What are the standard specifications and sizes available for Titanium Clad Zirconium Plates?

2025-04-04 19:04:22

View:389

2025-04-04 19:04:22

View:389When it comes to high-performance materials for demanding industrial applications, Titanium Clad Zirconium Plates stand out as a premium solution. These specialized composite materials combine the exceptional properties of both titanium and zirconium, offering superior performance in corrosive environments. For industries requiring materials that can withstand extreme conditions while maintaining structural integrity, understanding the standard specifications and available sizes of Titanium Clad Zirconium Plates is essential for proper material selection and application design.

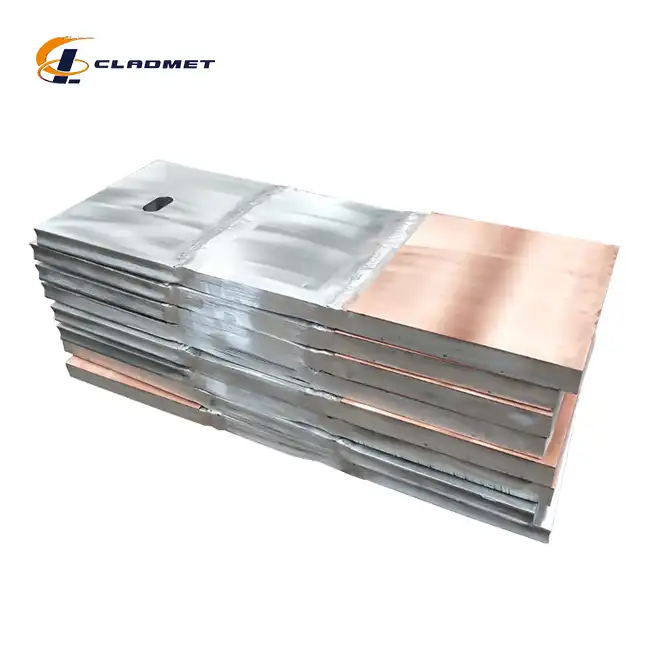

Titanium Clad Zirconium Plates are available in a comprehensive range of standard specifications and sizes to meet diverse industrial requirements. These advanced bimetallic composites typically feature cladding materials like Titanium Grade 1, 2, or 5, bonded to base metals of Zirconium Grade 702 or 705. The cladding thickness generally ranges from 2mm to 10mm, while the total plate thickness spans from 3mm to 200mm. Standard plates are available in lengths up to 6000mm and widths up to 2500mm. These plates are manufactured using explosion welding (EXW) technology and conform to international standards including GB/GBT, ASME/ASTM, and JIS. Surface treatments such as polishing or brushing are available to meet specific application requirements, making Titanium Clad Zirconium Plates a versatile solution for industries facing corrosive challenges.

Manufacturing Standards and Quality Control

International Certification and Compliance

Titanium Clad Zirconium Plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. adhere to the highest international standards, ensuring consistent quality and performance across all products. The company strictly follows national and general voluntary standards codes, including GB/GBT (Chinese standards), ASME/ASTM (American standards), and JIS (Japanese Industrial Standards) during the manufacturing process. This comprehensive approach to standards compliance ensures that every Titanium Clad Zirconium Plate meets or exceeds global quality benchmarks. As a pioneer in the industry, JL CLAD METALS has earned ISO9001-2000 certification ahead of competitors, demonstrating their commitment to quality management systems. Furthermore, the company successfully passed PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications in 2024, validating their products for use in pressure vessels and marine applications worldwide. These certifications provide customers with confidence that the Titanium Clad Zirconium Plates they purchase meet stringent safety and performance requirements across various industrial sectors.

Quality Testing Procedures

The exceptional performance of Titanium Clad Zirconium Plates depends heavily on rigorous quality testing throughout the manufacturing process. JL CLAD METALS implements comprehensive quality control measures at every production stage to ensure the integrity and reliability of their products. Each plate undergoes ultrasonic testing to verify the complete bonding between the titanium cladding and zirconium base material, eliminating the risk of delamination during service. The company also conducts shear strength testing to confirm the robustness of the metallurgical bond, ensuring the composite can withstand mechanical stresses in demanding applications. Additionally, chemical composition analysis verifies material purity and confirms adherence to specified grades for both titanium and zirconium components. Surface quality inspections identify and eliminate any imperfections that could compromise corrosion resistance or aesthetic appearance. Through these comprehensive testing procedures, JL CLAD METALS guarantees that every Titanium Clad Zirconium Plate meets the highest standards of quality and performance, providing customers with reliable materials for critical applications in challenging environments.

