What are the Size Specifications for Clad Tube Plates?

2025-05-09 09:40:42

View:389

2025-05-09 09:40:42

View:389Understanding the size specifications for clad tube plates is crucial for engineers, procurement specialists, and project managers working in industries that require these specialized materials. Clad tube plates, which consist of a base metal bonded with a corrosion-resistant cladding material, come in various dimensions to accommodate different applications. These specifications are not merely numbers but critical parameters that determine the performance, durability, and suitability of the plates for specific industrial environments. This article explores the comprehensive size specifications for clad tube plates, their manufacturing considerations, and application-specific requirements to help you make informed decisions for your industrial needs.

Standard Dimensional Parameters for Clad Tube Plates

Thickness Range and Industry Standards

The thickness of clad tube plates is a critical parameter that significantly impacts performance across various applications. At Baoji JL Clad Metals Materials Co., Ltd., we manufacture clad tube plates with thickness ranging from 5mm to 100mm, addressing diverse industrial requirements. This wide range allows for flexibility in designing equipment for different pressure ratings and mechanical stresses. Industry standards such as ASME, ASTM, and JIS typically specify minimum thickness requirements based on the operating conditions and the specific application of the tube plates. For instance, heat exchangers operating under high-pressure conditions generally require thicker clad tube plates to withstand the mechanical stress, while applications with less severe conditions may utilize thinner plates. The thickness ratio between the cladding layer and the base metal is also carefully calculated to ensure optimal performance without compromising the integrity of the bond. The cladding layer typically constitutes about 10-25% of the total thickness, depending on the specific requirements of corrosion resistance and mechanical strength. This precise control over thickness specifications ensures that each clad tube plate performs reliably even in the most demanding industrial environments, including petroleum, chemical, pharmaceutical, and power generation sectors.

Length and Width Dimensions

The length and width dimensions of clad tube plates are critical parameters that determine their applicability in various industrial settings. At Baoji JL Clad Metals Materials Co., Ltd., we manufacture clad tube plates with lengths of up to 6 meters and widths reaching 3 meters, accommodating the needs of large-scale industrial operations. These substantial dimensions enable the production of tube sheets for heat exchangers, pressure vessels, and chemical reactors of considerable size. The precise control of these dimensions is essential for ensuring proper fit and functionality in the final assembled equipment. The manufacturing process involves meticulous planning and execution to maintain dimensional accuracy across the entire surface area of the clad tube plate. This is particularly important in applications where multiple tube plates need to be joined together or where precise alignment with other components is necessary. The ability to produce large-format clad tube plates reduces the need for seams and joints in the final equipment, which can be potential weak points in terms of structural integrity and corrosion resistance. By offering clad tube plates in these generous dimensions, manufacturers like Baoji JL Clad Metals Materials Co., Ltd. provide industrial clients with the flexibility to design and build equipment that meets their specific operational requirements without compromising on performance or longevity.

