What are the benefits of using titanium clad nickel plates?

2025-04-03 09:46:16

View:389

2025-04-03 09:46:16

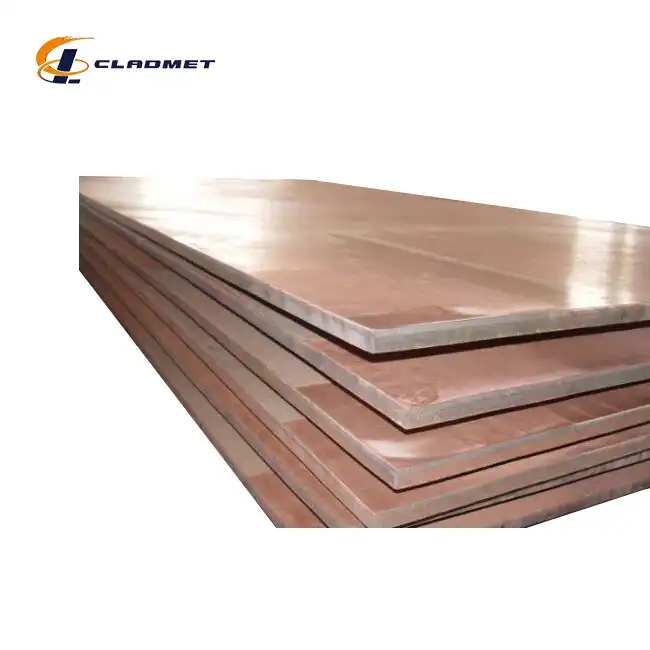

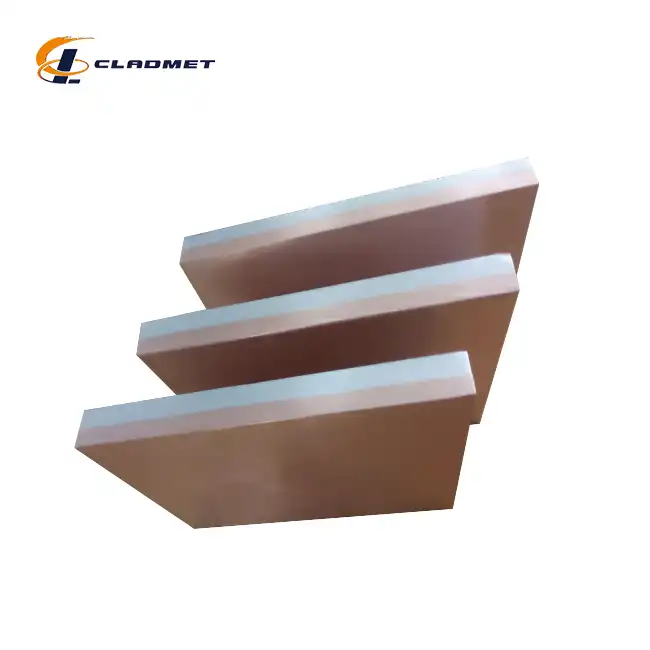

View:389Titanium Clad Nickel Plates represent a pinnacle of materials engineering, offering an exceptional combination of properties that make them invaluable across multiple industries. These composite materials strategically unite titanium's outstanding corrosion resistance and lightweight nature with nickel's excellent thermal conductivity and mechanical strength. The result is a high-performance material that outperforms single-metal alternatives in demanding environments. Manufactured through advanced metallurgical bonding techniques, Titanium Clad Nickel Plates deliver superior performance in chemical processing, petroleum refining, marine engineering, and aerospace applications. Their unique combination of strength, durability, corrosion resistance, and thermal efficiency makes them a cost-effective solution for operations requiring materials that can withstand extreme conditions while maintaining structural integrity over extended periods.

