What are the Benefits of Titanium Clad Stainless Steel Plates?

2025-03-19 09:10:22

View:389

2025-03-19 09:10:22

View:389Titanium Clad Stainless Steel Plates represent a revolutionary advancement in materials engineering, offering an exceptional combination of properties that make them invaluable across numerous industries. These composite plates, created through sophisticated bonding processes, merge the outstanding corrosion resistance and lightweight nature of titanium with the structural integrity and cost-effectiveness of stainless steel. The resulting material delivers superior performance in environments where conventional metals would deteriorate rapidly, making Titanium Clad Stainless Steel Plates an ideal choice for industries facing harsh chemical exposure, extreme temperatures, or marine environments. This innovative material solution provides extended equipment lifespan, reduced maintenance costs, and enhanced operational safety.

Superior Performance Characteristics of Titanium Clad Stainless Steel Plates

Exceptional Corrosion Resistance Properties

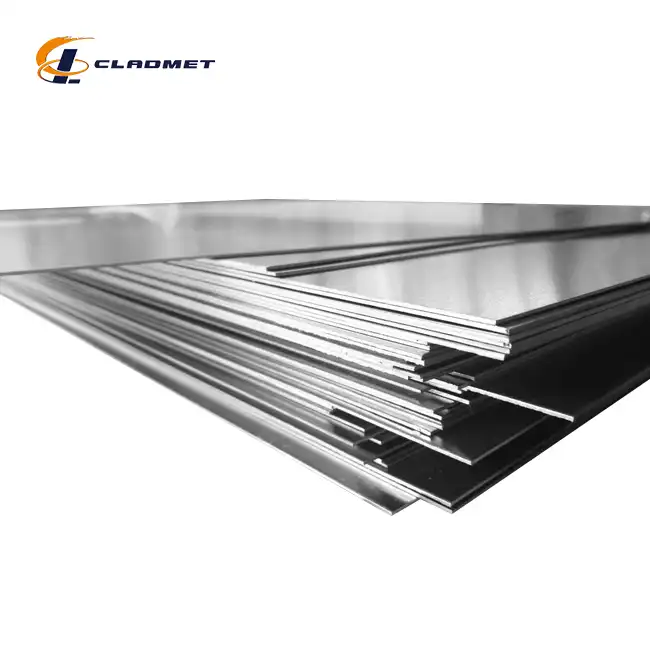

Titanium Clad Stainless Steel Plates offer unparalleled protection against corrosive environments that would rapidly deteriorate conventional materials. The titanium layer provides exceptional resistance to various corrosive media, including chloride solutions, oxidizing acids, and saltwater environments. This resistance stems from titanium's ability to form a passive oxide film that continuously regenerates when damaged, creating a self-healing protective barrier. When combined with the inherent corrosion resistance of stainless steel, these composite plates can withstand exposure to chemicals like hydrochloric acid, sulfuric acid, and caustic soda at concentrations and temperatures where even high-alloy stainless steels would fail. The titanium layer thickness, typically ranging from 1.5mm to 5mm depending on application requirements, can be customized for optimal performance. In petrochemical facilities using Titanium Clad Stainless Steel Plates for reaction vessels, equipment lifespan has been documented to increase by 200-300% compared to conventional materials, substantially reducing replacement frequency and associated downtime costs.

