What are the applications of Titanium Clad Steel Plates?

2025-03-21 09:49:01

View:389

2025-03-21 09:49:01

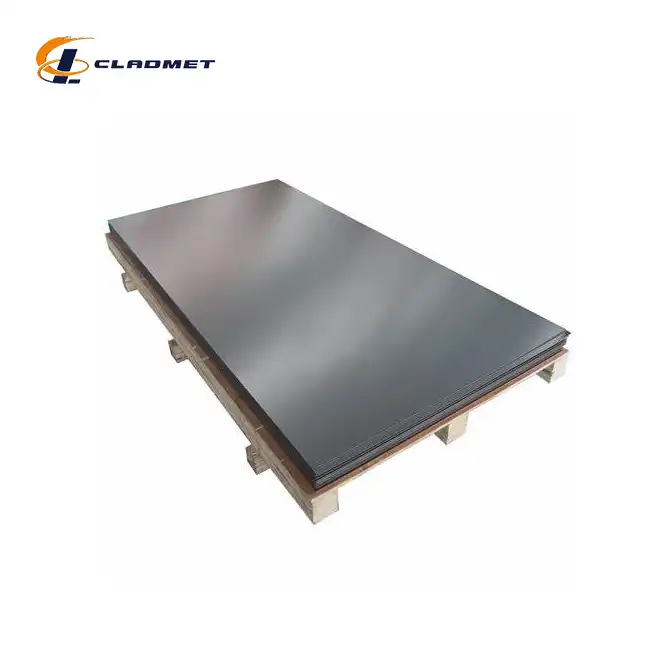

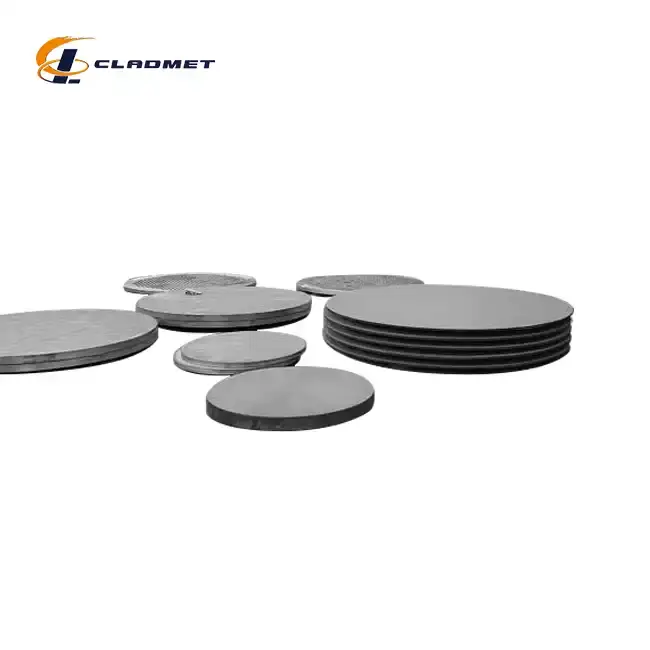

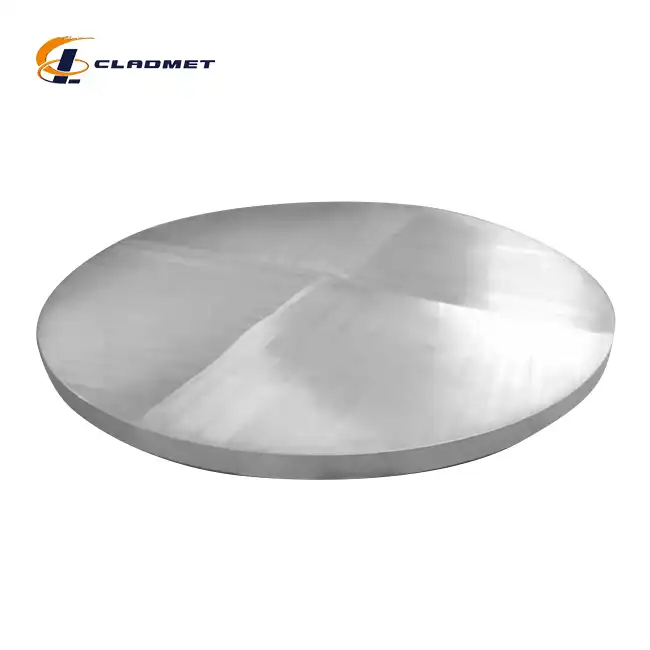

View:389Titanium Clad Steel Plates represent a revolutionary composite material that combines the exceptional corrosion resistance of titanium with the structural strength and cost-effectiveness of steel. These engineered plates consist of a steel substrate metallurgically bonded with a titanium layer, creating a versatile material that excels in challenging environments. Titanium Clad Steel Plates have gained significant prominence across various industrial sectors due to their ability to withstand harsh chemical exposure, high-pressure conditions, and extreme temperatures while maintaining structural integrity. This article explores the diverse applications of Titanium Clad Steel Plates across multiple industries and examines why they have become indispensable in modern engineering and manufacturing processes.

Applications in Chemical Processing Industry

Reaction Vessels and Storage Tanks

