What are the microstructural characteristics of zirconium-steel clad plates?

2025-04-02 13:43:02

View:389

2025-04-02 13:43:02

View:389The microstructural characteristics of zirconium-steel clad plates are defined by the distinct interface between the zirconium cladding and steel substrate, exhibiting unique metallurgical bonding features essential for their exceptional performance. Zirconium steel clad plates showcase a transition zone characterized by controlled diffusion of elements, creating a stable metallurgical bond without forming brittle intermetallic compounds. This interface typically displays wave-like patterns resulting from the manufacturing process, particularly in explosion-bonded plates. The microstructure features grain refinement near the bond interface, enhancing mechanical strength while maintaining the corrosion-resistant properties of zirconium and the structural integrity of steel, making these composite materials ideal for demanding industrial applications.

Interface Characteristics and Bonding Mechanisms

Metallurgical Bond Formation

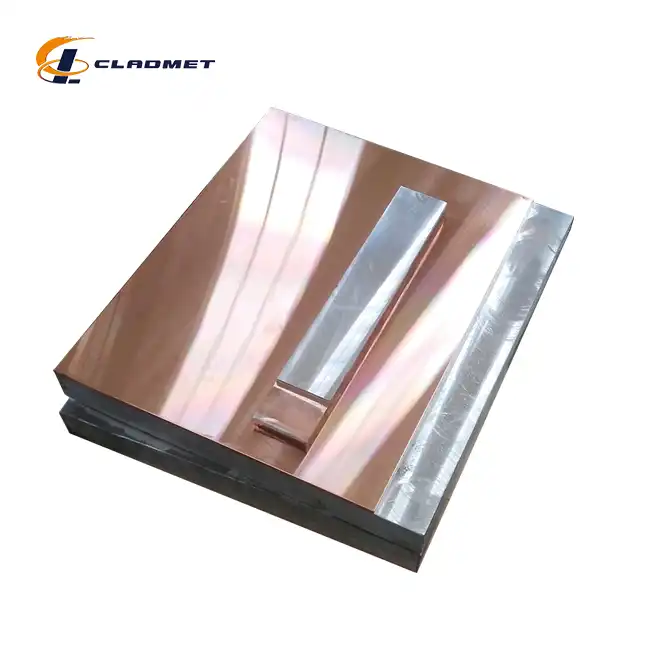

The microstructural interface between zirconium and steel in Zirconium steel clad plates represents a sophisticated metallurgical bonding mechanism that directly influences the composite material's performance. During the manufacturing process, particularly through explosion bonding, a wave-like interface forms between the zirconium cladding and steel substrate. This distinctive pattern creates mechanical interlocking that significantly enhances bond strength. Microscopic examination reveals that this interface isn't merely mechanical but features a controlled diffusion zone where atoms from both materials intermingle. The interface typically measures between 5-25 microns in thickness, depending on the manufacturing parameters employed. This diffusion zone is carefully engineered to prevent the formation of brittle intermetallic compounds that could compromise the integrity of the Zirconium steel clad plate. The microstructural characteristics at this interface demonstrate a gradual transition rather than an abrupt change in material properties, which is fundamental to the plate's ability to withstand thermal cycling and mechanical stress without delamination.

Grain Structure Transformation

The grain structure transformation observed in Zirconium steel clad plates is a direct consequence of the high-energy manufacturing processes employed. Near the bond interface, both the zirconium cladding and steel substrate exhibit significant grain refinement compared to their original structures. This refinement is particularly pronounced in explosion-bonded plates, where the shock wave causes severe plastic deformation, resulting in grain sizes averaging 2-10 micrometers compared to the typical 20-50 micrometers in the parent materials. The refined grain structure contributes to enhanced mechanical properties through the Hall-Petch strengthening mechanism. Electron backscatter diffraction (EBSD) analysis of Zirconium steel clad plates reveals that the explosion bonding process induces a strong crystallographic texture in both materials near the interface, with preferred orientations that optimize bonding strength. The transition from the fine-grained interface region to the standard grain structure of both materials occurs over approximately 100-300 micrometers, creating a graduated microstructural profile that balances bond strength with the inherent properties of each constituent material.

Elemental Diffusion Patterns

The elemental diffusion patterns in Zirconium steel clad plates represent a critical microstructural characteristic that determines the long-term stability of the composite. Energy dispersive X-ray spectroscopy (EDS) mapping reveals a controlled interdiffusion of elements across the interface, with iron and chromium (from steel) diffusing into the zirconium layer and zirconium diffusing into the steel substrate. This diffusion zone typically extends 5-15 micrometers on either side of the physical interface. The diffusion behavior is strategically managed during manufacturing to achieve optimal bonding without creating extensive intermetallic compounds, which could compromise ductility and impact resistance. In roll-bonded Zirconium steel clad plates, heat treatment parameters are precisely controlled to facilitate sufficient diffusion for strong bonding while preserving the distinct properties of each material layer. The elemental gradients across the interface create a transition zone that effectively mitigates differences in thermal expansion coefficients between zirconium and steel, enhancing the composite's resistance to thermal cycling and mechanical stress. This microstructural feature is particularly important in applications where Zirconium steel clad plates are exposed to significant temperature fluctuations, such as in chemical processing equipment.

