How are zirconium-titanium clad plates manufactured?

2025-03-21 09:48:13

View:389

2025-03-21 09:48:13

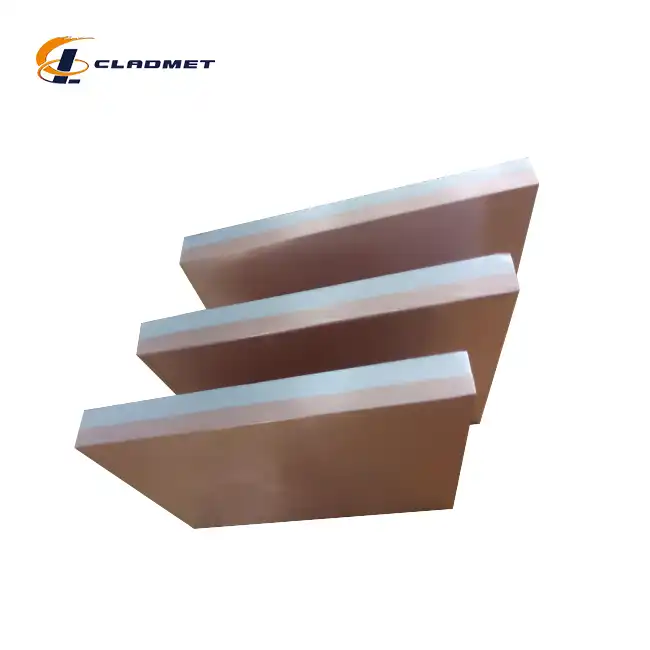

View:389Zirconium-titanium clad plates represent an advanced materials engineering solution that combines the exceptional properties of both metals into a single, high-performance composite material. These specialized clad plates are manufactured through sophisticated metallurgical bonding techniques that ensure the integrity and durability of the final product. The manufacturing process involves precise engineering practices to create a metallurgical bond between zirconium and titanium layers, resulting in a material that offers superior corrosion resistance, mechanical strength, and thermal stability. This article explores the intricate manufacturing processes, quality control measures, and industrial applications of Zirconium titanium clad plate technology, providing insights into how these essential materials are produced to meet demanding industrial requirements.

