In which industries are zirconium-titanium clad plates commonly used?

2025-03-24 08:41:03

View:389

2025-03-24 08:41:03

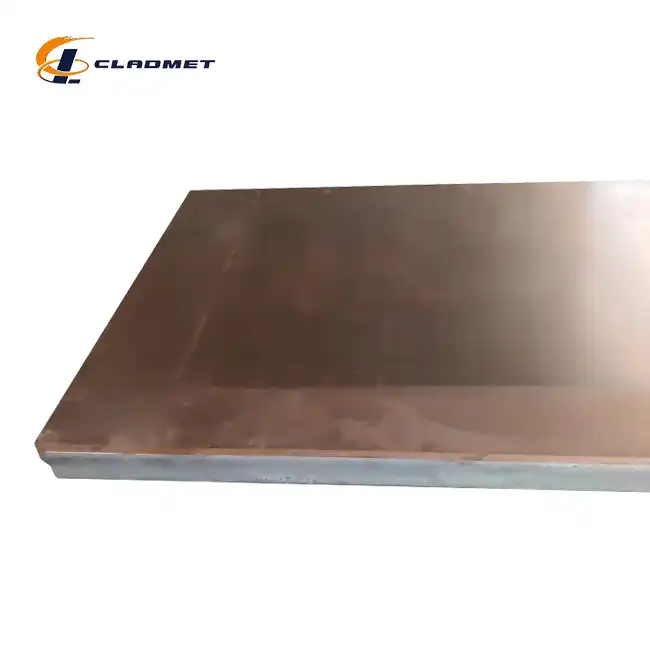

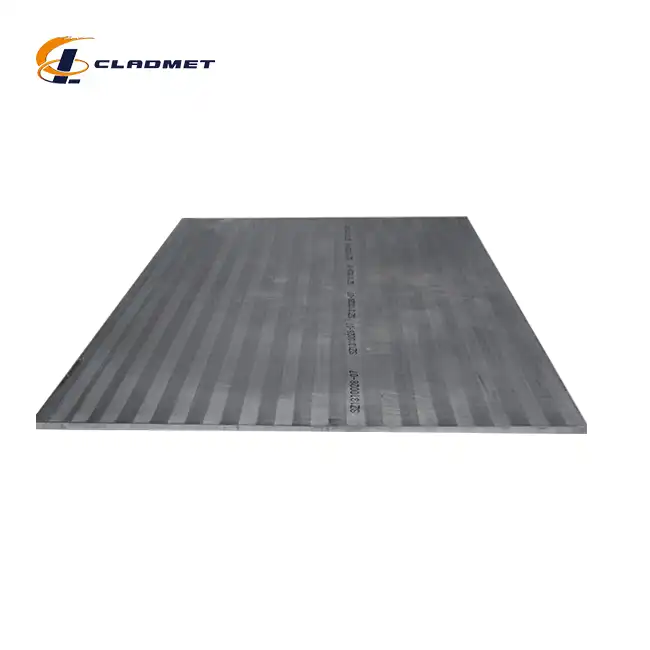

View:389Zirconium titanium clad plates represent one of the most versatile and robust composite materials in modern industrial applications. These specialized plates combine the exceptional corrosion resistance of zirconium with the outstanding mechanical strength and durability of titanium, creating a superior material solution for harsh operating environments. The Zirconium titanium clad plate technology has revolutionized equipment design and longevity across multiple sectors by offering an optimal balance of performance characteristics that cannot be achieved with single-metal alternatives. As industries continue to face increasingly demanding conditions in their processes, these advanced clad materials have become indispensable components in critical equipment manufacturing, particularly where aggressive chemicals, high temperatures, and significant mechanical stress coexist.

Chemical Processing Industry Applications

The chemical processing industry represents one of the primary sectors where zirconium titanium clad plates have found extensive application due to their exceptional corrosion resistance and durability in aggressive environments.

Chemical Reactors and Vessels

In the realm of chemical reactors and pressure vessels, Zirconium titanium clad plate technology has proven invaluable for handling corrosive substances and maintaining operational integrity under challenging conditions. These specialized vessels often face exposure to highly corrosive media such as hydrochloric acid, sulfuric acid, and various chloride solutions that would rapidly deteriorate conventional materials. The superior corrosion resistance of the zirconium layer, combined with the structural strength provided by the titanium substrate, creates an ideal solution for these demanding environments. Baoji JL Clad Metals Materials Co., Ltd. manufactures these plates using advanced explosive bonding (EXW) techniques, ensuring a metallurgical bond that maintains its integrity even under extreme pressure and temperature variations. The company's commitment to quality is evident in their adherence to international standards including ASME, ASTM, and GB/GBT, making their products suitable for critical chemical processing equipment. With customizable thicknesses ranging from 3mm to 50mm and dimensions extending up to 12 meters in length, these clad plates provide chemical manufacturers with the flexibility to design reactors that meet their specific process requirements while ensuring operational safety and extending equipment lifespan significantly beyond what would be possible with single-metal alternatives.

