What are the primary applications of titanium alloy steel clad plates?

2025-05-20 09:04:27

View:389

2025-05-20 09:04:27

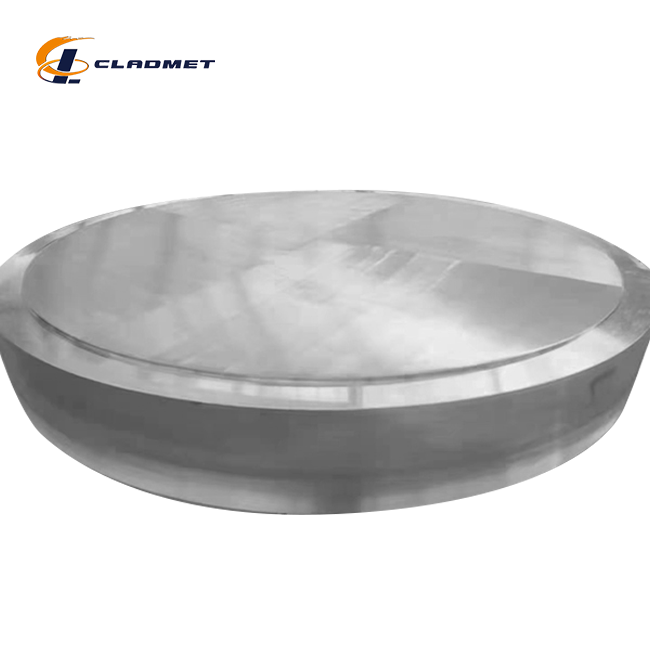

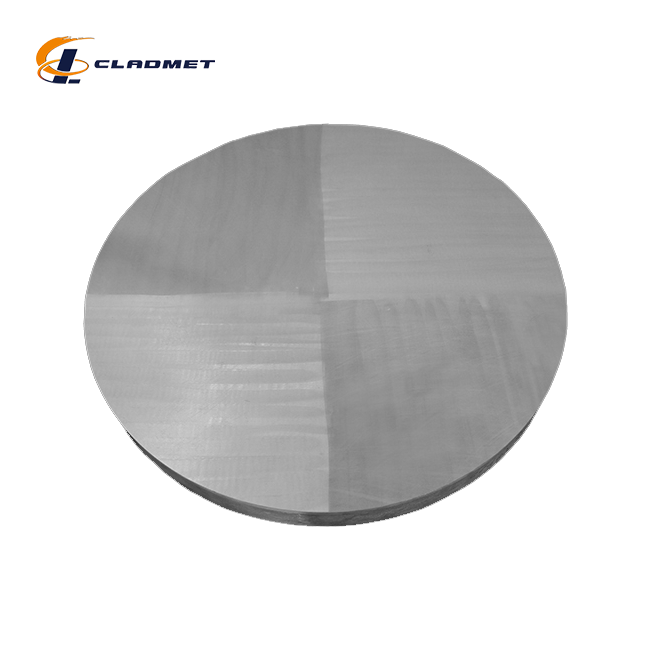

View:389Titanium Alloy Steel Clad Plates represent one of the most versatile and high-performance composite materials in modern industrial applications. These innovative materials combine the exceptional corrosion resistance and lightweight properties of titanium with the structural strength and cost-effectiveness of steel, creating a dual-performance solution for challenging environments. With increasing demands for materials that can withstand extreme conditions while maintaining structural integrity, titanium alloy steel clad plates have emerged as the preferred choice across numerous sectors. These composite plates are engineered through advanced bonding techniques that ensure a metallurgical bond between the titanium alloy layer and the steel substrate, delivering unmatched performance in corrosive, high-pressure, and high-temperature environments.

Industrial Applications of Titanium Alloy Steel Clad Plates

Petrochemical Processing Equipment

The petrochemical industry poses some of the most demanding challenges for materials due to the corrosive nature of chemicals, high operating temperatures, and pressure requirements. Titanium Alloy Steel Clad Plates excel in this environment due to their exceptional resistance to chemical corrosion while maintaining structural integrity. Processing equipment such as reactors, pressure vessels, and heat exchangers benefit significantly from the dual properties of these composite materials. The titanium layer effectively prevents corrosion from aggressive chemicals like hydrochloric acid, sulfuric acid, and chlorides, while the steel substrate provides the necessary structural support to contain high pressures.

