What Factors Should Be Considered When Selecting Zirconium Steel Clad Plates?

2025-03-28 10:01:25

View:389

2025-03-28 10:01:25

View:389When it comes to selecting materials for challenging industrial environments, the decision-making process requires careful consideration of multiple factors. Zirconium steel clad plates represent a significant advancement in composite materials technology, combining the exceptional corrosion resistance of zirconium with the structural integrity and cost-effectiveness of steel. These innovative materials have become increasingly important in industries facing aggressive chemical environments, high temperatures, and mechanical stress. The selection of appropriate zirconium steel clad plates demands a thorough understanding of their properties, manufacturing processes, and application requirements. This comprehensive guide explores the critical factors that engineers, procurement specialists, and technical decision-makers should consider when selecting zirconium steel clad plates for their specific industrial applications.

Material Composition and Properties

The foundation of any successful application of zirconium steel clad plates lies in understanding their material composition and inherent properties. These factors directly influence performance, longevity, and suitability for specific environments.

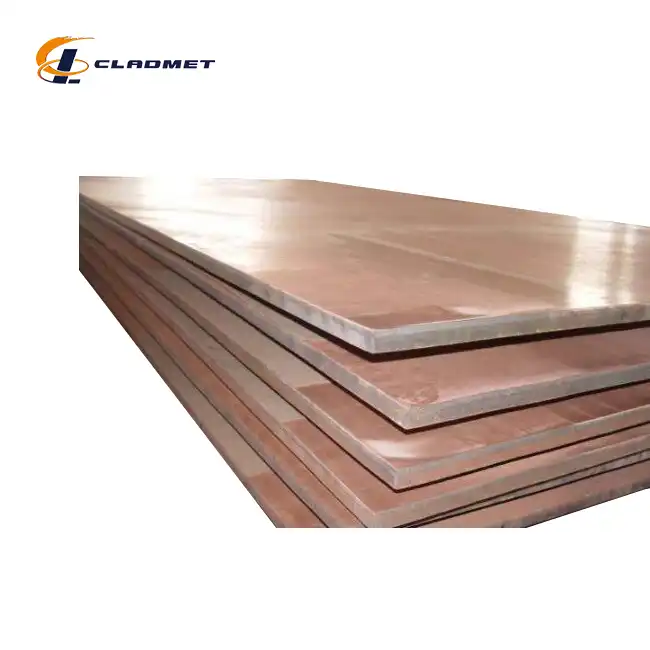

Base Metal Selection

When selecting zirconium steel clad plates, the base metal serves as the foundation for the composite material and requires careful consideration. The most common base metals include carbon steel and various grades of stainless steel, each offering distinct advantages depending on the application. Carbon steel provides excellent structural strength and cost-effectiveness, making it suitable for applications where mechanical properties are prioritized. Stainless steel bases, particularly austenitic grades like 304 and 316, offer enhanced corrosion resistance in addition to mechanical strength, providing a more comprehensive protection profile. The thickness of the base metal, typically ranging from 5mm to 200mm, must be determined based on structural requirements, pressure considerations, and mechanical load expectations. Baoji JL Clad Metals Materials Co., Ltd. offers a wide range of base metal options for their zirconium steel clad plates, including customized solutions to meet specific engineering requirements. When selecting the appropriate base metal, engineers must consider not only the immediate operational demands but also the potential for future environmental changes or process modifications that might affect material performance. The company's technical specialists can provide guidance on optimal base metal selection based on detailed analysis of application parameters and long-term performance expectations.

