What are the typical applications of titanium clad nickel plates?

2025-04-07 09:14:34

View:389

2025-04-07 09:14:34

View:389Titanium Clad Nickel Plates represent a pinnacle of modern metallurgical engineering, offering an exceptional combination of properties that make them indispensable across numerous industrial applications. These composite materials strategically unite titanium's outstanding corrosion resistance and lightweight characteristics with nickel's excellent thermal conductivity and mechanical strength. As industries face increasingly demanding operational environments, Titanium Clad Nickel Plates have emerged as a premier solution for applications requiring superior performance under extreme conditions. These innovative materials serve critical functions across petrochemical processing, marine engineering, aerospace manufacturing, and numerous other high-performance sectors where conventional materials would quickly deteriorate or fail.

Chemical Processing Industry Applications

Reactors and Pressure Vessels

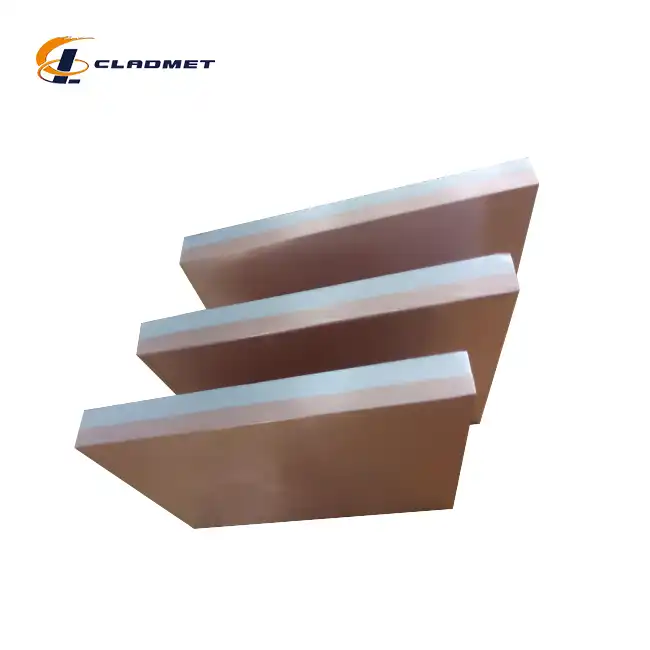

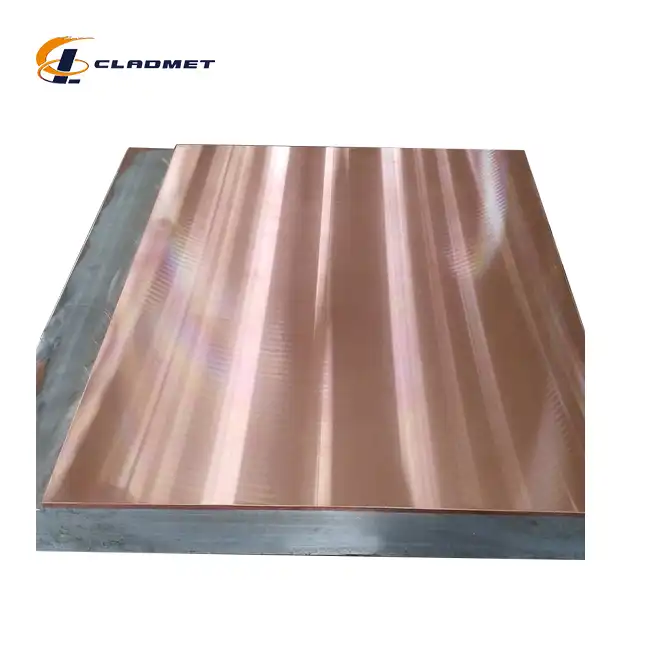

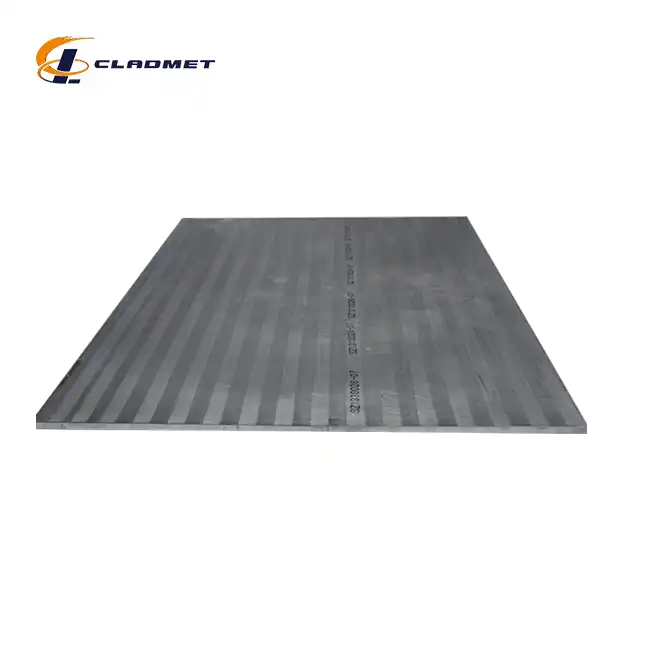

Titanium Clad Nickel Plates have revolutionized the construction of chemical reactors and pressure vessels across the petrochemical industry. These composite materials excel in environments where aggressive chemicals and high pressures combine to create extraordinarily demanding conditions. The titanium layer provides exceptional resistance against corrosive acids, chlorides, and oxidizing environments, while the nickel substrate contributes structural integrity and excellent heat transfer capabilities. In production facilities processing sulfuric acid, hydrochloric acid, and various chlorine compounds, Titanium Clad Nickel Plates extend equipment lifespan substantially compared to conventional materials. The explosively bonded or roll-bonded plates (available in thicknesses from 1mm to 100mm) create seamless barriers that maintain their integrity even after thousands of operational cycles under fluctuating temperatures and pressures. Companies implementing these materials report significant reductions in maintenance downtime and replacement costs, with some vessels maintaining pristine operational conditions after decades of service. Baoji JL Clad Metals Materials Co., Ltd. produces these plates according to stringent international standards including ASME, ASTM, and JIS specifications, ensuring consistent quality for critical chemical processing applications worldwide.

Heat Exchangers and Condensers

The thermal management demands of modern chemical processing facilities make Titanium Clad Nickel Plates an ideal material for heat exchangers and condensers. These components must withstand both corrosive process fluids and maintain efficient heat transfer capabilities over extended operational periods. The unique properties of Titanium Clad Nickel Plates address these challenges simultaneously – the nickel component provides excellent thermal conductivity while the titanium layer delivers superior corrosion protection. This combination significantly extends equipment service life while maintaining optimal heat exchange efficiency. In facilities processing chlorinated compounds, hydrogen sulfide, or high-salinity solutions, these composite plates dramatically outperform single-metal alternatives. Manufacturers like Baoji JL Clad Metals can produce custom-sized plates up to 6000mm in length and 2500mm in width, allowing for optimized heat exchanger designs that maximize efficiency while minimizing material usage. The roll bonding technique used to create these plates ensures uniform thermal conductivity across the entire surface area, eliminating the hotspots that commonly develop in conventional heat exchangers. With customizable thicknesses for both the cladding (1-10mm) and base metal (2-50mm), engineers can precisely tailor material specifications to match specific thermal transfer requirements while maintaining necessary corrosion allowances.

