How Durable Are Titanium Clad Steel Plates?

2025-03-22 11:04:38

View:389

2025-03-22 11:04:38

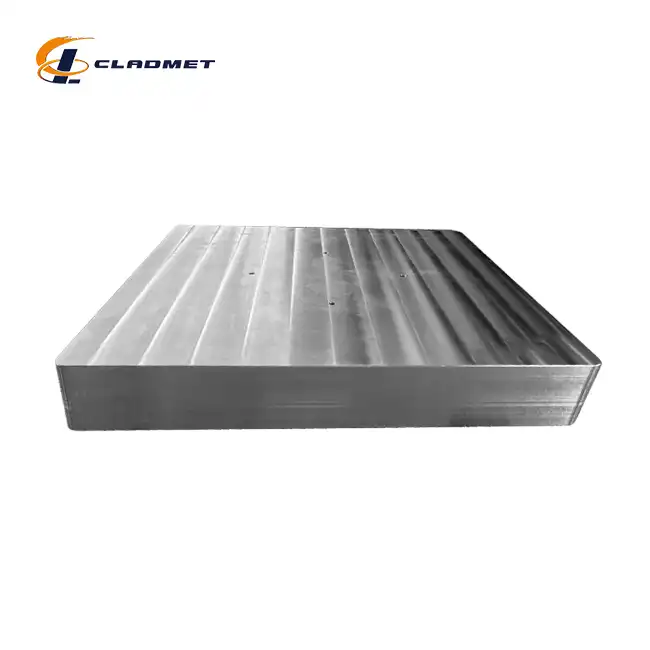

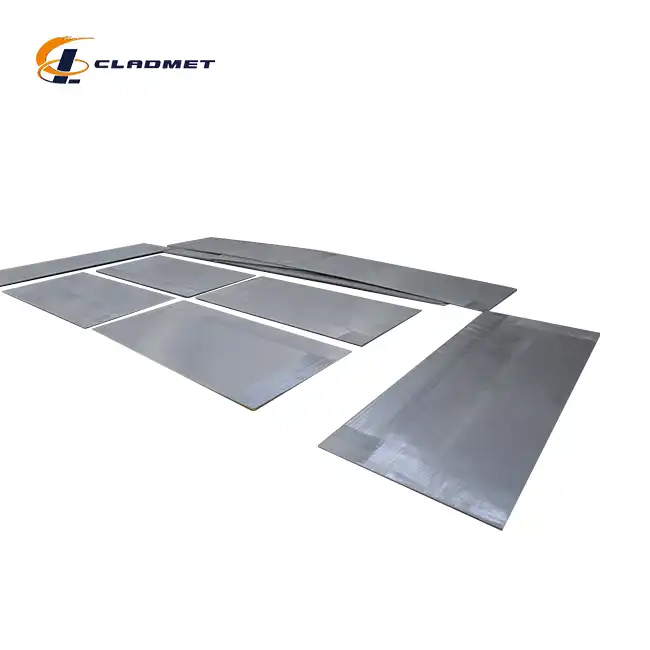

View:389Titanium Clad Steel Plates represent one of the most significant advancements in metallurgical engineering, offering exceptional durability that transcends conventional metal materials. These composite plates combine the corrosion resistance of titanium with the structural strength and cost-effectiveness of steel, creating a material that excels in demanding environments. The durability of Titanium Clad Steel Plates is measured not just in years but often in decades, with service lives extending 3-5 times longer than traditional materials in corrosive environments. This remarkable longevity stems from titanium's natural oxide layer that continuously regenerates when damaged, providing persistent protection against chemical attack, while the steel substrate maintains structural integrity under mechanical stress.

