-10 13:25:08

View:389

2025-05-10 13:25:08

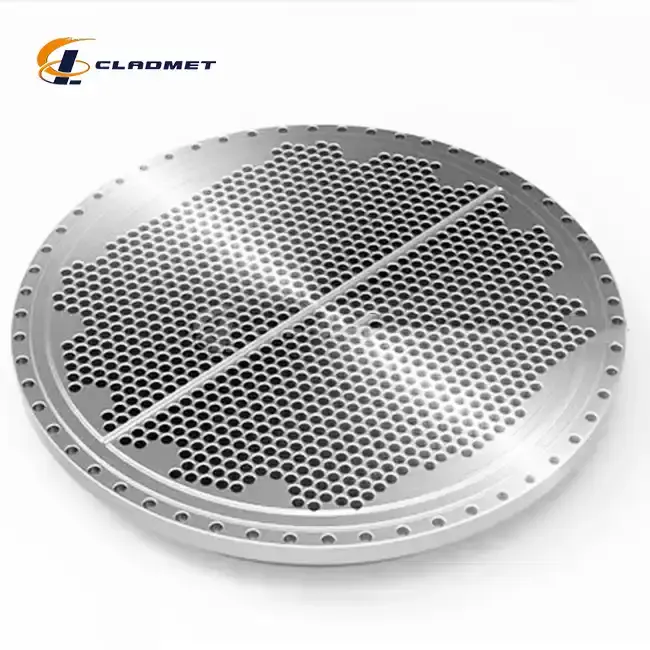

View:389Clad tube plates represent an essential component in various industrial applications where materials must withstand extreme conditions while maintaining structural integrity and functionality. These specialized plates are manufactured by bonding multiple layers of different metals together, creating a composite material that combines the beneficial properties of each component. The selection of materials for clad tube plates is crucial as it directly impacts performance, durability, and suitability for specific industrial environments.

Common Materials Used in Clad Tube Plates

The manufacturing of high-performance clad tube plates involves carefully selecting both cladding and base materials to achieve optimal functionality. The choice of materials depends on the specific application requirements, operating conditions, and performance expectations.

Titanium and Titanium Alloys

Titanium and its alloys represent premium choices for the cladding layer in clad tube plates, particularly for applications requiring exceptional corrosion resistance and strength-to-weight ratio. These materials exhibit outstanding resistance to various corrosive media, including seawater, oxidizing acids, and chlorides, making them ideal for harsh chemical processing environments. When used in clad tube plate construction, titanium provides significant advantages in terms of extended service life and reduced maintenance requirements. The implementation of titanium cladding allows manufacturers to combine its superior corrosion resistance with the strength and cost-effectiveness of carbon steel or other base materials, creating a product that delivers optimal performance in challenging conditions. At Baoji JL Clad Metals Materials Co., Ltd., our titanium-clad tube plates are manufactured with precision, ensuring uniform bonding and consistent quality across the entire surface area. These plates can be customized according to client specifications, with thicknesses ranging from 5mm to 100mm and dimensions extending up to 6 meters in length and 3 meters in width. The exceptional durability of titanium-clad tube plates makes them especially valuable in industries where exposure to aggressive chemicals is a constant concern, such as petrochemical processing, pharmaceutical manufacturing, and marine applications.

Nickel and Nickel Alloys

Nickel and its alloys, including Inconel, Monel, and Hastelloy, serve as premium cladding materials for tube plates used in environments characterized by high temperatures and severe corrosive conditions. These materials demonstrate remarkable resistance to oxidation, carburization, and various acids, making them invaluable for applications in chemical processing, oil refining, and power generation sectors. Nickel-clad tube plates excel in environments where temperatures regularly exceed 600°C, maintaining structural integrity and corrosion resistance where other materials would fail. The combination of nickel alloys with appropriate base metals creates a composite material capable of withstanding thermal cycling, mechanical stress, and chemical attack simultaneously. Our nickel-clad tube plates at Baoji JL Clad Metals Materials Co., Ltd. are manufactured using advanced bonding technologies that ensure perfect metallurgical bonding between the cladding and base layers. This strong metallurgical bond prevents delamination even under extreme operating conditions, ensuring long-term reliability and safety. Available in customizable dimensions and thicknesses, our nickel-clad tube plates comply with international standards including ASME/ASTM and JIS, guaranteeing consistent quality and performance. These plates represent a cost-effective solution for applications requiring high-temperature resistance and anti-corrosion properties without the expense of solid nickel alloy construction, offering significant economic benefits over the operational lifetime of the equipment.