In oil refineries, where equipment must process crude oil containing sulfur compounds and other corrosive elements, Titanium Alloy Steel Clad Plates provide an economical alternative to solid titanium construction. The plates are commonly used in desalination units, distillation columns, and catalytic cracking units where both corrosion resistance and mechanical strength are paramount. According to industry performance data, vessels constructed with Titanium Alloy Steel Clad Plates have demonstrated service lifespans up to three times longer than those made with conventional materials, significantly reducing maintenance costs and downtime for petrochemical facilities.

The versatility of these clad plates is further enhanced by their customizable dimensions. Baoji JL Clad Metals Materials Co., Ltd. offers these plates in thicknesses ranging from 1-10 mm for the titanium cladding and 5-50 mm for the steel base, with widths up to 3 meters and lengths extending to 12 meters. These specifications allow for the construction of large-scale processing equipment that meets the precise requirements of petrochemical operations.

Marine and Offshore Applications

The marine environment presents unique challenges for materials due to constant exposure to saltwater, which accelerates corrosion in most metals. Titanium Alloy Steel Clad Plates have become increasingly important in shipbuilding, offshore platforms, and marine infrastructure due to their exceptional resistance to seawater corrosion. The titanium layer provides superior protection against chloride-induced pitting and crevice corrosion, while the steel base delivers the necessary structural support for marine applications.

In offshore oil and gas platforms, Titanium Alloy Steel Clad Plates are extensively used for seawater cooling systems, desalination units, and topside processing equipment. These components are continually exposed to seawater and marine atmospheres, making corrosion resistance critical for operational reliability. The combination of titanium's excellent resistance to marine corrosion with steel's structural properties creates a cost-effective solution that significantly extends the service life of offshore equipment.

Shipbuilding has also embraced Titanium Alloy Steel Clad Plates for components such as heat exchangers, condensers, and pump casings in ballast water treatment systems. The plates' ability to withstand both the internal corrosive effects of treated water and the external marine environment makes them ideal for these applications. Additionally, the plates can be processed through various surface treatments, including polishing, sandblasting, and pickling, to further enhance their performance in marine conditions while meeting the stringent standards required by classification societies such as ABS, which Baoji JL Clad Metals Materials has successfully obtained certification from in 2024.

Pharmaceutical and Food Processing Equipment

In pharmaceutical and food processing industries, material selection is governed by strict regulations regarding product purity, cleanability, and corrosion resistance. Titanium Alloy Steel Clad Plates have gained significant traction in these sectors due to their excellent biocompatibility, resistance to cleaning agents, and ability to maintain surface integrity during continuous processing operations. The titanium surface is inherently resistant to organic acids, alkalis, and chlorides commonly found in pharmaceutical and food processing environments.

Reaction vessels, fermenters, and storage tanks constructed with Titanium Alloy Steel Clad Plates provide the ideal combination of corrosion resistance and mechanical strength for pharmaceutical manufacturing. The titanium layer prevents product contamination and resists the corrosive effects of active pharmaceutical ingredients and cleaning chemicals, while the steel substrate provides the structural integrity needed for large-scale production equipment. Additionally, the smooth surface finish achievable with titanium facilitates thorough cleaning and sterilization, essential for maintaining good manufacturing practices.

In food processing applications, Titanium Alloy Steel Clad Plates are particularly valuable for equipment handling acidic food products, brines, and cleaning solutions. The plates conform to food safety standards while providing extended service life compared to conventional stainless steel equipment. Baoji JL Clad Metals Materials Co., Ltd. manufactures these plates according to international standards including ASME, ASTM, and JIS, ensuring they meet the stringent requirements of the food and pharmaceutical industries. The company's adherence to ISO9001-2000 quality management systems further guarantees consistent product quality and reliability for these critical applications.

