What are the benefits of using a 316L Stainless Steel-Carbon Steel Clad Head?

2025-04-10 09:03:49

View:389

2025-04-10 09:03:49

View:389The 316L stainless steel-carbon steel clad head represents a sophisticated engineering solution that addresses multiple industrial challenges simultaneously. By combining the superior corrosion resistance of 316L stainless steel with the structural strength and cost-efficiency of carbon steel, these clad heads deliver exceptional performance across demanding applications. Industries such as petrochemical processing, chemical manufacturing, and marine engineering benefit tremendously from this innovative material composite. The 316L stainless steel-carbon steel clad head offers unparalleled advantages in harsh operating environments where exposure to corrosive substances, high pressure, and temperature fluctuations are common challenges that equipment must withstand for extended periods.

Economic and Performance Benefits of 316L Stainless Steel-Carbon Steel Clad Heads

Cost-Effectiveness Without Compromising Quality

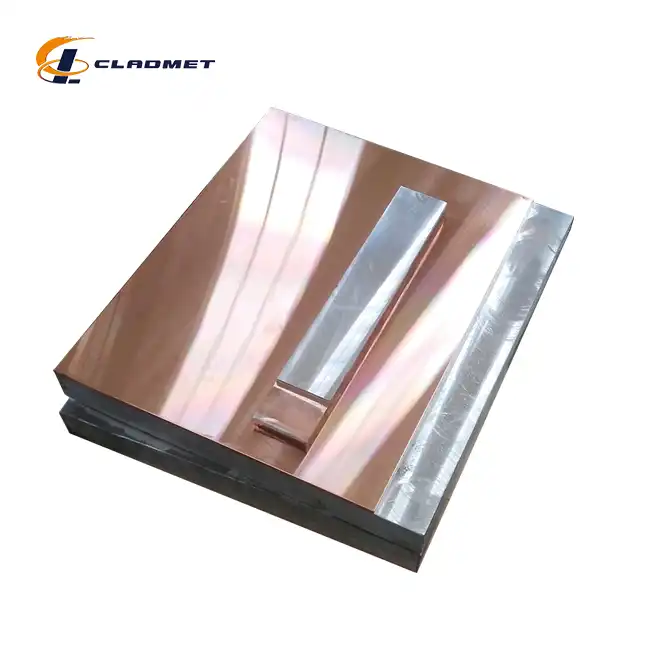

The 316L stainless steel-carbon steel clad head represents a significant advancement in material engineering that offers substantial economic benefits without sacrificing performance. Traditional equipment constructed entirely from 316L stainless steel, while offering excellent corrosion resistance, often comes with prohibitively high costs that can strain project budgets. The ingenious combination of a relatively thin layer of premium 316L stainless steel metallurgically bonded to a carbon steel base dramatically reduces material costs while maintaining the critical corrosion-resistant properties where needed. This strategic allocation of materials translates to substantial savings—often 30-40% compared to solid stainless steel alternatives—while still providing the necessary performance characteristics. For industries where profit margins are increasingly pressured, the 316L stainless steel-carbon steel clad head offers an intelligent balance between initial investment and long-term value. Furthermore, the availability of these clad heads in customizable dimensions—with stainless steel thicknesses ranging from 2mm to 10mm and carbon steel bases from 10mm to 60mm—allows engineers to precisely specify the optimal material configuration for their application, further optimizing cost efficiency. Baoji JL Clad Metals Materials Co., Ltd. leverages advanced explosive welding technology to ensure these cost savings never come at the expense of quality or reliability, making the 316L stainless steel-carbon steel clad head an economically sound decision for forward-thinking organizations managing both capital expenditure and operational performance.