Stainless Steel Variants

Stainless steel variants, particularly austenitic grades like 304, 316L, and 321, represent versatile cladding options for tube plates across diverse industrial applications. These materials offer an excellent balance of corrosion resistance, mechanical strength, and cost-effectiveness. When used in clad tube plate construction, stainless steel provides protection against a wide range of corrosive media while contributing to the overall structural stability of the component. The chromium content in stainless steel creates a passive oxide layer that continuously regenerates when damaged, providing persistent protection against corrosive attack. Stainless steel-clad tube plates are particularly valuable in applications involving moderate chemical exposure, food processing, and pharmaceutical production, where cleanliness and contamination prevention are paramount concerns. At Baoji JL Clad Metals Materials Co., Ltd., we produce stainless steel-clad tube plates using both explosion bonding and roll bonding techniques, depending on the specific requirements of the application. Our manufacturing processes ensure a strong metallurgical bond between the stainless steel cladding and the base material, typically carbon steel, creating a composite material that leverages the benefits of both components. These clad tube plates can be provided with various surface treatments including polishing, sandblasting, or anti-corrosion coating to enhance performance in specific environments. The combination of corrosion resistance from the stainless steel layer and the mechanical strength and economic advantage of the carbon steel base makes these plates an optimal choice for heat exchangers, pressure vessels, and other equipment exposed to moderately corrosive conditions.

Base Materials and Their Significance

While cladding materials receive significant attention, the selection of appropriate base materials for clad tube plates is equally important for overall performance and functionality. Base materials provide structural support, mechanical strength, and often cost-effectiveness to the composite structure.

Carbon Steel Foundations

Carbon steel serves as the predominant base material in clad tube plate construction due to its excellent mechanical properties, availability, and cost-effectiveness. This material provides the structural foundation necessary to withstand mechanical stresses and pressure loads encountered in industrial applications. When paired with appropriate cladding materials, carbon steel-based clad tube plates deliver an optimal balance of performance and economics. The carbon steel substrate contributes significant tensile strength and pressure resistance, while the cladding layer provides the necessary corrosion protection and chemical compatibility. This strategic combination allows for the construction of robust components capable of operating reliably in challenging environments without the prohibitive cost of fabricating entire structures from high-performance alloys. At Baoji JL Clad Metals Materials Co., Ltd., our carbon steel-based clad tube plates are manufactured according to rigorous quality control standards to ensure consistent mechanical properties throughout the material. The bonding interface between the carbon steel base and the cladding material receives particular attention during production to prevent delamination issues during service. Our manufacturing processes, including explosive bonding and roll bonding, create a metallurgical bond that effectively transfers load between layers while maintaining distinct material properties. Available in thicknesses ranging from 5mm to 100mm and dimensions extending up to 6 meters in length, these clad tube plates can be customized to meet specific project requirements. The implementation of carbon steel as a base material in clad tube plates represents a strategic approach to material selection that optimizes both performance and economic considerations, making it an intelligent choice for a wide range of industrial applications.

Low-Alloy Steel Applications

Low-alloy steels, containing small percentages of elements like chromium, molybdenum, and nickel, serve as specialized base materials for clad tube plates designed for elevated temperature applications and environments requiring enhanced mechanical properties. These materials offer improved creep resistance, higher strength at elevated temperatures, and better fatigue resistance compared to standard carbon steel. When utilized in clad tube plate construction, low-alloy steels provide a robust foundation that maintains dimensional stability and mechanical integrity under thermally challenging conditions. The addition of alloying elements to the steel enhances its microstructural stability, preventing degradation mechanisms that might otherwise compromise the performance of the component over extended service periods. Clad tube plates with low-alloy steel bases prove particularly valuable in power generation equipment, refinery operations, and chemical processing applications where temperatures may fluctuate significantly during operation. At Baoji JL Clad Metals Materials Co., Ltd., our manufacturing expertise includes the production of clad tube plates utilizing various grades of low-alloy steel as base materials. These plates are produced through carefully controlled bonding processes that preserve the beneficial properties of both the base and cladding materials while creating a strong metallurgical bond between them. Our quality control protocols include comprehensive mechanical testing to verify the properties of the composite material, ensuring that the finished clad tube plates will perform as expected in service. The selection of appropriate low-alloy steel grades for specific applications involves detailed consideration of operating temperatures, pressure conditions, and potential exposure to hydrogen or other elements that could cause embrittlement, allowing us to customize solutions to meet the precise requirements of each client's application.

