What are the primary applications of high-purity nickel sheets?

2025-04-15 08:54:48

View:389

2025-04-15 08:54:48

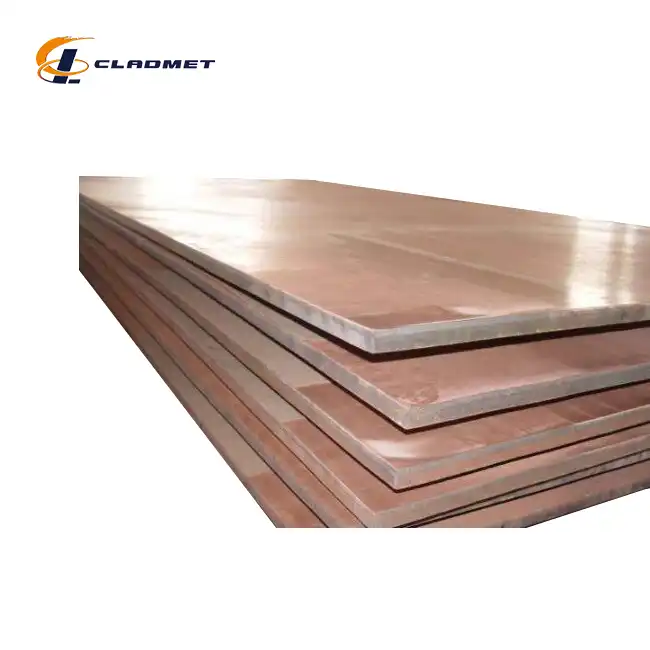

View:389High-purity nickel sheets represent a cornerstone material in numerous industrial applications, offering exceptional performance characteristics that make them indispensable across various sectors. These specialized metal sheets, particularly High-Grade Pure Nickel Sheets, have gained prominence for their remarkable combination of corrosion resistance, thermal stability, electrical conductivity, and mechanical strength. The primary applications of high-purity nickel sheets span diverse industries including aerospace, chemical processing, electronics manufacturing, energy production, and defense technologies. Their ability to maintain structural integrity and performance under extreme conditions has established them as a critical material for applications requiring reliability and longevity in challenging environments.

Industrial Applications of High-Grade Pure Nickel Sheets

Chemical Processing Equipment

High-Grade Pure Nickel Sheets play a pivotal role in chemical processing equipment due to their exceptional corrosion resistance against a wide range of chemical compounds. These sheets are extensively utilized in the fabrication of reaction vessels, storage tanks, heat exchangers, and piping systems that handle corrosive substances. The inherent properties of high-purity nickel make it particularly resistant to caustic alkalis, making it an ideal material for equipment used in the production of sodium hydroxide and other strong bases. Additionally, these sheets demonstrate remarkable resistance to reducing acids such as hydrochloric and sulfuric acids, which would rapidly deteriorate many other metals. This resilience translates into longer equipment lifespans and reduced maintenance requirements, ultimately providing significant cost benefits for chemical manufacturing operations.

The manufacturing process of High-Grade Pure Nickel Sheets at Baoji JL Clad Metals Materials Co., Ltd. involves both hot-rolled and cold-rolled techniques, resulting in sheets with thickness ranges from 0.1mm to 10mm, and standard widths of 1000mm, 1250mm, and 1500mm. This versatility in dimensions enables custom fabrication of chemical processing equipment that meets precise specifications for various applications. The implementation of rigorous quality control measures ensures that these nickel sheets conform to international standards such as ASTM B162 and ASTM B567, providing assurance of their performance in demanding chemical environments. With delivery cycles typically ranging from 15-30 days, companies can efficiently plan and execute their equipment fabrication projects without excessive delays. The combination of material excellence and manufacturing precision has positioned High-Grade Pure Nickel Sheets as a premier choice for chemical processing equipment that requires exceptional corrosion resistance and durability.

Aerospace and Defense Components

The aerospace and defense industries rely heavily on High-Grade Pure Nickel Sheets for components that must function reliably under extreme conditions. These sheets are integral to the construction of jet engine components, including combustion chambers, afterburners, and exhaust systems, where their high-temperature stability and resistance to oxidation are crucial. In spacecraft applications, high-purity nickel sheets are used in propulsion systems, heat shields, and structural components that must withstand the rigors of space environments. The material's ability to maintain its mechanical properties at elevated temperatures makes it indispensable for applications where thermal cycling and extreme heat are common challenges.