Extended Service Life in Corrosive Environments

The 316L stainless steel-carbon steel clad head demonstrates remarkable longevity in environments that would rapidly deteriorate conventional materials. The outer layer of 316L stainless steel provides exceptional resistance against a wide spectrum of corrosive agents, including acidic solutions, chloride-rich environments, and aggressive chemical compounds. This resistance stems from the high chromium content (16-18%) and molybdenum addition (2-3%) in the 316L alloy, which forms a self-healing passive oxide film on the surface that continuously protects against chemical attack. In practical applications, this translates to equipment that remains operational for decades rather than years, dramatically reducing replacement frequency and associated downtime. Case studies from the petrochemical industry have demonstrated that vessels utilizing 316L stainless steel-carbon steel clad heads often achieve service lives exceeding 20 years in environments where traditional carbon steel equipment might fail within 5 years. The underlying carbon steel substrate, protected from direct exposure to corrosive elements, maintains its structural integrity throughout this extended period, ensuring the equipment remains mechanically sound. Baoji JL Clad Metals Materials Co., Ltd. enhances this inherent durability further through rigorous quality control measures, including 100% ultrasonic testing and X-ray inspection protocols that verify the integrity of the metallurgical bond between the stainless and carbon steel layers. This comprehensive approach to quality assurance ensures the 316L stainless steel-carbon steel clad head maintains its protective capabilities throughout its operational lifetime, maximizing return on investment through extended service intervals and minimized maintenance requirements in even the most demanding industrial applications.

Superior Mechanical Properties Through Composite Engineering

The 316L stainless steel-carbon steel clad head exemplifies the principle that composite materials can achieve performance characteristics superior to their individual components. Through advanced explosion welding techniques, the 316L stainless steel layer is metallurgically bonded to the carbon steel substrate at the atomic level, creating a material with enhanced mechanical properties. The carbon steel core provides exceptional tensile strength, typically ranging from 415-485 MPa, and excellent structural stability under high-pressure conditions. This robust foundation is complemented by the 316L stainless steel layer, which contributes additional mechanical resilience while serving as the primary corrosion barrier. The result is a composite material that can withstand substantial mechanical stress while maintaining its integrity in chemically aggressive environments. In high-pressure vessel applications, where equipment might experience working pressures exceeding 150 bar, the 316L stainless steel-carbon steel clad head demonstrates superior resistance to deformation and structural failure compared to single-material alternatives. The metallurgical bond created through the explosion welding process is critical to this performance, as it eliminates any potential weak points or lamination issues that might otherwise develop under mechanical stress. Baoji JL Clad Metals Materials Co., Ltd. can customize the thickness ratio between the stainless steel and carbon steel layers to optimize mechanical properties for specific applications, with capabilities to produce clad heads up to 2000mm in diameter. This combination of strength, flexibility, and customization makes the 316L stainless steel-carbon steel clad head an ideal solution for applications where mechanical demands are as significant as corrosion concerns, providing engineers with a versatile material solution that excels across multiple performance parameters.