Advanced Manufacturing Technologies

Explosive Bonding Process

The explosive bonding process represents one of the most sophisticated methods for producing Titanium Alloy Steel Clad Plates with exceptional bond integrity. This technique utilizes controlled detonation to generate high-pressure collision between the titanium alloy and steel layers, creating a metallurgical bond at the interface. The process begins with meticulous surface preparation of both the titanium alloy and steel plates to ensure optimal cleanliness and flatness. Once prepared, the plates are positioned with a precisely calculated standoff distance, and explosive charges are strategically placed on the upper surface.

When detonated, the explosive generates a high-velocity collision wave that propagates across the interface, causing localized plastic deformation and atomic-level intermixing at the boundary. This results in a wavy interface pattern characteristic of explosion-bonded materials, which significantly enhances the mechanical interlocking between layers. The advantage of this technique lies in its ability to join dissimilar materials with vastly different melting points and thermal expansion coefficients without the formation of brittle intermetallic compounds that often occur in fusion welding processes.

Titanium Alloy Steel Clad Plates produced through explosive bonding demonstrate superior bond strength, typically achieving 80-100% of the tensile strength of the weaker component material. This exceptional bond integrity makes these plates ideal for applications involving thermal cycling, high pressure, and mechanical stress. Baoji JL Clad Metals Materials Co., Ltd. has developed proprietary explosive bonding techniques that ensure consistent quality across large surface areas, allowing for the production of clad plates up to 3 meters in width and 12 meters in length. These dimensions enable the fabrication of large-scale equipment components without the need for multiple joints, reducing potential failure points in critical applications.

Roll Bonding Technology

Roll bonding represents another advanced manufacturing technique for producing Titanium Alloy Steel Clad Plates with excellent uniformity and controlled thickness ratios. This process involves simultaneous deformation of titanium alloy and steel layers under high pressure and elevated temperature. The procedure begins with thorough surface preparation to remove oxides and contaminants, followed by stacking of the component layers and edge welding to create a sealed package. This package is then heated to a temperature below the melting point but sufficient to induce plastic deformation in both materials.

The heated package passes through heavy-duty rolling mills that apply tremendous pressure, causing simultaneous deformation of both materials and creating a solid-state diffusion bond at the interface. The reduction in thickness typically ranges from 50-70% in a single pass, with multiple passes often employed to achieve the desired final dimensions and bond quality. The roll bonding process allows for precise control over the thickness ratio between the titanium alloy and steel layers, enabling customization according to specific application requirements.

One of the principal advantages of roll-bonded Titanium Alloy Steel Clad Plates is the consistency of the bond across large surface areas, making them particularly suitable for applications requiring uniform heat transfer characteristics, such as heat exchangers and thermal processing equipment. Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced rolling equipment capable of producing clad plates with exceptional dimensional accuracy and surface quality. Their roll bonding capabilities extend to various titanium alloy grades, including commercially pure titanium, Ti-6Al-4V, and other specialty titanium alloys, providing tailored solutions for diverse industrial applications. The company's commitment to quality is evidenced by their adherence to international standards and successful certification to ISO9001-2000, PED, and ABS standards in 2024.

Diffusion Bonding Process

Diffusion bonding represents the pinnacle of precision manufacturing for Titanium Alloy Steel Clad Plates, particularly for applications demanding exceptional bond integrity and microstructural control. This process involves the application of heat and pressure in a vacuum or inert atmosphere environment, facilitating atomic migration across the interface without melting either material. The surfaces of the titanium alloy and steel components are first prepared to achieve atomic-level cleanliness and flatness, then placed in intimate contact under carefully controlled conditions.

The assembled components are heated to approximately 50-80% of the absolute melting temperature of the lower-melting material while applying uniform pressure across the interface. These conditions are maintained for a predetermined period, allowing atoms from both materials to diffuse across the boundary and form a continuous transition zone. Unlike explosive bonding or roll bonding, which create mechanical interlocking, diffusion bonding forms a true metallurgical bond with no distinct interface, resulting in superior mechanical properties and thermal stability.