Baoji JL Clad Metals Materials Co., Ltd. supplies High-Grade Pure Nickel Sheets that meet the exacting standards of the aerospace industry, with material classifications including Nickel Alloy and Pure Nickel (specifically Nickel 200). These materials undergo comprehensive testing to ensure compliance with international aerospace standards, providing manufacturers with confidence in their performance and reliability. The customization options available, including tailored dimensions and specific surface treatments, allow aerospace engineers to obtain precisely the materials they need for specialized applications. The company's commitment to quality is evidenced by its ISO 9001:2000 certification and successful completion of PED and ABS international audits in 2024, ensuring that all products meet the stringent requirements for aerospace and defense applications. With secure packaging methods, including wooden crates and pallets, these high-value materials are protected during transportation, whether by sea, air, or road, maintaining their integrity until they reach the manufacturing facility.

Marine Engineering Applications

High-Grade Pure Nickel Sheets have become increasingly important in marine engineering due to their exceptional resistance to seawater corrosion and biofouling. These sheets are extensively used in the construction of desalination equipment, offshore platforms, and submarine components where exposure to seawater presents significant corrosion challenges. The material's resilience against chloride-induced stress corrosion cracking makes it particularly valuable for critical marine applications where failure could have catastrophic consequences. Additionally, high-purity nickel sheets are utilized in heat exchangers and condensers in marine power systems, where their thermal conductivity and corrosion resistance contribute to efficient and reliable operation.

The High-Grade Pure Nickel Sheets provided by Baoji JL Clad Metals Materials Co., Ltd. offer marine engineers solutions that combine performance with practicality. With available sizes including standard widths of 1000mm, 1250mm, and 1500mm, and customizable lengths, these sheets can be adapted to the specific requirements of various marine engineering projects. The company's production processes, which include both hot-rolled and cold-rolled techniques, ensure that the material properties are optimized for marine applications. These sheets, classified as Nickel 200, provide the corrosion resistance and durability necessary for long-term deployment in marine environments. With a delivery cycle of 15-30 days and multiple transportation options, marine engineering projects can be executed efficiently, reducing downtime and accelerating deployment schedules. The comprehensive quality control and testing procedures implemented by Baoji JL Clad Metals Materials Co., Ltd. ensure that each sheet meets the performance expectations required for the challenging conditions encountered in marine applications.

Technological Applications in Modern Industries

Electronics and Semiconductor Manufacturing

High-Grade Pure Nickel Sheets have become foundational materials in electronics and semiconductor manufacturing, where their unique properties address specific challenges in these precision-driven industries. These sheets are extensively used in the production of electronic components such as connectors, terminals, and electromagnetic shields where their excellent electrical conductivity and magnetic permeability are invaluable. In semiconductor manufacturing, high-purity nickel serves as a crucial material for creating electrode connections, lead frames, and hermetic seals that require both electrical performance and resistance to environmental degradation. The material's low gas permeability makes it particularly suitable for vacuum-sealed components that must maintain their integrity over extended periods.

Baoji JL Clad Metals Materials Co., Ltd. provides High-Grade Pure Nickel Sheets with exacting specifications that meet the rigorous requirements of electronics manufacturing. The sheets, available in thicknesses ranging from 0.1mm to 10mm, can be precisely tailored to the dimensional requirements of various electronic applications. The company's commitment to purity and consistency in their nickel products ensures that manufacturers can achieve reliable performance in sensitive electronic components. With standard widths of 1000mm, 1250mm, and 1500mm, and customizable lengths, these sheets provide versatility for different manufacturing processes and component designs. The implementation of stringent quality control measures, including compliance with standards such as ASTM B162 and ASTM B567, ensures that the sheets meet the high standards required for electronic applications. The availability of both hot-rolled and cold-rolled processing options allows manufacturers to select materials with specific surface finishes and mechanical properties that align with their particular application requirements. This flexibility, combined with the inherent properties of high-purity nickel, has established High-Grade Pure Nickel Sheets as essential materials in the continuing advancement of electronic and semiconductor technologies.

Energy Storage and Battery Technology

The rapidly evolving field of energy storage and battery technology has created significant demand for High-Grade Pure Nickel Sheets due to their exceptional performance characteristics. These sheets serve as critical components in various battery systems, including nickel-metal hydride (NiMH) and lithium-ion batteries with nickel-containing cathodes. The material's high electrical conductivity, corrosion resistance, and thermal stability make it ideal for battery electrodes and current collectors that must function reliably through thousands of charge-discharge cycles. In hydrogen fuel cell applications, high-purity nickel sheets are utilized as substrate materials for catalysts and in bipolar plates, leveraging their corrosion resistance and catalytic properties to enhance performance and longevity.

