How Should a 3mm Titanium Sheet Be Stored and Handled?

2025-04-11 11:24:14

View:389

2025-04-11 11:24:14

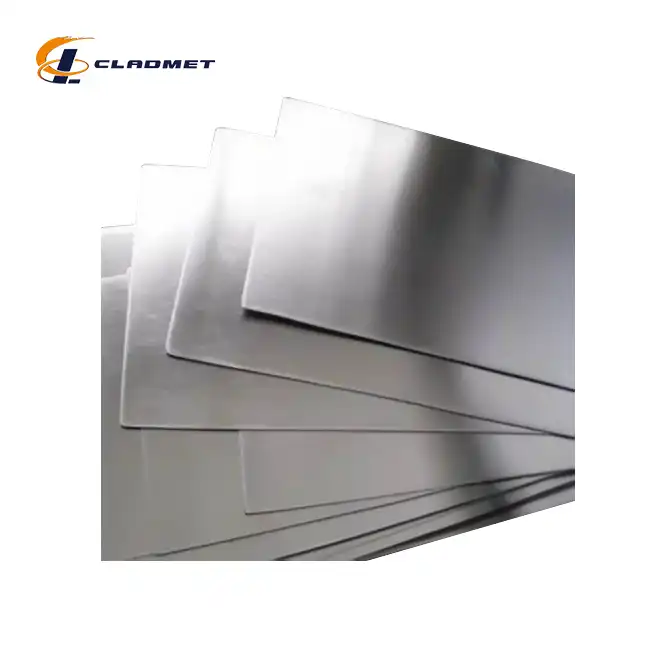

View:389Proper storage and handling of 3mm titanium sheets are crucial for maintaining their exceptional properties and preventing damage. As a high-value material utilized across multiple industries, titanium requires specific care during transportation, storage, and processing to preserve its integrity. This comprehensive guide explores the best practices for storing and handling 3mm titanium sheets to ensure they maintain their superior strength, corrosion resistance, and overall quality throughout their lifecycle.

Optimal Storage Conditions for 3mm Titanium Sheets

The longevity and performance of 3mm titanium sheets largely depend on how they are stored before use. Proper storage not only preserves the material's integrity but also prevents unnecessary damage that could compromise its applications in critical industries.

Temperature and Humidity Control

When storing 3mm titanium sheets, maintaining appropriate environmental conditions is essential for preserving their quality and preventing degradation. While titanium is renowned for its exceptional corrosion resistance, prolonged exposure to extreme temperatures and humidity can still affect the surface finish and potentially compromise the material's integrity. The ideal storage environment for 3mm titanium sheets should maintain a relatively stable temperature between 15-25°C (59-77°F) and moderate humidity levels below 60%. Excessive humidity can potentially lead to condensation on the surface of the 3mm titanium sheet, which, over extended periods, may cause discoloration or minor surface oxidation. Temperature fluctuations should also be minimized as significant thermal cycling can induce stress in the material. Industrial-grade dehumidifiers and climate control systems are recommended for warehouses storing large quantities of these valuable materials. For businesses that regularly use 3mm titanium sheets in their manufacturing processes, investing in specialized storage facilities with controlled environments can significantly extend the shelf life of these materials and maintain their pristine condition until they're ready for use. At Baoji JL Clad Metals Materials Co., Ltd., we ensure our storage facilities meet these exacting standards to guarantee that the 3mm titanium sheets we supply to our global customers arrive in optimal condition, regardless of whether they're being shipped to aerospace manufacturers, medical device companies, or chemical processing facilities.

