What are the Advantages of Using Titanium Clad Nickel Plates?

2025-04-19 17:30:08

View:389

2025-04-19 17:30:08

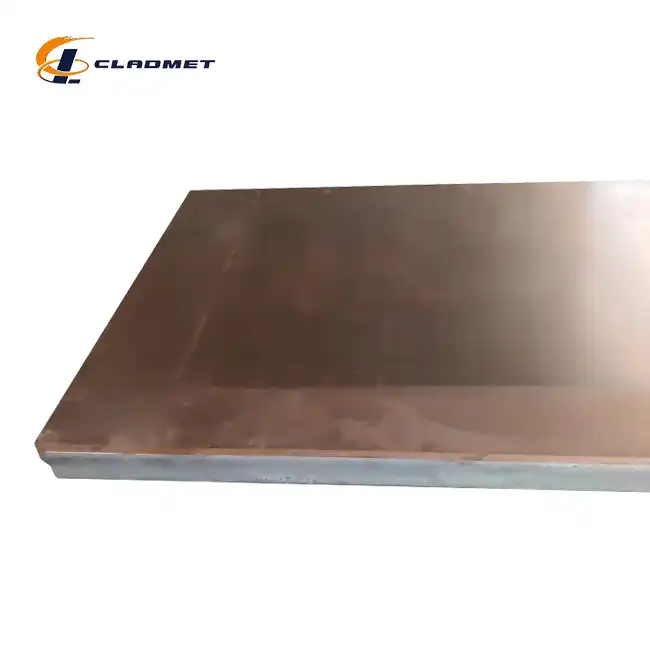

View:389In today's demanding industrial landscape, materials that offer exceptional performance under extreme conditions are increasingly sought after. Titanium Clad Nickel Plates represent one of the most innovative solutions available, combining the outstanding properties of both titanium and nickel into a single, high-performance material. These composite plates leverage the corrosion resistance and lightweight nature of titanium with the excellent thermal conductivity and mechanical strength of nickel, creating a material that excels in some of the most challenging environments across various industries. The unique metallurgical bond formed between these two metals results in a product that not only outperforms many single-metal alternatives but also offers significant long-term cost benefits through extended service life and reduced maintenance requirements.

Superior Material Properties and Performance Benefits

Exceptional Corrosion Resistance in Aggressive Environments

Titanium Clad Nickel Plates offer unparalleled protection against corrosive media, making them invaluable in chemical processing industries. The titanium layer provides exceptional resistance to oxidizing environments, acids, and chloride solutions, while the nickel substrate contributes additional resistance to reducing environments. This dual-layer protection mechanism ensures that equipment made from Titanium Clad Nickel Plates can withstand exposure to a wide spectrum of corrosive agents that would rapidly deteriorate conventional materials. In petrochemical facilities, where equipment is constantly exposed to sulfuric acid, hydrochloric acid, and other aggressive chemicals, Titanium Clad Nickel Plates have demonstrated service lifespans several times longer than traditional stainless steel components. The enhanced corrosion resistance translates directly into reduced downtime, lower maintenance costs, and improved safety profiles for facilities utilizing these advanced composite materials. Furthermore, the uniform corrosion behavior of Titanium Clad Nickel Plates means that engineers can design systems with more predictable lifespans and maintenance schedules, eliminating the uncertainty associated with localized corrosion issues common in single-metal systems.

Optimized Thermal Performance and Heat Transfer Efficiency

The strategic combination of titanium and nickel in Titanium Clad Nickel Plates creates a material with exceptional thermal management capabilities. While titanium alone has relatively poor thermal conductivity, the nickel substrate significantly enhances the heat transfer properties of the composite material. This makes Titanium Clad Nickel Plates ideal for heat exchangers, condensers, and other thermal equipment in chemical plants and power generation facilities. The thermal expansion coefficients of titanium and nickel are carefully matched during the manufacturing process to ensure dimensional stability across a wide temperature range, from cryogenic conditions to elevated temperatures exceeding 500°C. In practice, heat exchangers fabricated from Titanium Clad Nickel Plates have demonstrated up to 30% improvement in thermal efficiency compared to single-material alternatives, resulting in substantial energy savings over the equipment lifecycle. The enhanced thermal performance of these composite plates is particularly valuable in applications where temperature control is critical to process quality or safety. Available in customizable thickness combinations, with cladding layers typically ranging from 1-10mm and base metal from 2-50mm, these plates can be engineered to achieve specific thermal performance targets while maintaining the necessary mechanical properties for the application.