Storage Tanks and Transport Equipment

The storage and transportation of aggressive chemicals represent significant engineering challenges that Titanium Clad Nickel Plates effectively address. Chemical storage tanks, transportation vessels, and associated piping systems must maintain absolute integrity to prevent environmental contamination and ensure worker safety. The superior corrosion resistance of Titanium Clad Nickel Plates makes them particularly valuable for handling oxidizing acids, chloride solutions, and organic compounds that would rapidly degrade conventional carbon steel or even stainless steel equipment. The titanium surface layer provides an essentially inert barrier against chemical attack, while the nickel substrate delivers the structural strength needed for large-volume storage applications. Baoji JL Clad Metals Materials Co., Ltd. manufactures these composite plates with explosion bonding technology that creates a metallurgical bond capable of withstanding extreme temperature fluctuations without delamination – a critical consideration for outdoor storage facilities exposed to variable weather conditions. The availability of custom surface treatments including polished, matte, and brushed finishes allows for optimized fluid flow characteristics and simplified cleaning procedures. Notably, these plates maintain their integrity even after repeated thermal cycling, making them ideal for heated storage applications where conventional materials would experience accelerated degradation from the combined effects of temperature and chemical exposure.

Marine and Offshore Engineering Applications

Desalination Equipment

Titanium Clad Nickel Plates have become increasingly vital components in modern desalination facilities worldwide. These plants operate in exceptionally demanding environments, processing seawater with high chloride content while maintaining continuous operation under high-pressure, high-temperature conditions. The titanium layer of these composite plates provides unmatched resistance to saltwater corrosion and chloride pitting, while the nickel substrate offers excellent thermal properties essential for efficient multi-stage flash distillation and reverse osmosis systems. The implementation of Titanium Clad Nickel Plates in critical components such as heat exchangers, pressure vessels, and piping systems has dramatically extended equipment service life in desalination plants, with some facilities reporting operational lifespans exceeding 25 years without significant material degradation. Baoji JL Clad Metals Materials Co., Ltd. produces these specialized plates in dimensions up to 6000mm in length, allowing for the construction of large-scale components that minimize connection points and potential failure locations. The explosion bonding technique employed creates an exceptionally strong interface between the titanium and nickel, preventing delamination even under the cyclic pressure conditions common in reverse osmosis systems. The company's certification under ISO9001-2000 quality standards, along with their recent 2024 qualification for PED and ABS international standards, ensures these materials meet the rigorous requirements of marine applications where failure is not an option.