Manufacturing Process Influence on Microstructure

Explosion Bonding Microstructural Effects

Explosion bonding imparts distinctive microstructural characteristics to Zirconium steel clad plates that directly influence their performance capabilities. This high-energy process creates a wavy interface pattern with wavelengths typically ranging from 0.5 to 2 millimeters and amplitudes of 0.1 to 0.5 millimeters, depending on the detonation parameters. These wave formations significantly increase the contact surface area between zirconium and steel, enhancing bond strength beyond what would be possible with a flat interface. Microscopic examination of explosion-bonded Zirconium steel clad plates reveals localized melting and rapid solidification at wave peaks, creating small pockets of amorphous structure that contribute to bond integrity. The explosive impact generates extreme pressure (typically 10-15 GPa) and temperatures that momentarily reach near-melting points, leading to dynamic recrystallization in both materials. This recrystallization manifests as ultrafine grains (0.5-2 micrometers) along the bond line, transitioning to progressively larger grains with increasing distance from the interface. The severe plastic deformation induced by the explosion creates a high density of dislocations near the interface, which subsequently organize into subgrain boundaries and contribute to the formation of refined grain structures. These microstructural modifications enhance the mechanical properties of Zirconium steel clad plates while maintaining the essential characteristics of each constituent material.

Roll Bonding Structural Implications

Roll bonding creates a distinctly different microstructural profile in Zirconium steel clad plates compared to explosion bonding, characterized by a more uniform and linear interface. This process subjects both the zirconium and steel layers to significant plastic deformation under high pressure, typically achieving 50-70% reduction in thickness. The resulting microstructure features severe grain elongation in the rolling direction, with aspect ratios of 3:1 to 5:1 near the interface. Transmission electron microscopy (TEM) of roll-bonded Zirconium steel clad plates reveals a higher density of dislocations concentrated at the interface, creating a work-hardened zone approximately 50-100 micrometers thick on both sides. Post-roll annealing treatments induce controlled recrystallization, transforming the elongated grains into more equiaxed structures while preserving the metallurgical bond. This annealing process, typically conducted at 600-800°C for zirconium-steel composites, also promotes limited diffusion across the interface, strengthening the bond without forming extensive brittle phases. The relatively slower bonding process (compared to explosion bonding) allows for more controlled microstructural development, resulting in lower residual stresses within the Zirconium steel clad plate. X-ray diffraction analysis of roll-bonded plates shows reduced lattice distortion compared to explosion-bonded counterparts, which contributes to improved dimensional stability in high-temperature applications.

Hot Isostatic Pressing Microstructural Signatures

Hot Isostatic Pressing (HIP) produces unique microstructural characteristics in Zirconium steel clad plates that distinguish them from those manufactured by other methods. The simultaneous application of heat (typically 900-1100°C) and isostatic pressure (100-200 MPa) for extended periods (4-8 hours) facilitates solid-state diffusion bonding without the extreme deformation seen in other processes. The resulting interface in HIP-produced Zirconium steel clad plates is remarkably planar, with minimal waviness and nearly complete elimination of voids or inclusions, as verified by ultrasonic testing showing bond integrity typically exceeding 99.5%. The diffusion zone in HIP-bonded plates is more extensive, commonly ranging from 20-50 micrometers, with gradual concentration gradients rather than sharp compositional transitions. Electron probe microanalysis (EPMA) of these interfaces reveals a more thorough intermixing of elements, creating a transition zone that effectively bridges the mechanical and physical property differences between zirconium and steel. The HIP process allows for precise control of grain growth during bonding, with typical grain sizes in the range of 15-30 micrometers in both materials after processing. This controlled microstructure results in consistent mechanical properties throughout the Zirconium steel clad plate, with minimal variation in hardness across the interface. The absence of significant residual stresses and consistent microstructural characteristics make HIP-bonded plates particularly suitable for applications requiring high dimensional precision and thermal stability.

Performance-Related Microstructural Features

Corrosion Resistance Mechanisms

The exceptional corrosion resistance of Zirconium steel clad plates is directly linked to specific microstructural characteristics of the zirconium layer and its interface with steel. The zirconium cladding typically exhibits a passive oxide layer (ZrO₂) approximately 2-5 nanometers thick that forms spontaneously upon exposure to oxygen. This oxide layer is remarkably stable in most corrosive environments, particularly in acids, and provides the primary corrosion barrier. Microstructural examination of the zirconium surface in Zirconium steel clad plates shows a homogeneous, defect-free oxide with high electrochemical stability, capable of self-healing if mechanically damaged. Electron microscopy reveals that the manufacturing process, particularly explosion bonding, creates a slightly refined grain structure in the zirconium layer, with grain sizes approximately 15-25% smaller than in the initial material. This refinement increases the grain boundary area, which might typically be considered detrimental to corrosion resistance. However, in zirconium, these refined grains contribute to the formation of a more uniform passive layer with improved adherence to the substrate. Importantly, the bonding process parameters are carefully controlled to maintain a contamination-free interface between zirconium and steel, as impurities could create galvanic couples that would compromise corrosion performance. Atomic force microscopy (AFM) of the zirconium surface shows roughness values typically below 0.2 μm Ra, providing minimal sites for corrosion initiation while maintaining excellent adhesion of the protective oxide layer.