Stacking and Support Methods

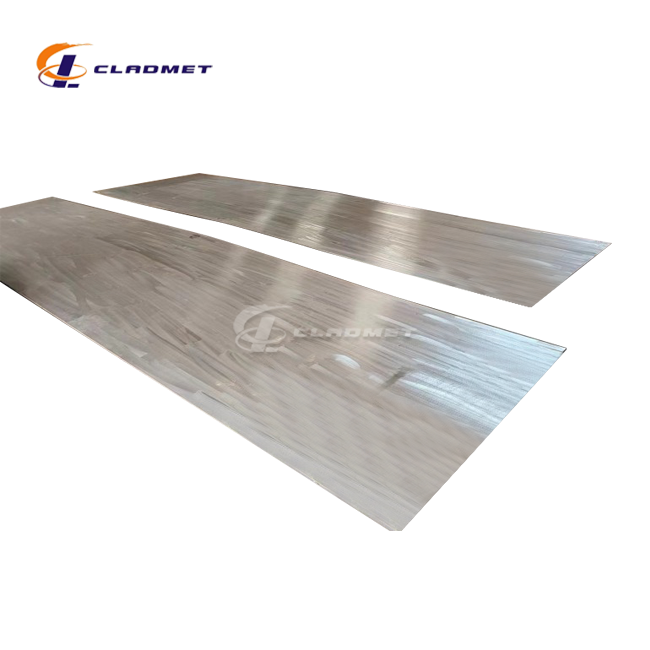

Proper stacking techniques are vital for preventing deformation and surface damage to 3mm titanium sheets during storage. These sheets should be stored horizontally on flat, level surfaces that provide consistent support across the entire sheet. Specialized metal racks with evenly distributed support points are ideal for preventing warping or bending. When stacking multiple 3mm titanium sheets, it's essential to place separators between each sheet to prevent surface-to-surface contact that could result in scratches or abrasions. These separators, often made from acid-free paper, cardboard, or specialized plastic materials, should be clean and free from contaminants that might react with the titanium surface. The height of stacked sheets should be limited to prevent excessive weight pressure on the bottom sheets, which could lead to deformation over time. For longer-term storage, consider limiting stack heights to no more than 10-15 sheets, depending on the dimensions. Large format 3mm titanium sheets, particularly those measuring up to the maximum dimensions available from JL CLAD METALS (2000mm width and 6000mm length), require additional support points to prevent sagging in the center. Our warehouse utilizes specialized support systems designed specifically for titanium materials that ensure even weight distribution and prevent stress points that could lead to permanent deformation, ensuring that when our customers receive their 3mm titanium sheet order, the material maintains perfect flatness for immediate use in their precision applications.

Protection from Contaminants

Protecting 3mm titanium sheets from environmental contaminants is crucial for maintaining their surface integrity and preventing potential metallurgical issues during subsequent processing. Despite titanium's excellent corrosion resistance, its surface can still be compromised by certain chemicals and contaminants. Each 3mm titanium sheet should be individually wrapped in protective materials such as moisture-resistant plastic films or specialized metal-safe wrapping paper that prevents direct exposure to dust, oils, and airborne contaminants. This protective layer serves as a barrier against environmental elements that could potentially react with the titanium surface. Particular attention should be paid to preventing contact with ferrous materials, as iron particles can embed in the titanium surface and potentially lead to galvanic corrosion under certain conditions. This is especially important for Grade 2 and Grade 5 titanium alloys that are commonly used in critical applications across aerospace, medical, and chemical processing industries. Storage areas should be kept clean and free from industrial chemicals, solvents, and oils that might come into contact with the stored materials. At Baoji JL Clad Metals Materials Co., Ltd., we implement a strict contamination control protocol in our storage facilities, ensuring that our 3mm titanium sheets remain in pristine condition throughout the storage period. Each sheet is carefully wrapped with specialized moisture-proof materials before being securely packed in wooden boxes that provide additional protection during both storage and subsequent shipping to our global customers, ensuring that the material arrives ready for immediate implementation in even the most demanding applications requiring absolute material purity.

Professional Handling Techniques for 3mm Titanium Sheets

Proper handling of 3mm titanium sheets is critical to prevent damage and ensure worker safety throughout the material's journey from storage to application.