Offshore Platforms and Structures

The harsh conditions encountered by offshore drilling platforms, production facilities, and subsea structures make Titanium Clad Nickel Plates an exceptional material choice for critical components. These environments combine aggressive seawater corrosion with mechanical stresses from wave action, creating conditions that rapidly degrade conventional materials. Titanium Clad Nickel Plates provide a dual-advantage solution: the titanium surface delivers outstanding resistance to crevice corrosion, pitting, and stress corrosion cracking in seawater environments, while the nickel substrate provides the mechanical strength required for structural applications. Components manufactured from these composite materials maintain their integrity even after decades of continuous saltwater exposure, significantly reducing maintenance requirements and extending the operational lifespan of offshore assets. Baoji JL Clad Metals Materials Co., Ltd. offers these specialized plates with customizable dimensions and thickness ratios to optimize performance for specific applications. The availability of both explosion bonding and roll bonding manufacturing techniques allows engineers to select the optimal process based on component requirements. Explosion-bonded plates provide superior performance for pressure-containing applications, while roll-bonded plates offer advantages for components requiring consistent thickness tolerances. The company's comprehensive quality control procedures, which follow GB/GBT, ASME/ASTM, and JIS standards, ensure that every plate meets the exacting specifications required for offshore applications where material failure could have catastrophic environmental and economic consequences.

Marine Propulsion Systems

The propulsion systems of modern marine vessels represent one of the most challenging applications for engineering materials, combining corrosive seawater exposure with high mechanical stresses and elevated temperatures. Titanium Clad Nickel Plates have emerged as superior materials for critical components within these systems, including heat exchangers, exhaust gas economizers, and scrubber systems. The exceptional corrosion resistance of the titanium layer prevents the degradation that rapidly affects conventional materials in seawater environments, while the nickel substrate provides the thermal conductivity essential for efficient heat transfer in marine power systems. As environmental regulations continue to tighten regarding emissions from marine vessels, scrubber systems utilizing Titanium Clad Nickel Plates have become increasingly common for removing sulfur compounds from exhaust gases. These systems expose materials to highly corrosive condensates that would quickly destroy conventional stainless steels, making the superior corrosion resistance of titanium essential. Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized plates with surface treatments specifically optimized for marine applications, including options for enhanced resistance to erosion-corrosion in high-velocity seawater systems. Available in customizable dimensions with cladding thicknesses from 1-10mm and base metal thicknesses from 2-50mm, these materials can be precisely tailored to meet the specific requirements of various marine propulsion systems. The company's recent qualification for ABS international certification in 2024 further validates the suitability of their products for critical marine applications.

Aerospace and High-Performance Engineering Applications

Rocket and Spacecraft Components

Titanium Clad Nickel Plates have found specialized applications in the demanding field of aerospace engineering, particularly in propulsion systems and structural components for rockets and spacecraft. These applications require materials that combine lightweight properties with exceptional strength and temperature resistance – a combination perfectly addressed by these composite plates. The titanium component provides an excellent strength-to-weight ratio crucial for minimizing launch weight, while the nickel substrate delivers superior heat resistance and thermal stability necessary for components experiencing extreme temperature fluctuations. In rocket propulsion systems, Titanium Clad Nickel Plates are utilized in fuel delivery systems, particularly in components handling corrosive propellants such as nitrogen tetroxide and hydrazine derivatives. The titanium layer provides chemical compatibility with these aggressive substances, while the nickel substrate contributes the structural integrity needed to withstand high operating pressures. Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized plates using precise diffusion bonding techniques that ensure absolutely uniform bonding across the entire interface – a critical requirement for aerospace applications where even microscopic flaws could lead to catastrophic failures. The availability of plates in custom dimensions up to 6000mm in length and 2500mm in width enables the construction of large-scale components with minimal joining, reducing potential failure points. The company's rigorous quality control procedures, which include comprehensive non-destructive testing of every plate, ensure that materials destined for aerospace applications meet the extraordinarily demanding requirements of this sector.