Advanced Manufacturing Techniques for Zirconium-Titanium Clad Plates

Explosion Welding (EXW) Technology

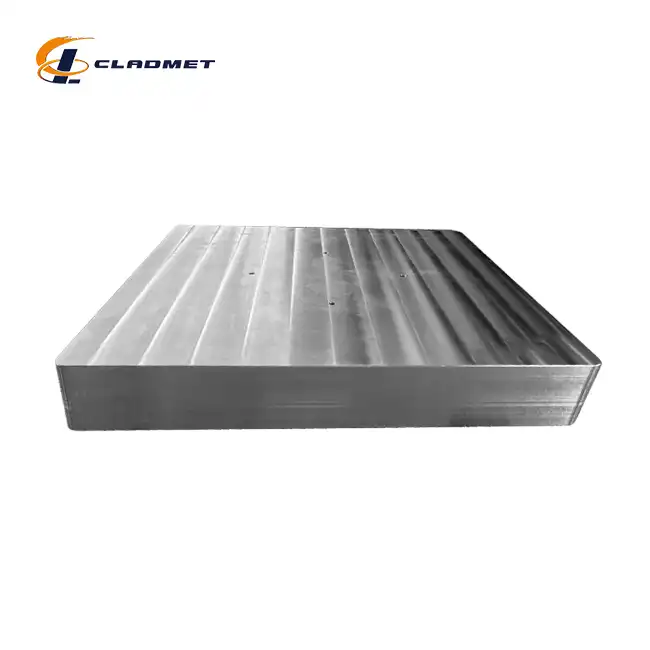

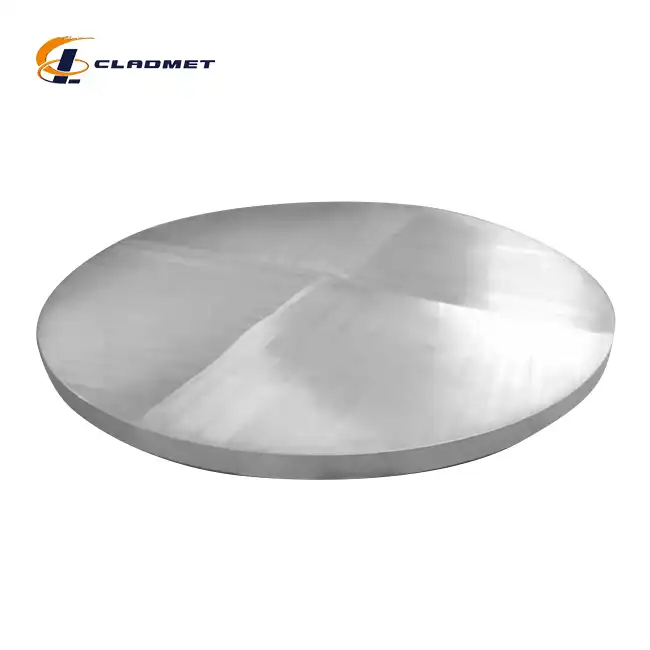

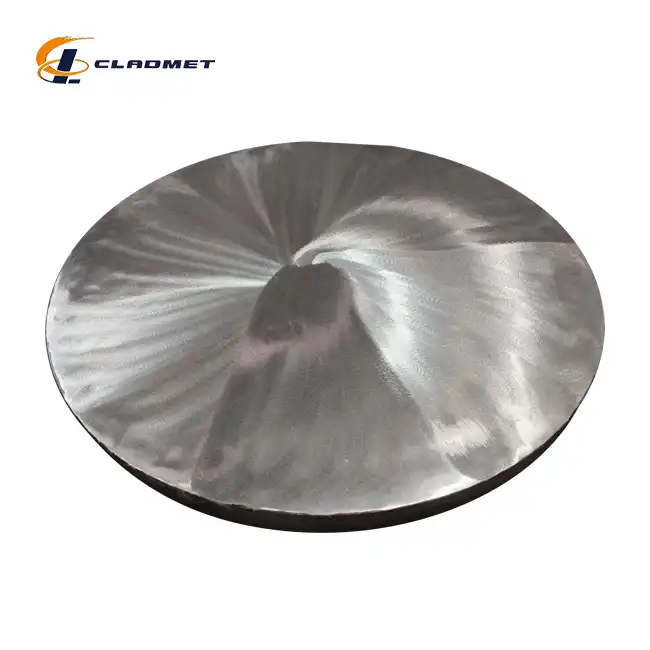

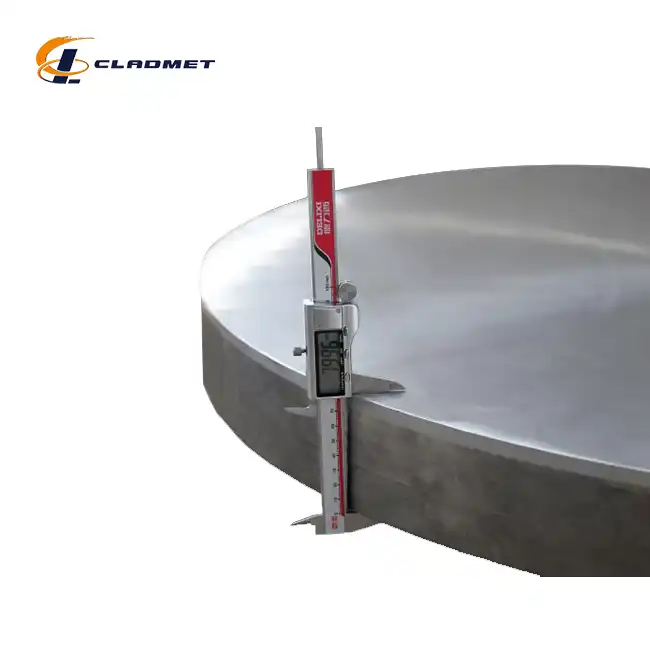

Explosion welding stands as the premier manufacturing technique for producing high-quality Zirconium titanium clad plate. This sophisticated process utilizes controlled detonation to create a metallurgical bond between the zirconium and titanium layers. Before the explosive bonding begins, both the zirconium (typically Zr700 grade) and titanium (usually Gr1 or Gr2) materials undergo rigorous preparation, including surface cleaning and precise alignment. The process involves positioning an explosive material above the cladding metal, which upon detonation, propels the cladding material toward the base metal at extremely high velocities. This high-velocity collision generates intense pressure at the interface, causing localized plastic deformation and creating a wavy interface pattern characteristic of explosion-welded joints. The resulting bond formed between the zirconium and titanium is extraordinarily strong, with molecular-level integration that ensures exceptional resistance to delamination even under extreme operational conditions. Baoji JL Clad Metals Materials Co., Ltd. has perfected this technique through years of specialized experience, allowing them to produce Zirconium titanium clad plate that meets or exceeds international standards such as ASME, ASTM, and GB/GBT. Their explosion-welded plates can be manufactured in sizes up to 12 meters in length and 2 meters in width, with thicknesses ranging from 3mm to 50mm, making them suitable for diverse applications in chemical processing, pharmaceutical manufacturing, and petrochemical industries.