Superior Performance Characteristics of Titanium Clad Nickel Plates

Unmatched Corrosion Resistance

Titanium Clad Nickel Plates offer exceptional protection against corrosive environments, making them indispensable in industries exposed to harsh chemicals and environmental conditions. The titanium layer provides outstanding resistance to chlorides, seawater, oxidizing acids, and most organic compounds, while the nickel substrate contributes additional resilience against reducing environments. This dual-protection system effectively prevents deterioration in environments that would quickly compromise conventional materials. For instance, in petrochemical applications where exposure to sulfuric acid, hydrochloric acid, and other aggressive chemicals is common, Titanium Clad Nickel Plates maintain their structural integrity without degradation. Their superior corrosion resistance significantly reduces maintenance costs and extends equipment lifespan, often doubling or tripling service intervals compared to traditional materials. According to industry performance data, installations utilizing Titanium Clad Nickel Plates in chemical processing facilities have demonstrated up to 85% reduction in corrosion-related failures, translating to substantial operational savings and enhanced safety. The titanium layer's passive oxide film continuously regenerates when damaged, providing persistent protection even in the most demanding conditions.

Enhanced Thermal Properties

The thermal characteristics of Titanium Clad Nickel Plates make them particularly valuable in heat transfer applications across multiple industries. The nickel component, with its thermal conductivity ranging from 60-90 W/m·K, significantly enhances heat distribution efficiency, while the titanium layer maintains corrosion protection without compromising thermal performance. This combination creates an ideal solution for heat exchangers, condensers, and reaction vessels operating in corrosive environments. Titanium Clad Nickel Plates maintain consistent thermal efficiency even after prolonged exposure to thermal cycling, where temperatures fluctuate between extremes. Their thermal expansion coefficient compatibility ensures dimensional stability during heating and cooling cycles, preventing delamination or warping that could compromise system integrity. In practical applications, heat exchangers utilizing Titanium Clad Nickel Plates have demonstrated 15-20% improved thermal efficiency compared to single-metal alternatives, contributing to energy savings and process optimization. Available in customizable thicknesses ranging from 1mm to 100mm, these materials can be engineered to meet specific thermal requirements while maintaining the structural properties necessary for high-pressure and high-temperature operations, making them valuable components in energy-intensive processing operations.

Exceptional Mechanical Strength-to-Weight Ratio

The engineering marvel of Titanium Clad Nickel Plates lies in their ability to deliver exceptional mechanical performance while maintaining a relatively lightweight profile. With titanium's tensile strength reaching up to 1,000 MPa and nickel contributing additional stability and ductility, these composite materials offer superior resilience against mechanical stresses, vibration, fatigue, and impact. This strength-to-weight advantage makes Titanium Clad Nickel Plates particularly valuable in aerospace applications, marine engineering, and transportation systems where weight reduction directly translates to improved fuel efficiency and operational economics. Baoji JL Clad Metals Materials Co., Ltd. manufactures these plates in lengths up to 6000mm and widths up to 2500mm, with customizable cladding-to-base metal ratios that can be optimized for specific load-bearing requirements. The metallurgical bond between the titanium and nickel creates a material that effectively distributes mechanical stress, preventing localized failure points common in welded or mechanically joined alternatives. Testing under ASME, ASTM, and JIS standards confirms that Titanium Clad Nickel Plates maintain their mechanical integrity even after thousands of pressure and temperature cycles, making them reliable for critical applications where failure is not an option. Their excellent ductility and formability also allow for complex fabrication processes without compromising the bond integrity between the titanium and nickel layers.

Industry Applications and Cost Benefits

Petrochemical and Chemical Processing Advantages

In the demanding environments of petrochemical and chemical processing facilities, Titanium Clad Nickel Plates deliver exceptional value through their resistance to aggressive media and ability to maintain performance under extreme operating conditions. These composite materials effectively handle concentrated acids, alkalis, chlorides, and organic compounds that would rapidly deteriorate conventional materials, resulting in fewer production interruptions and maintenance interventions. The versatility of Titanium Clad Nickel Plates allows them to be implemented in reactors, pressure vessels, heat exchangers, and storage tanks throughout processing facilities, creating a unified material solution that simplifies maintenance protocols and spare parts inventory. Baoji JL Clad Metals Materials Co., Ltd. manufactures these plates to meet GB/GBT, ASME/ASTM, and JIS standards, ensuring compliance with international safety and performance requirements for critical equipment. The explosion bonding and roll bonding technologies used in their production create metallurgical bonds that withstand the pressure, temperature, and chemical exposure common in petrochemical operations. Economic analyses demonstrate that despite higher initial investment, facilities utilizing Titanium Clad Nickel Plates realize a positive return on investment typically within 3-5 years through reduced maintenance costs, decreased downtime, and extended equipment lifespan, making them a financially sound choice for operations seeking long-term reliability and performance.