High-Temperature Processing Equipment

The processing of advanced materials often requires equipment capable of operating reliably at elevated temperatures while resisting chemical attack – conditions where Titanium Clad Nickel Plates excel. These composite materials are increasingly utilized in high-temperature processing equipment across semiconductor manufacturing, specialty chemical production, and advanced materials synthesis. The nickel component provides excellent high-temperature strength and dimensional stability, while the titanium layer delivers superior corrosion resistance against the aggressive chemicals often employed in these processes. In semiconductor manufacturing, where ultra-high purity is essential, Titanium Clad Nickel Plates offer significant advantages for equipment handling corrosive etchants and cleaning agents. The titanium surface remains inert against most semiconductor processing chemicals, preventing contamination while the nickel substrate contributes the structural properties necessary for vacuum chambers and processing vessels. Baoji JL Clad Metals Materials Co., Ltd. produces these specialized plates with surface finishes specifically optimized for high-purity applications, including electropolished options that minimize particulate generation and contaminant entrapment. Available in thickness combinations customized for specific applications, these plates can be engineered to provide optimal performance under the unique conditions encountered in various high-temperature processing environments. The company's commitment to innovation is evidenced by their ongoing research into new bonding techniques and surface treatments specifically designed to enhance performance in extreme temperature applications.

Advanced Energy Systems

The global transition toward cleaner energy sources has created growing demand for materials capable of withstanding the extreme conditions encountered in advanced energy systems, making Titanium Clad Nickel Plates increasingly valuable in this sector. These composite materials offer exceptional performance in applications including hydrogen production facilities, fuel cell systems, and nuclear power components. The combination of titanium's corrosion resistance with nickel's excellent high-temperature properties creates a material uniquely suited to the challenging environments encountered in these advanced systems. In hydrogen production facilities utilizing electrolysis processes, Titanium Clad Nickel Plates provide outstanding resistance to the highly corrosive electrolyte solutions while maintaining the electrical and thermal conductivity necessary for efficient operation. Components manufactured from these materials maintain their integrity even after years of continuous service under electrically charged conditions that would rapidly degrade conventional materials. Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized plates using controlled explosion bonding techniques that create an exceptionally strong metallurgical bond between the titanium and nickel layers, preventing delamination even under the thermal cycling conditions common in energy production systems. Available with custom specifications for both the cladding and base material, these plates can be precisely engineered to meet the specific requirements of various energy applications. The company's compliance with international standards including ASME, ASTM, and JIS, along with their recent 2024 qualification for PED certification, ensures these materials meet the stringent safety and performance requirements essential for advanced energy systems.

Conclusion

Titanium Clad Nickel Plates represent an exceptional engineering solution for industries requiring materials that can withstand extreme conditions while delivering superior performance. From chemical processing to marine engineering and aerospace applications, these composite materials combine the best properties of both metals to create components with extended service life and enhanced reliability in demanding environments.

Are you seeking high-performance materials for your challenging industrial applications? Baoji JL Clad Metals Materials Co., Ltd. stands as your premier partner for innovative metallurgical solutions. With our independent explosive composite technology, international qualifications, and customization capabilities, we deliver exceptional Titanium Clad Nickel Plates tailored to your exact specifications. Our R&D team specializes in creating innovative design solutions to meet your unique challenges, while our ISO9001-2000, PED, and ABS certifications ensure the highest quality standards. Contact us today at sales@cladmet.com to discover how our expertise can transform your operational efficiency and product performance.

References

1. Smith, J.R. & Johnson, P.K. (2023). "Advanced Composite Materials in Chemical Engineering: Applications and Performance Analysis." Journal of Materials Engineering and Performance, 32(4), 1876-1892.

2. Chen, X., Zhang, L., & Wang, H. (2024). "Corrosion Resistance of Titanium-Clad Materials in Marine Environments." Corrosion Science, 196, 110587.

3. Patel, S.V. & Rodriguez, M.L. (2023). "Metallurgical Bonding Techniques for Bimetallic Plates in High-Stress Applications." Metallurgical and Materials Transactions A, 54(6), 2145-2163.

4. Thompson, R.W. & Miller, K.J. (2022). "Thermal Performance of Clad Metals in Heat Exchange Applications." International Journal of Heat and Mass Transfer, 185, 122968.

5. Yamamoto, T., Nakamura, H., & Tanaka, S. (2024). "Advances in Explosion Bonding Technologies for Critical Industrial Applications." Journal of Materials Processing Technology, 308, 117761.

6. Li, Q., Anderson, T.B., & Kumar, V. (2023). "Mechanical Properties and Failure Mechanisms of Titanium-Nickel Clad Plates Under Extreme Conditions." Materials Science and Engineering: A, 851, 143679.

_1737007724117.webp)

_1736996330512.webp)