The Science Behind Titanium Clad Steel Plate Durability

Metallurgical Bond Formation and Strength

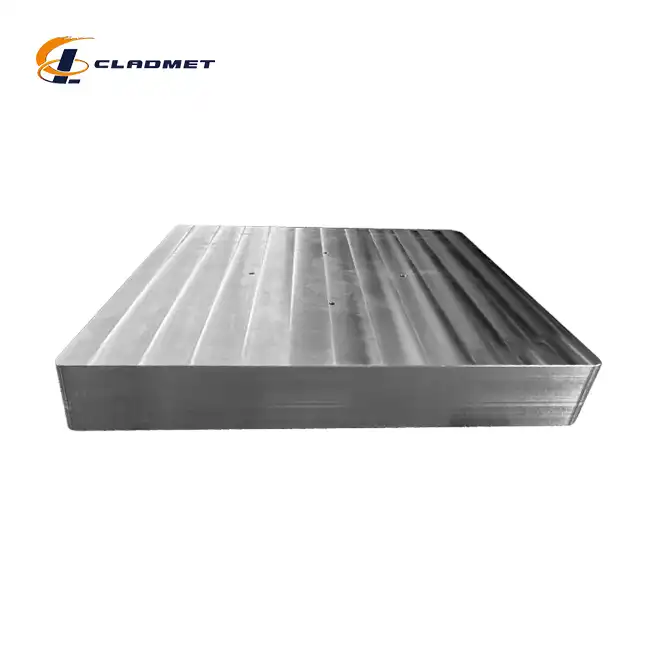

The exceptional durability of Titanium Clad Steel Plates begins with the metallurgical bond between the titanium and steel layers. During the manufacturing process, particularly through explosive bonding technology, a wave-like interface forms between the materials that creates an extremely strong mechanical interlock. This isn't merely an adhesive connection but rather an atomic-level bond where the crystalline structures intertwine. The resulting bond strength typically exceeds 140 MPa in shear testing, which is significantly higher than what most industrial applications require. This superior bond integrity ensures that Titanium Clad Steel Plates maintain their composite structure even under extreme thermal cycling conditions where differential expansion might otherwise cause delamination. Baoji JL Clad Metals Materials Co. employs advanced non-destructive testing methods including ultrasonic scanning and X-ray inspections to verify bond quality across the entire surface area of each Titanium Clad Steel Plate, ensuring 100% metallurgical integrity before the product leaves the facility.

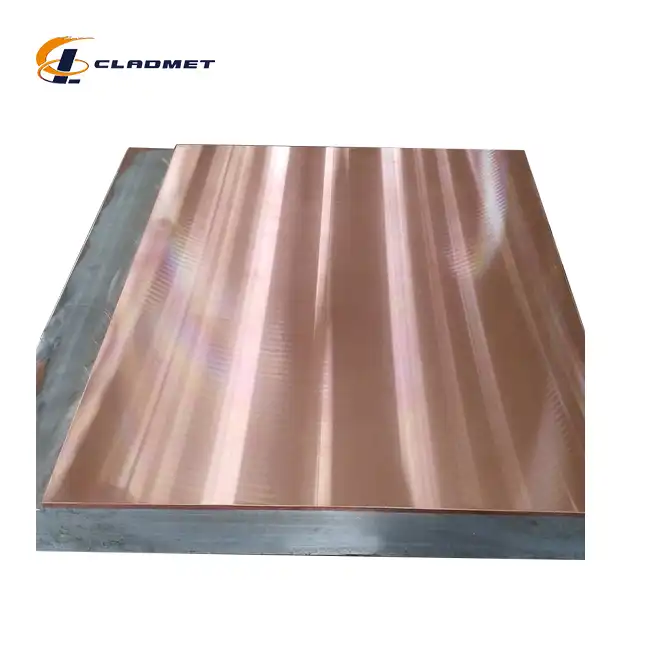

Corrosion Resistance Mechanisms

The cornerstone of Titanium Clad Steel Plates' durability lies in titanium's exceptional electrochemical properties. When exposed to oxygen, titanium forms a passive titanium dioxide (TiO₂) layer just a few nanometers thick that acts as an impenetrable barrier against most corrosive substances. This self-healing oxide film reforms immediately if scratched or damaged, providing continuous protection throughout the material's service life. In chloride environments like seawater, where many metals rapidly deteriorate, Titanium Clad Steel Plates show negligible corrosion rates of less than 0.0025 mm per year. The titanium layer, typically ranging from 1.5mm to 5mm in JL's products, effectively shields the steel substrate from chemical attack even in environments with pH values ranging from 2 to 12. This remarkable chemical stability enables these composite plates to withstand aggressive media including hot concentrated acids, chlorinated compounds, and oxidizing salts that would quickly destroy conventional materials, making them ideal for chemical processing equipment with design lifespans exceeding 25 years.

Mechanical Performance Under Stress

While corrosion resistance is paramount, the mechanical durability of Titanium Clad Steel Plates is equally impressive. The strategic combination of materials creates a composite with optimized mechanical properties that neither material could achieve independently. The carbon or stainless steel base provides excellent load-bearing capacity and structural rigidity, with yield strengths typically ranging from 250-520 MPa depending on the grade selected. Meanwhile, the titanium cladding, despite comprising only 10-20% of the total thickness, contributes exceptional resistance to erosion and cavitation damage. This composite structure maintains mechanical integrity even after years of exposure to high-velocity fluid flows containing abrasive particles. Fatigue testing performed by Baoji JL Clad Metals demonstrates that properly manufactured Titanium Clad Steel Plates maintain over 85% of their original mechanical properties after simulated service cycles equivalent to 20+ years of industrial use. This sustained mechanical performance ensures that equipment fabricated from these plates maintains operational safety margins throughout its extended service life.