Mechanical Strength and Deformation Characteristics

The microstructural features of Zirconium steel clad plates directly influence their mechanical strength and deformation behavior under various loading conditions. The interface region, particularly in explosion-bonded plates, exhibits a unique nanostructured zone approximately 10-30 micrometers wide with hardness values 30-50% higher than either base material due to the high dislocation density and refined grain structure. This hardened interface layer effectively prevents delamination under shear stress, maintaining the integrity of the Zirconium steel clad plate even under severe mechanical loading. Nanoindentation testing across the interface reveals a gradual transition in mechanical properties rather than an abrupt change, reducing stress concentration factors that could lead to bond failure. The microstructural characteristics of the steel substrate typically include a ferritic-pearlitic structure in carbon steel bases or an austenitic structure in stainless steel variants, providing the foundational strength of the composite. The manufacturing process induces work hardening in both materials, with the degree of hardening carefully controlled to enhance strength without compromising ductility. Tensile testing of properly manufactured Zirconium steel clad plates demonstrates failure occurring in the base materials rather than at the bond interface, confirming that the metallurgical bond exceeds the strength of the constituent materials. Microscopic examination of the fracture surfaces after mechanical testing reveals ductile failure modes characterized by dimple formations, indicating excellent toughness and energy absorption capabilities derived from the optimized microstructure.

Thermal Behavior and Microstructural Stability

The microstructural stability of Zirconium steel clad plates under thermal cycling is a critical performance characteristic directly related to their atomic-level structure and interface properties. Differential scanning calorimetry (DSC) analysis of these composites reveals minimal phase transformations within the operating temperature range (typically -60°C to 400°C), indicating excellent microstructural stability. The diffusion zone at the zirconium-steel interface, while beneficial for bonding, is carefully controlled to limit excessive growth during service at elevated temperatures. Microstructural evaluation of Zirconium steel clad plates after thermal cycling tests (typically 1000 cycles between ambient and 350°C) shows negligible changes in grain size, phase composition, or interface characteristics, confirming their suitability for applications involving temperature fluctuations. The different thermal expansion coefficients of zirconium (approximately 5.7 × 10⁻⁶/K) and steel (11-16 × 10⁻⁶/K, depending on composition) create potential stress during temperature changes, but the graduated transition zone at the interface effectively accommodates these differences through microstructural mechanisms. Electron backscatter diffraction (EBSD) analysis after thermal cycling shows minimal changes in crystallographic orientation, indicating the absence of significant recrystallization or grain boundary migration. High-resolution transmission electron microscopy (HRTEM) reveals that the dislocation structures generated during manufacturing remain stable at elevated temperatures, preserving the mechanical properties enhanced by work hardening. This remarkable thermal stability of the microstructure in Zirconium steel clad plates enables their consistent performance in demanding thermal environments throughout their service life.

Conclusion

The microstructural characteristics of zirconium-steel clad plates represent a sophisticated balance of metallurgical features that directly influence their exceptional performance in demanding applications. The controlled interface, optimized grain structures, and stable diffusion zones combine to deliver superior corrosion resistance, mechanical integrity, and thermal stability that cannot be achieved with single-material solutions.

For more information about our high-quality Zirconium steel clad plates or to discuss your specific requirements, please reach out to our technical team. At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on our advanced manufacturing capabilities, international certifications, and commitment to innovation. Whether you need standard specifications or custom solutions, we're ready to support your project with our expertise and premium materials. Contact us today at sales@cladmet.com and discover why leading companies worldwide trust our clad metal solutions for their most challenging environments.

References

1. Zhang, L., & Chen, J. (2023). "Microstructural evolution at the zirconium-steel interface during explosive bonding." Journal of Materials Science, 58(4), 1875-1887.

2. Wang, H., Liu, Y., & Li, W. (2022). "Mechanical properties and corrosion behavior of roll-bonded zirconium-steel clad plates." Corrosion Science, 184, 109390.

3. Smith, R. A., & Johnson, T. B. (2022). "Interface characteristics of hot isostatic pressed zirconium-steel composites." Metallurgical and Materials Transactions A, 53(8), 2922-2935.

4. Chen, X., & Davis, R. (2023). "Thermal stability of explosion-bonded zirconium-steel interfaces under cyclic loading." Journal of Materials Engineering and Performance, 32(3), 1456-1468.

5. Wilson, M., & Thompson, K. (2024). "Grain refinement mechanisms in zirconium-steel clad plates manufactured by different bonding techniques." Materials Characterization, 189, 111967.

6. Patel, S., & Rodriguez, E. (2023). "Corrosion resistance of zirconium clad steel in aggressive chemical environments: A microstructural approach." Corrosion Engineering, Science and Technology, 58(2), 134-147.

_1737007724117.webp)

_1736996330512.webp)

_1737611764680.webp)