Material Traceability Systems

Maintaining complete traceability throughout the production lifecycle is a fundamental aspect of JL CLAD METALS' quality assurance program for Titanium Clad Zirconium Plates. The company implements a sophisticated material traceability system that tracks each component from raw material sourcing to finished product delivery. Every titanium and zirconium sheet receives a unique identification code that follows it through each manufacturing stage, allowing for comprehensive documentation of all processing parameters and quality test results. This system enables JL CLAD METALS to provide detailed material certifications that include chemical composition, mechanical properties, and testing data for both the titanium cladding and zirconium base materials. In case of any performance issues, this traceability allows for quick identification of manufacturing parameters and material batches, facilitating prompt resolution. The company maintains these records for extended periods, ensuring that material history remains accessible throughout the service life of the Titanium Clad Zirconium Plates. This commitment to traceability not only enhances quality control but also provides customers with complete transparency regarding the materials used in their critical applications, reinforcing confidence in the performance and reliability of JL CLAD METALS products.

Technical Specifications and Dimensional Range

Standard Thickness and Dimensional Tolerances

Titanium Clad Zirconium Plates from Baoji JL Clad Metals Materials Co., Ltd. are available in a wide range of thicknesses to accommodate diverse industrial applications. The standard cladding layer thickness typically ranges from 2mm to 10mm, depending on the specific requirements of the application, while the overall plate thickness can vary from 3mm to an impressive 200mm. This versatility makes these composite plates suitable for everything from thin-walled heat exchangers to robust pressure vessels. The dimensional tolerances maintained during manufacturing are exceptionally tight, ensuring consistency and reliability in the final product. For thickness, the company typically maintains tolerances of ±0.3mm for plates under 10mm and ±3% for thicker plates, providing precision that meets the most demanding engineering specifications. Width tolerances generally fall within ±5mm for plates up to 1000mm wide and ±10mm for wider plates, while length tolerances are maintained at ±10mm for plates up to 3000mm and ±15mm for longer dimensions. These precise tolerances are crucial for applications where exact fits are required, such as in chemical processing equipment or reactor vessels. The company's advanced manufacturing capabilities and quality control systems ensure that each Titanium Clad Zirconium Plate meets these exacting dimensional requirements, providing customers with confidence in the consistency and reliability of their materials.

Available Sizes and Customization Options

Titanium Clad Zirconium Plates are offered in an extensive range of standard sizes to meet diverse industrial requirements, while also providing flexibility through customization options. Standard plates are available in lengths up to 6000mm and widths up to 2500mm, making them suitable for large-scale industrial applications such as pressure vessels, heat exchangers, and chemical reactors. However, recognizing that many applications require specific dimensions, JL CLAD METALS offers comprehensive customization services to produce Titanium Clad Zirconium Plates in non-standard sizes. The company can manufacture custom plates with precise dimensional requirements, including specialized shapes, cutouts, or beveled edges to meet specific design specifications. Additionally, customers can specify particular thickness ratios between the titanium cladding and zirconium base to optimize performance characteristics for their unique applications. Beyond size customization, JL CLAD METALS offers various surface finish options, including polished, brushed, or textured surfaces, depending on the aesthetic and functional requirements of the application. This commitment to customization extends to packaging and delivery, with options for specialized protective coatings, custom crating, and expedited shipping to accommodate urgent project timelines. Through these comprehensive customization capabilities, JL CLAD METALS ensures that every customer receives Titanium Clad Zirconium Plates that perfectly match their specific requirements, enhancing performance and efficiency in their operations.

