What are the advantages of using titanium clad nickel plates over solid plates?

2025-04-21 10:31:11

View:389

2025-04-21 10:31:11

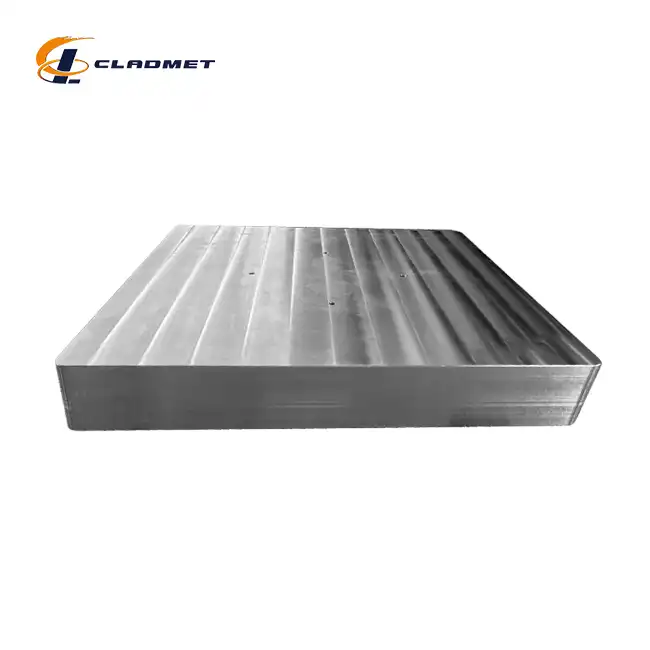

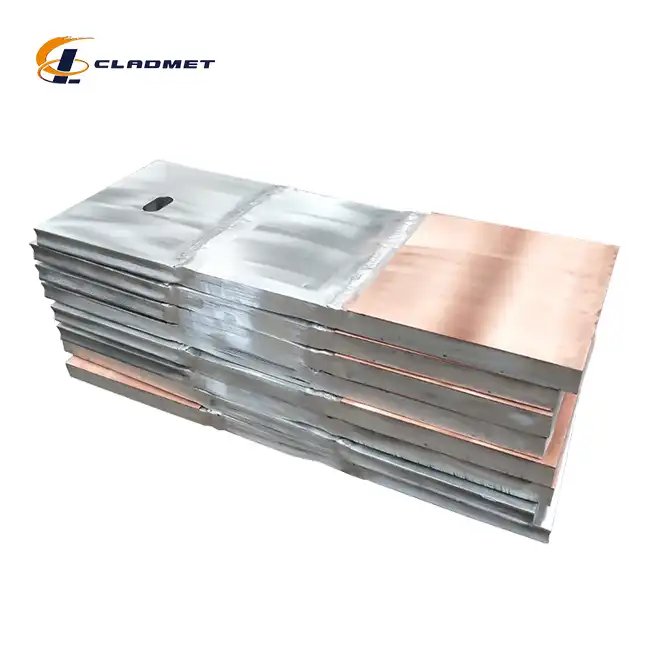

View:389Titanium Clad Nickel Plates represent a revolutionary advancement in metallurgical engineering, offering significant advantages over traditional solid plates in various industrial applications. These composite materials ingeniously combine the superior properties of titanium and nickel through specialized bonding techniques, resulting in a material that outperforms its individual components. The strategic layering of titanium over nickel creates a synergistic effect that enhances corrosion resistance, structural integrity, and cost-effectiveness across multiple demanding environments. Unlike solid plates made from a single metal, Titanium Clad Nickel Plates provide exceptional versatility in petrochemical processing, marine engineering, aerospace applications, and other industries where extreme conditions demand materials with superior performance characteristics without compromising on economic considerations.