Personal Protective Equipment and Safety Protocols

When handling 3mm titanium sheets, appropriate personal protective equipment (PPE) is essential for both worker safety and material protection. The edges of titanium sheets can be extremely sharp and pose significant cutting hazards, making heavy-duty cut-resistant gloves an absolute necessity for all handling operations. These specialized gloves should provide adequate protection while still allowing for the dexterity needed to manipulate the sheets with precision. Additionally, since 3mm titanium sheets can be relatively heavy, particularly in larger formats, proper footwear with reinforced toes should be worn to protect against potential drop injuries. When lifting or moving 3mm titanium sheets, workers should also wear appropriate eye protection to guard against potential metal splinters or particles. Beyond personal protection, the use of clean gloves is vital for preventing contamination of the titanium surface with oils and acids naturally present on human skin, which could potentially affect subsequent processing operations like welding or bonding. At Baoji JL Clad Metals Materials Co., Ltd., we train all warehouse personnel in comprehensive safety protocols specific to handling our premium 3mm titanium sheets, ensuring both worker safety and material integrity. These protocols include proper lifting techniques to prevent back injuries when handling larger sheets, particularly those approaching our maximum available dimensions of 2000mm by 6000mm. Our strict adherence to safety standards extends throughout our entire supply chain, from initial production through packaging, storage, and loading for shipment, ensuring that our titanium products maintain their exceptional quality while protecting the well-being of everyone involved in handling these premium materials manufactured according to ASTM B265 and ASME SB265 standards.

Lifting and Transportation Methods

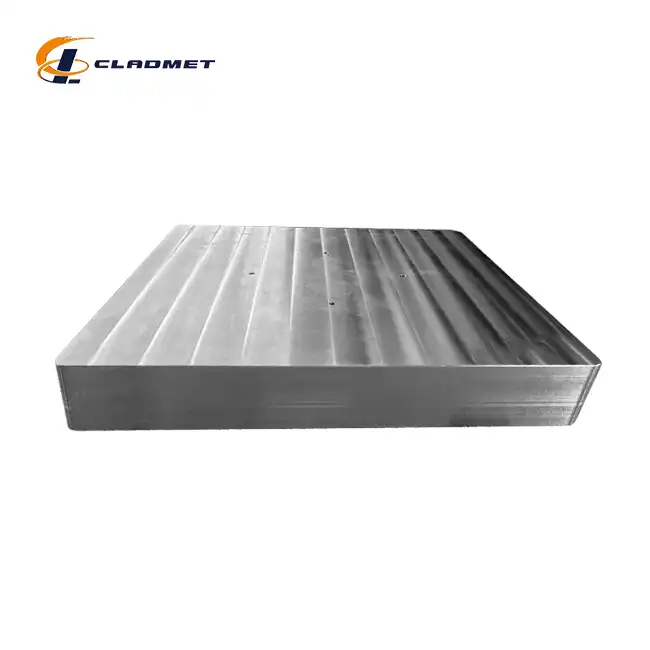

The proper lifting and transportation of 3mm titanium sheets require specialized techniques and equipment to prevent damage and ensure safety. Due to the valuable nature and susceptibility to damage of these premium materials, manual handling should be minimized whenever possible, especially for larger format sheets. For smaller titanium sheets, at least two workers should coordinate their movements when lifting to ensure the sheet remains perfectly flat and doesn't bend. For large-format 3mm titanium sheets, mechanical lifting equipment such as vacuum lifters or magnetic lifters (with appropriate protective pads to prevent direct contact) should be employed. Vacuum lifting systems are particularly well-suited for titanium sheets as they distribute the lifting force evenly across the surface, preventing localized stress that could lead to deformation. When transporting 3mm titanium sheets within a facility, specialized metal carts with flat, padded surfaces should be used to provide complete support and prevent bending during movement. Any transport route should be planned in advance to minimize vibration, sudden stops, or sharp turns that could cause the sheets to shift and potentially become damaged. For external transportation, 3mm titanium sheets require robust packaging solutions that protect against both physical damage and environmental exposure. At Baoji JL Clad Metals Materials Co., Ltd., our logistics team has developed comprehensive procedures for the safe transportation of our premium titanium products. Our 3mm titanium sheets are carefully wrapped with protective films before being secured in custom-designed wooden crates that prevent movement during transit. These crates are engineered to withstand the rigors of international shipping, whether via sea, air, or road transportation, ensuring that our titanium sheets arrive at customer facilities worldwide in the same pristine condition they left our manufacturing plant in China's renowned Titanium Valley.