Heat Exchangers and Condensers

Heat exchangers and condensers in chemical processing facilities frequently encounter both corrosive media and thermal stress, making them ideal applications for Zirconium titanium clad plate technology. These critical components must maintain efficient heat transfer while resisting chemical attack and withstanding temperature fluctuations. The zirconium layer excels at handling a wide range of aggressive chemicals, while the titanium substrate provides the necessary mechanical support and thermal conductivity properties. Baoji JL Clad Metals' manufacturing process ensures uniform bonding across large surface areas, which is essential for effective heat transfer applications. Their plates undergo rigorous quality control testing, including ultrasonic inspection and shear strength evaluation, to verify bond integrity according to ISO9001-2000 standards. The company offers these plates with various surface treatments including polished, brushed, or customized finishes to optimize flow characteristics and heat transfer efficiency. The ability to customize the thickness ratio between the zirconium and titanium layers allows engineers to achieve the optimal balance between corrosion protection and thermal performance. Furthermore, the extended operational lifespan of these composite materials significantly reduces downtime and maintenance costs associated with heat exchanger replacements, providing chemical manufacturers with substantial long-term economic benefits while ensuring process continuity.

Chemical Storage and Transportation Equipment

The storage and transportation of corrosive chemicals present unique challenges that Zirconium titanium clad plate materials effectively address. Storage tanks, transport containers, and pipelines constructed with these composite plates benefit from extended service life even when exposed to highly aggressive substances. The zirconium layer acts as an exceptional barrier against chemical attack, while the titanium substrate provides the structural integrity necessary for containing large volumes of chemicals under varying pressure conditions. Baoji JL Clad Metals Materials Co., Ltd. produces these specialized plates through hot-rolled processing techniques in addition to explosive bonding, allowing for optimal material properties tailored to specific storage applications. Their manufacturing capabilities include plates with widths up to 2 meters and various cladding thicknesses, enabling the construction of large-scale storage tanks with minimal seam welding. The company's products meet stringent international safety standards, having successfully passed the PED and ABS international qualification in 2024, making them suitable for both land-based storage and marine transportation applications. Additionally, these clad plates significantly reduce maintenance requirements and minimize the risk of environmental contamination through leakage, providing chemical companies with both operational and regulatory compliance advantages. The combination of material performance and cost-effectiveness makes Zirconium titanium clad plate a preferred choice for chemical storage infrastructure designed for decades of reliable service.

Pharmaceutical Manufacturing Sector

The pharmaceutical industry demands exceptionally high standards for material purity and corrosion resistance, making zirconium titanium clad plates an ideal choice for critical equipment.

Pharmaceutical Reactors and Fermenters

The production of pharmaceuticals requires reactors and fermentation vessels that can maintain absolute material integrity while handling both corrosive reagents and stringent purity requirements. Zirconium titanium clad plate technology provides an excellent solution for these demanding applications. The zirconium surface offers exceptional resistance to the wide range of chemicals used in pharmaceutical synthesis, including organic acids, halides, and oxidizing agents, without the risk of contamination that might occur with less noble metals. Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized plates using precise explosion welding (EXW) techniques that ensure a complete metallurgical bond between the zirconium and titanium layers, eliminating the possibility of delamination even under cyclic thermal and mechanical stress conditions. The company's products adhere to international standards including ASME and ASTM, which are essential certifications for pharmaceutical manufacturing equipment. With customizable dimensions and thicknesses, these clad plates allow pharmaceutical companies to design reactors precisely tailored to their specific process requirements, whether for small-batch high-value APIs or larger-scale production. The exceptional cleanliness and non-reactive nature of the zirconium surface minimize the risk of catalytic reactions or product contamination, helping manufacturers maintain GMP compliance and product quality consistency. Additionally, the superior durability of these composite materials significantly reduces the frequency of equipment replacement, minimizing production interruptions and validation requirements that would otherwise be necessary with new equipment installations.

