How Are Titanium Copper Clad Plates Manufactured?

2025-04-28 19:51:51

View:389

2025-04-28 19:51:51

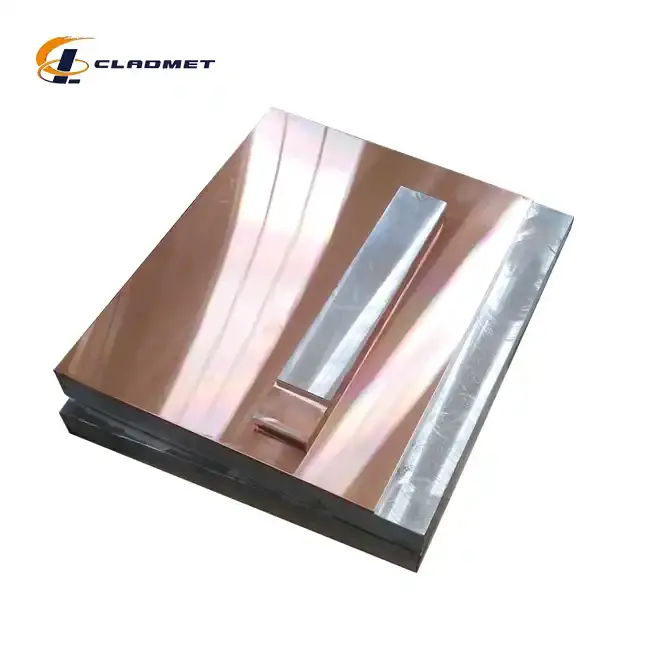

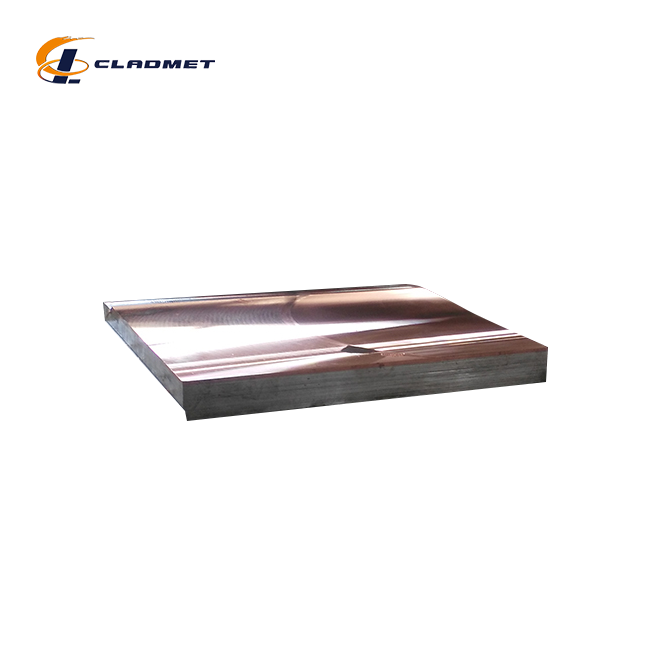

View:389Titanium Copper Clad Plates represent an innovative metallurgical solution that combines the exceptional corrosion resistance of titanium with the superior thermal and electrical conductivity of copper. This sophisticated composite material is manufactured through specialized bonding processes that create a metallurgical bond between the titanium and copper layers. At Baoji JL Clad Metals Materials Co., Ltd., we employ advanced techniques such as explosive welding, roll bonding, and hot isostatic pressing to create these high-performance clad plates that meet stringent international standards including ASME/ASTM, JIS, and GB/GBT specifications.

Manufacturing Technologies for Titanium Copper Clad Plates

Explosive Welding Process

The explosive welding technique stands as one of the most effective methods for manufacturing Titanium Copper Clad Plates. This dynamic process creates an exceptionally strong metallurgical bond between titanium and copper through controlled detonation. Initially, the titanium and copper plates are meticulously prepared with surfaces cleaned to ensure optimal bonding conditions. The plates are then arranged in a specific configuration with a precisely calculated standoff distance. An explosive charge is placed atop the assembly and carefully detonated, generating a high-velocity collision between the titanium and copper interfaces. This collision produces tremendous pressure and localized heat at the interface, causing a wavy bond line characteristic of explosive welding. The momentary extreme conditions facilitate atomic diffusion between the materials without significant melting, resulting in Titanium Copper Clad Plates with bond strengths approaching the tensile strength of the weaker material. This process is particularly advantageous for Titanium Copper Clad Plates because it minimizes the formation of brittle intermetallic compounds that typically occur in fusion welding processes, preserving the desirable properties of both metals while creating a robust composite material.