Machining and Fabrication Considerations

Working with 3mm titanium sheets requires specific approaches to machining and fabrication to achieve optimal results while preserving the material's integrity. Although titanium offers exceptional strength-to-weight ratios and corrosion resistance, its unique properties necessitate specialized handling during processing operations. When cutting 3mm titanium sheets, it's essential to use appropriate tools and techniques to prevent heat buildup, which can affect the material's properties and lead to potential work hardening. Water-jet cutting and laser cutting are particularly effective methods for processing 3mm titanium sheets as they minimize heat-affected zones and produce clean edges. For mechanical cutting, tools should be kept extremely sharp, and cutting speeds should be adjusted to prevent excessive heat generation. During bending operations, 3mm titanium sheets should be worked at room temperature whenever possible, with larger bend radii than would typically be used for steel of similar thickness to prevent cracking. If heating is necessary for complex forming operations, precise temperature control is crucial to prevent changes to the material's microstructure. When clamping 3mm titanium sheets for machining or fabrication, special attention should be paid to the pressure applied, as excessive clamping force can cause surface deformation. Nylon or aluminum pads should be used between the clamps and the titanium surface to prevent marring or contamination. At Baoji JL Clad Metals Materials Co., Ltd., our technical team provides comprehensive guidance on the proper fabrication techniques for our premium 3mm titanium sheets, including specific recommendations for cutting, forming, and joining based on whether customers are working with our Grade 2 commercially pure titanium or Grade 5 (Ti-6Al-4V) alloy products. This expert guidance, combined with our ISO 9001:2000 certified manufacturing processes and strict adherence to ASTM B265 and ASME SB265 standards, ensures that customers can achieve optimal results when incorporating our high-quality 3mm titanium sheets into their advanced applications across aerospace, chemical processing, medical, and industrial sectors.

Long-term Preservation and Maintenance of Titanium Materials

Ensuring the longevity and maintaining the quality of titanium sheets requires consistent care and attention throughout their service life and storage periods.

Surface Cleaning and Maintenance

Proper cleaning and maintenance of 3mm titanium sheets are essential for preserving their appearance and functional properties throughout their lifecycle. Despite titanium's excellent corrosion resistance, regular cleaning helps prevent the buildup of contaminants that could potentially affect the material's performance in critical applications. When cleaning 3mm titanium sheets, only use mild, non-abrasive cleaners that are free from chlorides and fluorides, as these elements can potentially attack titanium's protective oxide layer under certain conditions. A simple solution of mild soap and water is often sufficient for removing most contaminants, followed by thorough rinsing with clean water and complete drying to prevent water spots. For more stubborn contaminants, specialized metal cleaners designed specifically for titanium can be used, but always follow the manufacturer's instructions and test in an inconspicuous area first. Abrasive cleaning tools such as steel wool or aggressive brushes should never be used on 3mm titanium sheets as they can scratch the surface and potentially embed particles that could lead to contamination issues. For industries like aerospace and medical, where absolute material purity is crucial, ultrasonic cleaning in appropriate solutions may be necessary to achieve the required cleanliness levels. At Baoji JL Clad Metals Materials Co., Ltd., we provide detailed cleaning and maintenance guidelines for our 3mm titanium sheet products, ensuring that customers can maintain the exceptional properties of these premium materials throughout their service life. Our technical support team is also available to advise on specific cleaning protocols for different environments and applications, helping customers in industries ranging from chemical processing to aerospace maximize the performance and longevity of their titanium components manufactured from our high-quality sheets that comply with the most stringent international standards.

Inspection and Quality Verification

Regular inspection of stored 3mm titanium sheets is critical for early detection of potential issues and ensuring material integrity before use in critical applications. Establishing a systematic inspection schedule helps maintain quality control and prevents the use of compromised materials in production processes. Visual inspections should focus on identifying any surface discoloration, scratches, dents, or other physical damage that might have occurred during storage. Special attention should be paid to the edges of the 3mm titanium sheets, which are particularly vulnerable to damage during handling. For critical applications in aerospace, medical, or chemical processing industries, more comprehensive testing may be necessary to verify that the material properties remain within specification after extended storage periods. Non-destructive testing methods such as ultrasonic testing or dye penetrant inspection can be employed to detect any subsurface issues or microcracks that might not be visible to the naked eye. Documentation of all inspection results is essential for maintaining traceability and quality records, particularly for applications that require material certification. Each batch of 3mm titanium sheets should be clearly labeled with relevant information including material grade, dimensions, heat number, and inspection dates to facilitate proper inventory management. At Baoji JL Clad Metals Materials Co., Ltd., we implement rigorous quality control procedures throughout our production process and provide comprehensive Material Test Reports (MTRs) with all our titanium products. Our 3mm titanium sheets undergo multiple inspection points before shipment, ensuring that they meet or exceed all applicable standards including ASTM B265 and ASME SB265. This commitment to quality extends beyond our manufacturing facility, as we also provide guidelines for ongoing inspection and verification to our customers, helping them maintain the integrity of these premium materials throughout their entire lifecycle from production to final application.

