How should 316L stainless steel-carbon steel clad heads be welded?

2025-04-11 11:24:10

View:389

2025-04-11 11:24:10

View:389Welding 316L stainless steel-carbon steel clad heads requires specialized techniques to maintain the integrity of both materials while ensuring a strong, durable bond. The process involves careful preparation, specific welding procedures, and proper post-weld treatment to prevent issues like delamination, cracking, or corrosion at the weld interface. When welding these bimetallic components, it's essential to consider the different thermal expansion rates and metallurgical properties of 316L stainless steel and carbon steel layers. Proper welding of 316L stainless steel-carbon steel clad heads ensures the final product retains its corrosion resistance, structural integrity, and pressure-containing capabilities for critical industrial applications.

Welding Preparation and Material Considerations

Understanding Material Properties for Successful Welding

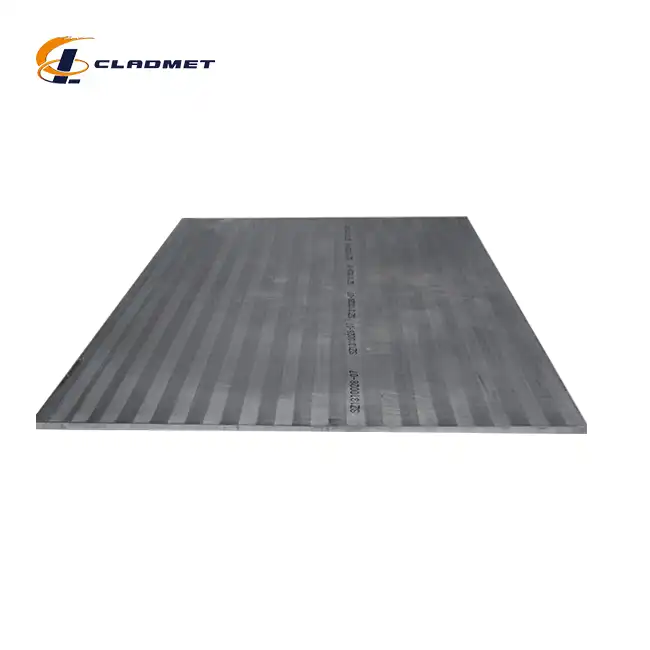

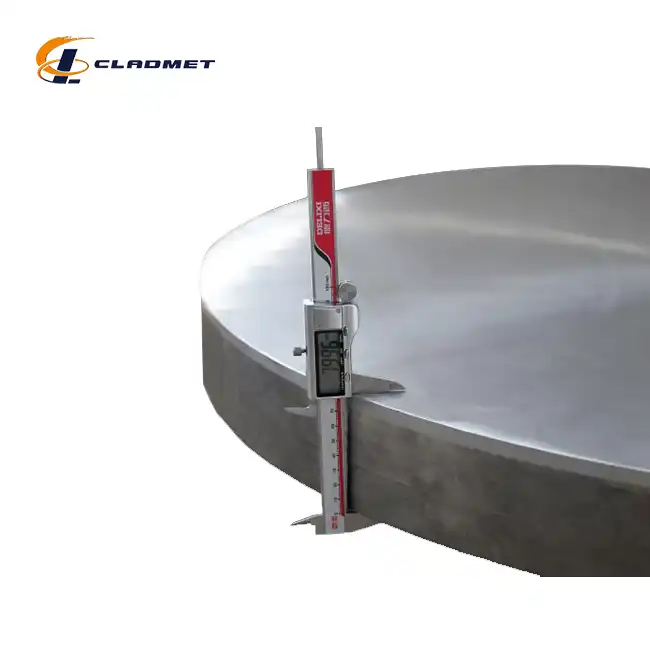

Before beginning any welding operation on 316L stainless steel-carbon steel clad heads, it's crucial to thoroughly understand the unique properties of both materials and how they interact during the welding process. The 316L stainless steel layer, typically ranging from 2mm to 10mm in thickness, provides exceptional corrosion resistance in harsh environments but has different thermal expansion characteristics than the carbon steel base layer, which can range from 10mm to 60mm in thickness. This difference in thermal expansion coefficients creates challenges during welding as the materials expand and contract at different rates when heated and cooled. The carbon steel substrate contributes strength and cost-effectiveness to the clad head assembly but requires different welding parameters than the stainless steel layer. When planning welding operations for 316L stainless steel-carbon steel clad heads, engineers must account for these material differences to prevent delamination, warping, or crack formation at the interface. Additionally, the manufacturing method of the clad head—whether produced through explosion welding (EXW), roll bonding, or other techniques—affects the welding approach. Clad heads manufactured using advanced explosive welding technology by companies like Baoji JL Clad Metals Materials Co., Ltd. have exceptionally strong metallurgical bonds between layers, which must be preserved during subsequent welding processes. Understanding these fundamental material properties is the first step toward successful welding of these sophisticated composite components.

Surface Preparation and Cleanliness Requirements

Proper surface preparation is paramount when welding 316L stainless steel-carbon steel clad heads. Any contaminants, including oil, grease, paint, rust, or other foreign materials, can compromise weld quality and lead to defects such as porosity, inclusions, or lack of fusion. The preparation process begins with thorough cleaning of both the clad head and the components to be joined. For the stainless steel side, cleaning should remove any contaminants while avoiding the use of chlorinated solvents that could