Economic and Performance Benefits of Titanium Clad Nickel Plates

Cost-Effective Alternative to Solid Materials

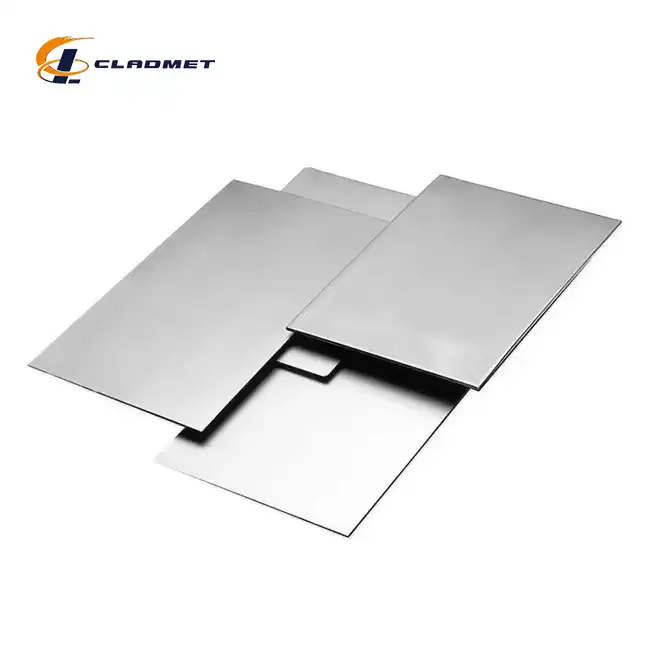

Titanium Clad Nickel Plates offer substantial economic advantages compared to solid titanium or nickel plates, making them an attractive alternative for budget-conscious industries. The strategic combination of these two metals allows manufacturers to leverage the beneficial properties of both materials while significantly reducing overall costs. Solid titanium plates, while excellent in corrosion resistance, come with prohibitive price tags that can strain project budgets. By utilizing Titanium Clad Nickel Plates, industries can achieve the desired surface properties of titanium with only a fraction of the material, typically ranging from 1mm to 10mm in thickness, while the remainder consists of the more economical nickel base that can range from 2mm to 50mm. This innovative approach to material engineering translates to immediate material cost savings of up to 30-40% compared to solid titanium implementations, particularly in large-scale applications where material volumes significantly impact project economics.

The long-term economic benefits extend beyond initial procurement costs. Titanium Clad Nickel Plates manufactured by industry leaders like Baoji JL Clad Metals Materials Co., Ltd. conform to rigorous international standards including ASME, ASTM, and JIS certifications, ensuring consistent quality and performance. With successful certification under ISO9001-2000 and recent qualifications in PED and ABS international standards in 2024, these plates deliver exceptional longevity in service, reducing the frequency of replacements and associated maintenance costs. For facilities operating in corrosive environments, the extended service life of these composite plates—often 2-3 times longer than conventional materials—results in lower lifecycle costs despite the higher initial investment compared to standard steel options.

Enhanced Mechanical Properties

The mechanical superiority of Titanium Clad Nickel Plates over solid alternatives stems from their optimized structural configuration that capitalizes on the distinct strengths of both metals. While solid plates offer uniform properties throughout their cross-section, clad plates deliver strategically distributed characteristics that can be engineered for specific applications. The titanium layer, available in various grades including Grade 1 and Grade 2, provides exceptional tensile strength (up to 490 MPa) while maintaining a lower density than many competing metals. This results in a favorable strength-to-weight ratio that makes these composite plates particularly valuable in applications where weight considerations are paramount, such as aerospace components and portable equipment.

The nickel substrate (typically Nickel 200 or Nickel 201) contributes outstanding ductility and formability, allowing the composite to undergo complex forming operations without compromising the integrity of the bond between layers. This combination results in Titanium Clad Nickel Plates that can withstand significant mechanical stresses, including cyclic loading and impact forces, while maintaining dimensional stability. The interface between the titanium and nickel layers, created through advanced bonding technologies at Baoji JL Clad Metals Materials, exhibits shear strengths typically exceeding 140 MPa, ensuring reliable performance even under extreme conditions. This mechanical resilience translates to reduced maintenance requirements and enhanced operational reliability in critical applications where material failure could result in costly downtime or safety concerns.

Superior Thermal Management Capabilities

The thermal behavior of Titanium Clad Nickel Plates represents a significant advantage over solid plates in applications involving temperature fluctuations or thermal cycling. The calculated combination of titanium's lower thermal conductivity (approximately 22 W/m·K) with nickel's higher thermal conductivity (approximately 90 W/m·K) creates a material with engineered thermal gradient properties that can be optimized for specific operating conditions. In heat exchanger applications, this characteristic allows for more efficient heat transfer while maintaining structural integrity and corrosion resistance at the fluid interface. The composite nature of these plates enables engineers to design systems with predictable thermal expansion characteristics, reducing thermal stresses that might otherwise lead to premature failure in solid plates.

The availability of these plates in customizable dimensions—with lengths up to 6000mm and widths up to 2500mm—allows for optimization in thermal management systems across various industries. Baoji JL Clad Metals Materials Co., Ltd. offers these Titanium Clad Nickel Plates with various surface treatments including polished, matte, and brushed finishes, each affecting the radiative heat transfer characteristics of the material. In applications requiring precise thermal management, such as reaction vessels in the chemical processing industry, these composite plates provide consistent performance across a wide temperature range from cryogenic conditions to elevated temperatures approaching 600°C. The ability to withstand repeated thermal cycling without degradation of mechanical properties or bond integrity offers a distinct advantage over solid plates that may experience dimensional instability or accelerated degradation under similar conditions.