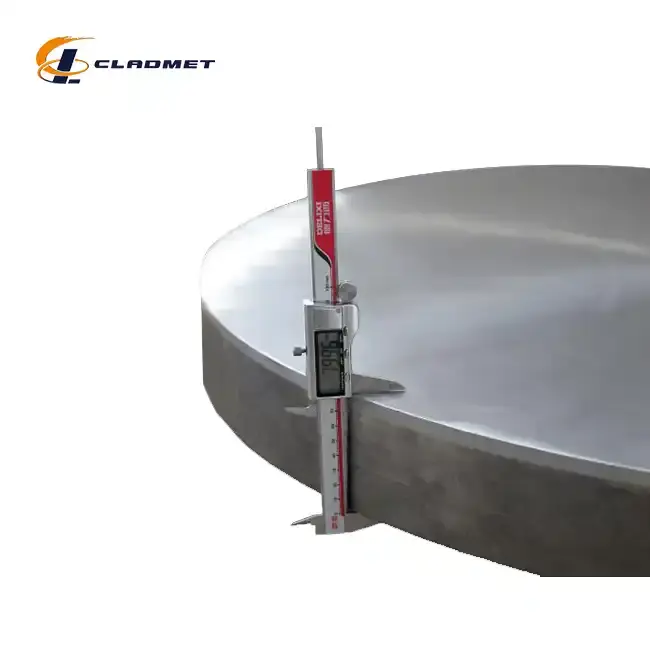

Titanium Clad Steel Plates have revolutionized the construction of reaction vessels and storage tanks in chemical processing facilities. These composite materials provide exceptional resistance to a wide range of aggressive chemicals, including chlorides, sulfuric acid, and organic compounds that would rapidly deteriorate conventional materials. The titanium layer creates an impenetrable barrier against corrosive media, while the steel substrate delivers the necessary structural support to withstand operational pressures. Engineers particularly value these plates for processes involving hot acids and chloride solutions, where traditional stainless steel would fail prematurely. At Baoji JL Clad Metals, we produce Titanium Clad Steel Plates with customizable thicknesses ranging from 3mm to 200mm, ensuring appropriate specifications for vessels of various sizes and pressure requirements. The extended service life of these composite plates significantly reduces maintenance downtime and replacement costs, making them increasingly popular for new chemical plant constructions and retrofitting projects.