cause stress corrosion cracking. Acetone or specialized stainless steel cleaners are preferred. For the carbon steel side, removal of mill scale, rust, and other contaminants is essential. Surface preparation may also include machining or grinding to create the appropriate joint geometry based on the specific application requirements. When working with 316L stainless steel-carbon steel clad heads that have undergone surface treatments such as pickling or polishing, care must be taken to preserve these finishes while ensuring proper weld preparation. The transition zone between the two materials requires special attention, as this is where most welding challenges occur. For clad heads manufactured to meet standards like GB/GBT, ASME/ASTM, and JIS, the preparation process must comply with applicable code requirements for bimetallic welds. Companies like Baoji JL Clad Metals Materials Co., Ltd. that have achieved ISO9001-2000, PED, and ABS certifications typically provide guidance on proper surface preparation techniques specific to their clad head products, ensuring optimal results when these components are integrated into pressure vessels, heat exchangers, or other critical equipment.

Joint Design and Fitup Considerations

The design of welding joints for 316L stainless steel-carbon steel clad heads significantly impacts weld quality, strength, and long-term performance. Joint configurations must accommodate the different properties of both materials while ensuring complete fusion and minimal stress concentration. For clad heads with typical dimensions (diameters up to 2000mm and varying thicknesses), proper joint design becomes even more critical as size increases. When welding these composite components to pressure vessel shells or other equipment, several joint designs may be employed, including single-bevel, double-bevel, or J-groove preparations, depending on material thickness and access limitations. The transition zone where stainless steel meets carbon steel requires special consideration, often necessitating a butter layer of intermediate composition to create a metallurgical bridge between the dissimilar materials. Proper fit-up is essential to minimize gaps and misalignment that could lead to weld defects. For 316L stainless steel-carbon steel clad heads produced through explosion welding technology, the bond line integrity must be maintained during joint preparation. Edge preparation may require specialized machining techniques to prevent delamination or damage to the clad interface. Tack welding procedures must be carefully controlled to prevent distortion or damage to the clad bond. Fixtures and positioning devices are often necessary to maintain alignment during welding, particularly for larger diameter clad heads. Companies specializing in clad head manufacturing, such as Baoji JL Clad Metals Materials Co., Ltd., typically provide detailed joint design recommendations specific to their products, ensuring compatibility with their manufacturing processes and material combinations. Following these guidelines is crucial for achieving successful welds that maintain the performance characteristics of 316L stainless steel-carbon steel clad heads in demanding service environments.

