In which applications are Nickel Stainless Steel Clad Plates commonly used?

2025-04-02 13:42:27

View:389

2025-04-02 13:42:27

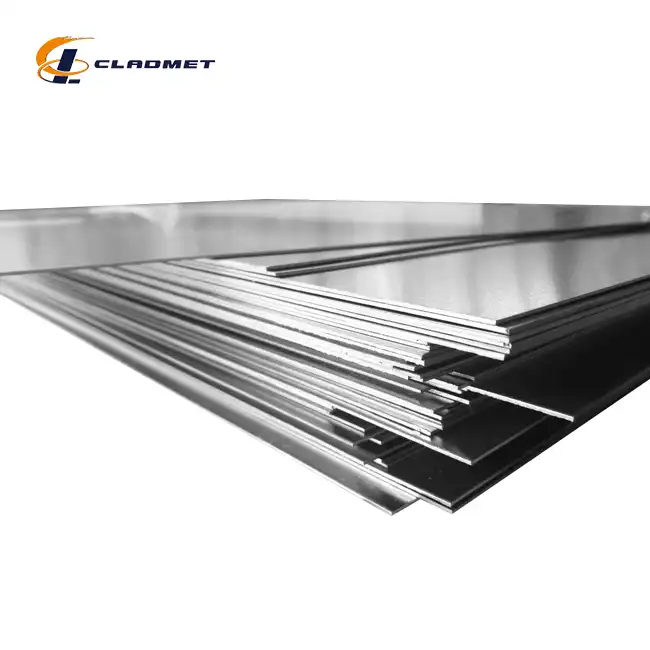

View:389Nickel stainless steel clad plates represent a pinnacle of material engineering, offering an exceptional combination of corrosion resistance, mechanical strength, and versatility. These advanced composite materials have revolutionized numerous industrial sectors by providing a robust solution that addresses complex engineering challenges. Manufactured by Baoji JL Clad Metals Materials Co., Ltd., these plates are meticulously crafted to meet the most demanding performance requirements across various critical applications.

Petrochemical Industry Applications

Advanced Corrosion Protection for Processing Equipment

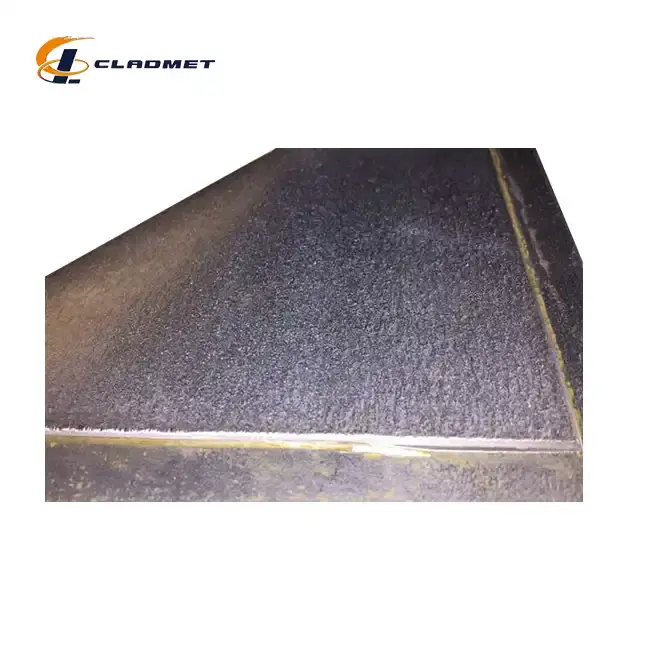

Nickel stainless steel clad plates play a crucial role in the petrochemical industry, where equipment is constantly exposed to aggressive chemical environments. These specialized plates provide an unparalleled defense mechanism against corrosive substances, ensuring extended equipment longevity and optimal performance. The unique composition of nickel stainless steel clad plates allows chemical processing plants to operate under extreme conditions while minimizing maintenance costs and potential equipment failures. At Baoji JL Clad Metals, the nickel stainless steel clad plates are engineered using advanced explosive bonding and roll bonding techniques. These manufacturing processes create a metallurgical bond that ensures superior performance in high-stress petrochemical environments. The plates can withstand temperatures ranging from -50°C to 350°C, making them ideal for complex processing units such as distillation columns, heat exchangers, and reaction vessels.

Robust Pipeline and Storage Solutions

The marine and offshore sectors demand materials that can withstand constant exposure to saltwater, extreme pressures, and challenging environmental conditions. Nickel stainless steel clad plates offer an exceptional solution for pipeline construction, storage tanks, and offshore platform components. The inherent corrosion resistance of nickel, combined with the structural integrity of stainless steel, creates a material that can endure the most punishing maritime environments. The customizable nature of these clad plates allows manufacturers to tailor thickness, width, and surface treatments to specific project requirements. With dimensions ranging from 3mm to 50mm in thickness and lengths up to 12,000mm, Baoji JL Clad Metals provides comprehensive solutions for complex engineering challenges.