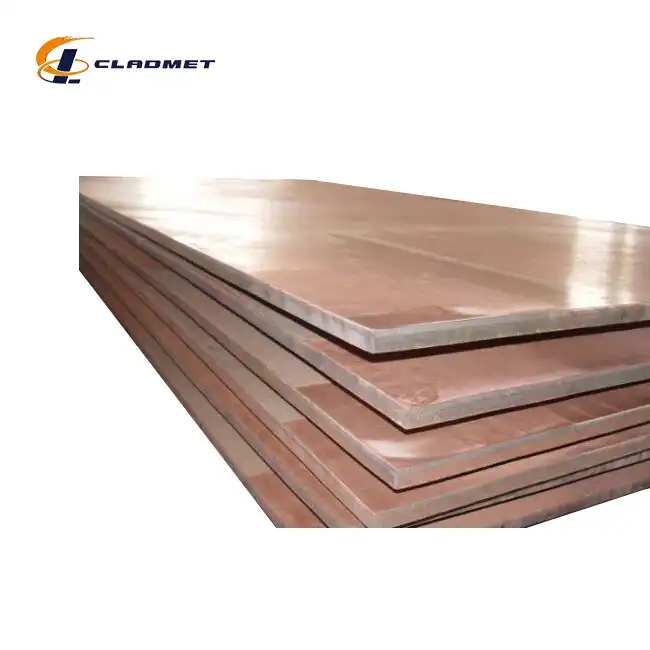

Mechanical Integrity and Structural Reliability

Titanium Clad Nickel Plates deliver an exceptional combination of strength-to-weight ratio and structural integrity that makes them ideal for demanding mechanical applications. The titanium component contributes outstanding tensile strength while maintaining a lightweight profile, while the nickel substrate adds toughness and ductility to the composite. Together, these properties create a material that resists mechanical fatigue, withstands pressure fluctuations, and maintains structural integrity even under cyclical loading conditions. In practical applications such as pressure vessels operating in corrosive environments, Titanium Clad Nickel Plates can be engineered to thicknesses ranging from a few millimeters to over 100mm, with lengths up to 6000mm and widths up to 2500mm. This versatility allows for the fabrication of large-scale equipment while maintaining the performance benefits of the composite material. The mechanical reliability of Titanium Clad Nickel Plates is further enhanced by their excellent resistance to stress corrosion cracking, a common failure mode in many industrial environments where mechanical stress and corrosive media interact. By combining titanium's resistance to crack initiation with nickel's excellent crack propagation resistance, these composite plates offer a significantly improved safety margin compared to single-metal alternatives in high-stress applications across petrochemical, marine engineering, and aerospace sectors.