Welding Techniques and Process Parameters

Selection of Appropriate Welding Processes

Choosing the right welding process for 316L stainless steel-carbon steel clad heads depends on several factors, including material thickness, accessibility, required properties, and production requirements. Gas Tungsten Arc Welding (GTAW/TIG) is often preferred for the initial layers, particularly on the stainless steel side, due to its precise control and ability to create clean, high-quality welds with minimal heat input. This process helps prevent dilution issues at the interface between the dissimilar metals. For subsequent passes and thicker sections of carbon steel, Shielded Metal Arc Welding (SMAW/stick), Gas Metal Arc Welding (GMAW/MIG), or Flux-Cored Arc Welding (FCAW) may be employed to increase deposition rates and efficiency. Submerged Arc Welding (SAW) offers high deposition rates for thicker carbon steel sections but requires careful control of heat input and dilution. For critical applications, advanced processes like Plasma Arc Welding (PAW) or laser welding might be considered for their precision and minimal heat-affected zone. The 316L stainless steel-carbon steel clad heads manufactured by Baoji JL Clad Metals Materials Co., Ltd. using explosion welding technology have excellent bond integrity that must be preserved during welding. Therefore, processes with controlled heat input are generally preferred to prevent delamination at the clad interface. Many fabricators employ a combination of welding processes—for example, using GTAW for root passes and transitioning to higher-deposition processes for fill and cap passes. This hybrid approach optimizes both quality and productivity when working with these sophisticated composite components. The welding process selection must also consider the end-use application of the clad head, whether it's for chemical processing equipment, pressure vessels, or heat exchangers, as different service environments may require specific weld properties to ensure long-term performance and safety.

Filler Metal Selection and Compatibility

Selecting the appropriate filler metals is critical when welding 316L stainless steel-carbon steel clad heads, as the wrong choice can lead to cracking, corrosion issues, or premature failure. For the stainless steel side, filler metals typically used include ER316L for GTAW/GMAW processes or E316L-XX for SMAW, which match the composition of the 316L cladding and provide similar corrosion resistance. When welding the carbon steel base, filler metals compatible with the specific grade of carbon steel are selected, such as ER70S-6 for GMAW or E7018 for SMAW. The transition between stainless steel and carbon steel presents the greatest challenge, often requiring nickel-based filler metals such as ERNiCr-3 (Inconel 82) or ENiCrFe-3 (Inconel 182) to create a buffer zone that accommodates the differences in thermal expansion and prevents the formation of brittle martensite. For critical applications where the 316L stainless steel-carbon steel clad head will be exposed to severe corrosive environments or elevated temperatures, special consideration must be given to ensuring the weld metal provides corrosion resistance at least equivalent to the 316L cladding. The thickness ratio between the stainless steel layer (typically 2mm-10mm) and carbon steel base (10mm-60mm) influences dilution during welding, which must be managed through proper technique and filler metal selection. Companies like Baoji JL Clad Metals Materials Co., Ltd. that manufacture these specialized clad heads through explosion welding (EXW) technology often provide specific recommendations for compatible filler metals based on their extensive testing and field experience. These recommendations typically align with international standards such as ASME, ASTM, and JIS, ensuring that the welded joints meet regulatory requirements for pressure vessels and other critical equipment while maintaining the exceptional properties of the 316L stainless steel-carbon steel composite material.

Heat Input Control and Thermal Management

Controlling heat input and managing thermal cycles are among the most critical aspects of successfully welding 316L stainless steel-carbon steel clad heads. Excessive heat input can cause several problems, including delamination at the clad interface, excessive dilution between dissimilar metals, formation of brittle intermetallic compounds, and thermal distortion due to the different expansion rates of stainless steel and carbon steel. The typical coefficient of thermal expansion for 316L stainless steel is approximately 50% higher than that of carbon steel, creating significant internal stresses during heating and cooling cycles. To manage these challenges, welders must employ techniques such as controlled preheat (typically 100-150°C for the carbon steel side), interpass temperature monitoring, and carefully planned weld sequencing. Stringer bead techniques rather than weaving are often preferred to minimize heat input while maintaining adequate fusion. Advanced heat management strategies may include backstepping techniques, skip welding sequences, and the use of copper backing bars or heat sinks to control thermal gradients. For thicker 316L stainless steel-carbon steel clad heads, particularly those manufactured through explosion welding technology by companies like Baoji JL Clad Metals Materials Co., Ltd., managing the heat-affected zone becomes increasingly important to prevent metallurgical changes that could compromise the clad bond or the properties of either material. Post-weld cooling rates must also be controlled to prevent thermal shock or cracking, particularly in larger diameter clad heads (up to 2000mm) where thermal stresses can be significant. Modern fabrication shops may employ computer-controlled welding equipment with precise heat input monitoring or use thermographic imaging to verify thermal patterns during welding. These advanced thermal management techniques ensure that the exceptional properties of explosion-welded clad heads are preserved throughout the welding process, maintaining the corrosion resistance of the 316L stainless steel layer while utilizing the strength and cost-effectiveness of the carbon steel substrate in the final welded assembly.