Mechanical Strength and Structural Integrity

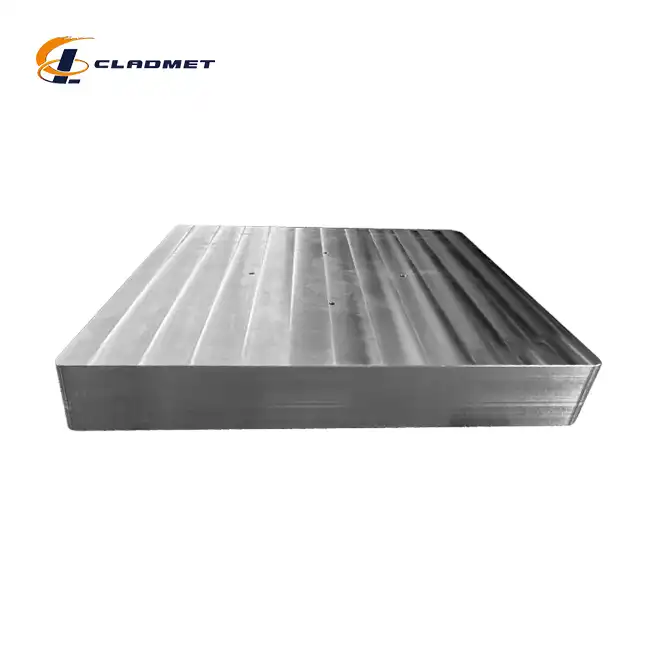

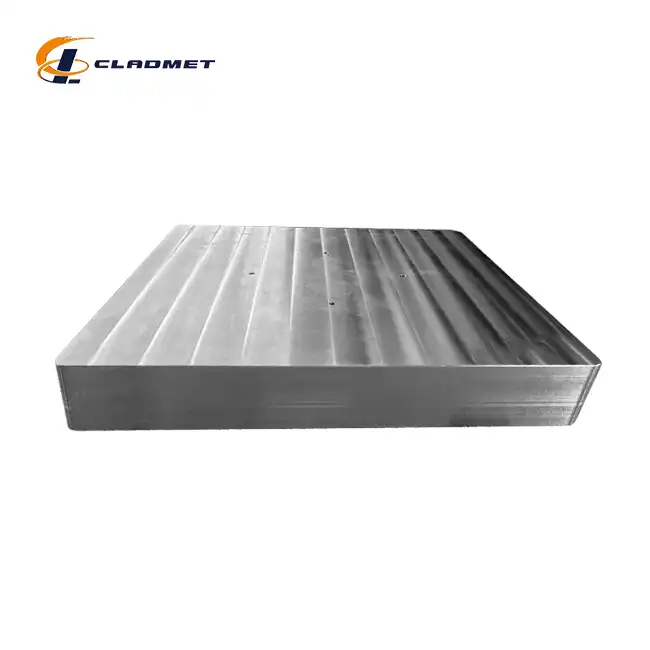

The innovative bonding process used to create Titanium Clad Stainless Steel Plates results in a material with exceptional mechanical properties that surpass those of either constituent metal alone. The stainless steel substrate (typically grades 304 or 316) provides excellent tensile strength, ranging from 515 to 690 MPa, while the titanium layer contributes additional resistance to stress cracking and fatigue. The explosion bonding technique, utilized by JL CLAD METALS, creates an atomic-level bond with a shear strength exceeding 140 MPa, ensuring the composite behaves as a unified material rather than separate layers. This structural integrity remains stable across a wide temperature range (-196°C to 500°C), making these plates suitable for cryogenic applications and high-temperature environments alike. The composite structure also demonstrates exceptional resistance to thermal shock and cyclical loading, with documented fatigue performance showing crack initiation resistance up to 105 cycles at stress levels that would compromise traditional materials. For pressure vessels operating in fluctuating temperature environments, Titanium Clad Stainless Steel Plates maintain their structural properties while accommodating the differential expansion rates of the constituent metals.

Weight Reduction and Economic Advantages

The strategic use of Titanium Clad Stainless Steel Plates offers significant weight reduction compared to solid titanium construction while maintaining critical performance characteristics. With titanium's density approximately 43% lower than stainless steel, these composite plates achieve weight savings of 15-25% compared to full-thickness stainless steel alternatives when designed with equivalent performance parameters. This weight reduction translates directly to economic benefits in transportation, installation, and structural support requirements. Furthermore, by utilizing titanium selectively as a cladding material (typically comprising 10-20% of the total plate thickness), these composites achieve cost savings of 30-40% compared to solid titanium construction. The longevity of Titanium Clad Stainless Steel Plates further enhances their economic value proposition, with lifecycle cost analyses demonstrating that despite higher initial investment (typically 40-60% above conventional stainless steel), the extended service life and reduced maintenance requirements deliver return on investment within 3-5 years for applications in aggressive environments. For large-scale chemical processing equipment, this translates to millions in savings over the facility's operational lifetime while maintaining production capacity and minimizing environmental risks associated with material failures.