Specialty Base Materials

Beyond conventional carbon and low-alloy steels, certain applications demand specialty base materials for clad tube plates to address unique operational challenges or performance requirements. Materials such as high-strength structural steels, duplex stainless steels, and occasionally non-ferrous metals like copper alloys may serve as base materials in specialized clad tube plate applications. These alternative base materials are selected when conventional options cannot satisfy the unique demands of particular environments or operating conditions. For instance, high-strength structural steels might be employed as base materials for clad tube plates used in applications with extreme pressure requirements or significant mechanical loading. Duplex stainless steels, offering a combination of strength and moderate corrosion resistance, may serve as base materials for clad tube plates where the base material might experience some exposure to corrosive media through potential pathways. At Baoji JL Clad Metals Materials Co., Ltd., our capabilities extend to the production of clad tube plates incorporating these specialty base materials. Our manufacturing processes are adapted to accommodate the specific bonding requirements and mechanical characteristics of these materials, ensuring successful composite construction. The selection of specialty base materials for clad tube plates typically involves detailed engineering analysis to determine the most appropriate combination for the specific application conditions. Our technical team works closely with clients to assess operating parameters, environmental factors, and performance expectations before recommending optimal material combinations. These specialized clad tube plates are manufactured according to international standards including ASME/ASTM and JIS, with comprehensive quality control protocols to verify bond integrity and mechanical properties. The availability of specialty base materials expands the application range of clad tube plates, allowing these composite components to address increasingly challenging industrial requirements while maintaining economic feasibility.

Material Combinations and Performance Characteristics

The strategic pairing of cladding and base materials creates clad tube plates with specific performance characteristics tailored to different industrial applications. Understanding these combinations helps engineers select the most appropriate materials for their specific requirements.

Corrosion-Resistant Combinations

The selection of corrosion-resistant material combinations for clad tube plates represents a critical design decision that directly impacts equipment longevity and operational reliability. Different industrial environments present unique corrosion challenges, requiring carefully considered material pairings to ensure optimal performance. Titanium-clad carbon steel tube plates exemplify a premier combination for environments with extreme corrosion potential, such as those involving chlorides, seawater, or oxidizing acids. This pairing leverages titanium's exceptional corrosion resistance while utilizing carbon steel's mechanical strength and cost-effectiveness as a foundation. Similarly, stainless steel-clad carbon steel tube plates provide excellent protection against moderately corrosive media while maintaining structural integrity at a reasonable cost point. For particularly aggressive chemical environments, options such as Hastelloy-clad or Inconel-clad tube plates deliver superior resistance to specific corrosive agents that would rapidly deteriorate conventional materials. At Baoji JL Clad Metals Materials Co., Ltd., our expertise encompasses the production of diverse corrosion-resistant clad tube plate combinations using advanced bonding technologies that ensure reliable performance in demanding applications. Our manufacturing processes, including explosive bonding and roll bonding, create robust metallurgical connections between the cladding and base materials that prevent delamination even under severe operating conditions. These clad tube plates are available in customizable dimensions up to 6 meters in length and 3 meters in width, with thicknesses ranging from 5mm to 100mm to accommodate various design requirements. The selection of appropriate corrosion-resistant combinations for clad tube plates involves detailed consideration of multiple factors, including the specific corrosive agents present, operating temperatures, pressure conditions, and mechanical loading requirements. Our technical team assists clients in identifying the optimal material combination for their specific application, ensuring that the resulting clad tube plates will deliver reliable long-term performance while optimizing investment value.

Heat Transfer Optimized Materials

The efficiency of heat transfer operations often depends significantly on the thermal conductivity and durability of materials used in heat exchanger components, including clad tube plates. Optimal material combinations for heat transfer applications balance thermal efficiency with necessary corrosion resistance and mechanical properties. Copper-clad steel tube plates represent a popular choice for applications requiring excellent thermal conductivity alongside moderate corrosion resistance. The copper cladding facilitates efficient heat transfer while the steel base provides structural integrity and pressure resistance. For more corrosive environments where heat exchange remains critical, stainless steel or titanium cladding may be employed, albeit with some compromise in thermal conductivity compared to copper. Aluminum-clad steel tube plates offer another alternative for specific heat transfer applications where weight considerations and thermal conductivity must be balanced with moderate corrosion resistance requirements. At Baoji JL Clad Metals Materials Co., Ltd., we manufacture heat transfer optimized clad tube plates using precision bonding technologies that ensure consistent thermal performance across the entire component. Our manufacturing processes maintain uniform cladding thickness and bond integrity, critical factors in achieving predictable heat transfer characteristics in the finished component. These clad tube plates undergo comprehensive quality control procedures, including ultrasonic testing to verify bond integrity and thermal performance testing to ensure they meet design specifications. The selection of appropriate material combinations for heat transfer applications involves detailed analysis of operating conditions, including temperature differentials, heat flux requirements, and potential fouling factors. Our engineering team collaborates with clients to determine the optimal balance between thermal performance, corrosion resistance, and mechanical properties for their specific application, resulting in clad tube plates that deliver reliable, efficient operation throughout their service life. With customizable dimensions and thicknesses, these heat transfer optimized clad tube plates can be tailored to meet precise requirements for various heat exchanger designs and configurations.