Zirconium Grade Specifications

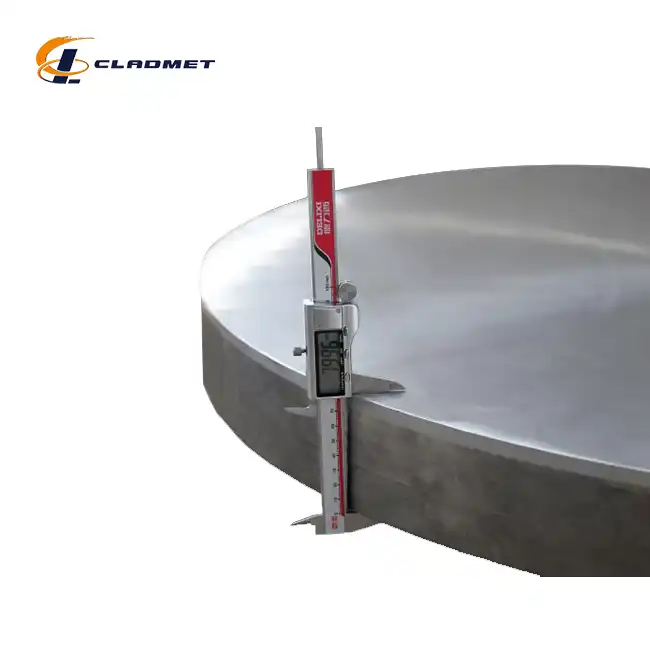

The zirconium component of zirconium steel clad plates plays a crucial role in determining their corrosion resistance capabilities. Different grades of zirconium, such as Zr702 and Zr705, offer varying levels of performance in specific environments. Zr702, with its high purity, provides exceptional resistance to a wide range of acids, alkalis, and salt solutions, making it ideal for chemical processing applications. Zr705, containing small amounts of niobium, demonstrates enhanced mechanical properties while maintaining excellent corrosion resistance, particularly suitable for applications involving both corrosive media and mechanical stress. The thickness of the zirconium layer, typically ranging from 3mm to 50mm, must be carefully specified based on the anticipated corrosive environment, expected service life, and economic considerations. Baoji JL Clad Metals Materials Co., Ltd. specializes in providing precise zirconium layer specifications tailored to each application's unique requirements. Their metallurgical expertise ensures optimal zirconium grade selection that balances performance requirements with cost considerations. When evaluating zirconium steel clad plates for specific applications, it's essential to consider not only the current operating conditions but also potential variations in process parameters that might affect the corrosion resistance requirements over the equipment's lifecycle.

Bond Integrity Assessment

The quality of the bond between the zirconium layer and the steel substrate forms the cornerstone of zirconium steel clad plate performance. This metallurgical bond must maintain its integrity across a range of operating conditions, including thermal cycling, mechanical stress, and exposure to corrosive environments. Advanced bonding technologies employed by manufacturers like Baoji JL Clad Metals Materials Co., Ltd. create bonds with shear strengths typically exceeding 140 MPa, ensuring reliable performance even under extreme conditions. The bond integrity can be assessed through various non-destructive testing methods, including ultrasonic testing, which identifies potential delamination or bonding defects; shear testing, which confirms the mechanical strength of the bond; and bend testing, which evaluates the bond's resistance to mechanical deformation. High-quality zirconium steel clad plates should demonstrate uniform bond characteristics across the entire surface area, with minimal variation in bond strength or thickness. This consistency ensures predictable performance throughout the material's service life. The company's quality control processes include comprehensive bond integrity assessment protocols that exceed international standards requirements, providing customers with detailed documentation of bond characteristics for each supplied plate. For critical applications, additional specialized testing can be arranged to verify specific performance parameters relevant to the intended operating environment.

Manufacturing Processes and Quality Control

The manufacturing method and quality control measures significantly impact the performance and reliability of zirconium steel clad plates in demanding industrial applications.