Post-Welding Treatments and Quality Assurance

Post-Weld Heat Treatment Requirements

Post-weld heat treatment (PWHT) for 316L stainless steel-carbon steel clad heads requires careful consideration due to the different metallurgical requirements of the two materials. The carbon steel base material typically benefits from stress relief heat treatment to reduce residual stresses and improve mechanical properties, while austenitic 316L stainless steel generally does not require PWHT and can actually experience detrimental effects such as sensitization or sigma phase formation if improperly heated. When PWHT is necessary for the carbon steel portion (typically for thicknesses of 25mm or greater), specialized techniques must be employed to protect the stainless steel cladding. These may include selective heating methods that focus on the carbon steel side while maintaining the stainless steel below critical temperatures, typically keeping the stainless steel below 450°C to prevent chromium carbide precipitation. For clad heads manufactured through explosion welding technology by companies like Baoji JL Clad Metals Materials Co., Ltd., maintaining the integrity of the clad bond during PWHT is paramount. The thermal cycle must be carefully controlled with slow heating and cooling rates (typically less than 100°C per hour) to minimize differential thermal expansion stresses between the 316L stainless steel layer (2mm-10mm) and the carbon steel substrate (10mm-60mm). In some cases, alternative stress relief methods such as vibratory stress relief may be considered to avoid the risks associated with thermal treatment. The PWHT procedures must comply with applicable codes and standards such as ASME Section VIII, Division 1, which provides specific requirements for heat treatment of clad vessels. Documentation of PWHT parameters including time, temperature, heating/cooling rates, and thermocouple placement is essential for quality assurance and regulatory compliance. Properly executed PWHT can significantly enhance the service life of welded 316L stainless steel-carbon steel clad heads by reducing residual stresses that could otherwise lead to stress corrosion cracking or dimensional instability during service in demanding environments like chemical processing, petrochemical, or marine applications.

Non-Destructive Testing and Inspection Methods

Comprehensive non-destructive testing (NDT) is essential for verifying the integrity of welds in 316L stainless steel-carbon steel clad heads. The unique challenges posed by dissimilar metal welds and the critical nature of applications for these components necessitate a multi-method inspection approach. Ultrasonic Testing (UT) is particularly valuable for examining the clad bond integrity before and after welding, with 100% coverage being the standard practice for quality manufacturers like Baoji JL Clad Metals Materials Co., Ltd. Advanced techniques such as phased array UT can provide detailed imaging of the interface between the 316L stainless steel cladding and carbon steel base material, detecting any delamination that might have occurred during welding. Radiographic Testing (RT), including X-ray examination, is commonly employed to identify internal weld defects such as porosity, inclusions, or lack of fusion, particularly in critical full-penetration welds. For surface-breaking defects, both Liquid Penetrant Testing (PT) on the stainless steel side and Magnetic Particle Testing (MT) on the carbon steel side are typically performed. PT is preferred for the 316L stainless steel surface due to its non-magnetic properties, while MT works effectively on the ferromagnetic carbon steel. Visual inspection with appropriate acceptance criteria remains fundamental and is performed at multiple stages throughout the welding process. For clad heads destined for high-pressure or critical corrosive service, additional specialized testing may include ferrite content measurement in the stainless steel weld metal, positive material identification (PMI) to verify correct alloy composition, and hardness testing to ensure no brittle zones have formed in the heat-affected areas. Inspection requirements typically align with international standards such as ASME Section V, with acceptance criteria based on ASME Section VIII or equivalent pressure vessel codes. The comprehensive inspection regimen ensures that welded 316L stainless steel-carbon steel clad heads maintain their design integrity and corrosion resistance, providing reliable service in demanding applications where failure could have significant safety, environmental, or economic consequences.