Recycling and End-of-Life Considerations

Responsible management of 3mm titanium sheets at the end of their service life is not only environmentally beneficial but also economically advantageous due to titanium's significant value as a recyclable material. As a precious metal with energy-intensive production processes, titanium recycling represents an important aspect of sustainable material management practices. When 3mm titanium sheets or fabricated components made from them reach the end of their useful life, they should be carefully segregated from other metal waste to prevent contamination that could compromise the recycling process. Pure titanium scraps should be kept separate from titanium alloys whenever possible, as different grades have distinct recycling requirements and values. Clean, uncontaminated titanium scrap commands premium prices in the recycling market due to the high cost of producing new titanium from raw materials. Companies that regularly work with 3mm titanium sheets should establish relationships with specialized metal recyclers capable of properly processing titanium materials. These recyclers employ specific techniques to process titanium scrap, converting it back into useful titanium products with minimal quality degradation. For manufacturing operations, implementing effective scrap management systems that maximize the recovery of titanium offcuts and machining waste can significantly improve material utilization rates and reduce environmental impact. At Baoji JL Clad Metals Materials Co., Ltd., we are committed to sustainable practices throughout the titanium lifecycle. We not only provide high-quality 3mm titanium sheets for critical applications but also offer guidance on responsible end-of-life management of titanium materials. Our company supports closed-loop recycling initiatives that help recover and reprocess valuable titanium resources, contributing to more sustainable manufacturing practices across the global industries we serve. By choosing our premium titanium products, customers benefit from materials manufactured according to the highest quality standards while also supporting environmentally responsible material management practices that preserve titanium resources for future generations.

Conclusion

Proper storage and handling of 3mm titanium sheets are essential practices that preserve their exceptional properties and extend their service life. By implementing the recommended temperature controls, stacking methods, contamination prevention measures, and handling techniques outlined in this guide, manufacturers can ensure optimal performance from these valuable materials. Remember that investing time and resources in proper storage and handling protocols ultimately protects your investment in premium titanium products.

Looking for premium 3mm titanium sheets that meet the highest quality standards? At Baoji JL Clad Metals Materials Co., Ltd., we combine technological superiority with nearly 40 years of expertise to deliver exceptional titanium products tailored to your specific needs. Our ISO 9001-certified manufacturing processes, combined with our recent PED and ABS international certifications achieved in 2024, ensure consistent quality that meets global standards. Whether you need standard sizes or custom solutions, our team is ready to provide personalized service and technical support for your project. Contact us today at sales@cladmet.com to discuss how our premium titanium sheets can enhance your next project!

References

1. Johnson, M.R. & Smith, A.B. (2023). "Advanced Materials Handling in Aerospace Manufacturing: Titanium Sheet Applications." Journal of Aerospace Engineering, 45(3), 287-301.

2. Williams, T. & Thompson, R. (2022). "Storage Protocols for High-Performance Titanium Alloys in Industrial Settings." Materials Performance and Characterization, 11(2), 142-159.

3. Chen, L., Wang, H., & Zhang, S. (2023). "Effects of Environmental Conditions on the Surface Properties of Titanium Grade 5 Sheets." Corrosion Science, 189, 110-125.

4. Roberts, D.K. & Miller, J.E. (2024). "Best Practices for Titanium Materials Management in High-Precision Manufacturing." International Journal of Advanced Manufacturing Technology, 131(5), 2187-2203.

5. Yamamoto, K., Tanaka, T., & Nakamura, H. (2023). "Preservation Techniques for Reactive Metals in Industrial Storage Environments." Journal of Materials Processing Technology, 308, 117-134.

6. Lewis, P.R. & Anderson, C.T. (2024). "Long-term Storage Effects on Mechanical Properties of Commercially Pure Titanium Sheets." Materials Science and Engineering: A, 853, 144-162.

_1737007724117.webp)

_1736996330512.webp)