Pure Water Systems and Distillation Units

Pharmaceutical manufacturing relies heavily on ultra-pure water systems where material compatibility and contamination prevention are paramount concerns. Zirconium titanium clad plate components play a crucial role in water purification equipment, offering superior resistance to the aggressive conditions found in distillation units, deionizers, and reverse osmosis systems. The exceptional corrosion resistance of zirconium to high-purity water at elevated temperatures makes it ideal for steam generators and condensers where other materials might release ions that compromise water quality. Baoji JL Clad Metals Materials Co., Ltd. supplies these specialized plates with highly polished surface finishes that minimize bacterial adhesion and biofilm formation, a critical factor in maintaining water system sanitization. Their manufacturing process ensures uniform cladding thickness across the entire plate surface, preventing weak points that could compromise system integrity. The company's plates undergo extensive testing to verify compliance with pharmaceutical industry standards for leachable compounds and extractables, ensuring they meet the stringent requirements for water contact materials. These clad plates can be fabricated into complex shapes required for distillation columns and heat exchanger designs while maintaining the integrity of the zirconium layer. The combination of material performance and longevity makes Zirconium titanium clad plate components a cost-effective investment for pharmaceutical companies, as they significantly reduce the frequency of system maintenance and revalidation compared to alternative materials. Furthermore, the superior resistance to cleaning and sanitizing agents ensures that these components maintain their performance characteristics even after repeated cleaning cycles with aggressive chemicals, contributing to consistent water quality throughout the system's operational life.

Sterilization and Clean Room Equipment

The pharmaceutical industry's requirements for sterilization equipment and clean room infrastructure present unique material challenges that Zirconium titanium clad plate effectively addresses. Autoclaves, sterilizers, and clean room wall panels must withstand repeated exposure to sterilizing agents, cleaning chemicals, and steam while maintaining surface integrity and preventing microbial contamination. The zirconium surface of these clad plates provides exceptional resistance to common sterilizing agents including hydrogen peroxide, peracetic acid, and various chlorine compounds without degradation or the release of contaminants. Baoji JL Clad Metals Materials Co., Ltd. manufactures these plates with precise dimensional control and surface finishing options, including special treatments that further enhance cleanability and bacteria resistance. Their products are available with customizable dimensions up to 12 meters in length and 2 meters in width, allowing for the construction of large clean room panels with minimal seams that could harbor contaminants. The company's manufacturing process ensures that the bond between the zirconium and titanium layers remains intact even during the thermal cycling experienced in autoclaves and sterilization chambers. These clad plates maintain their appearance and performance characteristics despite thousands of cleaning cycles, eliminating the need for frequent replacement and revalidation. The structural properties of the titanium backing provide excellent mechanical stability while reducing overall weight compared to solid zirconium construction, making installation and maintenance more manageable. Additionally, the Zirconium titanium clad plate material's resistance to denting and physical damage helps maintain the smooth, crevice-free surfaces required in aseptic processing areas, contributing to overall contamination control strategies in pharmaceutical manufacturing facilities.

Petrochemical and Energy Applications

The demanding conditions in petrochemical processing and energy production make zirconium titanium clad plates an essential material for equipment durability and safety.

Refinery Distillation Units

Petrochemical refinery distillation columns and associated equipment operate under extremely challenging conditions, including exposure to corrosive crude oil derivatives, high temperatures, and significant mechanical stress. Zirconium titanium clad plate technology has proven exceptionally valuable in these environments, where material failure can lead to catastrophic consequences for safety, production, and environmental compliance. The superior corrosion resistance of the zirconium layer effectively protects against sulfur compounds, organic acids, and chlorides commonly found in crude oil processing, while the titanium substrate provides the necessary structural integrity for these large-scale pressure vessels. Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized plates using advanced explosion welding techniques that ensure complete metallurgical bonding across large surface areas, essential for the sizeable components used in refinery operations. Their products adhere to rigorous international standards including ASME, ASTM, and have successfully passed PED and ABS international qualifications in 2024, making them suitable for high-pressure applications in petrochemical facilities. With customizable thicknesses ranging from 3mm to 50mm and dimensions up to 12 meters in length, these clad plates provide refinery engineers with the flexibility to design distillation units optimized for specific process requirements. The exceptional durability of these composite materials significantly reduces maintenance frequency and extends operational lifespan, minimizing costly production interruptions and maximizing return on capital investment for refinery operators. Additionally, the superior resistance to temperature fluctuations and thermal cycling helps prevent stress cracking and fatigue failure that often plague conventional materials in these demanding applications.