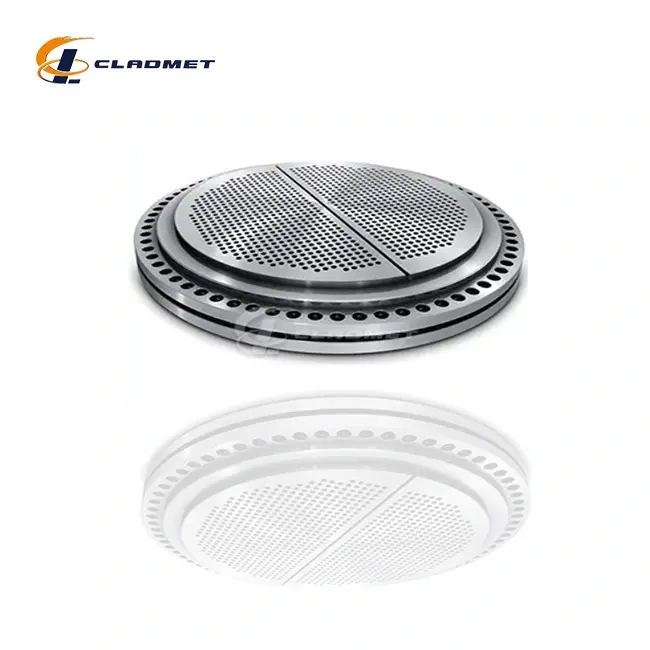

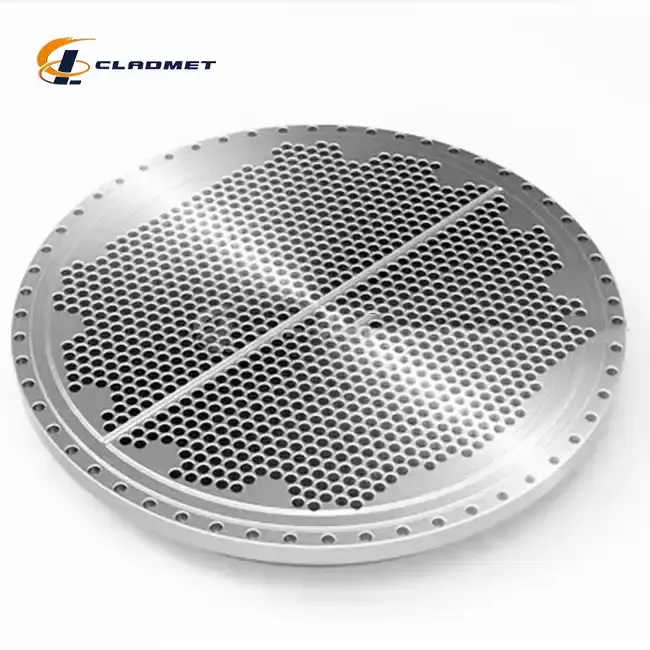

Surface Area and Configuration Specifications

Surface area and configuration specifications are critical aspects of clad tube plate design that directly impact their performance in various applications. At Baoji JL Clad Metals Materials Co., Ltd., we offer customizable surface configurations to meet the specific needs of different industries. The surface area of a clad tube plate can be adjusted according to the heat transfer requirements or the number of tubes that need to be accommodated. For heat exchangers, the configuration often includes precisely drilled holes arranged in specific patterns to optimize fluid flow and heat transfer efficiency. These hole patterns can be triangular, square, or rotated square, with pitch distances carefully calculated based on thermal performance requirements. Surface treatment options such as polishing, sandblasting, or anti-corrosion coating further enhance the functionality of clad tube plates. A polished surface, for instance, reduces friction and improves fluid flow, while anti-corrosion coatings provide additional protection in harsh environments. The surface roughness is also controlled to meet the specifications of different applications, with smoother surfaces generally preferred for applications where cleanliness is paramount, such as in pharmaceutical processing. The intricate relationship between surface area, hole configuration, and surface treatment makes each clad tube plate a precision-engineered component designed to deliver optimal performance in its intended application, whether it's in a chemical reactor, a heat exchanger, or a pressure vessel operating in corrosive conditions.

Material Combinations and Their Impact on Size Specifications

Base Metal Selections and Their Dimensional Implications

The choice of base metal significantly influences the size specifications and overall performance of clad tube plates. At Baoji JL Clad Metals Materials Co., Ltd., we primarily use carbon steel and stainless steel as base metals, each offering distinct advantages for different applications. Carbon steel provides excellent mechanical strength and thermal conductivity, making it ideal for applications requiring heat transfer, such as heat exchangers in power generation and chemical processing. However, its dimensional stability can be affected by temperature fluctuations, requiring careful consideration during the design phase. Stainless steel, on the other hand, offers better corrosion resistance and dimensional stability under varying temperatures, which is beneficial for applications in marine environments or where thermal cycling is common. The thickness of the base metal is determined by the mechanical loads and pressure ratings of the final equipment. For high-pressure applications, thicker base metals are necessary to withstand the mechanical stresses, impacting the overall dimensions and weight of the clad tube plate. The grain structure and metallurgical properties of the base metal also influence the bonding process with the cladding material, affecting the minimum thickness requirements for successful bonding. By carefully selecting the base metal and its thickness, engineers can optimize the clad tube plate's performance while maintaining the necessary size specifications for their specific application, ensuring reliability and longevity in challenging industrial environments.