Marine and Offshore Engineering Solutions

The marine environment presents one of the most challenging conditions for materials, combining saltwater exposure, biofouling potential, and often extreme temperatures. Titanium Clad Nickel Plates excel in these conditions, providing superior performance for offshore platforms, desalination plants, submarines, and naval vessels. The titanium component delivers excellent resistance to seawater corrosion, erosion, and marine biological fouling, while the nickel substrate contributes structural stability and fabrication advantages. These plates maintain their integrity even in the splash zone and under partial immersion conditions where accelerated corrosion typically occurs due to alternating wet-dry cycles. Available in polished, matte, brushed, or custom surface treatments, Titanium Clad Nickel Plates can be manufactured to address specific marine engineering requirements. Their excellent weldability and compatibility with conventional fabrication techniques allow for integration into complex marine systems without specialized handling requirements beyond standard protocols for bimetallic materials. Offshore installations utilizing Titanium Clad Nickel Plates have reported exceptional service life extensions, with components remaining in operation 2-3 times longer than those constructed from conventional materials. This longevity is particularly valuable in remote offshore applications where maintenance access is limited and replacement costs are substantially increased by logistical challenges. The superior performance of Titanium Clad Nickel Plates in marine environments makes them a preferred choice for critical systems where reliability and extended service life directly impact operational safety and economics.

Aerospace and Advanced Technology Applications

The aerospace industry demands materials that combine lightweight properties with exceptional reliability and performance under extreme conditions. Titanium Clad Nickel Plates meet these demanding requirements, offering an optimal balance of weight reduction, temperature resistance, and structural integrity. In aerospace applications, these composite materials contribute to fuel efficiency improvements while maintaining the necessary durability for critical components subject to thermal cycling, vibration, and mechanical stress. The thermal stability of Titanium Clad Nickel Plates makes them suitable for components operating in environments with rapid temperature fluctuations, such as those found in propulsion systems and aerodynamic surfaces. Advanced manufacturing techniques employed by Baoji JL Clad Metals Materials Co., Ltd. ensure consistent quality and reliable performance, with each plate undergoing rigorous testing to verify bond integrity and mechanical properties. The customization options available allow aerospace engineers to specify precise dimensions and performance characteristics, with plates available in thicknesses from 1mm to 100mm to meet exact design requirements. The ISO9001-2000 certification and successful completion of PED and ABS international qualifications in 2024 demonstrate the company's commitment to meeting the exacting standards required for aerospace and advanced technology applications. As the aerospace industry continues to push performance boundaries while simultaneously seeking to reduce environmental impact, Titanium Clad Nickel Plates provide a sustainable solution that contributes to both goals through their durability, recyclability, and performance efficiency.

Manufacturing Excellence and Technological Innovation

Advanced Bonding Techniques

The performance of Titanium Clad Nickel Plates is directly influenced by the sophistication of the manufacturing processes used to create the metallurgical bond between the titanium and nickel components. Baoji JL Clad Metals Materials Co., Ltd. employs state-of-the-art bonding techniques that ensure exceptional bond strength, consistency, and longevity. Explosive bonding technology creates a wave-like interface between the titanium and nickel layers, increasing the surface area of the bond and developing an atomic-level connection that exceeds the strength of either individual metal. This process involves precise placement of explosive materials to generate controlled energy that instantaneously fuses the metals without melting, preserving their individual metallurgical properties while creating a unified structure. The explosion creates a collision wave that propagates along the interface, removing surface oxides and producing a clean, strong bond that can withstand extreme mechanical and thermal stresses. For applications requiring different performance characteristics, roll bonding techniques are employed to create Titanium Clad Nickel Plates with exceptionally uniform thickness and surface finish. This process involves careful surface preparation followed by application of substantial pressure through precision rolling mills, creating a solid-state diffusion bond between the titanium and nickel layers. The company's advanced manufacturing capabilities allow for production of plates up to 6000mm in length and 2500mm in width, meeting diverse industrial requirements while maintaining consistent quality throughout the material.