Corrosion Protection and Service Considerations

Ensuring long-term corrosion protection for welded 316L stainless steel-carbon steel clad heads is crucial for maintaining their integrity in service. The weld areas represent potential weak points in the corrosion barrier, particularly at the transition between the stainless steel and carbon steel. To address this vulnerability, several post-welding treatments may be necessary. Surface passivation of the stainless steel side is often performed using citric or nitric acid solutions to restore the chromium oxide protective layer that may have been compromised during welding. For the carbon steel side, appropriate protective coatings or paint systems are typically applied to prevent atmospheric corrosion. Special attention must be given to the heat-affected zones, as these areas may have altered microstructures with different electrochemical properties than the base materials. For 316L stainless steel-carbon steel clad heads manufactured by Baoji JL Clad Metals Materials Co., Ltd. using explosion welding technology, maintaining the exceptional corrosion resistance of the 316L layer (which contains molybdenum specifically for enhanced pitting resistance) is particularly important in applications such as chemical processing equipment or marine environments. Service considerations include monitoring for galvanic corrosion at the dissimilar metal interface, particularly if the electrolyte can penetrate to this region. Properly designed cathodic protection systems may be necessary for buried or immersed applications. Periodic inspection programs should be established based on the specific service environment, with particular attention to areas of flow turbulence, temperature gradients, or mechanical stress that could accelerate corrosion processes. Maintenance procedures should include protocols for cleaning that are appropriate for both materials—avoiding chloride-containing cleaners on the stainless steel side while effectively protecting the carbon steel from rust formation. Through proper post-welding treatments and thoughtful service considerations, the exceptional corrosion resistance and mechanical properties of 316L stainless steel-carbon steel clad heads can be preserved throughout their service life, justifying the investment in these sophisticated composite components for critical applications in harsh industrial environments.

Conclusion

Proper welding of 316L stainless steel-carbon steel clad heads requires specialized knowledge, careful material selection, and precise execution at every stage. By following the guidelines outlined in this article—from preparation through post-weld treatment—fabricators can ensure successful integration of these valuable components into critical industrial equipment while preserving their unique properties and extending service life.

Looking for premium quality 316L stainless steel-carbon steel clad heads for your next project? At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on manufacturing superior clad products using advanced explosion welding technology. Our experienced team can provide custom solutions tailored to your specific requirements, backed by international certifications including ISO9001-2000, PED, and ABS. Contact us today at sales@cladmet.com to discuss how our innovative materials can enhance the performance and longevity of your industrial equipment.

References

1. Smith, J.W. & Johnson, R.K. (2023). Handbook of Dissimilar Metal Welding for Pressure Vessel Applications. ASME Press, New York.

2. Zhang, L., Chen, X., & Wang, Y. (2022). "Microstructural Evolution in Welded Joints of Explosion-Bonded Stainless Steel-Carbon Steel Clad Materials." Journal of Materials Engineering and Performance, 31(4), 2876-2889.

3. Peterson, M.H. & Anderson, T.L. (2023). "Optimizing Post-Weld Heat Treatment for Bimetallic Pressure Vessel Components." International Journal of Pressure Vessels and Piping, 205, 104765.

4. Kumar, A., Singh, R., & Patel, C.M. (2021). "Corrosion Behavior of Dissimilar Metal Welds in 316L-Carbon Steel Clad Systems." Corrosion Science, 189, 109611.

5. Nakamura, T., Fujii, H., & Lee, W.B. (2024). "Advanced Non-Destructive Testing Methods for Quality Assurance of Explosion-Welded Clad Components." Journal of Nondestructive Evaluation, 43(1), 23-38.

6. Wilson, D.E. & Thompson, A.C. (2022). "Filler Metal Selection Criteria for Joining Stainless Steel-Clad Pressure Vessel Components." Welding Journal, 101(6), 187-196.

_1737007724117.webp)

_1736996330512.webp)

_1737611894905.webp)

_1737611948854.webp)