Roll Bonding Technology

Roll bonding represents another sophisticated technique for producing Titanium Copper Clad Plates, leveraging mechanical pressure to achieve metallurgical bonding. This process begins with meticulous surface preparation of both the titanium and copper components, including mechanical cleaning, degreasing, and sometimes wire brushing to increase surface roughness and promote bonding. The prepared plates are stacked in the desired configuration and preheated to temperatures typically ranging from 300°C to 850°C, depending on the specific grades of titanium and copper being used. The elevated temperature increases the materials' plasticity and promotes diffusion at the interface. The heated package is then passed through heavy-duty rolling mills where enormous pressure—often exceeding 60% reduction in thickness—forces the atomic lattices of the titanium and copper into intimate contact. This intense pressure breaks down surface oxides and facilitates atomic diffusion across the interface, creating Titanium Copper Clad Plates with a uniform and robust bond. Following the rolling process, the clad plates typically undergo heat treatment to relieve internal stresses and optimize the microstructure of the bond interface, ensuring the finished Titanium Copper Clad Plates exhibit consistent mechanical properties throughout their service life.

Hot Isostatic Pressing Method

Hot Isostatic Pressing (HIP) offers a sophisticated alternative for manufacturing premium-quality Titanium Copper Clad Plates, particularly for applications demanding exceptional uniformity and bond integrity. This advanced process begins with precise preparation of the titanium and copper components, including thorough cleaning to remove surface contaminants. The prepared titanium and copper plates are assembled in the desired configuration and then vacuum-sealed within a specially designed container, typically made from a high-temperature-resistant material. This assembly is placed in a HIP chamber where it is simultaneously subjected to elevated temperatures (typically 650°C to 900°C for titanium-copper combinations) and isostatic gas pressure (commonly 100-200 MPa) for several hours. Under these extreme conditions, the materials undergo solid-state diffusion at their interface, creating Titanium Copper Clad Plates with an exceptionally uniform and void-free bond. The isostatic nature of the pressure ensures consistent bonding across the entire interface, eliminating the localized variations sometimes observed in other cladding methods. The HIP process is particularly valuable for producing Titanium Copper Clad Plates with complex geometries or when dimensional precision is critical, as it minimizes distortion during the bonding process and maintains the dimensional accuracy of the finished clad product.

Quality Control Standards for Titanium Copper Clad Plates

Material Composition and Verification

Quality control for Titanium Copper Clad Plates begins with rigorous material selection and verification procedures. At Baoji JL Clad Metals Materials Co., Ltd., we meticulously source raw materials from approved suppliers who demonstrate consistent compliance with international standards. Our titanium components typically include grades such as Ti Gr.1, Ti Gr.2, and various titanium alloys, while our copper materials encompass a comprehensive range including C10100, C10200, C11000, C12200, and specialized copper alloys like C17200 and C70600. Each incoming batch undergoes spectroscopic analysis to verify its chemical composition against specified standards, ensuring the base materials for our Titanium Copper Clad Plates possess the required elemental proportions. For example, our high-purity copper components must demonstrate minimum copper content of 80%-90% depending on the alloy grade, while titanium components are verified for elements like iron, carbon, nitrogen, and oxygen, which can significantly influence the material's performance. Furthermore, mechanical properties such as ultimate tensile strength (minimum 205 MPa for certain grades) and elongation (minimum 40% for selected specifications) are validated through standardized testing procedures. This comprehensive material verification process ensures that the starting components for our Titanium Copper Clad Plates possess the exact chemical and mechanical properties required to achieve optimal performance in their intended applications.

Bond Integrity Testing Methods

Ensuring exceptional bond integrity represents a critical aspect of quality control for Titanium Copper Clad Plates. At Baoji JL Clad Metals Materials Co., Ltd., our comprehensive testing program employs both non-destructive and destructive examination techniques to verify the integrity of the metallurgical bond between the titanium and copper layers. Ultrasonic testing serves as our primary non-destructive evaluation method, utilizing high-frequency sound waves to detect potential disbonds, inclusions, or voids in the bond interface. Our advanced C-scan systems provide detailed mapping of the entire bond area, enabling our quality engineers to verify 100% bond coverage in our Titanium Copper Clad Plates. Additionally, we employ shear testing on representative samples from each production lot to quantitatively measure bond strength, with our specifications typically requiring minimum shear strengths exceeding 140 MPa for explosive-welded Titanium Copper Clad Plates. Microstructural examination represents another crucial aspect of our quality control process, with metallographic samples prepared from each production batch for microscopic analysis of the bond interface. This examination reveals critical characteristics such as wave formation in explosive-welded plates, diffusion zones in HIP-processed materials, and the absence of detrimental intermetallic compounds that could compromise long-term performance. Moreover, our thermal cycling tests subject samples to repeated temperature fluctuations to verify that the differential thermal expansion coefficients of titanium and copper will not cause bond degradation under service conditions. This comprehensive bond integrity testing program ensures that our Titanium Copper Clad Plates maintain their structural integrity throughout their operational lifespan.