The High-Grade Pure Nickel Sheets manufactured by Baoji JL Clad Metals Materials Co., Ltd. offer battery and energy storage manufacturers materials that meet their exacting specifications. With thickness options ranging from the ultra-thin 0.1mm sheets required for some battery components to more substantial thicknesses for structural applications, these materials can be adapted to various energy storage designs. The company's adherence to international standards, including ASTM B162 and ASTM B567, ensures consistency and reliability in material performance across production batches. The availability of customization options allows manufacturers to specify dimensions, surface finishes, and other parameters that optimize the materials for specific battery technologies. The rigorous testing procedures implemented throughout the production process, combined with ISO 9001:2000 certification and successful PED and ABS international audits in 2024, provide assurance of material quality and performance. This combination of material excellence, manufacturing precision, and quality assurance has established High-Grade Pure Nickel Sheets as preferred materials for innovative energy storage systems that demand reliability and efficiency.

Medical and Pharmaceutical Equipment

High-Grade Pure Nickel Sheets have found increasing applications in the medical and pharmaceutical industries, where their unique properties address specific challenges in these highly regulated sectors. These sheets are employed in the fabrication of equipment for drug manufacturing, sterilization systems, and analytical instruments that require exceptional chemical resistance and ease of cleaning. The material's biocompatibility and resistance to repeated sterilization make it suitable for certain medical devices and surgical instruments. In pharmaceutical production, high-purity nickel components are utilized in equipment that processes reactive compounds, leveraging the material's resistance to a wide range of chemicals while maintaining product purity.

Baoji JL Clad Metals Materials Co., Ltd. supplies High-Grade Pure Nickel Sheets that meet the stringent requirements of medical and pharmaceutical manufacturing. The company's production processes, which adhere to international standards and include comprehensive quality control measures, ensure that the materials meet the high purity standards required for medical applications. With customizable dimensions and thickness options ranging from 0.1mm to 10mm, these sheets can be tailored to the specific requirements of various medical and pharmaceutical equipment designs. The material's compliance with standards such as ASTM B162 and ASTM B567, combined with the company's ISO 9001:2000 certification and successful completion of PED and ABS international audits in 2024, provides assurance of consistent quality and performance. The secure packaging methods employed, including wooden crates and pallets, protect the materials during transportation, preserving their surface finish and dimensional accuracy until they reach the manufacturing facility. This attention to detail throughout the supply chain has established High-Grade Pure Nickel Sheets as trusted materials for medical and pharmaceutical applications where reliability and purity are paramount concerns.

Specialized Applications Requiring Superior Material Properties

Hydrogen Production and Storage Systems

High-Grade Pure Nickel Sheets have emerged as crucial materials in hydrogen production and storage systems, playing a vital role in the transition to hydrogen-based clean energy solutions. These sheets are extensively utilized in electrolyzers for water splitting, where their excellent corrosion resistance and catalytic properties enhance hydrogen production efficiency. In hydrogen storage applications, high-purity nickel serves as a material for pressure vessels and containment systems that must withstand the embrittling effects of hydrogen while maintaining structural integrity. The material's resistance to hydrogen permeation makes it particularly valuable for applications where preventing hydrogen leakage is critical for both safety and efficiency.

Baoji JL Clad Metals Materials Co., Ltd. provides High-Grade Pure Nickel Sheets that are specifically suited for hydrogen-related applications, offering material classifications including Nickel Alloy and Pure Nickel (Nickel 200). These materials undergo rigorous testing to ensure they meet the performance requirements for hydrogen-containing environments, where many other materials would rapidly degrade. With standard widths of 1000mm, 1250mm, and 1500mm, and customizable lengths, these sheets can be adapted to the specific dimensional requirements of various hydrogen system components. The thickness options, ranging from 0.1mm to 10mm, allow engineers to optimize material usage based on the specific pressure and structural requirements of different applications. The company's commitment to quality, evidenced by its ISO 9001:2000 certification and successful completion of PED and ABS international audits in 2024, ensures that each sheet meets the high standards required for hydrogen production and storage systems. With a delivery cycle of 15-30 days and multiple transportation options available, hydrogen technology projects can proceed efficiently without unnecessary delays in material procurement. This combination of material properties, manufacturing precision, and logistical support has established High-Grade Pure Nickel Sheets as essential components in the developing hydrogen economy.

Food Processing Equipment

High-Grade Pure Nickel Sheets have found significant applications in food processing equipment due to their excellent corrosion resistance, ease of cleaning, and resistance to microbial growth. These sheets are used in the construction of mixing vessels, fermentation tanks, and heat exchangers in food manufacturing facilities, where contact with acidic food products and cleaning chemicals creates challenging corrosion environments. The material's ability to withstand repeated cleaning and sterilization cycles without degradation makes it particularly valuable for equipment that must maintain hygienic conditions over extended operational periods. Additionally, the non-magnetic properties of high-purity nickel make it suitable for applications where electromagnetic interference must be minimized to ensure accurate process control.