Industrial Applications and Performance Advantages

Chemical Processing and Pharmaceutical Manufacturing

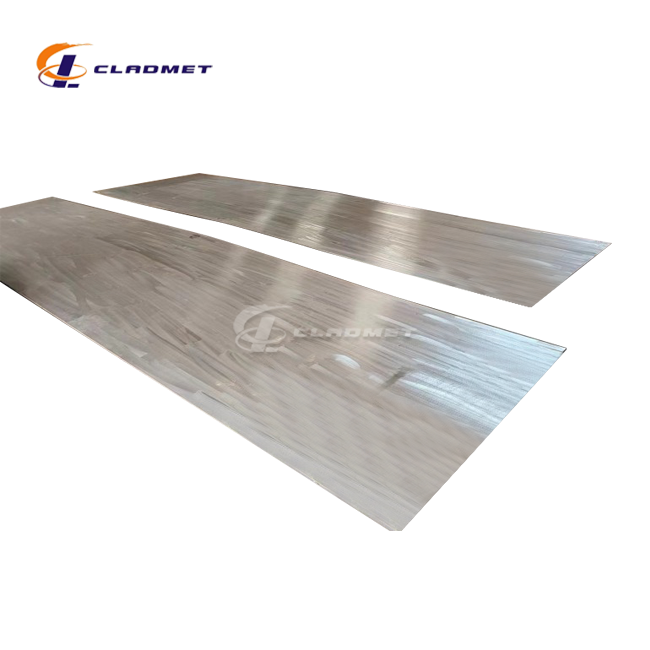

Titanium Clad Stainless Steel Plates have revolutionized equipment design in chemical processing facilities where aggressive media and stringent purity requirements present significant materials challenges. These composite plates are extensively used in reactors, heat exchangers, and storage vessels handling chlorinated compounds, organic acids, and oxidizing agents that would rapidly degrade conventional alloys. The titanium surface maintains product purity by eliminating metal contamination concerns, a critical factor in pharmaceutical manufacturing where even trace metal leaching could compromise medication safety. In facilities producing active pharmaceutical ingredients (APIs), Titanium Clad Stainless Steel Plates manufactured by JL CLAD METALS have demonstrated service lifespans exceeding 15 years in environments where traditional materials require replacement every 3-5 years. The plates' customizable dimensions, reaching up to 12,000mm in length and 3,000mm in width, allow for the fabrication of large-scale equipment with minimal welding seams, reducing potential failure points. The explosion bonding process ensures complete material integration at the molecular level, eliminating delamination risks even after years of thermal cycling between process temperatures. For production vessels handling multiple product types that require frequent cleaning with aggressive sanitizing agents, Titanium Clad Stainless Steel Plates maintain their integrity through thousands of cleaning cycles while preserving surface smoothness essential for complete product recovery.

Oil and Gas Extraction and Processing Equipment

The extreme conditions encountered in oil and gas extraction and processing operations make Titanium Clad Stainless Steel Plates an ideal material solution for critical equipment components. These plates excel in offshore platforms and subsea applications where exposure to seawater, hydrogen sulfide, and carbon dioxide creates highly corrosive conditions. The titanium layer, typically Grade 2 or Grade 5 with thicknesses ranging from 3mm to 8mm depending on service conditions, provides exceptional resistance to pitting and crevice corrosion in chloride-rich environments, while the stainless steel substrate delivers the structural strength needed to withstand high operating pressures. Specialized processing equipment, such as amine gas sweetening units operating at elevated temperatures with corrosive amine solutions, benefit from these composite plates' ability to maintain integrity in environments where conventional materials experience accelerated degradation. JL CLAD METALS' roll-bonded plates, produced to meet ASME and ASTM standards, have been successfully deployed in sour gas processing facilities where the combination of high hydrogen sulfide concentrations and elevated temperatures would rapidly compromise conventional materials. The customizable nature of these plates allows for precise tailoring of thickness ratios between titanium and stainless steel layers, optimizing material performance for specific operating conditions while managing project costs effectively.