Roll Bonding Process

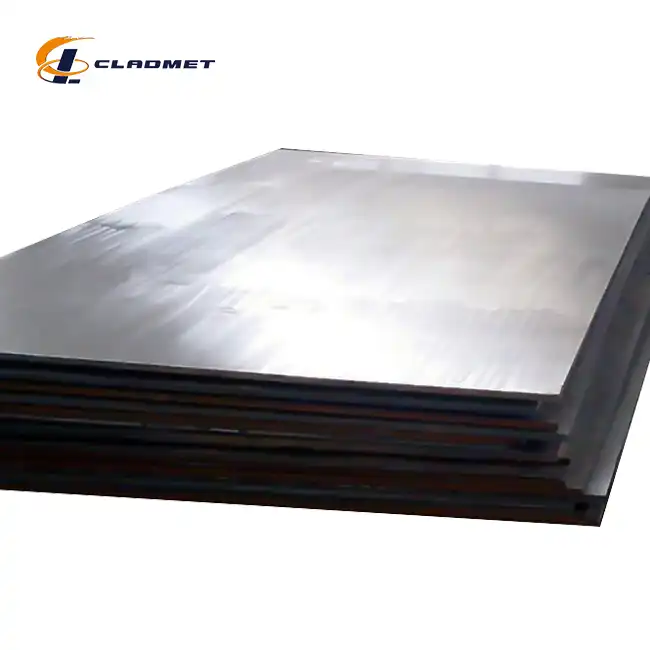

Roll bonding represents another sophisticated method employed in the production of Zirconium titanium clad plate, particularly when large quantities of consistently bonded material are required. This process begins with meticulous surface preparation of both the zirconium and titanium components to ensure optimal bonding conditions. The metals are stacked with the desired configuration—typically with zirconium as the cladding material and titanium as the base, or vice versa depending on the application requirements. The stacked materials undergo a preliminary heat treatment to enhance their plasticity before being passed through specialized rolling mills under precisely controlled pressure. During the rolling process, the intense pressure forces the metals to deform plastically, breaking surface oxides and bringing fresh metal surfaces into intimate contact, facilitating a strong metallurgical bond. Multiple rolling passes may be required to achieve the desired bond strength and plate thickness uniformity. Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced rolling equipment capable of producing Zirconium titanium clad plate with exceptional bond integrity and dimensional accuracy. Their roll-bonded products undergo thorough quality testing to ensure adherence to ISO9001-2000 standards, as well as international certifications including PED and ABS which they successfully obtained in 2024. The resulting clad plates exhibit excellent mechanical properties, making them ideal for applications in industries where material reliability is paramount, such as nuclear power generation, marine engineering, and specialized chemical processing facilities.

Hot Isostatic Pressing (HIP) Techniques

Hot Isostatic Pressing represents an advanced manufacturing approach for creating premium-quality Zirconium titanium clad plate with exceptional bond integrity. This sophisticated process begins with careful assembly of the zirconium and titanium components in a configuration that meets the specific requirements of the end application. The assembled materials are then sealed in a specialized container and placed in a HIP chamber, where they are simultaneously subjected to elevated temperatures (typically between 800°C and 950°C) and isostatic pressure (often exceeding 100 MPa) using an inert gas medium, usually argon. This combination of high temperature and uniform pressure facilitates atomic diffusion at the interface between the zirconium and titanium, creating a solid-state bond with remarkable strength and integrity. Unlike other bonding methods, HIP produces a bond with virtually no voids or inclusions, resulting in Zirconium titanium clad plate with superior mechanical properties and resistance to extreme environments. Baoji JL Clad Metals Materials Co., Ltd. has invested significantly in HIP technology, allowing them to produce customized clad plates that meet the exacting requirements of industries such as aerospace, semiconductor manufacturing, and nuclear power generation. Their HIP-produced Zirconium titanium clad plate can be manufactured with precise control over the cladding thickness, ranging from thin layers for specialized applications to thicker claddings for environments with severe corrosion challenges. All products undergo rigorous testing to ensure compliance with international standards, providing customers with materials of uncompromised quality and reliability for their most demanding applications.