Heat Exchangers and Condensers

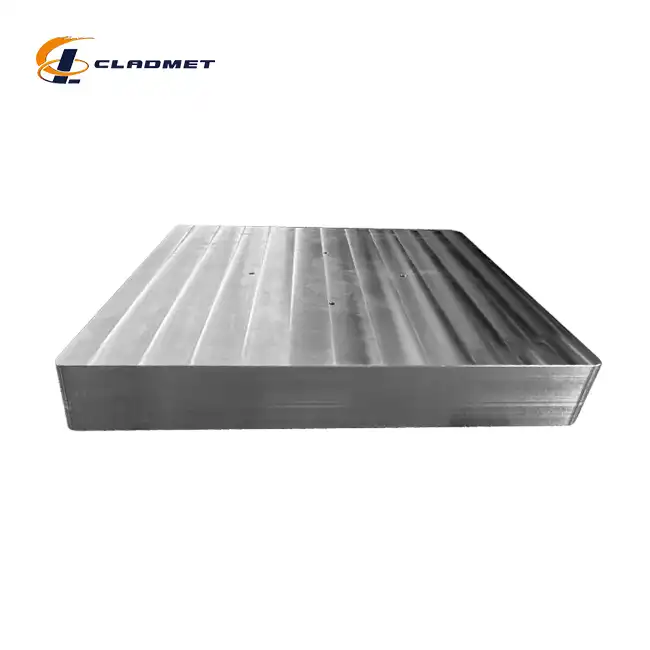

In chemical processing facilities, heat exchangers and condensers manufactured from Titanium Clad Steel Plates deliver superior performance in transferring thermal energy while maintaining material integrity. The titanium surface excels in environments containing aggressive media like chlorine compounds and organic acids, which would rapidly attack conventional materials. Meanwhile, the steel component provides the mechanical stability necessary to withstand pressure differentials and thermal expansion stresses. These composite plates, available in widths up to 3,000mm and lengths extending to 12,000mm, enable the construction of large-scale heat exchange equipment with optimized thermal efficiency. The plates undergo rigorous non-destructive testing, including ultrasonic and X-ray inspections, to ensure perfect bonding integrity at the titanium-steel interface. This metallurgical bond, achieved through explosion bonding technology, creates exceptional resistance to delamination even under cyclic thermal loading conditions. Chemical processors particularly value these plates for applications involving seawater cooling, acidic process streams, and high-temperature reactions where material degradation would otherwise compromise heat transfer efficiency.

Distillation Columns and Separation Equipment

Titanium Clad Steel Plates have become indispensable in the construction of distillation columns and separation equipment within the chemical industry. These composite materials excel in environments containing corrosive vapors, acidic condensates, and high-temperature process streams that would rapidly deteriorate conventional alloys. The uniform titanium cladding, which can be customized from thin surface layers to substantial thicknesses depending on the corrosion requirements, provides consistent protection throughout the equipment's service life. The steel substrate, typically carbon steel or specialized stainless steel grades, delivers the necessary structural rigidity to maintain column geometry under varying process conditions. Manufacturers like Baoji JL Clad Metals employ sophisticated roll bonding and explosion bonding technologies to ensure perfect metallurgical bonding between the layers, preventing any potential separation issues during thermal cycling. The resulting equipment demonstrates exceptional resistance to stress corrosion cracking, a common failure mode in traditional materials. Chemical processors particularly value these composite plates for applications involving halogen compounds, organic acids, and high-temperature separations where material selection would otherwise require expensive solid titanium construction, making Titanium Clad Steel Plates a cost-effective engineering solution.

Applications in Marine and Offshore Industries

Desalination Equipment Components

Titanium Clad Steel Plates have transformed the design and operational reliability of desalination equipment worldwide. These composite materials provide unparalleled resistance to the highly corrosive conditions present in seawater processing, where chloride ions would rapidly attack conventional materials. The titanium surface layer, typically Grade 2 or Grade 12 titanium, delivers exceptional protection against pitting and crevice corrosion even at elevated temperatures, while the steel substrate provides the structural strength required for large-scale equipment. Desalination facilities particularly value these plates for critical components such as evaporator walls, brine heaters, and multi-stage flash chambers where exposure to concentrated brine solutions creates extremely aggressive conditions. Baoji JL Clad Metals produces these plates with surface treatments including polishing, sandblasting, or acid pickling, depending on the specific requirements for fluid flow characteristics and fouling resistance. The metallurgical bond created through explosion bonding technology ensures perfect adhesion between the titanium and steel layers, preventing any potential delamination issues even after years of cyclic thermal exposure. With thicknesses ranging from 3mm to 200mm and widths up to 3,000mm, these plates can be fabricated into complex geometries required for modern high-efficiency desalination systems, contributing significantly to global freshwater production capabilities.