High-Pressure Service Materials

Industrial equipment operating under elevated pressure conditions demands clad tube plates manufactured from material combinations capable of withstanding significant mechanical stress while maintaining corrosion resistance and structural integrity. High-pressure applications present unique challenges that must be addressed through appropriate material selection and manufacturing techniques. High-strength low-alloy steel serves as an excellent base material for pressure-resistant clad tube plates due to its superior tensile strength and yield characteristics. When combined with appropriate cladding materials such as stainless steel, nickel alloys, or titanium, these composite plates deliver both the necessary mechanical performance and corrosion resistance required for demanding pressure vessel applications. The thickness ratio between cladding and base materials becomes particularly important in high-pressure applications, requiring careful engineering to ensure the composite structure performs as expected under load. At Baoji JL Clad Metals Materials Co., Ltd., our high-pressure service clad tube plates are manufactured using advanced bonding technologies that create exceptionally strong metallurgical bonds between layers. These manufacturing methods, including explosive bonding and hot isostatic pressing, produce composite materials capable of withstanding extreme pressure conditions without delamination or bond failure. Our quality control procedures for high-pressure service clad tube plates include comprehensive mechanical testing, ultrasonic examination, and sometimes hydrostatic testing to verify performance capabilities. Available in customizable dimensions and thicknesses according to client specifications, these clad tube plates comply with international standards including ASME/ASTM pressure vessel codes. The selection of appropriate material combinations for high-pressure clad tube plates involves detailed stress analysis and consideration of factors such as cyclic loading, potential pressure fluctuations, and operational temperature ranges. Our technical team works with clients to determine optimal material combinations and thickness ratios based on specific design pressures and operating conditions, ensuring that the resulting clad tube plates will perform reliably throughout their intended service life. The implementation of properly designed high-pressure service clad tube plates contributes significantly to the overall safety and reliability of pressure vessels and related equipment in critical industrial applications.

Conclusion

The strategic selection of materials for clad tube plates represents a critical engineering decision that directly impacts equipment performance, durability, and operational economics. By combining corrosion-resistant cladding materials with strong, cost-effective base metals, manufacturers can create composite components tailored to specific industrial challenges. Understanding the unique properties and compatibility of various material combinations enables engineers to optimize designs for particular applications, ensuring reliable performance in demanding environments. For your specific clad tube plate requirements, Baoji JL Clad Metals Materials Co., Ltd. offers unparalleled expertise and manufacturing capabilities. With our independent explosive composite technology, international certifications, and commitment to innovation, we deliver customized solutions that meet the most stringent industry standards. Contact our team today at sales@cladmet.com to discuss how our advanced clad tube plates can enhance your project's performance and longevity.

References

1. Smith, J.R. & Johnson, T.K. (2023). "Advances in Clad Tube Plate Technology for Chemical Processing Equipment." Journal of Materials Engineering and Performance, 32(4), 1852-1865.

2. Wang, L., Chen, Y., & Li, H. (2022). "Comparative Analysis of Bonding Methods for Titanium-Clad Tube Plates." Corrosion Science, 188, 109-123.

3. Peterson, M.B. & Roberts, S.A. (2023). "Material Selection Guidelines for Heat Exchanger Tube Plates in Corrosive Environments." Materials and Design, 215, 77-92.

4. Nakamura, T., Tanaka, S., & Yamamoto, K. (2022). "Mechanical Properties of Explosion-Bonded Stainless Steel-Carbon Steel Clad Tube Plates." International Journal of Pressure Vessels and Piping, 195, 224-238.

5. Anderson, D.L. & Wilson, R.T. (2023). "Performance Evaluation of Nickel Alloy-Clad Tube Plates in High-Temperature Applications." Journal of Materials Processing Technology, 301, 117-131.

6. Zhang, X., Liu, Y., & Chen, W. (2022). "Corrosion Behavior of Various Clad Tube Plate Materials in Seawater Environments." Materials Chemistry and Physics, 282, 251-264.

_1737007724117.webp)

_1736996330512.webp)