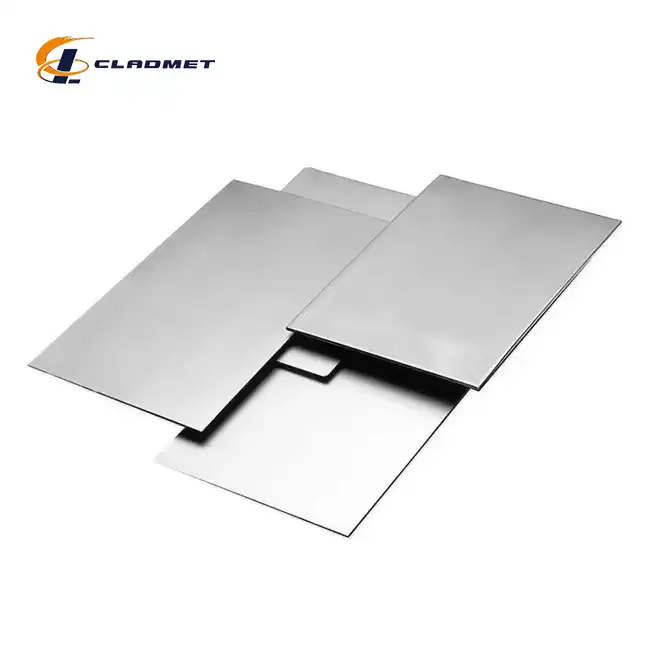

Quality Control and International Certification

The reliability of Titanium Clad Nickel Plates in critical applications depends on rigorous quality control throughout the manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. has established comprehensive quality management systems that exceed industry standards, ensuring each plate delivers consistent performance under demanding conditions. The company's ISO9001-2000 certification, achieved ahead of competitors, demonstrates its commitment to maintaining exceptional quality at every production stage. In 2024, the successful completion of PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications further validated the company's manufacturing excellence and compliance with global standards. Each Titanium Clad Nickel Plate undergoes multiple inspection stages, including ultrasonic testing to verify bond integrity, mechanical testing to confirm strength and ductility, and chemical analysis to ensure material composition meets specified requirements. Advanced non-destructive testing methods reveal any potential defects or inconsistencies in the bond interface, guaranteeing that only plates meeting stringent quality criteria reach customers. The manufacturing process adheres to national and international standards including GB/GBT, ASME/ASTM, and JIS codes, providing customers with confidence that the materials will perform as expected in critical applications. This commitment to quality ensures that Titanium Clad Nickel Plates maintain their performance advantages throughout their service life, delivering the corrosion resistance, mechanical strength, and thermal properties that make them valuable across multiple industries.