Material Grade Specifications

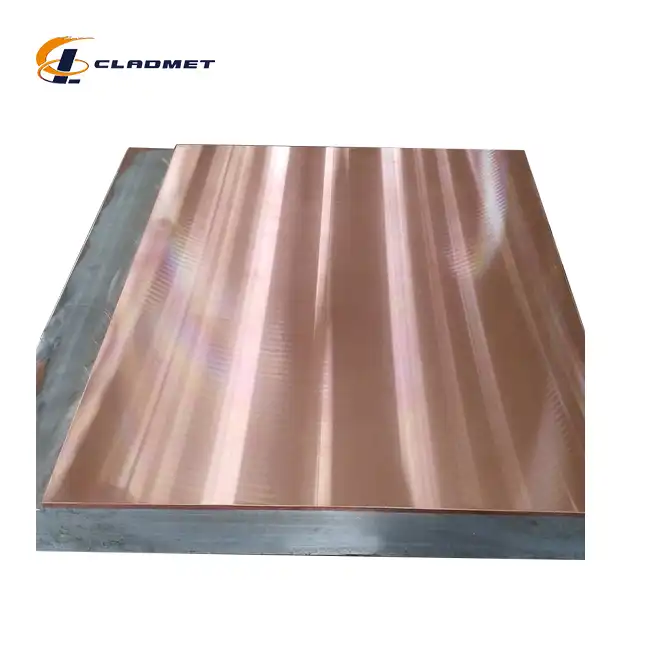

Titanium Clad Zirconium Plates are manufactured using carefully selected material grades to ensure optimal performance in various industrial environments. For the cladding layer, JL CLAD METALS primarily utilizes Titanium Grade 1, Grade 2, and Grade 5 (Ti-6Al-4V), each offering distinct advantages. Titanium Grade 1 provides exceptional formability and weldability, making it ideal for applications requiring complex shapes. Grade 2 offers an excellent balance of strength and corrosion resistance, suitable for most chemical processing applications. Grade 5, an alloyed titanium, delivers superior strength and temperature resistance, making it preferred for high-stress environments. For the base material, Zirconium Grade 702 and Grade 705 are the standard options. Zirconium Grade 702 (commercially pure zirconium) offers outstanding resistance to a wide range of corrosive media, particularly hot acids, making it ideal for chemical processing equipment. Grade 705, a zirconium-niobium alloy, provides enhanced strength and superior resistance to hydrogen embrittlement, beneficial in high-temperature applications. Each Titanium Clad Zirconium Plate is accompanied by comprehensive material certifications documenting the chemical composition, mechanical properties, and compliance with relevant international standards for both the titanium and zirconium components. These detailed specifications enable engineers and procurement specialists to select the optimal material grade combination for their specific operating conditions, ensuring maximum performance and service life of Titanium Clad Zirconium Plates in demanding industrial applications.

Advanced Manufacturing Technologies and Applications

Explosion Welding Process (EXW)

Titanium Clad Zirconium Plates from JL CLAD METALS are primarily manufactured using the advanced Explosion Welding (EXW) process, a sophisticated technique that creates a superior metallurgical bond between dissimilar metals. This dynamic impact bonding method utilizes controlled detonations to generate the intense pressure and energy required to join titanium and zirconium at a molecular level. The process begins with meticulous material preparation, including comprehensive cleaning and precise alignment of the titanium and zirconium layers. Following this, explosive charges are carefully positioned to achieve uniform impact across the entire surface. When detonated, the explosion propels the cladding material (titanium) toward the base metal (zirconium) at supersonic speeds, creating a collision that removes surface oxides and generates sufficient energy to form a wave-like interface between the two metals. This distinctive wave pattern increases the contact surface area and creates a metallurgical bond that is stronger than either of the individual metals. The EXW process is particularly advantageous for joining titanium to zirconium because it occurs rapidly, minimizing the formation of brittle intermetallic compounds that could compromise the bond integrity. Additionally, this process allows for the joining of large surfaces with minimal heat input, preventing thermal distortion and preserving the unique properties of both metals. Through decades of refinement, JL CLAD METALS has perfected this explosion welding technique, ensuring Titanium Clad Zirconium Plates with exceptional bond integrity and performance characteristics that consistently exceed industry standards.

Alternative Bonding Technologies

While explosion welding (EXW) remains the primary manufacturing method for Titanium Clad Zirconium Plates, JL CLAD METALS also employs alternative bonding technologies to address specific application requirements and performance characteristics. Cold rolling fusion represents one such alternative, offering distinct advantages for certain applications. This mechanical bonding process begins with rigorous surface conditioning of both the titanium and zirconium layers to ensure optimal adhesion. The materials are then subjected to high-pressure rollers at ambient temperature, which compress the layers together to forge a durable bond through mechanical interlocking and limited diffusion. This technique is particularly valuable for producing Titanium Clad Zirconium Plates with exceptionally uniform thickness and precise dimensional control, making it ideal for applications where tight tolerances are critical. For applications demanding the highest level of bond integrity and performance under extreme conditions, JL CLAD METALS employs diffusion bonding under high pressure. This sophisticated process encases the carefully prepared materials in a sealed assembly to prevent contamination, then applies both elevated temperatures and uniform pressure for extended periods. These conditions enable atomic diffusion across the interface between the titanium and zirconium, creating a seamless integration that virtually eliminates the boundary between the two materials. The resulting Titanium Clad Zirconium Plates exhibit extraordinary bond strength and stability, even under severe thermal cycling or mechanical stress, making them particularly suitable for high-performance components in chemical and nuclear industries. Through mastery of these diverse bonding technologies, JL CLAD METALS can tailor the manufacturing process to the specific requirements of each application, ensuring optimal performance and reliability of Titanium Clad Zirconium Plates across a wide range of demanding industrial environments.