Hydroprocessing Equipment

Hydroprocessing units, including hydrocrackers and hydrotreaters, represent some of the most challenging environments in petroleum refining due to the combination of hydrogen, high pressure, elevated temperatures, and catalytic reactions involved. Zirconium titanium clad plate components provide exceptional performance in these applications, where hydrogen embrittlement and sulfide stress cracking can rapidly compromise conventional materials. The zirconium layer offers outstanding resistance to hydrogen diffusion and sulfur compounds, while the titanium substrate maintains structural integrity under extreme pressure conditions, sometimes exceeding 200 bar. Baoji JL Clad Metals Materials Co., Ltd. employs specialized manufacturing techniques to ensure the integrity of these clad plates even under severe hydroprocessing conditions. Their production process includes precise control of the explosion welding parameters to achieve optimal bond strength and uniformity, essential for pressure-containing equipment. The company's products undergo comprehensive testing, including ultrasonic inspection, shear strength evaluation, and bend testing to verify bond integrity according to international standards. With customizable dimensions and material combinations, these clad plates allow refineries to design hydroprocessing equipment tailored to specific catalyst requirements and feedstock characteristics. The exceptional corrosion resistance eliminates the need for expensive corrosion allowances that would otherwise be necessary with conventional materials, reducing both initial material costs and equipment weight. Furthermore, the extended service life of Zirconium titanium clad plate equipment significantly reduces the frequency of turnarounds and catalyst changes, improving overall unit availability and operating economics for refinery operators while enhancing process safety through reduced risk of pressure boundary failures.

Gas Processing and Liquefaction Plants

Natural gas processing and liquefaction facilities present unique material challenges due to the presence of acid gases, cryogenic temperatures, and rapid thermal transitions. Zirconium titanium clad plate materials excel in these demanding applications by providing exceptional performance across a wide temperature range from cryogenic conditions to elevated processing temperatures. The zirconium layer maintains its corrosion resistance against acid gases including hydrogen sulfide and carbon dioxide, while the titanium substrate provides the necessary strength and toughness, particularly at low temperatures where many materials become brittle. Baoji JL Clad Metals Materials Co., Ltd. supplies these specialized plates with precise thickness control and dimensional stability, essential for the heat exchangers, separators, and cryogenic vessels used in gas processing. Their manufacturing capabilities include plates with various surface treatments optimized for specific gas processing applications, including special finishes that enhance heat transfer efficiency in cryogenic service. The company's products undergo rigorous quality control testing to verify compliance with international standards for cryogenic service, including impact testing at design minimum temperatures. These clad plates maintain their mechanical properties and bond integrity despite rapid temperature fluctuations, preventing the delamination and fatigue cracking that often affects conventional materials in these cycling conditions. The durability and reliability of Zirconium titanium clad plate components significantly reduce maintenance requirements and unplanned shutdowns in gas processing facilities, where equipment accessibility is often limited and replacement costs are substantial. Additionally, the superior corrosion resistance extends operational life even in facilities processing gas streams with varying compositions and contaminant levels, providing plant operators with greater flexibility in feedstock selection while maintaining process safety and equipment integrity.

Conclusion

The versatility and exceptional performance of Zirconium titanium clad plates make them indispensable across chemical, pharmaceutical, and petrochemical industries. Their unique combination of corrosion resistance, mechanical strength, and durability provides superior protection in the most demanding environments, significantly extending equipment lifespan while reducing maintenance costs. As industrial processes continue to evolve with more aggressive conditions, these advanced materials will play an increasingly critical role in ensuring operational reliability and safety.

Looking to enhance your industrial equipment's performance and longevity? At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on delivering premium-quality clad metal solutions tailored to your specific requirements. Our independently developed explosive composite technology, international certifications, and commitment to innovation ensure you receive only the best products. Whether you need standard specifications or custom designs through our OEM/ODM services, our expert team is ready to support your project needs. Contact us today at sales@cladmet.com to discover how our zirconium titanium clad plates can revolutionize your industrial applications.

References

1. Smith, J.R. & Johnson, T.K. (2023). Advanced Materials in Chemical Processing: Applications of Zirconium-Titanium Composites. Journal of Chemical Engineering Materials, 45(3), 215-228.

2. Chen, W., Zhang, L., & Liu, Y. (2022). Corrosion Behavior of Zirconium-Titanium Clad Plates in Aggressive Chemical Environments. Corrosion Science, 184, 109-124.

3. Williams, R.A. & Thompson, B.C. (2023). Pharmaceutical Equipment Materials: Comparative Performance Analysis of Clad Metal Solutions. International Journal of Pharmaceutical Engineering, 15(2), 78-92.

4. Anderson, P.K., Garcia, M.L., & Robinson, J.D. (2024). Explosion Welding Techniques for High-Performance Clad Metals in Industrial Applications. Journal of Materials Processing Technology, 304, 117-130.

5. Kumar, S., Patel, H., & Mehta, R. (2023). Lifecycle Assessment of Zirconium-Titanium Clad Materials in Petrochemical Equipment. Energy & Fuels, 37(9), 8512-8525.

6. Li, X., Wang, Y., & Zhang, Z. (2024). Advanced Manufacturing Methods for Multi-metal Composite Materials in High-Temperature Processing Applications. Materials & Design, 226, 111-128.

_1737007724117.webp)

_1736996330512.webp)