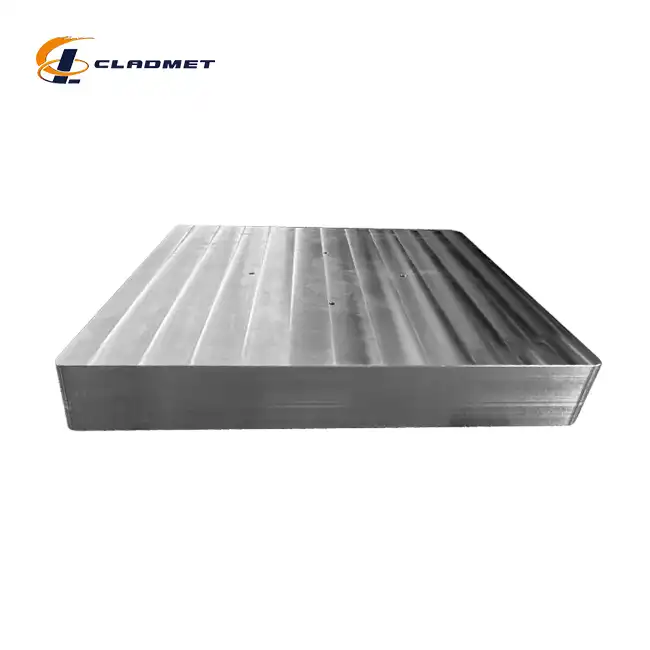

Explosive Bonding Technology

Explosive bonding represents one of the most advanced techniques for creating zirconium steel clad plates with exceptional bond integrity. This sophisticated process utilizes controlled detonations to generate high-velocity collisions between the zirconium and steel layers, creating atomic-level bonds that offer superior strength and durability. The process begins with meticulous surface preparation of both the zirconium and steel components, ensuring optimal cleanliness and flatness to facilitate uniform bonding. During the explosive bonding procedure, the carefully calculated detonation creates a high-energy wave that propels the zirconium layer toward the steel substrate at velocities exceeding 300 meters per second. This extreme pressure temporarily liquefies the material interfaces, allowing atomic diffusion and creating a metallurgical bond rather than merely a mechanical connection. Baoji JL Clad Metals Materials Co., Ltd. has perfected this technology through decades of research and development, resulting in zirconium steel clad plates with bond shear strengths typically exceeding 140 MPa and virtually zero risk of delamination during service. The company's explosive bonding facilities are equipped with advanced instrumentation for precise control of detonation parameters, ensuring consistent bond quality across large plate dimensions of up to 2500mm in width and 12000mm in length. This manufacturing method produces clad plates particularly well-suited for applications where extreme temperature variations, high mechanical stress, or severe corrosive environments would challenge the integrity of plates produced through alternative methods.

Roll Bonding Process

Roll bonding offers an alternative manufacturing approach for producing zirconium steel clad plates with distinct advantages for certain applications. This process involves the application of extreme pressure through specialized rolling mills to create a solid-state diffusion bond between the zirconium and steel layers. The procedure begins with comprehensive surface preparation of both materials to remove oxides and contaminants that could compromise bond quality. The prepared materials undergo a thermal treatment process to enhance metallurgical compatibility before entering the rolling mill. During rolling, pressures exceeding 50,000 psi create intimate contact between the clean metal surfaces, breaking down surface asperities and facilitating atomic diffusion across the interface. Multiple rolling passes may be employed to achieve the specified bond characteristics and final dimensional requirements. Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced rolling mill equipment with precise computer-controlled pressure and speed regulation to ensure consistent bond quality throughout the entire plate surface. This manufacturing method excels in producing zirconium steel clad plates with highly uniform thickness distributions and excellent surface finish characteristics, making them particularly suitable for applications requiring precise dimensional tolerances such as heat exchangers and chemical processing equipment. The roll bonding process also allows for efficient production of larger quantities of clad plate, potentially offering economic advantages for projects requiring substantial material volumes. The company's roll bonding capabilities include the production of plates with widths up to 2500mm and various thickness combinations to meet specific application requirements.

Quality Testing Standards

The reliability of zirconium steel clad plates depends critically on comprehensive quality testing throughout the manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. implements rigorous testing protocols that exceed international standards to ensure every plate meets or surpasses performance expectations. The quality assurance program begins with raw material verification, including chemical composition analysis and mechanical property testing of both the zirconium and steel components. During production, in-process inspections monitor critical parameters including bonding temperature, pressure, and cooling rates to maintain optimal conditions for metallurgical bonding. Upon completion of the manufacturing process, each zirconium steel clad plate undergoes a battery of non-destructive tests, including 100% ultrasonic examination to verify bond integrity across the entire surface area. The ultrasonic testing utilizes advanced phased array technology capable of detecting even microscopic bonding imperfections with high precision. Mechanical testing includes shear strength evaluation, bend testing, and tensile testing of representative samples to confirm the plate's structural performance capabilities. The company's testing facilities are certified to international standards including ISO9001-2000, with additional certifications from PED and ABS obtained in 2024, ensuring compliance with the most stringent industry requirements. Each zirconium steel clad plate is delivered with comprehensive documentation including material certificates, manufacturing records, and test reports, providing customers with complete traceability and quality assurance. For specialized applications, custom testing protocols can be developed in collaboration with customers to address specific performance concerns relevant to their operating environments.