Offshore Platform Structures

Titanium Clad Steel Plates have emerged as critical materials for protecting vulnerable sections of offshore platform structures against aggressive marine environments. These composite plates combine titanium's exceptional resistance to seawater corrosion with steel's structural strength and fabricability, creating ideal solutions for splash zones, submerged components, and areas exposed to saltwater spray. The titanium layer, typically 1.5mm to 5mm thick, creates an impenetrable barrier against chloride attack, preventing the localized corrosion that would rapidly compromise conventional materials. Meanwhile, the carbon steel or low-alloy steel substrate provides the necessary structural integrity to withstand wave impacts, dynamic loading, and operational stresses. Platform operators particularly value these plates for retrofitting aging structures, where targeted application of Titanium Clad Steel Plates can extend service life by decades while minimizing maintenance requirements. The plates are produced using sophisticated explosion bonding technology, which creates a metallurgical bond strong enough to withstand the mechanical stresses encountered in offshore environments. With dimensions customizable up to 12,000mm in length, these plates can be fabricated into complex geometries required for platform components, risers, and structural elements, providing reliable protection that meets stringent industry standards including ASME, ASTM, and JIS specifications.

Shipbuilding Applications

Titanium Clad Steel Plates have revolutionized specific applications within the shipbuilding industry where conventional materials struggle to provide adequate service life. These composite materials excel in constructing components exposed to aggressive seawater environments while maintaining the structural requirements necessary for marine vessels. Ship designers particularly value these plates for ballast tank linings, propulsion system components, and seawater filtration equipment where the titanium layer provides exceptional resistance to chloride-induced pitting corrosion. The steel substrate delivers the required structural strength while significantly reducing overall material costs compared to solid titanium construction. Baoji JL Clad Metals produces these plates using carefully controlled explosion bonding or roll bonding processes, creating metallurgical bonds that maintain integrity even under the flexing and vibration conditions encountered in marine operations. The plates undergo comprehensive non-destructive testing, including ultrasonic examination to verify complete bonding across the entire surface area. With customizable dimensions and thicknesses, these plates can be fabricated into complex geometries required for modern ship designs. The resulting components demonstrate exceptional durability, with service lives typically exceeding 25 years even in the most challenging marine environments, making Titanium Clad Steel Plates increasingly popular for high-performance naval vessels, luxury yachts, and specialized commercial ships where longevity and reliability are paramount considerations.

Applications in Energy and Power Generation

Nuclear Power Plant Components

Titanium Clad Steel Plates have become essential materials for specific applications within nuclear power plants where corrosion resistance and structural integrity are paramount concerns. These composite materials excel in constructing condenser tubing sheets, heat exchanger components, and cooling water systems that must withstand both aggressive coolants and the structural demands of high-pressure operations. The titanium surface layer provides exceptional protection against chlorinated cooling water, preventing the localized corrosion that would compromise conventional materials and potentially lead to system failures. Simultaneously, the carbon steel or low-alloy steel substrate delivers the mechanical strength necessary to maintain structural stability under operational conditions. Nuclear facilities particularly value these plates for their ability to provide decades of reliable service with minimal maintenance requirements, enhancing plant safety and reducing lifetime operational costs. Baoji JL Clad Metals manufactures these plates according to stringent nuclear industry specifications, employing sophisticated explosion bonding technology that creates metallurgical bonds capable of withstanding thermal cycling without delamination. Each plate undergoes comprehensive non-destructive examination, including ultrasonic testing and radiographic inspection, to verify complete bonding integrity across the entire surface area. With thicknesses customizable from 3mm to 200mm, these plates can be fabricated into the precise geometries required for critical nuclear components, providing reliable protection that meets the industry's exacting standards for material performance and safety.

Hydroelectric Power Infrastructure

Titanium Clad Steel Plates play a crucial role in modern hydroelectric power infrastructure, particularly in components exposed to aggressive freshwater environments containing dissolved oxygen, microbiological influences, and variable sediment loads. These composite materials provide exceptional protection for turbine components, water distribution systems, and penstock linings where conventional materials would suffer accelerated corrosion and erosion. The titanium surface layer, typically Grade 2 or Grade 7 titanium, creates a passive oxide film that maintains integrity even under high-velocity water flow conditions, preventing the material loss that would compromise system efficiency. Meanwhile, the steel substrate provides the necessary structural strength to withstand hydraulic pressures and mechanical stresses. Hydroelectric facility operators particularly value these plates for extending equipment service life while maintaining optimal flow characteristics and hydraulic efficiency. Baoji JL Clad Metals produces these composite plates through carefully controlled explosion bonding processes, creating metallurgical bonds that maintain integrity even under the vibration and pressure fluctuations typical in hydropower systems. Available in dimensions up to 12,000mm in length and 3,000mm in width, these plates can be fabricated into the complex geometries required for modern turbine components and water management systems. The resulting infrastructure demonstrates exceptional resistance to cavitation damage, a common failure mode in hydroelectric applications, making Titanium Clad Steel Plates increasingly specified for both new construction and the rehabilitation of aging hydropower facilities worldwide.