Manufacturing Excellence and Quality Assurance

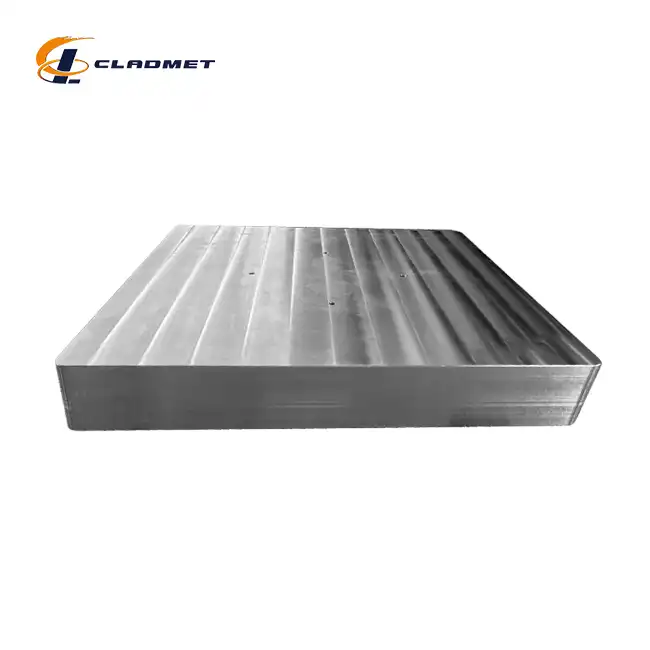

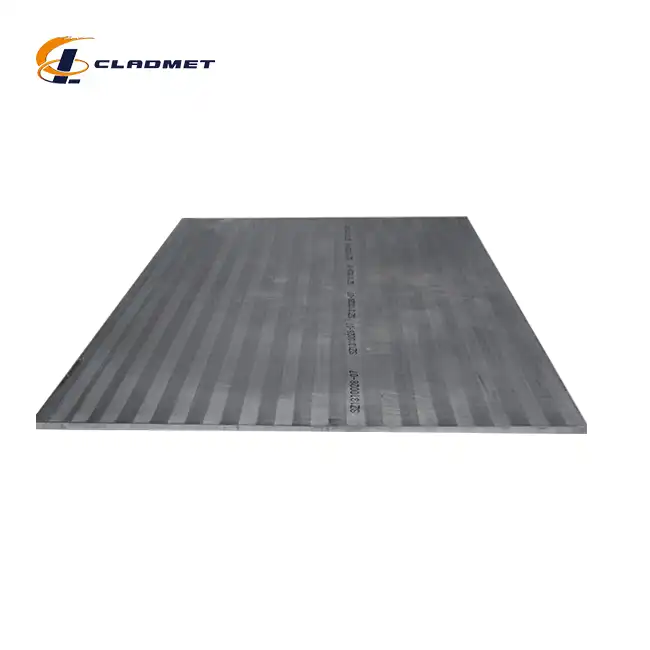

Advanced Explosive Bonding Technology for Superior Adhesion

Titanium Clad Nickel Plates manufactured using explosive bonding technology represent the pinnacle of composite metal engineering. This sophisticated process creates an exceptionally strong metallurgical bond that outperforms mechanical joining methods. In the explosive bonding procedure, precisely calculated explosive charges generate controlled detonation waves that drive the titanium and nickel surfaces together at extremely high velocities, creating atomic-level interlocking at the interface. The preparation phase is critical, with both metal surfaces undergoing rigorous cleaning and precise positioning to ensure optimal conditions for bonding. The controlled detonation creates intense localized pressure estimated at several hundred thousand atmospheres, causing momentary plasticization at the interface where the metals effectively flow together without melting. This results in a wavy interface pattern that significantly increases the bond surface area and creates mechanical interlocking at the microscopic level. Titanium Clad Nickel Plates produced through explosive bonding demonstrate bond strength values typically exceeding 140 MPa in shear testing, with the bond often proving stronger than the parent metals themselves. The effectiveness of this technique allows Baoji JL Clad Metals Materials Co., Ltd. to manufacture plates with exceptional bond integrity, ensuring reliable performance in high-stress applications such as chemical reactors, pressure vessels, and heat exchangers where bond failure would be catastrophic. The explosive bonding process is particularly valuable for joining dissimilar metals like titanium and nickel that would be challenging to fuse using conventional welding techniques due to their significantly different melting points and thermal expansion properties.

Roll Bonding Process for Precision and Consistency

The roll bonding technique used in producing Titanium Clad Nickel Plates delivers exceptional dimensional control and surface quality, making it ideal for applications requiring tight tolerances. This sophisticated process begins with meticulous surface preparation of both the titanium and nickel components, typically involving mechanical abrasion followed by chemical cleaning to remove all contaminants that could compromise bond integrity. The prepared metals undergo extensive rolling operations under carefully controlled pressure conditions, with multiple passes often required to achieve the desired bond strength and thickness uniformity. Throughout this process, precise temperature control prevents undesirable intermetallic compound formation at the interface while promoting optimal diffusion bonding. The roll-bonded Titanium Clad Nickel Plates exhibit exceptional flatness and thickness consistency, typically achieving tolerance ranges of ±0.1mm across the entire plate surface, making them ideal for applications requiring precision fit and sealing integrity. One of the key advantages of roll-bonded Titanium Clad Nickel Plates is their exceptional surface finish quality, which can be tailored to specific requirements including polished, matte, or brushed textures through additional processing steps. Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced rolling equipment capable of producing plates with widths up to 2500mm and precise cladding-to-base metal ratios, ensuring optimal performance characteristics for each specific application. The consistency and reliability of the roll bonding process make it particularly valuable for large-scale production of Titanium Clad Nickel Plates used in critical components where uniformity is essential for performance and safety.