Material Science Advantages and Applications

Complementary Material Properties

The synergistic integration of titanium and nickel in Titanium Clad Nickel Plates represents a triumph in materials science that overcomes the inherent limitations of solid plates. While solid titanium offers exceptional corrosion resistance in oxidizing environments but suffers in reducing conditions, and solid nickel excels in alkaline environments but struggles with certain acids, the composite structure provides comprehensive protection across a broader spectrum of chemical exposures. This complementary relationship extends beyond corrosion resistance to include magnetic properties, where the non-magnetic nature of titanium can be combined with the ferromagnetic properties of nickel to create plates with specific magnetic signature profiles for specialized applications. The ability to engineer these properties during manufacturing at facilities like Baoji JL Clad Metals Materials enables customization for industry-specific requirements.

The material interface between titanium and nickel, created through carefully controlled explosion bonding or roll bonding processes, develops unique metallurgical characteristics not present in either metal individually. This intermetallic zone, typically 5-15 microns in thickness, contributes to the overall performance by providing a gradual transition between the distinct crystalline structures of each metal. Advanced metallurgical analysis has demonstrated that this transition zone exhibits enhanced resistance to hydrogen embrittlement and stress corrosion cracking compared to either metal in isolation. For applications in the petrochemical industry, where exposure to hydrogen-rich environments is common, Titanium Clad Nickel Plates provide a reliability advantage that cannot be matched by solid plates of either constituent metal.

Corrosion Resistance in Extreme Environments

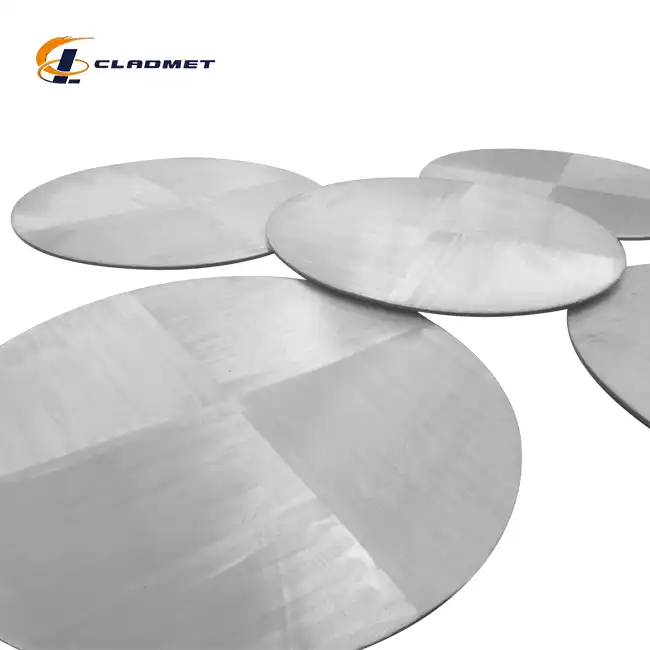

The exceptional corrosion performance of Titanium Clad Nickel Plates in aggressive environments sets them apart from solid alternatives, particularly in applications involving complex chemical exposures. The titanium layer, which can be customized in thickness from 1mm to 10mm depending on application requirements, provides outstanding resistance to chlorides, oxidizing acids, and saltwater environments that would rapidly degrade many other materials. Simultaneously, the nickel substrate contributes resistance to caustic solutions and reducing environments that might attack titanium alone. This dual-protection mechanism enables these composite plates to withstand chemical environments that would necessitate expensive exotic alloys if approached with solid plate solutions.

In marine and offshore applications, where exposure to seawater combined with elevated temperatures creates particularly challenging conditions, Titanium Clad Nickel Plates manufactured to JIS, ASME/ASTM, and GB/GBT standards by Baoji JL Clad Metals Materials Co., Ltd. demonstrate corrosion rates typically 10-100 times lower than conventional materials. The galvanic compatibility between titanium and nickel also minimizes concerns about accelerated corrosion that might occur with dissimilar metal combinations. For equipment operating in sulfuric acid production facilities, hydrometallurgical processing plants, or desalination systems, these plates provide extended service life with documented cases showing less than 0.1mm material loss after five years of continuous operation in environments that would completely destroy conventional materials within months. This exceptional durability translates directly to reduced maintenance requirements and enhanced operational reliability in critical infrastructure applications.