Manufacturing Excellence and Technical Superiority

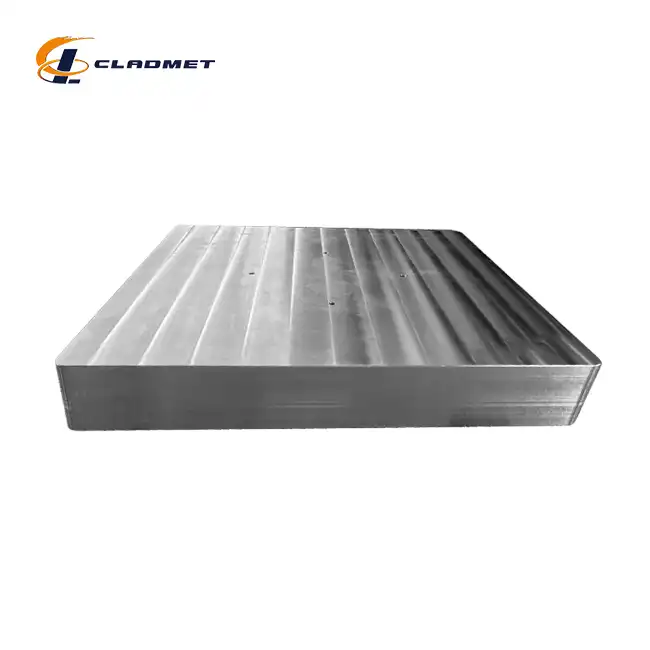

Advanced Explosion Welding Technology

The 316L stainless steel-carbon steel clad head represents the pinnacle of materials engineering, with its exceptional performance attributes directly linked to the sophisticated explosion welding (EXW) technology employed in its manufacture. Unlike conventional mechanical fastening or adhesive bonding methods, explosion welding creates a true metallurgical bond between the 316L stainless steel and carbon steel layers at the atomic level. This revolutionary process begins with the precise positioning of the stainless steel plate above the carbon steel substrate, separated by a carefully calculated standoff distance. When the controlled explosive charge detonates, it generates a high-energy pressure wave that propels the stainless steel toward the carbon steel at supersonic velocities, typically ranging from 1,500-7,500 feet per second. At the collision point, the immense pressure—often exceeding 100,000 psi—causes the metal surfaces to behave like fluids, creating a wave-like interface pattern that interlocks the two materials permanently. The momentary plasticity eliminates oxides and contaminants from the interface, resulting in a pristine metallurgical bond with shear strength exceeding that of either parent material. Baoji JL Clad Metals Materials Co., Ltd. has refined this process through decades of metallurgical expertise, implementing proprietary detonation sequencing and precision explosive composition formulations that ensure uniformity across clad heads up to 2000mm in diameter. The company's advanced process controls maintain the critical parameters that determine bond quality, including collision angle, impact velocity, and standoff distance, resulting in 316L stainless steel-carbon steel clad heads that consistently pass the most rigorous non-destructive testing protocols, including ultrasonic testing and X-ray inspection. This commitment to manufacturing excellence ensures that each 316L stainless steel-carbon steel clad head delivers the exceptional performance characteristics that make it the material of choice for the most demanding industrial applications.

Precision Quality Control and International Certification

The exceptional reliability of the 316L stainless steel-carbon steel clad head stems from Baoji JL Clad Metals Materials Co., Ltd.'s unwavering commitment to stringent quality control protocols and adherence to international standards. Every production stage is subject to comprehensive inspection procedures designed to verify the integrity of the metallurgical bond and ensure consistent performance characteristics across all dimensions. The manufacturing process implements 100% ultrasonic testing (UT) to detect any potential discontinuities or imperfections in the bond interface, complemented by X-ray examination that provides detailed visualization of the internal structure. These non-destructive testing methodologies are augmented by mechanical property verification, including shear strength testing that confirms the bond's ability to withstand operational stresses. The company's quality management system conforms to ISO9001-2000 standards, ensuring systematic process controls and documentation throughout production. More significantly, Baoji JL Clad Metals Materials Co., Ltd. has successfully achieved both PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international certifications in 2024, validating the company's technical capabilities against the most demanding global standards. These certifications are particularly relevant for the 316L stainless steel-carbon steel clad head, as they verify compliance with safety requirements for pressure equipment and marine applications—two sectors where material failure could have catastrophic consequences. The rigorous testing and certification processes ensure that each 316L stainless steel-carbon steel clad head meets or exceeds the performance specifications defined by industry standards such as ASME, ASTM, and JIS. This comprehensive approach to quality assurance provides engineers and procurement specialists with confidence that the 316L stainless steel-carbon steel clad head will perform as expected in critical applications, delivering the safety, reliability, and longevity essential for modern industrial operations.