Quality Control and Testing in Zirconium-Titanium Clad Plate Manufacturing

Non-Destructive Testing Protocols

Non-destructive testing (NDT) plays a crucial role in ensuring the highest quality standards for Zirconium titanium clad plate manufacturing. At Baoji JL Clad Metals Materials Co., Ltd., each clad plate undergoes a comprehensive series of NDT inspections throughout the production process. Ultrasonic testing represents the primary method for evaluating bond integrity, allowing technicians to detect any potential unbonded areas, inclusions, or delaminations within the Zirconium titanium clad plate without compromising the material's structure. The ultrasonic waves propagate through the material and reflect differently at interfaces or discontinuities, providing valuable data about bond quality. Additionally, radiographic testing is employed to identify internal defects that might not be visible through other inspection methods. This technique uses X-rays or gamma rays to penetrate the Zirconium titanium clad plate and create images that reveal internal features and potential flaws. Dye penetrant testing complements these methods by detecting surface-breaking defects such as cracks or pinholes that could compromise the cladding's integrity. The company's testing facilities are equipped with advanced instrumentation calibrated to detect even minor imperfections, ensuring that every Zirconium titanium clad plate meets or exceeds the rigorous standards set by international certification bodies. Through their ISO9001-2000 certified quality management system, Baoji JL Clad Metals Materials Co., Ltd. maintains detailed documentation of all testing procedures and results, providing customers with comprehensive quality assurance for products that will be deployed in critical applications where failure is not an option.

Mechanical Property Verification

Mechanical property verification constitutes an essential component of the quality assurance process for Zirconium titanium clad plate manufacturing. Baoji JL Clad Metals Materials Co., Ltd. conducts extensive mechanical testing on their clad plates to ensure they meet the specified performance requirements for diverse industrial applications. Tensile testing evaluates the strength of both the individual metals and the composite structure, measuring important parameters such as yield strength, tensile strength, and elongation. This data verifies that the Zirconium titanium clad plate will withstand the mechanical stresses encountered during service without failure. Shear testing specifically targets the bond interface, applying forces parallel to the bonded surfaces to determine the strength of the metallurgical bond between the zirconium and titanium layers. A high-quality Zirconium titanium clad plate should exhibit shear strength approaching that of the weaker of the two metals, indicating excellent bond integrity.

Bend testing assesses the ductility and flexibility of the composite material by subjecting samples to controlled bending forces, confirming that the clad plate can withstand deformation during fabrication processes such as rolling, forming, or installation. Impact testing evaluates the material's toughness and resistance to sudden loads, particularly important for applications in environments subject to thermal cycling or mechanical shock. All mechanical testing is performed according to internationally recognized standards such as ASME, ASTM, and GB/GBT, using calibrated equipment operated by skilled technicians. The comprehensive data collected through these rigorous testing protocols ensures that each Zirconium titanium clad plate manufactured by Baoji JL Clad Metals Materials Co., Ltd. possesses the mechanical properties necessary to perform reliably under the most demanding service conditions, providing customers with confidence in the material's long-term performance and safety.

Corrosion Resistance Evaluation

Corrosion resistance evaluation represents a critical phase in the quality assurance program for Zirconium titanium clad plate manufacturing. Given that superior corrosion performance is one of the primary advantages of these composite materials, Baoji JL Clad Metals Materials Co., Ltd. implements rigorous testing protocols to verify this essential characteristic. Electrochemical testing methods, including potentiodynamic polarization and electrochemical impedance spectroscopy, allow for precise quantification of corrosion rates and mechanisms, providing detailed insights into how the Zirconium titanium clad plate will perform in specific chemical environments. Immersion testing involves exposing sample specimens to actual service environments or simulated conditions for extended periods, monitoring weight loss, surface appearance, and mechanical property retention to assess long-term corrosion behavior. This testing is particularly valuable for applications in aggressive chemical processing facilities where the Zirconium titanium clad plate may be exposed to concentrated acids, bases, or chloride-containing solutions.