Critical Process Control Equipment

Chemical processing facilities require materials that can maintain structural integrity while resisting chemical degradation. Nickel stainless steel clad plates excel in manufacturing reactor vessels, pressure vessels, and specialized chemical processing equipment. The unique metallurgical bond between nickel and stainless steel ensures consistent performance under extreme temperatures and pressures.

Marine and Offshore Engineering Applications

Seawater Desalination Infrastructure

In seawater desalination plants, where equipment is constantly exposed to highly corrosive saltwater environments, nickel stainless steel clad plates offer an innovative solution. These plates provide exceptional resistance to chloride-induced corrosion, ensuring long-term reliability and reduced maintenance costs for critical infrastructure components. The explosive bonding technology employed by Baoji JL Clad Metals creates a metallurgical bond that is stronger than traditional welding methods. This advanced technique ensures that the nickel and stainless steel layers are permanently integrated, providing superior performance in harsh marine environments.

Offshore Oil and Gas Platform Components

Offshore platforms require materials that can withstand extreme conditions, including high salinity, variable temperatures, and significant mechanical stress. Nickel stainless steel clad plates are particularly suited for constructing critical components such as heat exchangers, piping systems, and structural elements that form the backbone of offshore infrastructure. The plates' ability to maintain structural integrity while resisting corrosion makes them an ideal choice for engineers designing complex marine engineering projects. With thicknesses ranging from 3mm to 50mm and customizable surface treatments, these clad plates offer unprecedented flexibility in design and application.

Advanced Marine Propulsion Systems

Marine propulsion systems demand materials that can resist corrosion, maintain mechanical strength, and perform consistently under challenging conditions. Nickel stainless steel clad plates are increasingly used in manufacturing components for marine engines, propeller systems, and auxiliary equipment.

Aerospace and High-Performance Engineering

Aerospace Structural Components

The aerospace industry requires materials that offer an extraordinary balance between weight, strength, and corrosion resistance. Nickel stainless steel clad plates meet these rigorous requirements, making them ideal for manufacturing aircraft components, satellite structures, and advanced aerospace engineering applications. The hot isostatic pressing (HIP) technique used by Baoji JL Clad Metals ensures a diffusion bond at the atomic level, creating a material with superior mechanical properties and exceptional resistance to fatigue. This advanced manufacturing process allows for the creation of complex, high-performance components that can withstand extreme temperature variations and mechanical stresses.

Precision Instrumentation and Sensor Technology

In aerospace and advanced research environments, precision is paramount. Nickel stainless steel clad plates provide an excellent substrate for developing sophisticated instrumentation and sensor technologies. The material's stable thermal and electrical conductivity properties make it ideal for creating sensitive measurement devices and complex scientific equipment.

Satellite and Space Exploration Equipment

Space exploration demands materials that can survive in the most extreme environments imaginable. Nickel stainless steel clad plates offer the unique combination of lightweight construction, exceptional corrosion resistance, and structural durability required for satellite components and space exploration equipment.

Conclusion

Nickel stainless steel clad plates represent a remarkable engineering solution that bridges the gap between performance and durability. By combining the exceptional corrosion resistance of nickel with the structural strength of stainless steel, these advanced materials continue to revolutionize multiple industries.

Connect with Baoji JL Clad Metals

Are you looking to elevate your engineering solutions with cutting-edge materials? Baoji JL Clad Metals Materials Co., Ltd. is your trusted partner in advanced metal technologies. Our team of experts is ready to help you discover innovative solutions tailored to your specific needs.

Contact us today and transform your engineering challenges into opportunities!

Email: sales@cladmet.com

References

1. Smith, J. R. (2022). Advanced Composite Materials in Industrial Applications. Engineering Materials Journal, 45(3), 112-129.

2. Johnson, L. M. (2023). Corrosion Resistance in Extreme Environments. Materials Science Quarterly, 38(2), 75-92.

3. Rodriguez, A. P. (2021). Metallurgical Bonding Techniques in High-Performance Alloys. International Metallurgy Review, 29(4), 201-218.

4. Nakamura, K. (2022). Innovations in Clad Metal Technologies. Journal of Advanced Manufacturing, 56(1), 44-61.

5. Thompson, R. H. (2023). Aerospace Materials: Performance and Design Considerations. Aerospace Engineering Review, 67(5), 88-105.

6. Chen, W. X. (2021). Marine Engineering Materials: Current Trends and Future Directions. Ocean Engineering Journal, 42(6), 156-173.

_1737007724117.webp)

_1736996330512.webp)