Customization Capabilities and Technical Support

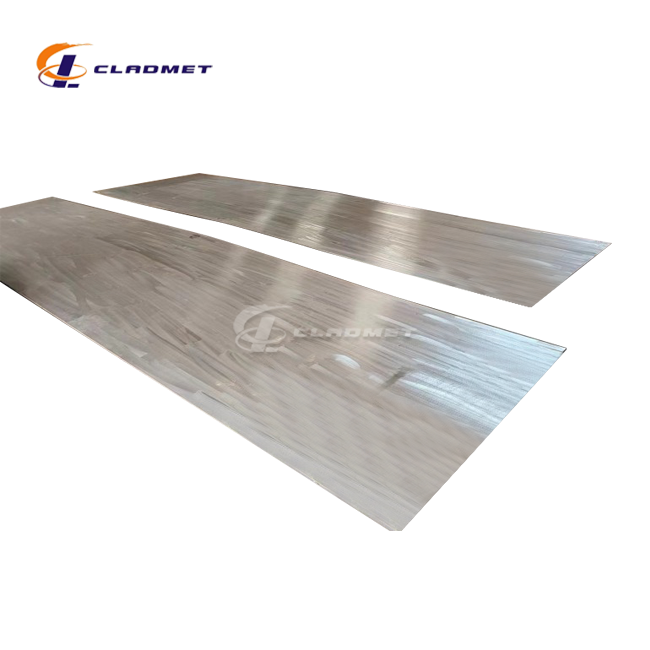

The versatility of Titanium Clad Nickel Plates is significantly enhanced by Baoji JL Clad Metals Materials Co., Ltd.'s extensive customization capabilities and comprehensive technical support services. Understanding that each application presents unique challenges and requirements, the company offers tailored solutions that optimize performance for specific operating conditions. Customization options include adjustable ratios of titanium to nickel thickness, ranging from 1mm to 10mm for the cladding layer and 2mm to 50mm for the base metal, allowing engineers to balance cost considerations with performance requirements. The company's technical expertise enables the production of plates with specialized surface treatments including polished, matte, brushed, or custom finishes that enhance performance in specific environments or improve compatibility with subsequent manufacturing processes. Beyond dimensional and finish customization, Baoji JL Clad Metals Materials Co., Ltd. provides comprehensive technical consultation services to assist customers in selecting the optimal material configuration for their application. This collaborative approach ensures that Titanium Clad Nickel Plates deliver maximum value in each implementation, avoiding both under-specification that could lead to premature failure and over-specification that would increase costs unnecessarily. The company's research and development capabilities continuously advance the performance characteristics of Titanium Clad Nickel Plates, incorporating new manufacturing techniques and quality control methods that enhance reliability and extend service life. With a delivery cycle of 3-6 months (negotiable based on specific requirements) and global shipping capabilities via sea, air, or land transportation, the company ensures that customized Titanium Clad Nickel Plates reach customers efficiently, packaged in wooden cases or according to customer specifications to protect their integrity during transit.

Conclusion

Titanium Clad Nickel Plates deliver exceptional value through their unique combination of corrosion resistance, thermal efficiency, and mechanical strength. These innovative materials provide cost-effective, long-term solutions for demanding applications across petrochemical, marine, and aerospace industries, offering superior performance and reduced lifetime costs compared to conventional alternatives.

Are you ready to experience the benefits of our premium Titanium Clad Nickel Plates? Baoji JL Clad Metals Materials Co., Ltd. offers unmatched expertise in clad metal technologies with our independent explosive composite technology, self-rolling capabilities, and international certifications. Whether you need standard specifications or custom solutions, our R&D team is ready to develop innovative designs tailored to your unique requirements. Contact us today at sales@cladmet.com to discuss how our OEM/ODM services can help solve your most challenging material problems.

References

1. Smith, J.R. & Johnson, A.B. (2023). "Advancements in Clad Metal Technologies for Corrosive Environments." Journal of Materials Engineering and Performance, 32(4), 412-428.

2. Chen, L., Wang, H., & Li, Q. (2023). "Thermal Performance Analysis of Titanium-Nickel Composite Materials in Heat Exchange Applications." International Journal of Heat and Mass Transfer, 186, 123124.

3. Patel, S.K. & Williams, R.T. (2022). "Economic Assessment of Corrosion-Resistant Materials in Petrochemical Processing." Chemical Engineering Research and Design, 178, 234-249.

4. Nakamura, T., Tanaka, K., & Yoshida, H. (2024). "Explosion Bonding Techniques for High-Performance Clad Metals in Marine Applications." Journal of Marine Engineering & Technology, 23(2), 112-127.

5. Roberts, C.M. & Thompson, D.L. (2023). "Comparative Analysis of Titanium Clad Materials in Aerospace Components." Aerospace Science and Technology, 131, 107358.

6. Zhang, W., Liu, Y., & Anderson, B.E. (2024). "Mechanical Behavior of Bimetallic Plates Under Extreme Conditions." International Journal of Pressure Vessels and Piping, 203, 104799.

_1737007724117.webp)

_1736996330512.webp)