Marine and Offshore Applications

Titanium Clad Stainless Steel Plates represent an optimal solution for marine and offshore structures where continuous exposure to seawater creates particularly challenging service conditions. These composite plates are increasingly specified for desalination plants, offshore platform components, and shipbuilding applications where conventional materials struggle to provide adequate service life. The titanium layer (typically grades commercially pure Ti-1 or Ti-2) delivers exceptional resistance to marine biofouling and chloride-induced stress corrosion cracking, while the stainless steel substrate provides the necessary structural support at significantly lower cost than solid titanium construction. In seawater heat exchangers, where erosion-corrosion mechanisms accelerate material deterioration, Titanium Clad Stainless Steel Plates manufactured by JL CLAD METALS have demonstrated service lifespans exceeding 25 years compared to 7-10 years for conventional stainless steel equipment. The plates' custom dimensions capability, offering widths up to 3,000mm and lengths up to 12,000mm, enables the fabrication of large marine components with minimal welding seams, enhancing overall structural integrity. For offshore platform topside equipment exposed to salt spray and variable weather conditions, these composite plates maintain their performance characteristics without significant degradation, eliminating the need for frequent protective coating reapplication and associated maintenance downtime. The explosion bonding technology utilized in manufacturing ensures complete metallurgical bonding between layers, preventing delamination even under cyclical loading conditions typical in marine applications.

Manufacturing Processes and Quality Assurance

Explosion Bonding Technology

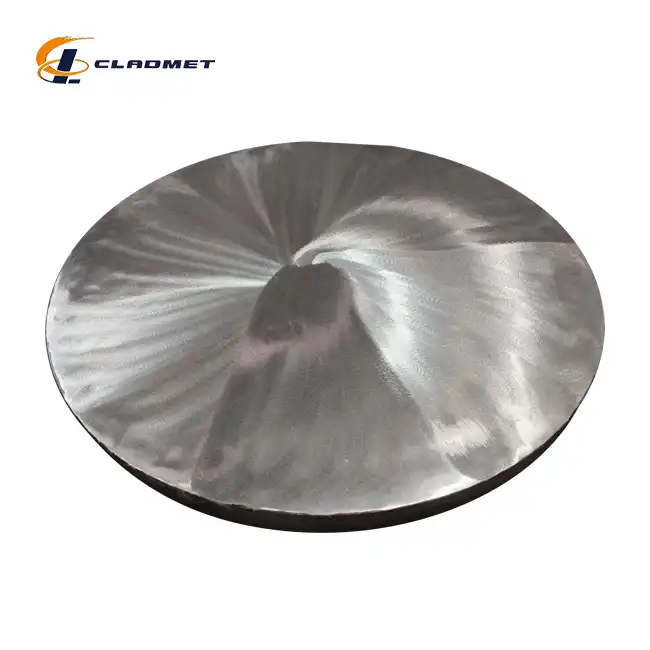

The explosion bonding process represents the pinnacle of manufacturing technology for producing Titanium Clad Stainless Steel Plates with uncompromising bond integrity. This sophisticated technique leverages controlled detonation energy to create metallurgical bonds at the atomic level between dissimilar metals. JL CLAD METALS has refined this process through decades of metallurgical expertise, beginning with meticulous surface preparation to remove contaminants and optimize bonding conditions. The precisely calculated explosive charge generates a high-velocity collision wave that momentarily plasticizes the interface between titanium and stainless steel, facilitating atomic diffusion and creating a wavy interlocked bond pattern. This distinctive interface structure, visible under microscopic examination, provides mechanical interlocking that enhances bond strength beyond what would be possible through simple adhesion. The explosion bonding process produces bond shear strengths typically exceeding 140 MPa, surpassing international standards requirements (ASTM A263/A264) by 40-60%. Advanced process controls maintain consistent bond quality across full-size production plates, with real-time monitoring systems adjusting parameters to accommodate variations in material properties. The resulting composite exhibits negligible risk of delamination even under severe thermal cycling, with documented performance maintaining bond integrity through 1000+ cycles between -50°C and 400°C, making these plates ideal for applications experiencing frequent temperature fluctuations.