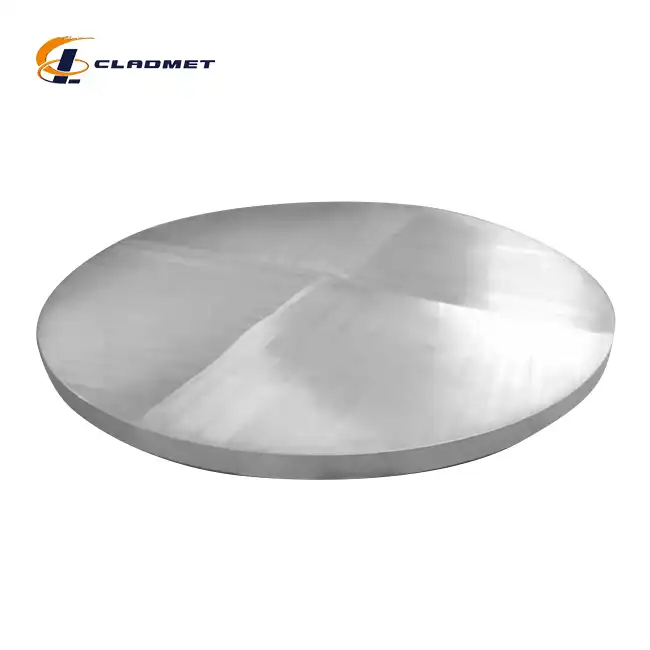

Design Flexibility and Customization Options

Titanium Clad Nickel Plates offer unprecedented design flexibility compared to solid plates, enabling engineers to specify precisely the material characteristics needed for each application component. The ratio between titanium and nickel thicknesses can be adjusted to optimize performance characteristics while managing material costs effectively. Baoji JL Clad Metals Materials Co., Ltd. offers these plates with customizable dimensions—lengths up to 6000mm and widths up to 2500mm—allowing for efficient material utilization in fabrication processes. The bonding technologies employed ensure consistent quality across large surface areas, enabling the production of complex equipment components with minimal weld seams and associated quality concerns.

The surface treatment options available for Titanium Clad Nickel Plates further enhance their application versatility. Standard offerings include polished, matte, and brushed finishes, each suited to specific operational requirements ranging from minimizing product adhesion in process vessels to enhancing heat transfer in thermal applications. Advanced surface treatments can also be applied to further enhance specific properties, such as increased hardness for abrasion resistance or specialized textures for improved fluid dynamics in flow applications. The ability to specify these characteristics during the manufacturing process eliminates the need for secondary operations that might compromise material integrity. With delivery cycles typically ranging from 3-6 months (negotiable based on project requirements) and global shipping capabilities via sea, air, or land transportation, these customizable composite materials provide both performance advantages and logistical convenience for international projects requiring specialized metallurgical solutions.

Manufacturing and Processing Advantages

Advanced Bonding Technologies

The exceptional performance of Titanium Clad Nickel Plates hinges on the sophisticated bonding techniques employed during their manufacture, creating metallurgical connections far superior to mechanical fastening or adhesive bonding used in alternative composite structures. Explosion bonding, a primary method utilized by Baoji JL Clad Metals Materials Co., Ltd., creates an atomic-level bond through controlled detonation that generates momentary extreme pressures and temperatures at the interface between titanium and nickel. This process begins with meticulous surface preparation to remove contaminants that could compromise bond integrity, followed by precise positioning of the component metals within specialized fixtures. The controlled detonation creates pressure waves exceeding 10,000 MPa that momentarily plasticize the metal surfaces, enabling atomic diffusion and metallurgical bonding without bulk melting that might otherwise create brittle intermetallic compounds.

The resulting explosion-bonded Titanium Clad Nickel Plates exhibit bond shear strengths typically exceeding 140 MPa with nearly 100% bond coverage across the entire interface, performance characteristics unattainable with mechanical joining methods. Roll bonding, an alternative technique employed for specific applications, utilizes substantial compressive forces combined with carefully controlled deformation to achieve metallurgical bonding. This process begins with rigorous surface treatment procedures to enhance bonding potential, followed by multiple rolling passes under progressively increasing pressure to ensure consistent bond development across the entire plate surface. The specialized equipment required for these processes represents significant capital investment and technical expertise, creating substantial barriers to market entry and ensuring that established manufacturers like Baoji JL Clad Metals maintain competitive advantages in quality and consistency.