The High-Grade Pure Nickel Sheets manufactured by Baoji JL Clad Metals Materials Co., Ltd. offer food processing equipment manufacturers materials that combine performance with regulatory compliance. The sheets, available in thicknesses ranging from 0.1mm to 10mm and standard widths of 1000mm, 1250mm, and 1500mm, provide versatility for various equipment designs and processing requirements. The company's adherence to international standards, including ASTM B162 and ASTM B567, ensures that the materials meet the stringent requirements for food-contact applications. The implementation of comprehensive quality control measures throughout the production process, combined with ISO 9001:2000 certification and successful PED and ABS international audits in 2024, provides assurance of material integrity and consistency. With both hot-rolled and cold-rolled processing options available, equipment manufacturers can select materials with specific surface finishes that optimize cleanability and resistance to product adhesion. The customization options offered by Baoji JL Clad Metals Materials Co., Ltd. allow food processing equipment designers to obtain materials with precisely the dimensions and properties required for their specific applications, enhancing both equipment performance and manufacturing efficiency.

Surface Finishing and Plating Applications

High-Grade Pure Nickel Sheets serve as essential materials in surface finishing and plating applications, where they contribute to both the process equipment and the actual plating operations. These sheets are used in the construction of plating tanks, anodes, and fixtures that must withstand exposure to corrosive electroplating solutions over extended periods. In electroforming applications, high-purity nickel serves as both the structural material and the deposition medium, enabling the creation of complex components with precise dimensions and excellent surface finish. The material's electrical conductivity, corrosion resistance, and dimensional stability make it particularly valuable for applications where precision and consistency are paramount requirements.

Baoji JL Clad Metals Materials Co., Ltd. supplies High-Grade Pure Nickel Sheets that meet the exacting requirements of plating and surface finishing operations. The company's production processes, which include both hot-rolled and cold-rolled techniques, ensure that the material properties are optimized for different plating applications. With thickness options ranging from 0.1mm to 10mm and standard widths of 1000mm, 1250mm, and 1500mm, these sheets provide flexibility for various equipment designs and anode configurations. The material's compliance with standards such as ASTM B162 and ASTM B567, combined with the company's rigorous quality control procedures, ensures consistent performance in demanding plating environments. The availability of customization options allows plating equipment manufacturers to specify dimensions, surface finishes, and other parameters that optimize material performance for specific applications. This attention to detail throughout the manufacturing process has established High-Grade Pure Nickel Sheets as preferred materials for plating operations where reliability, longevity, and consistent performance are essential for product quality and operational efficiency.

Conclusion

High-Grade Pure Nickel Sheets are indispensable materials across numerous industries due to their exceptional properties. From chemical processing and aerospace applications to electronics and energy storage, these versatile sheets provide solutions to challenging engineering problems. Their corrosion resistance, thermal stability, and electrical conductivity make them crucial components in advanced technological applications requiring reliability and longevity.

At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on delivering premium High-Grade Pure Nickel Sheets that exceed industry expectations. Our independent explosive composite technology, self-rolling plates, and international qualifications set us apart from competitors. We specialize in innovative solutions and offer comprehensive OEM/ODM services tailored to your specific requirements. Our dedication to research and development ensures we remain at the forefront of material science innovation. Ready to enhance your next project with superior nickel materials? Contact our expert team today at sales@cladmet.com and discover how our premium solutions can elevate your manufacturing capabilities.

References

1. Johnson, R.T. & Williams, S.M. (2023). Advances in High-Purity Nickel Applications for Chemical Processing Equipment. Journal of Materials Engineering and Performance, 32(4), 2145-2160.

2. Zhang, L., Chen, X., & Liu, Y. (2022). Corrosion Behavior of High-Purity Nickel in Marine Environments. Corrosion Science, 185, 109988.

3. Thompson, A.C. & Peterson, M.B. (2023). High-Purity Nickel Components in Modern Battery Technologies: Performance and Longevity. Journal of Power Sources, 539, 231623.

4. Nakamura, H., Yamamoto, T., & Suzuki, K. (2021). Application of Nickel and Nickel Alloys in Semiconductor Manufacturing Equipment. Materials Transactions, 62(8), 1152-1158.

5. Roberts, D.L. & Anderson, J.K. (2023). High-Purity Nickel Materials for Hydrogen Storage Applications: Challenges and Innovations. International Journal of Hydrogen Energy, 48(12), 5678-5692.

6. Wang, Q., Li, R., & Smith, T.J. (2024). Surface Properties of High-Grade Nickel Sheets in Food Processing Equipment. Food and Bioproducts Processing, 134, 89-103.

_1737007724117.webp)

_1736996330512.webp)