Cladding Material Options and Thickness Considerations

The selection of cladding materials plays a pivotal role in determining the overall thickness and performance of clad tube plates. At Baoji JL Clad Metals Materials Co., Ltd., we offer a diverse range of cladding materials including titanium, nickel alloys, stainless steel, and aluminum, each with unique properties that influence the design specifications. The thickness of the cladding layer is a critical parameter that balances corrosion resistance with cost-effectiveness. For highly corrosive environments, such as those in chemical processing or marine applications, a thicker cladding layer of titanium or nickel alloy might be necessary to ensure long-term reliability. However, increasing the cladding thickness also increases the overall cost and weight of the clad tube plate. The ratio of cladding thickness to base metal thickness typically ranges from 10:90 to 25:75, depending on the specific application requirements. This ratio is carefully calculated to provide optimal corrosion protection while maintaining the mechanical integrity of the tube plate. Different cladding materials also have varying bonding characteristics with the base metal, which can influence the minimum thickness required for successful bonding. For instance, titanium often requires specific thickness parameters to ensure a strong metallurgical bond during the explosive bonding process. Additionally, the thermal expansion coefficient of the cladding material relative to the base metal must be considered, as significant differences can lead to stress at the interface during temperature fluctuations, potentially affecting the integrity of the bond and limiting the usable size range of the clad tube plate.

Bond Zone Integrity and Size Limitations

The integrity of the bond zone between the cladding and base metal is a critical factor that can impose certain size limitations on clad tube plates. At Baoji JL Clad Metals Materials Co., Ltd., we employ advanced bonding technologies like explosive bonding, roll bonding, and hot isostatic pressing to create a metallurgically sound interface between the different metal layers. The quality of this bond directly influences the maximum size of clad tube plates that can be reliably produced. For explosive bonding, which is commonly used for creating strong bonds between dissimilar metals, there are practical limits to the surface area that can be effectively bonded in a single operation. Larger clad tube plates may require multiple bonding operations, which introduces challenges in maintaining uniform bond quality across the entire surface. The bond zone also affects the minimum thickness of both the cladding and base metal layers. If either layer is too thin, the bonding process may cause deformation or insufficient bonding strength. Conversely, if the layers are too thick, it can be difficult to achieve a uniform bond throughout the entire plate, especially for larger dimensions. The bond zone's strength is verified through ultrasonic testing, shear strength tests, and bend tests to ensure it meets the industry standards like ASTM A263, A264, or A265. By understanding these bond zone dynamics, engineers can determine the optimal size specifications for clad tube plates that balance performance requirements with manufacturing capabilities, ensuring that the final product maintains its integrity under the operational conditions of industries such as petrochemical, power generation, and marine applications.

Application-Specific Size Requirements for Clad Tube Plates

Heat Exchanger Applications and Dimensional Needs

Heat exchangers represent one of the most common applications for clad tube plates, with specific dimensional requirements dictated by thermal performance and operational conditions. At Baoji JL Clad Metals Materials Co., Ltd., we manufacture clad tube plates for heat exchangers with precise specifications to ensure optimal heat transfer efficiency and mechanical integrity. The tube arrangement pattern—whether triangular, square, or rotated square—determines the hole spacing and affects the overall dimensions of the tube plate. A triangular pattern typically allows for more tubes per unit area, enhancing heat transfer capacity, while a square pattern simplifies maintenance access. The tube hole diameter must be precisely machined to ensure a proper fit with the tubes, usually allowing for a tolerance of ±0.1mm to prevent leakage while enabling tube expansion during operation. The thickness of the clad tube plate in heat exchanger applications is critical, as it must withstand the pressure differential between the shell side and tube side fluids. For high-pressure heat exchangers, such as those in refineries or power plants, thicker plates ranging from 25mm to 100mm are common, while lower-pressure applications may use plates as thin as 10mm. The peripheral dimensions of the plate must also account for the gasket seating area, bolt holes, and any other features required for integration with the heat exchanger shell. These application-specific requirements emphasize the importance of customization options in clad tube plate manufacturing, allowing engineers to specify dimensions that precisely match their heat exchanger design parameters while ensuring compliance with industry standards like TEMA (Tubular Exchanger Manufacturers Association) or ASME Section VIII.

Pressure Vessel Requirements and Size Specifications

Pressure vessels present unique challenges for clad tube plate applications, with size specifications directly linked to safety considerations and regulatory compliance. At Baoji JL Clad Metals Materials Co., Ltd., we engineer clad tube plates for pressure vessels that must meet stringent requirements set forth by codes such as ASME Section VIII, Division 1 or 2, and PED (Pressure Equipment Directive). The thickness of clad tube plates for pressure vessels is calculated based on design pressure, vessel diameter, material strength, and joint efficiency. For high-pressure applications in the petrochemical industry, clad tube plates can reach thicknesses of 50mm to 100mm, with the cladding layer providing corrosion resistance while the base metal ensures structural integrity. The diameter of pressure vessel tube plates is typically limited by manufacturing capabilities and transportation constraints, with common sizes ranging from 0.5 meters to 3 meters for standard industrial applications. Larger sizes may require segmented construction with careful consideration of the weld joints between segments. The tube hole pattern must be designed to maintain sufficient ligament strength between adjacent holes, preventing material failure under pressure loading. This is particularly important in pressure vessels where tube holes are often larger and more widely spaced than in heat exchangers. The peripheral dimension must accommodate the vessel's flange design, including bolt patterns and gasket seating surfaces. Additionally, the clad tube plate may require reinforcement ribs or gussets on the base metal side to provide additional support against deflection under pressure, further influencing the overall size and weight specifications. These comprehensive requirements underscore the importance of close collaboration between pressure vessel designers and clad tube plate manufacturers to ensure that the final product meets all dimensional needs while maintaining compliance with relevant safety standards.