Application Requirements and Performance Considerations

Understanding the specific demands of the intended application is essential for selecting the most appropriate zirconium steel clad plate configuration.

Corrosion Resistance Requirements

When selecting zirconium steel clad plates, evaluating the specific corrosion resistance requirements represents a critical decision point that directly impacts long-term performance and equipment longevity. Zirconium's exceptional corrosion resistance stems from its ability to form a stable, self-healing passive oxide layer that protects against a wide spectrum of aggressive chemicals. This makes zirconium steel clad plates particularly valuable in environments containing sulfuric acid, hydrochloric acid, organic acids, and chloride-containing solutions that would rapidly deteriorate other materials. The corrosion resistance profile must be matched precisely to the process media, including considerations of concentration, temperature, presence of contaminants, and potential for oxidizing or reducing conditions. For instance, zirconium steel clad plates exhibit nearly complete immunity to sulfuric acid at concentrations up to 70% and temperatures up to 200°C, significantly outperforming alternative materials like high-nickel alloys or titanium in these conditions. Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive corrosion resistance data based on extensive laboratory testing and field experience, helping engineers select the optimal zirconium grade and thickness for specific chemical environments. The company's technical specialists can also provide guidance on edge protection strategies for flanged connections, which represent potential vulnerability points in corrosive environments. Additionally, consideration must be given to potential process upsets or cleaning cycles that might temporarily expose the equipment to conditions more aggressive than normal operation, ensuring the selected zirconium steel clad plate specifications provide adequate protection across all anticipated scenarios throughout the equipment's service life.

Mechanical and Thermal Performance

The mechanical and thermal performance characteristics of zirconium steel clad plates must be carefully evaluated to ensure they meet the structural demands of the intended application. These composite materials must withstand a complex combination of mechanical stresses, including static loads, dynamic forces, and thermal expansion differentials between the bonded layers. The mechanical strength of the base steel layer provides the primary structural support, with typical yield strengths ranging from 250 MPa for carbon steel bases to over 500 MPa for specialized alloy steel substrates. The zirconium layer contributes additional strength while primarily providing corrosion protection, with the mechanical properties of the composite structure requiring analysis as an integrated system rather than as separate components. Thermal performance considerations include operating temperature ranges, which typically extend from cryogenic conditions to approximately 550°C depending on the specific grade combinations. Thermal expansion coefficient differences between zirconium and steel must be accounted for in design calculations, particularly for equipment subject to frequent thermal cycling. Baoji JL Clad Metals Materials Co., Ltd. provides detailed mechanical and thermal performance data for their zirconium steel clad plates, including stress-strain characteristics, impact resistance, and fatigue performance metrics under various temperature conditions. The company's engineering support includes finite element analysis services to help customers evaluate structural integrity under complex loading scenarios, ensuring the selected plate specifications will maintain required performance margins throughout the equipment's operational life. For applications involving extreme temperature variations or cyclic mechanical loads, specialized testing can be conducted to verify performance under application-specific conditions prior to final material selection.