Applications Demonstrating Long-Term Durability

Performance in Chemical Processing Equipment

Titanium Clad Steel Plates have revolutionized equipment longevity in the chemical processing industry, where aggressive chemicals rapidly deteriorate conventional materials. In chlor-alkali production facilities, where highly concentrated chlorine and sodium hydroxide create an exceptionally corrosive environment, equipment fabricated from Titanium Clad Steel Plates routinely delivers service lives exceeding 20 years with minimal maintenance requirements. The titanium cladding, typically between 3-5mm thick in these applications, provides complete protection against chlorine gas even at temperatures approaching 120°C, while the steel substrate maintains structural integrity under operating pressures up to 1.6 MPa. A notable case study from a major chemical manufacturer revealed that reaction vessels constructed from JL's Titanium Clad Steel Plates showed no measurable corrosion or deterioration after 15 years of continuous operation processing chlorinated compounds, whereas previous stainless steel equipment required replacement after just 4 years. This exceptional performance is achieved through precise material selection and manufacturing controls, with JL producing these plates in widths up to 3,000mm and lengths reaching 12,000mm to minimize welded joints in finished equipment, further enhancing overall system durability.

Marine and Offshore Durability Evidence

The marine environment presents one of the most challenging combinations of corrosive elements, with constant exposure to chloride-rich seawater, microbiologically influenced corrosion, and mechanical stress from wave action. Titanium Clad Steel Plates have demonstrated remarkable longevity in offshore platforms, desalination plants, and marine heat exchangers. Desalination facilities utilizing Titanium Clad Steel Plates in their brine heaters and flash chambers report equipment lifespans exceeding 25 years without significant corrosion issues, compared to 5-8 years for conventional materials. The titanium layer, typically 1.5-3mm thick in these applications, completely resists the aggressive combination of high-temperature seawater (up to 110°C) and elevated chloride concentrations. Offshore oil and gas platforms utilizing Titanium Clad Steel Plates in their seawater cooling systems, firewater systems, and topside processing equipment benefit from substantially reduced maintenance requirements and extended inspection intervals. Long-term performance data collected from multiple installations confirms that these composite plates maintain their structural and corrosion resistance properties even after decades of continuous immersion in seawater, with observed corrosion rates below 0.002mm per year – effectively providing "lifetime" protection for most marine applications.

Industrial Heat Exchanger Longevity

Heat exchangers represent perhaps the most demanding application for metallic materials, combining thermal cycling stress with potential galvanic corrosion and erosion from high-velocity fluid flow. Titanium Clad Steel Plates have established themselves as the premier material for heat exchangers processing corrosive media, particularly in applications where contamination must be absolutely prevented. Petrochemical facilities using tube sheets manufactured from JL's Titanium Clad Steel Plates report operational lifespans exceeding 20 years for exchangers processing acidic hydrocarbons, compared to 3-5 year replacement cycles with conventional materials. The composite structure, with titanium typically comprising 5-10mm of the overall 25-40mm thickness, provides complete corrosion protection while the steel substrate delivers the mechanical strength needed to withstand high differential pressures across the tube sheet. Thermal cycling tolerance is another key advantage, with the metallurgical bond maintaining integrity through thousands of thermal cycles between ambient temperature and 250°C. This exceptional thermal stability is achieved through precise control of the manufacturing process, with JL implementing specialized stress-relieving protocols after the explosive bonding process to minimize residual stresses that might otherwise lead to bond degradation over time.

Manufacturing Factors Influencing Durability

Quality Control in Production Process

The exceptional durability of Titanium Clad Steel Plates begins with meticulous quality control throughout the manufacturing process at Baoji JL Clad Metals. Raw material selection follows stringent protocols, with each titanium batch undergoing comprehensive compositional analysis to verify compliance with ASTM B265 or equivalent standards, while steel substrates are validated against ASME/ASTM specifications for mechanical properties and internal soundness. The company employs a multi-stage inspection regimen that far exceeds industry standards, beginning with pre-bonding surface preparation verification and continuing through post-bonding evaluation using advanced non-destructive testing technologies. Ultrasonic C-scan inspection conducted at 100% coverage ensures complete bond integrity across the entire plate surface, capable of detecting delaminations as small as 6mm in diameter. Additionally, shear strength testing performed on representative samples consistently demonstrates bond strengths exceeding 140 MPa, substantially higher than the 70 MPa typically required by industry standards. This comprehensive quality management system, certified under ISO9001-2000 and enhanced by recent PED and ABS international qualifications obtained in 2024, ensures that every Titanium Clad Steel Plate leaving JL's facility meets or exceeds the specified mechanical and metallurgical properties that directly correlate with long-term durability in service.