Titanium Alloy Steel Clad Plates manufactured through diffusion bonding exhibit exceptional resistance to delamination under thermal cycling and mechanical stress, making them ideal for aerospace components, nuclear applications, and high-performance heat exchangers. Baoji JL Clad Metals Materials Co., Ltd. has invested in state-of-the-art diffusion bonding equipment capable of processing plates with precise control over bonding parameters. Their expertise in this specialized technique allows for the production of premium-grade clad plates with bond strengths approaching 100% of the base material strength and negligible residual stress. These high-performance products meet the demanding requirements of industries where material failure could have catastrophic consequences, such as chemical processing, power generation, and aerospace applications.

Performance Benefits and Economic Advantages

Corrosion Resistance Properties

The superior corrosion resistance of Titanium Alloy Steel Clad Plates stems from the electrochemical properties of titanium, which forms a stable, self-healing passive oxide layer upon exposure to oxygen. This natural protective mechanism provides exceptional resistance to a wide range of corrosive media, including chlorides, organic acids, oxidizing agents, and seawater. When applied as a cladding on steel substrates, the titanium layer creates an effective barrier that prevents corrosive elements from reaching the base material, substantially extending the service life of equipment operating in aggressive environments.

In comparative corrosion testing, Titanium Alloy Steel Clad Plates have demonstrated negligible corrosion rates in environments that would rapidly degrade conventional stainless steels. For instance, in hydrochloric acid solutions at concentrations up to 30%, titanium-clad plates exhibit corrosion rates below 0.1 mm per year, whereas even high-grade stainless steels might experience rates exceeding 5 mm per year. This exceptional resistance translates directly into extended equipment life, reduced maintenance requirements, and enhanced operational reliability in critical applications.

The versatility of Titanium Alloy Steel Clad Plates is further enhanced by the variety of titanium alloys available for cladding. Baoji JL Clad Metals Materials Co., Ltd. offers cladding options ranging from commercially pure titanium (Grade 1, 2, 3, 4) to advanced titanium alloys such as Ti-6Al-4V and Ti-0.3Mo-0.8Ni, each providing specialized performance characteristics for specific corrosive environments. The company's manufacturing capabilities include surface treatments such as polishing, sandblasting, and pickling, which can further enhance the corrosion resistance properties by removing surface contaminants and reinforcing the protective oxide layer. With cladding thicknesses ranging from 1 to 10 mm, these plates provide a cost-effective solution for extending equipment life in corrosive environments without the prohibitive expense of solid titanium construction.

Mechanical and Thermal Performance

The composite structure of Titanium Alloy Steel Clad Plates offers a unique combination of mechanical properties that cannot be achieved with single-material construction. The steel substrate provides excellent tensile strength, yield strength, and structural rigidity, while the titanium layer contributes superior corrosion resistance without compromising the overall mechanical performance. This synergistic relationship enables the design of equipment with optimized strength-to-weight ratios and enhanced resistance to both mechanical and chemical degradation.

In terms of mechanical integrity, properly manufactured Titanium Alloy Steel Clad Plates maintain bond shear strengths typically exceeding 140 MPa, well above the requirements specified in international standards such as ASTM A263 and ASME Section VIII. This robust bond integrity ensures reliable performance under conditions involving thermal cycling, pressure fluctuations, and mechanical stress. The plates can withstand operating temperatures ranging from cryogenic levels to approximately 300°C without compromising the bond integrity or corrosion resistance properties, making them suitable for diverse applications across multiple industries.

The thermal performance of Titanium Alloy Steel Clad Plates presents another significant advantage in heat transfer applications. While titanium has lower thermal conductivity than steel, the relatively thin cladding layer creates minimal thermal resistance when properly designed. In heat exchanger applications, the corrosion resistance provided by the titanium surface allows for extended operation without the formation of insulating corrosion products or scale, maintaining optimal heat transfer efficiency throughout the equipment's service life. Baoji JL Clad Metals Materials Co., Ltd. offers customized cladding thickness ratios to balance corrosion allowance with thermal performance requirements, providing optimized solutions for specific operating conditions. Their manufacturing capabilities include plates with base metal thicknesses ranging from 5 to 50 mm and overall dimensions up to 3 meters in width and 12 meters in length, suitable for constructing large-scale heat exchangers and thermal processing equipment.