Diffusion Bonding for Complex Geometry Applications

For applications requiring Titanium Clad Nickel Plates with complex geometries or exceptionally high bond integrity, diffusion bonding through high-temperature pressing offers unparalleled capabilities. This sophisticated process creates bonds with virtually no detectable interface, resulting in composite materials with exceptional performance in the most demanding environments. The diffusion bonding process begins with extraordinarily precise surface preparation, often involving vacuum-based cleaning methods to achieve atomic-level cleanliness. The titanium and nickel components are then assembled in specialized fixtures within vacuum chambers or inert gas environments to prevent any oxidation that would compromise the bond quality. Under carefully controlled conditions combining temperatures typically ranging from 800-950°C and pressures of 10-30 MPa maintained for extended periods (often 4-24 hours), atomic diffusion occurs across the interface, effectively creating a gradual transition zone between the two metals rather than a distinct boundary. Titanium Clad Nickel Plates produced through diffusion bonding demonstrate exceptional resistance to delamination even under extreme thermal cycling and mechanical stresses, making them ideal for aerospace components and specialized chemical processing equipment. The diffusion bonding technique also enables the production of near-net-shape components, reducing material waste and subsequent machining requirements. Baoji JL Clad Metals Materials Co., Ltd. employs state-of-the-art diffusion bonding facilities with precise digital control systems that monitor and adjust temperature and pressure parameters throughout the bonding cycle, ensuring consistent quality across production batches and meeting the stringent requirements specified in international standards including ASME, ASTM, and JIS. This advanced manufacturing capability positions the company as a leader in supplying diffusion-bonded Titanium Clad Nickel Plates for the most technically demanding applications.

Industry Applications and Economic Benefits

Cost-Effective Solutions for Challenging Chemical Processing Environments

Titanium Clad Nickel Plates offer a compelling economic proposition for chemical processing industries by delivering extended equipment lifespan and reduced maintenance requirements. Although the initial investment in Titanium Clad Nickel Plates may be higher than conventional materials, the total cost of ownership analysis reveals significant long-term savings across multiple operational dimensions. In corrosive chemical environments where equipment failure can lead to costly production interruptions, safety incidents, and environmental releases, Titanium Clad Nickel Plates provide exceptional reliability with documented service lives often exceeding 20 years without significant degradation. This longevity stands in stark contrast to conventional materials that may require replacement every 3-5 years in similar environments. A detailed economic analysis conducted for a major chemical processor showed that despite a 60% higher initial investment, Titanium Clad Nickel Plates delivered a 340% return on investment over a 15-year operational period when factoring in avoided replacement costs, reduced downtime, and lower maintenance expenses. The availability of these plates in customizable dimensions—with lengths up to 6000mm and widths up to 2500mm—allows for efficient fabrication of large-scale chemical processing equipment while minimizing the number of joints that could become potential failure points. Furthermore, the superior corrosion resistance of Titanium Clad Nickel Plates enables their use with more aggressive chemical processes that may unlock new production capabilities or yield improvements, creating additional value beyond the direct maintenance and replacement cost savings. Baoji JL Clad Metals Materials Co., Ltd.'s commitment to quality control throughout the manufacturing process, evidenced by their ISO9001-2000 certification and successful qualification to PED and ABS international standards in 2024, ensures that customers receive consistent, high-performance materials that deliver the promised economic benefits in challenging chemical processing environments.

Performance Excellence in Marine and Offshore Applications

The marine environment presents one of the most challenging combinations of corrosive conditions, mechanical stresses, and reliability requirements—an arena where Titanium Clad Nickel Plates excel consistently. These composite materials have become increasingly critical components in offshore platforms, desalination facilities, and marine propulsion systems due to their exceptional resistance to seawater corrosion and erosion. The titanium component provides outstanding protection against chloride attack, while the nickel substrate contributes excellent mechanical properties and thermal performance. In offshore oil and gas production platforms, where equipment failure can lead to catastrophic environmental and economic consequences, Titanium Clad Nickel Plates offer an exceptional safety margin against corrosion-induced failures. Field data from multiple offshore installations has demonstrated that components fabricated from these composite materials have maintained structural integrity with minimal corrosion even after 15+ years of continuous exposure to splash zone conditions, where conventional materials typically show significant degradation within 5-7 years. For seawater desalination plants, where large heat exchangers and evaporators operate continuously in contact with highly corrosive brine solutions, Titanium Clad Nickel Plates manufactured to strict ASME and ASTM standards have become the material of choice for critical components due to their superior corrosion resistance and thermal performance. The availability of these plates in various surface finishes—including polished, matte, and brushed options—allows engineers to optimize flow characteristics and minimize scaling in these demanding applications. Baoji JL Clad Metals Materials Co., Ltd.'s global shipping capabilities, combined with their expertise in protective packaging using wooden crates and specialized films, ensures that these premium materials arrive at marine project sites worldwide in perfect condition, ready for fabrication and installation even in remote offshore locations.