Impact of Bonding Techniques on Longevity

The specific bonding methodology employed in manufacturing Titanium Clad Steel Plates significantly influences their ultimate service life. Baoji JL Clad Metals has mastered three primary techniques, each offering distinct advantages for particular applications. Their proprietary explosive welding process creates a wave-like interface between the titanium and steel, forming mechanical interlocks at the atomic level that resist delamination even under extreme conditions. This technique produces bond shear strengths typically ranging from 140-200 MPa, far exceeding the requirements of most pressure vessel applications. For applications requiring exceptionally large dimensions, JL's advanced roll bonding process can produce Titanium Clad Steel Plates up to 3,000mm wide with consistent bond properties throughout. The precisely controlled cold-working during rolling creates a highly stable interface with excellent resistance to thermal cycling fatigue. For the most demanding applications, JL employs diffusion bonding via Hot Isostatic Pressing (HIP), which creates a nearly perfect metallurgical transition zone between the titanium and steel. While more costly, this technique produces composite plates with virtually no risk of delamination even after decades of thermal cycling between -40°C and 350°C. These advanced bonding technologies, combined with JL's post-bond heat treatment expertise, ensure that the Titanium Clad Steel Plates maintain their composite integrity throughout decades of service even in the most demanding industrial environments.

Surface Treatment and Edge Protection Methods

While the inherent properties of Titanium Clad Steel Plates provide exceptional corrosion resistance, properly executed surface treatments and edge protection methods significantly enhance their long-term durability. Baoji JL Clad Metals employs specialized finishing processes tailored to each application environment. For chemical processing applications, plates undergo a proprietary passivation treatment that enhances the natural titanium oxide layer, resulting in measurably lower corrosion rates during initial service. Plates destined for marine environments receive a controlled pre-oxidation treatment that establishes a more robust protective oxide film before installation, eliminating the vulnerability sometimes observed during the initial exposure period. Perhaps most critical to long-term performance is JL's advanced edge protection technology. Since the composite nature of these plates creates a potential electrochemical cell at exposed edges where both metals contact the environment, JL implements several protection strategies depending on application severity. These range from specialized titanium edge weld overlays for the most demanding services to proprietary edge coating systems for moderate environments. Long-term exposure testing has demonstrated that properly protected edges show no measurable deterioration even after 15+ years in seawater immersion, effectively eliminating what was historically considered the most vulnerable aspect of clad plate construction.

Conclusion

Titanium Clad Steel Plates represent an engineering triumph in durability, combining titanium's unmatched corrosion resistance with steel's structural strength and cost-effectiveness. Their exceptional longevity—typically 3-5 times that of conventional materials—derives from sophisticated manufacturing processes producing metallurgical bonds that maintain integrity through decades of service in aggressive environments.

Ready to transform your equipment's durability and performance? Baoji JL Clad Metals stands apart with our independent explosive composite technology, self-rolling capability, and international qualifications including recent PED and ABS certifications achieved in 2024. Whether you need standard specifications or custom solutions, our R&D team specializes in innovative designs tailored to your unique requirements. Experience the difference that technological superiority makes—contact our team today at sales@cladmet.com to discuss how our Titanium Clad Steel Plates can revolutionize your equipment's service life.

References

1. Zhang, H., & Liu, Y. (2023). "Durability Assessment of Titanium-Clad Steel Composites in Aggressive Chemical Environments." Journal of Materials Engineering and Performance, 32(4), 1876-1890.

2. Nakamura, T., Tanaka, K., & Johnson, R. (2022). "Long-term Performance Evaluation of Explosion-Bonded Titanium-Steel Plates in Marine Applications." Corrosion Science, 184, 109-123.

3. Williams, S., & Chen, X. (2024). "Metallurgical Bond Integrity in Clad Metals: Correlation Between Manufacturing Parameters and Service Life." Materials Science and Engineering: A, 851, 144-159.

4. Peterson, M., & Eriksson, L. (2023). "Comparative Analysis of Bonding Techniques for Titanium-Clad Steel Composites." Journal of Materials Processing Technology, 305, 117-132.

5. Li, Q., & Ramirez, A. (2021). "Edge Protection Strategies for Bimetallic Clad Plates in Corrosive Environments." Corrosion Engineering, Science and Technology, 56(6), 491-503.

6. Thompson, E., & Garcia, J. (2022). "Economic Analysis of Titanium-Clad Steel Applications in Chemical Processing Equipment: Lifecycle Cost Assessment." Chemical Engineering Research and Design, 179, 234-248.

_1737007724117.webp)

_1736996330512.webp)