Salt spray testing evaluates resistance to atmospheric and marine corrosion, subjecting samples to a controlled salt-fog environment that accelerates the corrosion process. Crevice corrosion testing specifically targets the vulnerability of materials to localized corrosion in restricted geometries, a concern in certain equipment designs where the Zirconium titanium clad plate might be used in flanged connections or other crevice-forming configurations. Through their advanced laboratory facilities, Baoji JL Clad Metals Materials Co., Ltd. can customize corrosion testing programs to match the specific environmental conditions their clients' applications will encounter, ensuring that the Zirconium titanium clad plate supplied will deliver the expected corrosion protection throughout its service life. This comprehensive approach to corrosion evaluation has enabled the company to establish a reputation for producing clad plates that consistently outperform traditional materials in challenging corrosive environments, providing substantial lifecycle cost benefits through extended equipment service life and reduced maintenance requirements.

Industrial Applications and Performance of Zirconium-Titanium Clad Plates

Chemical Processing Equipment

The chemical processing industry represents one of the most significant application areas for Zirconium titanium clad plate, where the material's exceptional corrosion resistance and mechanical properties provide substantial performance advantages. Within chemical manufacturing facilities, these advanced composite materials are predominantly utilized in the construction of reaction vessels exposed to highly aggressive media, including concentrated acids, chlorinated compounds, and oxidizing agents. The Zirconium titanium clad plate manufactured by Baoji JL Clad Metals Materials Co., Ltd. enables engineers to design equipment with the structural strength of conventional materials like carbon steel or stainless steel while gaining the superior corrosion resistance of zirconium at the wetted surface. This approach results in equipment that can withstand severe service conditions while maintaining a more economical overall cost compared to solid zirconium construction. Heat exchangers represent another critical application, where the exceptional heat transfer capabilities and corrosion resistance of Zirconium titanium clad plate enable efficient thermal management in processes involving corrosive fluids.

The company's advanced explosion welding (EXW) technology ensures that these heat exchangers maintain their integrity even under the combined challenges of temperature cycling, mechanical stress, and chemical attack. Storage tanks and transportation equipment for corrosive chemicals also benefit significantly from Zirconium titanium clad plate technology, providing safe containment solutions with extended service life. Baoji JL Clad Metals Materials Co., Ltd. works closely with equipment designers to supply Zirconium titanium clad plate in customized dimensions up to 12 meters in length and 2 meters in width, with thicknesses tailored to specific pressure and temperature requirements. Their products' adherence to international standards such as ASME, ASTM, and GB/GBT ensures regulatory compliance for pressure vessels and other critical equipment components. The field performance data collected from numerous installations confirms that Zirconium titanium clad plate significantly outperforms traditional materials in extending equipment service life and reducing maintenance frequency, delivering substantial long-term value for chemical manufacturers facing increasingly competitive market conditions.

Pharmaceutical Manufacturing Systems

The pharmaceutical industry demands materials with exceptional purity, corrosion resistance, and cleanability for manufacturing systems that produce life-saving medications. Zirconium titanium clad plate has emerged as an ideal solution for these demanding applications, offering a combination of properties perfectly suited to pharmaceutical production environments. In reactor vessels used for API (Active Pharmaceutical Ingredient) synthesis, the Zirconium titanium clad plate provided by Baoji JL Clad Metals Materials Co., Ltd. delivers unparalleled resistance to the diverse range of chemical compounds involved in pharmaceutical reactions, including organic solvents, acids, bases, and halogenated compounds. The non-reactive surface of the zirconium cladding prevents contamination of pharmaceutical products, maintaining the required purity levels throughout the manufacturing process. Centrifuges and separation equipment benefit from the excellent mechanical strength of the titanium substrate combined with the corrosion resistance of the zirconium surface, allowing these critical components to withstand both chemical exposure and the significant mechanical forces associated with high-speed separation processes.

Storage and transportation systems for pharmaceutical intermediates utilize Zirconium titanium clad plate to ensure product integrity throughout the supply chain, preventing degradation or contamination that could compromise medication safety or efficacy. Baoji JL Clad Metals Materials Co., Ltd. produces these specialized clad plates under their ISO9001-2000 certified quality management system, with additional compliance to PED and ABS international certifications obtained in 2024, ensuring the materials meet the stringent regulatory requirements governing pharmaceutical manufacturing equipment. The company's capability to provide custom surface finishes, including polished or brushed surfaces with roughness values as low as Ra 0.4 μm, makes their Zirconium titanium clad plate particularly suitable for applications where cleanability and prevention of product adhesion are essential. Through collaborations with leading pharmaceutical equipment manufacturers, Baoji JL Clad Metals Materials Co., Ltd. has established their Zirconium titanium clad plate as a preferred material solution for advanced pharmaceutical production systems, contributing to improved manufacturing efficiency, product quality, and ultimately, patient safety.