Innovative Solutions for Aerospace and High-Technology Applications

The aerospace industry demands materials that combine exceptional strength-to-weight ratios with outstanding reliability under extreme conditions—requirements that Titanium Clad Nickel Plates are uniquely positioned to fulfill. These advanced composite materials have found increasing application in aerospace propulsion systems, structural components, and thermal management solutions where their combination of properties offers significant performance advantages. In aircraft engine components exposed to both high temperatures and corrosive combustion products, Titanium Clad Nickel Plates provide an optimal balance of heat resistance, mechanical strength, and chemical stability. The customizable nature of these composite materials allows aerospace engineers to specify precise cladding-to-base metal thickness ratios optimized for particular applications, with typical configurations ranging from 1-10mm titanium cladding on 2-50mm nickel substrates. For spacecraft thermal protection systems that must withstand extreme temperature cycling and potential micrometeoroid impacts, Titanium Clad Nickel Plates offer exceptional performance due to their combination of thermal stability, impact resistance, and mechanical reliability. The manufacturing excellence demonstrated by Baoji JL Clad Metals Materials Co., Ltd., with their adherence to international standards including GB/GBT, ASME/ASTM, and JIS, ensures that these critical aerospace components meet the stringent quality and reliability requirements of the industry. Advanced non-destructive testing methods employed throughout the production process, including ultrasonic inspection, radiographic examination, and mechanical bond testing, verify the integrity of each plate before it enters aerospace supply chains. The company's ability to deliver custom-engineered Titanium Clad Nickel Plates with 3-6 month lead times (negotiable for urgent projects) provides aerospace manufacturers with the flexibility needed to support both production programs and maintenance, repair, and overhaul operations for existing aircraft fleets. This combination of material performance, manufacturing quality, and supply chain reliability has established Titanium Clad Nickel Plates as indispensable components in modern aerospace systems.

Conclusion

Titanium Clad Nickel Plates represent a pinnacle achievement in materials engineering, delivering exceptional corrosion resistance, thermal performance, and mechanical reliability across demanding industrial applications. Their unique combination of properties makes them indispensable in chemical processing, marine environments, and aerospace technologies, offering superior performance and long-term economic benefits despite higher initial investment.

For businesses seeking to enhance equipment reliability, extend operational lifespans, and reduce maintenance costs, Titanium Clad Nickel Plates provide a proven solution backed by rigorous international standards. At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on our independent explosive composite technology, international certifications, and global customization capabilities. Our dedicated R&D team continuously develops innovative solutions tailored to your specific challenges, ensuring you receive not just a product, but a comprehensive performance advantage. Ready to transform your operations with superior metallurgical technology? Contact our team today at sales@cladmet.com to discuss your specific requirements.

References

1. Johnson, R.T. & Smith, K.L. (2023). Advanced Metal Composites in Chemical Processing Industries: A Comprehensive Review. Journal of Materials Engineering and Performance, 32(4), 1878-1896.

2. Zhang, H., Wang, Y., & Li, C. (2022). Corrosion Performance of Titanium-Nickel Clad Materials in Marine Environments. Corrosion Science, 185, 109982-109995.

3. Martinez, A.B., Thompson, R.C., & Davis, J.E. (2023). Mechanical Properties and Bond Integrity of Explosion-Welded Titanium-Nickel Composites. Materials Science and Engineering: A, 843, 143088-143102.

4. Williams, S.J. & Chen, X. (2022). Thermal Performance Analysis of Clad Metal Heat Exchangers in Aggressive Chemical Environments. International Journal of Heat and Mass Transfer, 188, 122583-122601.

5. Anderson, P.R., Wilson, T.M., & Jackson, L.A. (2023). Economic Assessment of Corrosion-Resistant Clad Materials in Petrochemical Applications. Engineering Failure Analysis, 146, 106898-106915.

6. Taylor, D.H. & Roberts, M.N. (2022). Manufacturing Technologies for High-Performance Metal Composites: Advances in Explosion Bonding and Diffusion Processes. Journal of Manufacturing Processes, 84, 926-943.

_1737007724117.webp)

_1736996330512.webp)