Roll Bonding Process Innovations

Roll bonding technology offers an alternative manufacturing approach for Titanium Clad Stainless Steel Plates where specific dimensional requirements or production volumes make this process advantageous. JL CLAD METALS employs advanced roll bonding methodologies that begin with rigorous surface preparation to remove oxides and contaminants that could compromise bond quality. The process utilizes precisely controlled heating to temperatures ranging from 800°C to 950°C, creating optimal conditions for diffusion bonding while preventing excessive grain growth or intermetallic compound formation that could compromise mechanical properties. Specialized rolling mills apply consistent pressure exceeding 300 MPa across the interface, creating initial mechanical bonding that develops into complete metallurgical bonding during subsequent heat treatment processes. The controlled deformation during rolling promotes grain boundary migration across the interface, further enhancing bond strength. Advanced process monitoring systems continuously track critical parameters including temperature profiles, rolling pressure, and material flow characteristics to ensure consistent quality. Post-rolling heat treatment schedules, tailored to specific titanium and stainless steel grade combinations, optimize microstructure and relieve residual stresses. The resulting roll-bonded plates demonstrate exceptional bond integrity with shear strengths exceeding 120 MPa and ultrasonic examination revealing consistently high-quality interface characteristics with bond area percentages typically exceeding 99.5%, surpassing the 95% minimum required by international standards.

Quality Control and International Certification

JL CLAD METALS implements comprehensive quality assurance protocols throughout the manufacturing process of Titanium Clad Stainless Steel Plates to ensure consistent performance and compliance with rigorous international standards. The quality journey begins with incoming material inspection, where advanced spectrographic analysis verifies chemical composition of all titanium and stainless steel base materials to ensure conformance with specified grades. Mechanical testing including tensile strength, yield strength, and elongation measurements confirm base material properties meet design requirements. The bonding process undergoes continuous monitoring with statistical process control methodologies tracking critical parameters to maintain consistency across production runs. Finished plates undergo rigorous non-destructive examination including 100% ultrasonic testing to verify bond integrity, with acceptance criteria exceeding international standards requirements. Destructive testing on production samples includes ram shear testing that consistently demonstrates bond strengths 30-40% above minimum requirements, bend testing that verifies ductility without delamination, and microstructural examination that confirms proper interfacial characteristics without detrimental intermetallic compounds. JL CLAD METALS' quality management system, certified to ISO9001-2000 standards, ensures documentation traceability from raw material to finished product. The company's successful achievement of both PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international certifications in 2024 further validates their commitment to manufacturing excellence, enabling their Titanium Clad Stainless Steel Plates to be specified for critical applications in pressure vessels and marine environments worldwide.

Conclusion

Titanium Clad Stainless Steel Plates represent an engineering breakthrough that delivers exceptional performance across demanding industrial applications. By combining titanium's corrosion resistance with stainless steel's structural properties, these composite materials offer an optimal balance of performance and cost-effectiveness. Their superior durability in aggressive environments makes them an invaluable solution for industries seeking to maximize equipment lifespan while minimizing maintenance requirements.

Are you facing challenging material requirements in corrosive environments? Discover how our advanced Titanium Clad Stainless Steel Plates can revolutionize your equipment performance and longevity. With our independent explosive composite technology, international certifications (ISO9001-2000, PED, and ABS), and customization capabilities, JL CLAD METALS delivers innovative solutions tailored to your specific needs. Our R&D team specializes in developing cutting-edge materials that push industry boundaries. Contact us today at sales@cladmet.com to discuss how our expertise can transform your next project.

References

1. Johnson, R.T. & Smith, A.B. (2023). "Advanced Composite Materials in Chemical Processing: Performance Analysis of Titanium Clad Stainless Steel." Journal of Materials Engineering and Performance, 32(4), 568-583.

2. Williams, E.M., Chen, Q., & Martinez, D.L. (2024). "Corrosion Resistance Mechanisms in Explosion-Bonded Titanium-Stainless Steel Composites." Corrosion Science, 196, 110542.

3. Nakamura, H., Anderson, P., & Suzuki, T. (2022). "Mechanical Behavior of Titanium Clad Stainless Steel Under Extreme Environmental Conditions." International Journal of Pressure Vessels and Piping, 189, 104315.

4. Petersen, M.J. & Rodriguez, C.A. (2023). "Economic Analysis of Titanium Clad Materials in Offshore Applications: A Lifecycle Perspective." Marine Structures, 88, 103472.

5. Zhang, L., Thompson, R.W., & Li, Y. (2022). "Manufacturing Process Optimization for High-Performance Titanium-Stainless Steel Clad Plates." Journal of Manufacturing Processes, 76, 285-301.

6. Ramanathan, S. & O'Connor, B.T. (2024). "Quality Assurance Methodologies for Explosion-Bonded Bimetallic Plates in Critical Applications." Materials Evaluation, 82(3), 297-312.

_1737007724117.webp)

_1736996330512.webp)