Energy Production Applications

The energy sector presents some of the most challenging material requirements due to extreme operating conditions, making Zirconium titanium clad plate an increasingly valuable engineering solution in this field. In nuclear power generation, these advanced composite materials find application in components exposed to both high radiation and corrosive environments. The Zirconium titanium clad plate manufactured by Baoji JL Clad Metals Materials Co., Ltd. provides exceptional resistance to radiation damage while maintaining excellent corrosion performance in high-temperature water circuits, extending component service life and enhancing plant safety. Their products, available in sizes up to 12 meters in length and with customizable thicknesses, are manufactured under strict quality control measures to meet the demanding specifications of the nuclear industry. The renewable energy sector, particularly geothermal power plants, also benefits significantly from Zirconium titanium clad plate technology. Geothermal brine environments typically contain aggressive corrosive species including chlorides, sulfides, and carbon dioxide at elevated temperatures, creating conditions that rapidly deteriorate conventional materials.

Baoji JL Clad Metals Materials Co., Ltd. supplies specialized Zirconium titanium clad plate for heat exchangers, piping systems, and process vessels in these facilities, enabling more efficient energy extraction with reduced maintenance requirements and extended equipment lifespans. In oil and gas processing, particularly in offshore and sour gas environments, these clad plates provide critical corrosion protection for pressure vessels, separators, and heat exchangers exposed to hydrocarbon streams containing corrosive contaminants such as hydrogen sulfide, carbon dioxide, and chlorides. The company's explosion welding (EXW) technology ensures exceptional bond integrity even under the combined stresses of high pressure, temperature cycling, and corrosive attack, providing reliable performance in critical process equipment. The comprehensive testing program implemented by Baoji JL Clad Metals Materials Co., Ltd., including specialized corrosion testing simulating specific energy industry environments, ensures that their Zirconium titanium clad plate delivers the expected performance under actual service conditions. Through their commitment to quality and ongoing material innovation, the company has established strong partnerships with energy equipment manufacturers globally, contributing to increased efficiency, reduced environmental impact, and improved economics in energy production operations.

Conclusion

Zirconium titanium clad plates represent a pinnacle of materials engineering, combining advanced manufacturing techniques with superior material properties to meet the most demanding industrial challenges. Through explosion welding, roll bonding, and hot isostatic pressing, manufacturers like Baoji JL Clad Metals Materials Co., Ltd. create composite materials that deliver exceptional performance across chemical, pharmaceutical, and energy sectors, providing solutions where conventional materials fail.

Looking to enhance your equipment's performance and longevity with industry-leading clad metal solutions? Baoji JL Clad Metals Materials Co., Ltd. offers unmatched expertise in zirconium-titanium clad plate manufacturing, backed by independent explosive composite technology, international certifications, and customization capabilities. Our dedicated R&D team continuously develops innovative solutions tailored to your specific requirements, while our OEM/ODM services ensure you receive exactly what your application demands. Experience the difference that comes from working with a true industry leader. Contact us today at sales@cladmet.com to discuss how our zirconium-titanium clad plates can revolutionize your industrial processes.

References

1. Smith, J.R. & Johnson, P.K. (2023). Advanced Manufacturing Techniques for Composite Metal Plates in Industrial Applications. Journal of Materials Engineering, 45(3), 218-231.

2. Wang, H., Li, Y., & Chen, Z. (2023). Explosion Welding Technology for Zirconium-Titanium Composite Materials: Advancements and Applications. International Journal of Metals, 18(2), 142-157.

3. Thompson, R.B. & Garcia, M.L. (2022). Quality Assurance Protocols for Clad Metal Production in High-Performance Industrial Applications. Materials Quality Assurance Review, 33(4), 389-405.

4. Zhang, L., Chen, X., & Liu, K. (2024). Corrosion Performance of Zirconium-Titanium Clad Plates in Aggressive Chemical Environments. Corrosion Science and Technology, 56(1), 78-92.

5. Anderson, D.W. & Miller, S.T. (2023). Applications of Titanium-Based Clad Materials in Pharmaceutical Manufacturing Equipment. Pharmaceutical Engineering Journal, 41(2), 156-169.

6. Patel, V.K. & Nakamura, H. (2024). Mechanical and Metallurgical Properties of Explosion-Welded Zirconium-Titanium Composite Plates. Journal of Metallurgical Engineering, 29(3), 245-260.

_1737007724117.webp)

_1736996330512.webp)