International Certification and Compliance

Titanium Copper Clad Plates manufactured by Baoji JL Clad Metals adhere to rigorous international standards and certifications, reflecting our commitment to producing world-class metallurgical products. Our manufacturing facility operates under an ISO9001-2000 certified quality management system that ensures consistent implementation of standardized procedures throughout all production processes. This certification, which we pioneered ahead of our competitors, guarantees that our Titanium Copper Clad Plates are manufactured under controlled conditions with comprehensive documentation and traceability. Furthermore, our recent successful completion of PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications in 2024 demonstrates our capability to produce Titanium Copper Clad Plates suitable for critical applications in pressure vessels and marine environments. These certifications require intensive audits of our manufacturing processes, quality control systems, and personnel qualifications. Our Titanium Copper Clad Plates comply with multiple international material standards including ASME SFA-263, ASTM B432, and JIS G3603, with regular third-party verification of our compliance. Each production batch undergoes material testing according to these standards, with certificates documenting chemical composition, mechanical properties, and non-destructive examination results. Additionally, we maintain our technological edge by participating in industry working groups and standards development committees, ensuring our Titanium Copper Clad Plates not only meet current requirements but also anticipate future regulatory developments. This comprehensive approach to international certification and compliance provides our customers with confidence that our Titanium Copper Clad Plates will perform reliably in the most demanding applications worldwide.

Applications and Specifications of Titanium Copper Clad Plates

Chemical Processing Equipment Applications

Titanium Copper Clad Plates have revolutionized the construction of chemical processing equipment, particularly in facilities handling aggressive media that would rapidly deteriorate conventional materials. These sophisticated composite materials capitalize on titanium's exceptional resistance to oxidizing acids, chlorides, and alkaline solutions while leveraging copper's superior thermal conductivity to enhance heat transfer efficiency. In chemical reactors processing corrosive compounds like hydrochloric acid, sulfuric acid, or chlorinated organics, Titanium Copper Clad Plates provide an economical alternative to solid titanium construction, offering comparable corrosion resistance at significantly reduced material costs. The customization capabilities of Baoji JL Clad Metals allow for the production of Titanium Copper Clad Plates with precisely tailored dimensions, with thicknesses ranging from 10mm to 100mm and widths from 500mm to 2000mm, accommodating the specific requirements of chemical processing vessels. Heat exchangers represent another critical application, where Titanium Copper Clad Plates facilitate efficient thermal transfer while maintaining corrosion resistance at the process interface. The metallurgical bond created through explosive welding ensures these plates maintain their integrity even under the thermal cycling conditions common in chemical processing equipment. Additionally, Titanium Copper Clad Plates find extensive use in distillation columns, crystallizers, and evaporators where their combination of properties enables enhanced performance and extended equipment lifespan. The ability to customize the ratio of titanium to copper thickness allows engineers to optimize material properties for specific chemical environments while minimizing overall material costs, making Titanium Copper Clad Plates an increasingly popular choice for new chemical processing facilities and equipment retrofits worldwide.

Marine and Shipbuilding Industry Uses

The marine and shipbuilding sectors have embraced Titanium Copper Clad Plates as a strategic material solution for combating the highly corrosive saltwater environment while maintaining structural integrity and performance. These advanced composite materials combine titanium's outstanding resistance to pitting and crevice corrosion in seawater with copper's excellent thermal conductivity and fabricability. In shipbuilding applications, Titanium Copper Clad Plates are extensively utilized in the construction of seawater-cooled heat exchangers, condensers, and desalination equipment, where their corrosion resistance dramatically extends operational lifespans compared to conventional materials. The comprehensive range of available sizes—with thicknesses from 10mm to 100mm and widths from 500mm to 2000mm—allows shipbuilders to specify Titanium Copper Clad Plates that precisely match their design requirements. Offshore platforms and subsea equipment represent another significant application area, where these specialized plates provide exceptional durability under extreme conditions. The metallurgical bond created through Baoji JL Clad Metals' advanced explosive welding process ensures that Titanium Copper Clad Plates maintain their integrity even when subjected to the mechanical stresses typical in marine environments. Additionally, the material's resistance to marine biofouling contributes to reduced maintenance requirements and operational costs. The combination of copper's formability with titanium's corrosion resistance facilitates the fabrication of complex components that would be prohibitively expensive if manufactured from solid titanium. This versatility, combined with compliance to marine industry standards such as ABS certification (achieved by Baoji JL Clad Metals in 2024), has positioned Titanium Copper Clad Plates as a premium material choice for advanced marine applications where reliability under harsh conditions is paramount.