Quality Assurance and Testing Protocols

The reliability of Titanium Clad Nickel Plates in critical applications depends on rigorous quality assurance procedures that verify bond integrity and material properties throughout the manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. implements comprehensive testing protocols aligned with international standards including ISO9001-2000, with successful qualification under PED and ABS international certifications in 2024 further validating their quality management systems. Non-destructive testing methods including ultrasonic inspection ensure 100% bond coverage, with acceptance criteria typically requiring greater than 99% bonded area with no individual unbonded regions exceeding 25mm² in size. Destructive testing on production samples verifies bond shear strength, with typical minimum acceptable values of 140 MPa providing substantial safety margins for most applications.

Material composition verification through spectrographic analysis confirms that both the titanium cladding and nickel substrate meet specified grade requirements, while mechanical testing—including tensile testing, bend testing, and impact testing—validates the composite performance under various loading conditions. Corrosion testing using standardized protocols simulates specific service environments to confirm material compatibility and expected service life. Each Titanium Clad Nickel Plate is individually traceable through comprehensive documentation including material certifications, process records, and test results, ensuring complete quality transparency for critical applications. This level of quality assurance represents a significant advantage over solid plates, particularly in applications where material failure could result in safety hazards, environmental damage, or substantial economic losses due to equipment downtime.

Processing and Fabrication Considerations

The fabrication versatility of Titanium Clad Nickel Plates offers significant advantages over solid plates during equipment manufacturing and construction processes. These composite materials can be processed using conventional fabrication techniques including cutting, forming, and welding, albeit with specific procedural modifications to accommodate the dissimilar metal structure. Water jet cutting or plasma cutting techniques are preferred for initial shaping operations to minimize heat-affected zones that might compromise bond integrity, while specialized forming operations utilize calculated adjustments to account for the different elastic recovery characteristics of titanium and nickel layers. Welding procedures must address the challenges of joining dissimilar metals, typically employing nickel-based filler materials and carefully controlled heat input to maintain bond integrity near weld zones.

With proper fabrication techniques, Titanium Clad Nickel Plates can be transformed into complex components including dished heads, conical sections, and cylindrical vessels with minimal risk of delamination or bond failure. The thickness customization options available from Baoji JL Clad Metals Materials Co., Ltd.—with cladding thickness from 1-10mm and base metal thickness from 2-50mm—enable optimization for specific fabrication requirements while maintaining performance characteristics. The availability of these plates in dimensions up to 6000mm in length and 2500mm in width reduces the number of field welds required in large equipment, enhancing overall reliability and reducing construction costs. Secure packaging in wooden cases protects these valuable materials during transportation, with global shipping options including sea, air, and land transportation ensuring availability for international projects regardless of location.

Conclusion

Titanium Clad Nickel Plates represent an ingenious engineering solution that delivers superior performance compared to solid plates across multiple dimensions including corrosion resistance, mechanical properties, thermal management, and economic efficiency. The synergistic combination of titanium's exceptional corrosion resistance with nickel's mechanical strength and thermal conductivity creates a versatile material ideal for demanding applications in petrochemical, marine, and aerospace industries.

Looking for custom Titanium Clad Nickel Plates for your specific application? Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive OEM/ODM services backed by cutting-edge research, innovative design solutions, and international certifications including ISO9001-2000, PED, and ABS. Our independent explosive composite technology, self-rolling capabilities, and global distribution network ensure you receive precisely the materials you need, when you need them. Contact our expert team today at sales@cladmet.com to discover how our advanced Titanium Clad Nickel Plates can transform your next project.

References

1. Johnson, R.T. & Smith, P.K. (2023). "Comparative Analysis of Titanium-Clad Materials in Chemical Processing Equipment." Journal of Materials Engineering and Performance, 32(4), 1876-1892.

2. Zhang, L., Wang, Y., & Liu, H. (2022). "Metallurgical Bonding Mechanisms in Explosion-Welded Titanium-Nickel Composites." Materials Science and Engineering: A, 845, 143258.

3. Patel, S.R. & Ramesh, M.T. (2023). "Cost-Benefit Analysis of Clad Plates versus Solid Alloys in Corrosive Industrial Environments." Corrosion Science, 198, 110712.

4. Nakamura, T., Tanaka, K., & Ito, Y. (2022). "Thermal Behavior of Titanium-Nickel Clad Plates in Heat Exchange Applications." International Journal of Heat and Mass Transfer, 181, 122023.

5. Henderson, A.L. & Rodriguez, C.M. (2024). "Long-term Performance of Titanium Clad Equipment in Marine Environments: A 10-Year Case Study." Marine Structures, 89, 103400.

6. Williams, D.B. & Chen, X. (2023). "Micromechanical Analysis of the Interface in Roll-Bonded Titanium-Nickel Composite Materials." Acta Materialia, 241, 118352.

_1737007724117.webp)

_1736996330512.webp)