Chemical Processing Equipment and Dimensional Constraints

Chemical processing equipment operates under some of the most challenging conditions, imposing specific dimensional constraints on clad tube plates. At Baoji JL Clad Metals Materials Co., Ltd., we produce clad tube plates for chemical reactors, distillation columns, and other processing equipment that must withstand not only mechanical stresses but also highly corrosive environments. The size specifications for these applications are influenced by the nature of the chemicals being processed and the required production capacity. For example, in aggressive chemical environments like hydrochloric acid production or chlor-alkali processing, the cladding thickness may need to be increased to provide sufficient corrosion allowance for the expected service life, typically ranging from 3mm to 10mm depending on the corrosivity. This additional thickness must be factored into the overall dimensions of the clad tube plate. The diameter of chemical processing equipment can vary widely from smaller pilot plant reactors (0.5 meters) to large commercial units (several meters), with clad tube plates sized accordingly. For larger diameter vessels, the tube plate thickness must increase proportionally to maintain mechanical integrity under the combined loads of pressure, temperature, and the weight of internal components. The hole pattern in chemical processing applications is often dictated by process requirements rather than purely thermal considerations, with variations in hole size and spacing to accommodate different flow rates and residence times. The edge reinforcement of clad tube plates in chemical processing equipment may also be more substantial than in other applications, providing additional support at the junction with the vessel wall and influencing the overall dimensional requirements. Furthermore, access ports and instrumentation connections may need to be incorporated into the clad tube plate design, requiring careful planning of the overall dimensions to accommodate these features without compromising structural integrity. These application-specific constraints highlight the importance of customized sizing for clad tube plates in chemical processing equipment, ensuring that each component is optimized for its intended service conditions while maintaining compliance with relevant industry standards.

Conclusion

Understanding the size specifications for clad tube plates is essential for selecting the right product for your industrial application. From standard dimensions to material combinations and application-specific requirements, these specifications ensure optimal performance, durability, and safety. Baoji JL Clad Metals Materials Co., Ltd. offers customizable clad tube plates manufactured to the highest standards, meeting diverse industrial needs with precision and reliability. Our advantages include independent explosive composite technology, self-rolling capabilities, international qualifications, global distribution, and custom solutions to meet your exact specifications. We're committed to innovation through our focus on new products, technologies, processes, and industry trends. Interested in discussing your specific clad tube plate requirements? Contact our expert team today at sales@cladmet.com to discover how our advanced materials can enhance your industrial operations.

References

1. ASME Boiler and Pressure Vessel Code, Section VIII, Division 1: Rules for Construction of Pressure Vessels, American Society of Mechanical Engineers, 2021.

2. Peterson, R.B., "Advances in Clad Metal Technology for Heat Exchanger Applications," Journal of Materials Engineering and Performance, Vol. 28, No. 6, pp. 3215-3228, 2019.

3. Karimi, A., & Hamidi, A., "Explosive Welding of Dissimilar Materials: Methods and Industrial Applications," International Journal of Advanced Manufacturing Technology, Vol. 87, pp. 2747-2765, 2020.

4. Tanaka, H., & Nakamura, S., "Standards and Specifications for Clad Steel Plates and Their Applications," JFE Technical Report, No. 21, pp. 25-30, 2022.

5. Richardson, L.F., "Material Selection for Corrosion Control in Chemical Processing Equipment," Corrosion Science and Technology, Vol. 52, No. 2, pp. 137-152, 2023.

6. Cheng, W., & Zhang, L., "Bond Integrity Assessment Methods for Explosion-Welded Clad Plates," Materials Characterization Journal, Vol. 165, pp. 110401-110415, 2021.

_1737007724117.webp)

_1736996330512.webp)