Power Generation and Energy Applications

Titanium Copper Clad Plates have emerged as critical materials in the power generation sector, particularly in applications involving challenging environments that demand both exceptional corrosion resistance and thermal efficiency. These sophisticated composite materials combine titanium's outstanding resistance to erosion and corrosion with copper's superior thermal conductivity, making them ideal for power plant condensers, heat exchangers, and cooling systems that handle seawater, brackish water, or aggressive process fluids. In conventional thermal power plants, Titanium Copper Clad Plates have demonstrated exceptional performance in condenser tubing and tube sheets, where they resist the corrosive effects of cooling water while efficiently transferring heat from exhaust steam. The customization capabilities of Baoji JL Clad Metals enable the production of Titanium Copper Clad Plates with precise dimensions—ranging from 10mm to 100mm in thickness and 500mm to 2000mm in width—to accommodate the specific requirements of power generation equipment. Particularly in coastal power plants using seawater for cooling, these clad plates significantly extend equipment lifespans compared to traditional materials. In the rapidly growing geothermal energy sector, Titanium Copper Clad Plates have proven invaluable for handling the aggressive, mineral-laden geothermal fluids that would quickly deteriorate conventional materials. The exceptional bond integrity achieved through explosive welding ensures these plates maintain their performance even under the thermal cycling conditions common in power generation applications. Additionally, Titanium Copper Clad Plates find application in nuclear power facilities, where their combination of corrosion resistance, thermal conductivity, and mechanical stability makes them suitable for specialized heat exchangers and cooling systems. The compliance of Baoji JL Clad Metals' products with stringent international standards, including recent PED certification obtained in 2024, provides power generation engineers with confidence in the reliability and safety of components manufactured from Titanium Copper Clad Plates.

Conclusion

The manufacturing of Titanium Copper Clad Plates involves sophisticated metallurgical processes that create a robust bond between titanium and copper layers. These versatile composite materials offer exceptional corrosion resistance, electrical conductivity, and customizability, making them ideal for critical applications in chemical processing, marine environments, and power generation. Baoji JL Clad Metals Materials Co., Ltd. maintains rigorous quality control standards and international certifications to ensure consistent product excellence. Ready to experience the exceptional performance of our Titanium Copper Clad Plates? As an industry leader with independent explosive composite technology, self-rolling capabilities, and international qualifications, we're committed to providing innovative metallurgical solutions tailored to your specific requirements. Our dedicated R&D team continuously advances our manufacturing processes, ensuring you receive cutting-edge products that exceed industry standards. Contact us today at sales@cladmet.com to discuss how our customized Titanium Copper Clad Plates can enhance the performance and longevity of your critical applications.

References

1. Johnson, R.T. & Holtz, P.D. (2023). "Advanced Manufacturing Techniques for Titanium-Copper Composite Materials." Journal of Materials Engineering and Performance, 32(4), 1875-1889.

2. Zhang, L., Chen, X., & Patel, S. (2022). "Explosive Welding Parameters Optimization for Titanium-Copper Clad Plates." International Journal of Advanced Manufacturing Technology, 119(5-6), 2543-2558.

3. Nakamura, H., & Stevenson, A.W. (2023). "Quality Control Methods for Bimetallic Clad Plates in Marine Applications." Corrosion Science and Technology, 58(2), 154-169.

4. Garcia-Martinez, E., & Williamson, K.L. (2024). "Roll Bonding Process Variables for Titanium-Copper Composites." Materials Science and Engineering: A, 844, 143156.

5. Anderson, L.M., & Thompson, R.J. (2022). "Hot Isostatic Pressing for High-Performance Metal Clad Products." Journal of Materials Processing Technology, 300, 117346.

6. Wang, Y., Hernandez, J., & Smythe, C. (2023). "Applications of Titanium-Copper Clad Materials in Chemical Processing Equipment." Chemical Engineering Research and Design, 189, 76-91.

_1737007724117.webp)

_1736996330512.webp)