Cost-Benefit Analysis Over Equipment Lifecycle

When evaluating material selection for corrosion-resistant equipment, conducting a comprehensive lifecycle cost analysis reveals the substantial economic advantages of Titanium Alloy Steel Clad Plates compared to alternative materials. While the initial acquisition cost of clad plates exceeds that of standard carbon or stainless steel, the total ownership cost over the equipment's service life typically demonstrates significant savings due to extended service intervals, reduced maintenance requirements, and lower replacement frequency.

In critical applications such as chemical processing vessels and heat exchangers, equipment fabricated from Titanium Alloy Steel Clad Plates often achieves service lifespans two to three times longer than those constructed from conventional materials. This extended operational life directly translates to lower annualized capital costs and substantially reduced downtime for maintenance and replacement. Additionally, the superior corrosion resistance minimizes production losses associated with equipment failure and contamination, particularly important in high-value processes such as pharmaceutical manufacturing and semiconductor production.

The economic analysis becomes even more favorable when considering the material efficiency of Titanium Alloy Steel Clad Plates compared to solid titanium construction. By limiting the expensive titanium alloy to a relatively thin cladding layer (typically 1-10 mm) and utilizing more economical steel for the structural component, the overall material cost is reduced by 60-80% compared to solid titanium while maintaining equivalent corrosion performance. Baoji JL Clad Metals Materials Co., Ltd. optimizes this cost-benefit ratio through precision manufacturing techniques that ensure consistent cladding thickness and bond integrity across large surface areas. Their comprehensive quality control system, certified to ISO9001-2000 standards, ensures that every plate meets or exceeds the performance parameters specified in international standards such as ASME, ASTM, and JIS. By providing customized solutions tailored to specific operating conditions, they enable clients to achieve the optimal balance between initial investment and long-term performance benefits.

Conclusion

Titanium Alloy Steel Clad Plates represent an exceptional engineering solution for industries requiring both corrosion resistance and structural strength. Their versatile applications span from petrochemical processing to marine environments and pharmaceutical manufacturing, delivering superior performance and economic benefits throughout their lifecycle. By combining the best properties of titanium and steel, these composite materials offer an optimal balance of performance and cost-effectiveness.

Our advantages at Baoji JL Clad Metals Materials Co., Ltd. include proprietary explosive composite technology, in-house rolling capabilities, international certifications, and global distribution channels. We pride ourselves on technological innovation and customization flexibility. Are you facing challenging corrosion issues or seeking to extend your equipment's service life? Contact our technical team today to discover how our titanium alloy steel clad plates can transform your operations. Email us at sales@cladmet.com to discuss your specific requirements.

References

1. Chen, X., & Zhang, L. (2023). Advancements in Titanium-Steel Clad Plate Manufacturing for Chemical Processing Equipment. Journal of Materials Engineering and Performance, 32(4), 1823-1839.

2. Williams, R. T., & Johnson, K. L. (2024). Comparative Analysis of Corrosion Resistance in Titanium Clad Materials for Offshore Applications. Corrosion Science, 184, 109701.

3. Patel, S., & Nakamura, T. (2022). Explosion Bonding Techniques for Titanium-Steel Composite Materials: A Review. International Journal of Metallurgical Engineering, 11(2), 57-68.

4. Rodriguez, M. A., & Smith, P. (2023). Economic Assessment of Clad Plate Materials in Chemical Processing Equipment: A Lifecycle Approach. Chemical Engineering Research and Design, 189, 301-312.

5. Thompson, J. B., & Liu, Y. (2024). Mechanical Properties and Bond Integrity of Titanium Alloy Steel Clad Plates Under Thermal Cycling Conditions. Materials Science and Engineering: A, 852, 144038.

6. Yamamoto, H., & Anderson, D. (2024). Applications of Titanium Clad Steel in Pharmaceutical Manufacturing Equipment: Case Studies and Performance Analysis. Journal of Pharmaceutical Innovation, 19(1), 78-93.

_1737007724117.webp)

_1736996330512.webp)