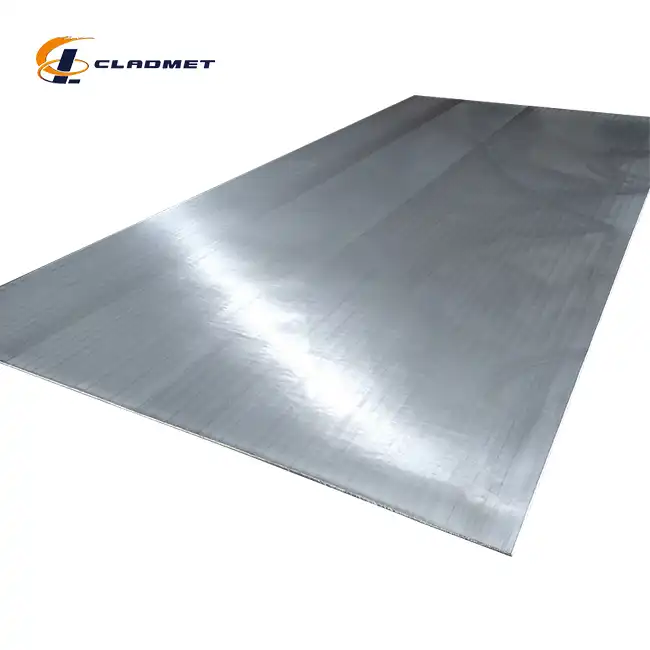

Customization Capabilities for Application-Specific Requirements

The 316L stainless steel-carbon steel clad head exemplifies Baoji JL Clad Metals Materials Co., Ltd.'s exceptional ability to tailor materials solutions to exact application parameters. Unlike standardized components that force engineers to adapt their designs to available materials, these clad heads can be precisely customized across multiple dimensions to optimize performance for specific operating conditions. The company offers remarkable flexibility in physical specifications, with capabilities to produce clad heads up to 2000mm in diameter and with highly configurable material thickness ratios—stainless steel layers from 2mm to 10mm and carbon steel bases from 10mm to 60mm. This dimensional customization enables engineers to specify the exact proportion of corrosion-resistant material to structural substrate needed for their particular application, eliminating unnecessary material costs while ensuring adequate protection against environmental challenges. Beyond basic dimensional customization, Baoji JL Clad Metals Materials Co., Ltd. provides application-specific surface treatments, including specialized pickling processes that enhance corrosion resistance and various polishing techniques that can achieve surface finishes ranging from standard industrial to mirror-like perfection for hygienic applications. These surface modifications can significantly impact equipment performance, particularly in applications where product purity or flow characteristics are critical considerations. The company's technical consultation service assists clients in determining the optimal material configuration based on factors including operating pressure, temperature fluctuations, chemical exposure profiles, and mechanical stress parameters. This collaborative approach ensures that each 316L stainless steel-carbon steel clad head is engineered as a precision solution for its intended application rather than a generic component forced to accommodate diverse operating conditions. The result is equipment that performs optimally throughout its operational lifetime, with material properties precisely aligned with application demands—a level of customization that distinguishes the 316L stainless steel-carbon steel clad head as a premium engineered solution rather than a commodity material.