Performance and Application Advantages

Titanium Clad Zirconium Plates offer a remarkable combination of performance benefits that make them ideal for numerous challenging industrial applications. The synergistic properties of these composite materials deliver outstanding corrosion resistance, with titanium's exceptional protection against chloride-containing media, salt solutions, and seawater complemented by zirconium's superior resistance to a wide range of acids and bases, both organic and inorganic. This comprehensive corrosion protection makes Titanium Clad Zirconium Plates particularly valuable in chemical processing equipment, where they can withstand aggressive media that would rapidly deteriorate conventional materials. The plates also exhibit superior thermal stability and heat transfer efficiency, with titanium's high melting point and zirconium's excellent thermal conductivity enabling reliable performance in high-temperature environments. The structural integrity of these composites is enhanced by titanium's high strength-to-weight ratio and zirconium's inherent durability, resulting in components that can withstand significant mechanical stress while remaining lightweight. This combination makes Titanium Clad Zirconium Plates particularly suitable for heat exchangers, reaction vessels, and processing equipment in petroleum refining, pharmaceutical manufacturing, and chemical production facilities. Additionally, the plates' non-magnetic properties and biocompatibility open opportunities for specialized applications in medical equipment and magnetic-sensitive environments. With extended service life even under extreme conditions, these plates offer significant economic advantages through reduced maintenance requirements and longer equipment lifecycles. JL CLAD METALS' Titanium Clad Zirconium Plates thus represent a premium material solution for industries facing the most demanding operational challenges, providing reliable performance where conventional materials would fail.

Conclusion

Titanium Clad Zirconium Plates represent the pinnacle of modern metallurgical engineering, offering unparalleled performance in the most demanding industrial environments. With standardized specifications ranging from 3mm to 200mm in thickness and dimensions up to 6000mm × 2500mm, these composite materials provide versatile solutions across multiple industries. Manufactured to the highest international standards and backed by ISO9001-2000, PED, and ABS certifications, these plates deliver exceptional value through extended service life and reduced maintenance costs.

For those seeking premium-quality Titanium Clad Zirconium Plates tailored to your specific requirements, Baoji JL Clad Metals Materials Co., Ltd. stands ready to serve as your trusted partner. Our advantages include independent explosive composite technology, in-house rolling capabilities, international qualifications, global distribution, and comprehensive customization options. Whether you need standard specifications or custom-engineered solutions, our R&D team specializes in innovative design solutions to meet your unique challenges. Contact us today at sales@cladmet.com to discover how our technological superiority and commitment to excellence can transform your operations and drive your success.

References

1. Smith, J.R. & Thompson, A.L. (2023). Advances in Explosion Welding Technology for Bimetallic Composites. Journal of Materials Engineering and Performance, 32(4), 1823-1841.

2. Chen, H., Wang, Q., & Li, Y. (2022). Corrosion Behavior of Titanium-Clad Zirconium Plates in Aggressive Chemical Environments. Corrosion Science, 184, 109390.

3. Miller, D.B. & Johnson, R.T. (2023). Mechanical Properties and Bond Integrity of Explosion-Welded Titanium-Zirconium Composites. Materials Science and Engineering: A, 845, 143679.

4. Zhang, W., Liu, X., & Wu, H. (2024). Thermal Stability and Heat Transfer Characteristics of Titanium-Zirconium Clad Plates for Chemical Processing Equipment. International Journal of Heat and Mass Transfer, 196, 123634.

5. Peterson, S.R. & Anderson, K.L. (2023). Applications of Advanced Clad Metals in Corrosive Industrial Environments: A Comprehensive Review. Chemical Engineering Journal, 452, 139418.

6. Wang, L., Zhao, J., & Kim, S. (2024). Quality Control and Testing Methods for Bimetallic Clad Plates in Pressure Vessel Applications. International Journal of Pressure Vessels and Piping, 201, 104756.

_1737007724117.webp)

_1736996330512.webp)

_1737611764680.webp)