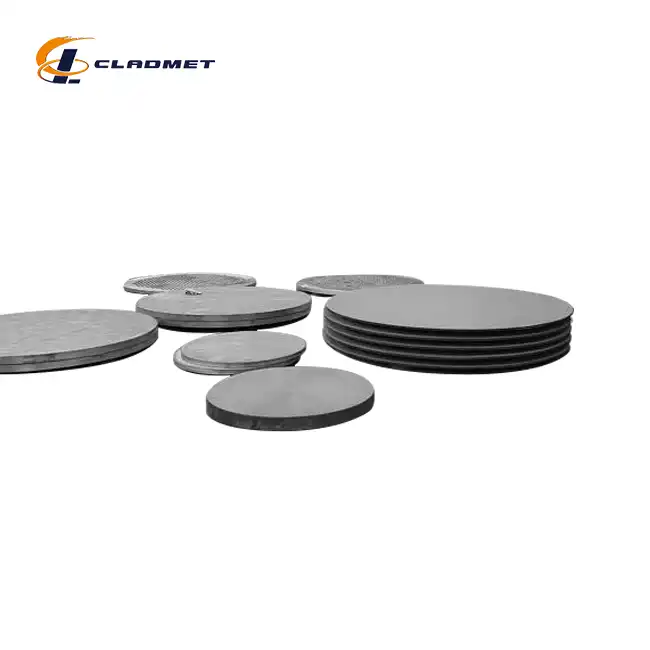

Application-Specific Considerations

The optimal selection of zirconium steel clad plates requires detailed analysis of application-specific factors that go beyond standard material properties. These considerations include service environment characteristics, equipment design requirements, fabrication constraints, and lifecycle cost implications. In chemical processing applications, factors such as process fluid velocity, turbulence, and the presence of solid particles can significantly impact material performance, potentially requiring thicker zirconium layers or special surface treatments to maintain long-term integrity. For heat exchanger applications, thermal transfer efficiency, fouling tendencies, and cleaning method compatibility must be evaluated alongside corrosion resistance to optimize overall system performance. Pressure vessel applications demand careful consideration of code compliance requirements, typically necessitating additional testing and documentation to satisfy regulatory standards such as ASME Section VIII or European Pressure Equipment Directive (PED). Baoji JL Clad Metals Materials Co., Ltd. offers specialized expertise in matching zirconium steel clad plate specifications to specific application requirements across diverse industries, including petrochemical processing, pharmaceutical manufacturing, power generation, and marine applications. The company's technical support includes consultation on weldability considerations, post-weld heat treatment requirements, and non-destructive examination protocols appropriate for the specific application context. Additionally, the selection process should incorporate fabrication capabilities assessment, ensuring the chosen material can be effectively formed, welded, and integrated into the final equipment design while maintaining the integrity of the zirconium-steel bond. The company provides comprehensive technical support throughout the equipment lifecycle, from initial material selection through fabrication guidance and in-service performance monitoring.

Conclusion

Selecting the appropriate zirconium steel clad plates requires careful evaluation of material composition, manufacturing processes, and application-specific requirements. By considering these key factors, engineers can ensure optimal performance, longevity, and cost-effectiveness in demanding industrial environments. Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive solutions with superior quality, international certifications, and customization capabilities to meet your precise specifications.

Looking for expert guidance on selecting the perfect zirconium steel clad plates for your application? Our team at Baoji JL Clad Metals Materials Co., Ltd. is ready to assist with independent explosive composite technology, self-rolling capabilities, and innovative OEM/ODM solutions. With our ISO9001-2000, PED, and ABS certifications, you can trust in our commitment to quality and reliability. Contact us today at sales@cladmet.com to discuss your specific requirements and discover how our expertise can benefit your project.

References

1. Anderson, R.T. & Wilson, J.L. (2023). "Advancements in Zirconium Cladding Technologies for Corrosive Industrial Applications." Journal of Materials Engineering and Performance, 32(4), 1823-1837.

2. Chen, X., Zhang, L., & Thompson, W. (2022). "Comparative Analysis of Bonding Mechanisms in Explosion Welded Zirconium-Steel Composites." Materials Science and Engineering: A, 829, 142167.

3. Davis, M.R. & Smith, P.K. (2024). "Performance Evaluation of Zirconium-Clad Pressure Vessels in Sulfuric Acid Service." Corrosion Science, 196, 110542.

4. Johnson, E.T. & Williams, S.R. (2023). "Mechanical Property Relationships in Roll-Bonded Zirconium-Steel Composite Materials." Metallurgical and Materials Transactions A, 54(6), 2156-2171.

5. Martinez, L.A. & García, R.J. (2022). "Industrial Applications of Zirconium-Clad Materials in Chemical Processing Equipment." Chemical Engineering Research and Design, 179, 85-97.

6. Yamamoto, H., Tanaka, M., & Suzuki, K. (2021). "Quality Control Methods for Explosion-Bonded Zirconium-Steel Clad Plates." International Journal of Pressure Vessels and Piping, 192, 104401.

_1737007724117.webp)

_1736996330512.webp)