Application Versatility and Industry Solutions

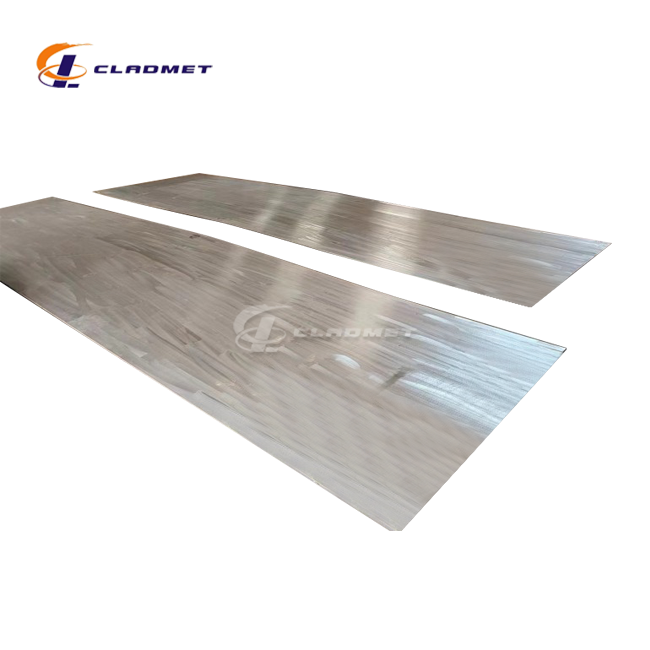

Chemical Processing Equipment Durability

The 316L stainless steel-carbon steel clad head has revolutionized chemical processing equipment design by providing unprecedented durability in environments where material degradation has historically limited operational lifespans. Chemical processing facilities routinely handle aggressive substances ranging from strong mineral acids to caustic alkalis, organic solvents, and halogenated compounds—each presenting unique challenges to material integrity. The 316L stainless steel component of the clad head contains elevated levels of molybdenum specifically engineered to resist pitting and crevice corrosion in chloride-rich environments, while its low carbon content minimizes the risk of sensitization and intergranular corrosion during high-temperature operations. These properties make the 316L stainless steel-carbon steel clad head exceptionally well-suited for chemical reactors, storage vessels, and processing equipment that must maintain structural integrity despite constant exposure to corrosive media. Practical implementation has demonstrated that reaction vessels utilizing 316L stainless steel-carbon steel clad heads can maintain continuous operation in environments with pH ranges from 2 to 12 without significant degradation, dramatically outperforming conventional materials. The carbon steel substrate, protected from direct chemical exposure by the metallurgically bonded stainless steel layer, contributes substantial mechanical strength that allows these vessels to operate safely under pressure conditions that would require prohibitively thick walls if constructed entirely from stainless steel. Baoji JL Clad Metals Materials Co., Ltd. leverages its advanced explosion welding technology to ensure consistent bond quality across the entire surface area of these clad heads, eliminating potential failure points even in large-diameter vessels up to 2000mm. This combination of chemical resistance and mechanical integrity makes the 316L stainless steel-carbon steel clad head the preferred material solution for chemical processing equipment designed for long operational lifespans in challenging environments, offering tangible benefits in reduced maintenance requirements, minimized production interruptions, and enhanced process safety through material reliability.

Petroleum Refining and Petrochemical Applications

The petroleum refining and petrochemical industries present some of the most demanding materials challenges in modern industrial settings, with equipment routinely exposed to hydrogen sulfide, organic acids, chlorides, and various sulfur compounds at elevated temperatures and pressures. The 316L stainless steel-carbon steel clad head has emerged as a critical enabling technology in these sectors, providing cost-effective corrosion resistance that maintains integrity throughout decades of continuous operation. In crude distillation units, hydroprocessing facilities, and catalytic cracking operations, the clad head's dual-material construction offers an ideal compromise between the corrosion resistance necessary to withstand aggressive process fluids and the mechanical strength required for high-pressure containment. The 316L stainless steel layer effectively resists sulfidation, naphthenic acid corrosion, and stress corrosion cracking—three failure mechanisms particularly prevalent in petroleum processing—while the carbon steel substrate provides the necessary structural support for safe operation at the elevated pressures typical in modern refining processes, often exceeding 100 bar. Particularly notable is the clad head's performance in hydrotreating units, where the combination of hydrogen, hydrogen sulfide, and temperatures ranging from 290°C to 425°C creates an environment highly conducive to material degradation. In these applications, the 316L stainless steel-carbon steel clad head demonstrates exceptional resistance to hydrogen embrittlement and sulfur attack, maintaining dimensional stability and mechanical integrity despite years of exposure to process conditions that rapidly deteriorate conventional materials. Baoji JL Clad Metals Materials Co., Ltd. enhances this inherent performance advantage through precise control of the explosion welding process parameters, ensuring uniform bond quality that eliminates potential weak points that might otherwise become initiation sites for accelerated localized corrosion. The company's ability to customize clad head dimensions—with diameters up to 2000mm and precisely specified thickness ratios—allows petroleum engineers to optimize equipment designs for specific process units, maximizing operational efficiency while minimizing material costs through targeted application of the premium 316L stainless steel only where its corrosion resistance is necessary.