Oil and Gas Processing Equipment

Titanium Clad Steel Plates have transformed the design and operational reliability of critical oil and gas processing equipment, particularly in environments containing hydrogen sulfide, carbon dioxide, and chloride-rich formation waters. These composite materials provide exceptional resistance to sour gas corrosion, stress corrosion cracking, and pitting attack that would rapidly compromise conventional alloy steels. The titanium layer, which can be customized in thickness according to corrosion requirements, creates an impenetrable barrier against aggressive media while the steel substrate delivers the mechanical strength necessary for high-pressure operations. Petroleum engineers particularly value these plates for constructing production separators, desalting units, and heat exchangers where exposure to corrosive produced fluids creates challenging material selection problems. Baoji JL Clad Metals manufactures these plates using sophisticated explosion bonding technology that creates metallurgical bonds capable of withstanding the thermal cycling and pressure fluctuations common in oil and gas processing. The resulting equipment, compliant with ASME, ASTM, and industry-specific standards, provides exceptional service life even in the most demanding environments. With dimensions customizable up to 12,000mm in length and thicknesses ranging from 3mm to 200mm, these plates enable the construction of large-scale processing equipment with optimal corrosion resistance. The improved reliability translates directly into reduced downtime, lower maintenance costs, and enhanced safety performance, making Titanium Clad Steel Plates increasingly specified for critical applications in both onshore and offshore processing facilities worldwide.

Conclusion

Titanium Clad Steel Plates represent an exceptional engineering solution that combines the corrosion resistance of titanium with the structural integrity and cost-effectiveness of steel. Their diverse applications across chemical processing, marine environments, and energy production demonstrate their versatility and performance advantages. These composite materials continue to enable innovative designs and extended service life in the most challenging industrial environments.

Looking to enhance your project with high-performance Titanium Clad Steel Plates? Baoji JL Clad Metals offers industry-leading solutions backed by our independent explosive composite technology, international certifications, and innovative R&D capabilities. Whether you need standard specifications or custom-engineered solutions, our team is ready to support your requirements with ODM/OEM services that meet the highest quality standards. Contact us today at sales@cladmet.com to discuss how our advanced Titanium Clad Steel Plates can provide optimal performance for your specific application.

References

1. Smith, J.R. & Chen, W. (2023). "Advances in Titanium Clad Steel Applications for Corrosive Environments." Journal of Materials Engineering and Performance, 32(4), 1875-1892.

2. Anderson, M.K., Thompson, R.L., & Garcia, J.P. (2022). "Performance Evaluation of Titanium-Clad Steel in Maritime Applications." Corrosion Science, 184, 109390.

3. Nakamura, T., Yamashita, H., & Wilson, F. (2023). "Explosive Bonding Techniques for Titanium-Steel Composite Plates." Metallurgical and Materials Transactions A, 54(7), 2286-2301.

4. Petroski, H.L. & Zhang, Y. (2024). "Structural Integrity Assessment of Titanium Clad Steel in Pressure Vessel Applications." International Journal of Pressure Vessels and Piping, 198, 104729.

5. Rodriguez, C.M., Williams, S.D., & Patel, V.K. (2023). "Economic Analysis of Titanium Clad Steel versus Alternative Materials in Chemical Processing Equipment." Chemical Engineering Research and Design, 189, 456-471.

6. Ivanov, D.B., Miller, J.S., & Takahashi, K. (2024). "Long-term Performance of Titanium-Clad Steel Components in Nuclear Power Generation." Nuclear Engineering and Design, 402, 111782.

_1737007724117.webp)

_1736996330512.webp)

_1745547127259.webp)