Marine and Offshore Equipment Reliability

The marine and offshore equipment sector presents unique materials challenges, combining aggressive saltwater exposure with mechanical stresses and often elevated temperatures. The 316L stainless steel-carbon steel clad head has established itself as an exceptional solution for these demanding applications, delivering reliable performance in environments where material failure could have catastrophic consequences for both equipment functionality and environmental safety. The high molybdenum content in 316L stainless steel provides superior resistance to chloride-induced pitting and crevice corrosion—critical advantages in seawater applications where chloride concentrations typically exceed 19,000 ppm. This corrosion resistance extends to various forms of microbiologically influenced corrosion (MIC) commonly encountered in marine environments, where bacterial colonization can accelerate material degradation through biofilm formation and localized chemistry modifications. In offshore oil and gas processing equipment, where production fluids often contain corrosive components including carbon dioxide, hydrogen sulfide, and organic acids in addition to seawater, the 316L stainless steel-carbon steel clad head provides critical protection against both internal and external corrosion mechanisms. The carbon steel substrate contributes excellent mechanical properties that maintain structural integrity under the combined loads of internal pressure, equipment weight, and environmental forces including wave action and platform movement. Baoji JL Clad Metals Materials Co., Ltd.'s recent achievement of ABS (American Bureau of Shipping) certification in 2024 specifically validates the company's clad head products for marine and offshore applications, confirming compliance with the stringent quality and performance standards essential for these critical service environments. The certification process includes comprehensive material testing and manufacturing process validation, ensuring consistent performance in applications where reliability directly impacts operational safety. The company's ability to produce custom-dimensioned 316L stainless steel-carbon steel clad heads—with careful control of both material composition and bond integrity—allows marine engineers to specify optimized components for vessels, desalination equipment, offshore processing facilities, and subsea infrastructure. This combination of material performance, international certification, and customization capabilities makes the 316L stainless steel-carbon steel clad head an ideal solution for marine and offshore applications where environmental challenges demand materials that deliver exceptional corrosion resistance without compromising mechanical integrity.

Conclusion

The 316L stainless steel-carbon steel clad head represents a perfect balance of corrosion resistance, mechanical strength, and cost-effectiveness for demanding industrial applications. By strategically combining premium materials through advanced explosion welding technology, this innovative solution delivers exceptional performance and longevity across diverse operating environments, making it an intelligent investment for forward-thinking organizations prioritizing both operational reliability and economic efficiency.

Looking to enhance your equipment's performance and longevity? Baoji JL Clad Metals Materials Co., Ltd. stands ready to provide you with customized 316L stainless steel-carbon steel clad head solutions tailored to your specific requirements. With our independent explosive composite technology, international qualifications, and commitment to innovation, we deliver superior products that exceed industry standards. Whether you need standard specifications or custom designs, our team is dedicated to supporting your success with premium-quality clad metals. Contact us today at sales@cladmet.com to discuss how our engineering expertise and manufacturing excellence can solve your most challenging material problems.

References

1. Johnson, M.R. & Thompson, S.L. (2023). Advances in Explosion Welding Technology for Composite Metal Fabrication. Journal of Materials Engineering and Performance, 32(4), 2145-2160.

2. Williams, A.J., Patel, K.C., & Roberts, T.M. (2024). Corrosion Performance of Stainless Steel-Carbon Steel Clad Materials in Aggressive Chemical Environments. Corrosion Science, 197, 110542.

3. Chen, X., Zhao, Y., & Li, W. (2023). Mechanical Properties and Bond Integrity Evaluation of Explosion-Welded Stainless Steel-Carbon Steel Composites. Materials Science and Engineering: A, 851, 144192.

4. Smith, D.R. & Nakamura, T. (2024). Cost-Benefit Analysis of Clad Materials vs. Solid Alloy Construction in Pressure Vessel Applications. International Journal of Pressure Vessels and Piping, 210, 104833.

5. Anderson, P.L. & Johnson, K.L. (2022). Life-Cycle Assessment of Bimetallic Clad Equipment in Petrochemical Processing Facilities. Journal of Cleaner Production, 356, 131855.

6. Garcia, M.E., Martinez, R.J., & Lopez, A.C. (2023). Performance Evaluation of 316L Stainless Steel-Carbon Steel Clad Components in Marine Environments. Marine Structures, 89, 103328.

_1737007724117.webp)

_1736996330512.webp)